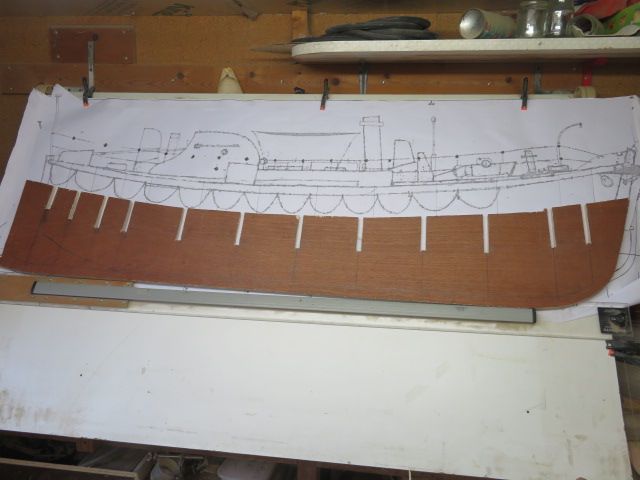

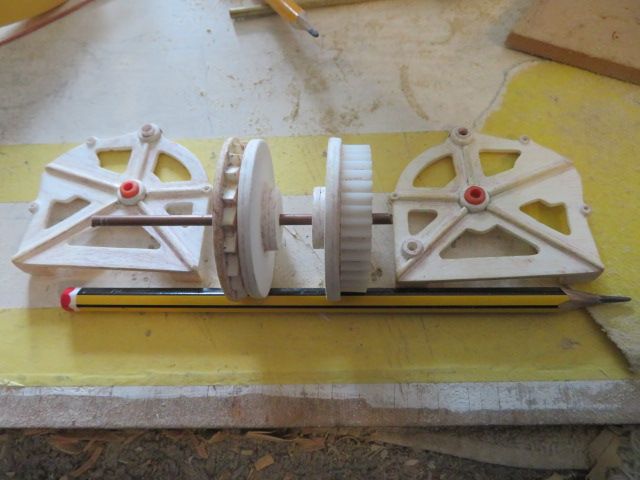

Whilst looking through my lifeboat fittings the other day for parts to use for my 61' Barnett I came across the masters for a major part that adorned the engine casing of my earlier 51' Barnett, RNLB Mary Stanford, probably thee most famous lifeboat in RNLI history.

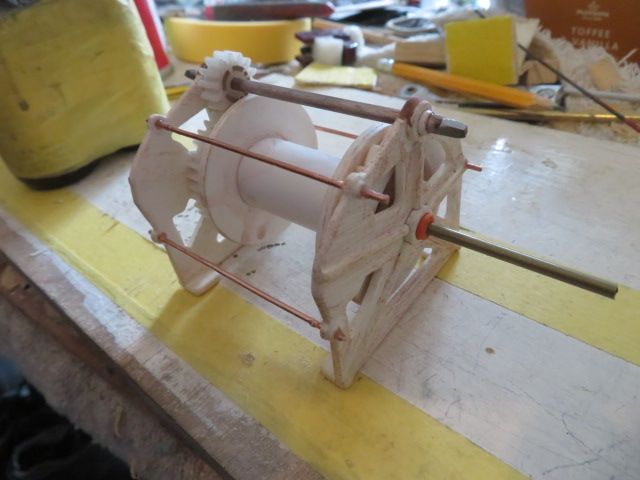

I used these masters to make moulds for producing white metal and resin mouldings. One set being sent to Mike Pendlebury for his modification to an a feature for a mark 2 52' Barnett he was bulding at the time.

To be honest I don't know whether I still have those moulds or sent them on to a friend for production purposes,

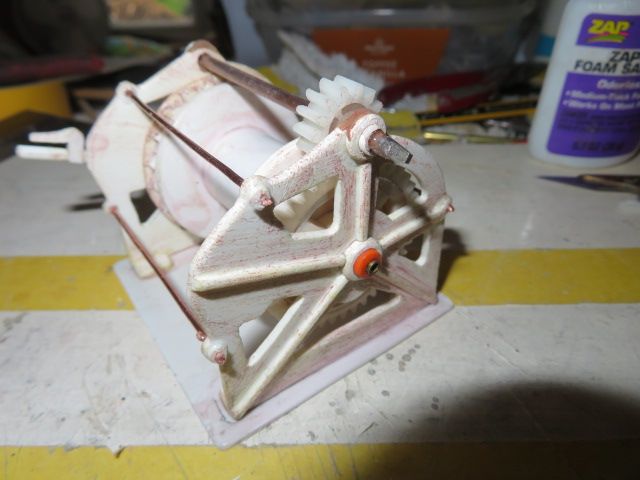

It was a hand wound windlass. the later mk2 52' Barnets carried an electric windlass.

And so I decided to check through Nicholas Leach's book on the 60/61' Barnetts to see if this item was on any of them, as it was a period piece of that era.

And the answer was yes [most probably] on two of the four boats that I could see, although the shapes were shrouded in black covers.

One of those boats was the RNLB Princess Mary of Padstow.

And so, I have decided to use these masters and with modellers licence, am going to eventually use it on the engine casing of my 61' Barnett.

Edited By neil howard-pritchard on 19/07/2022 18:07:26

neil hp.