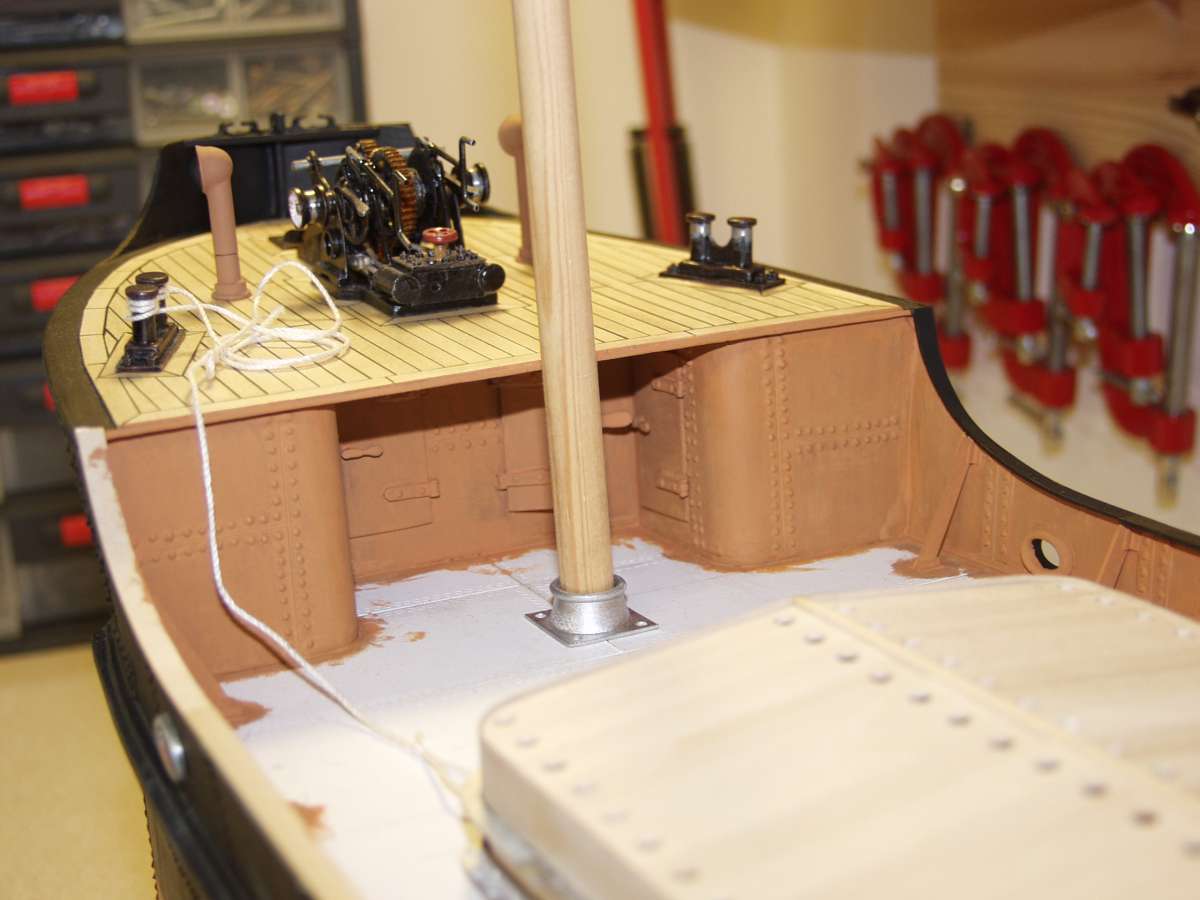

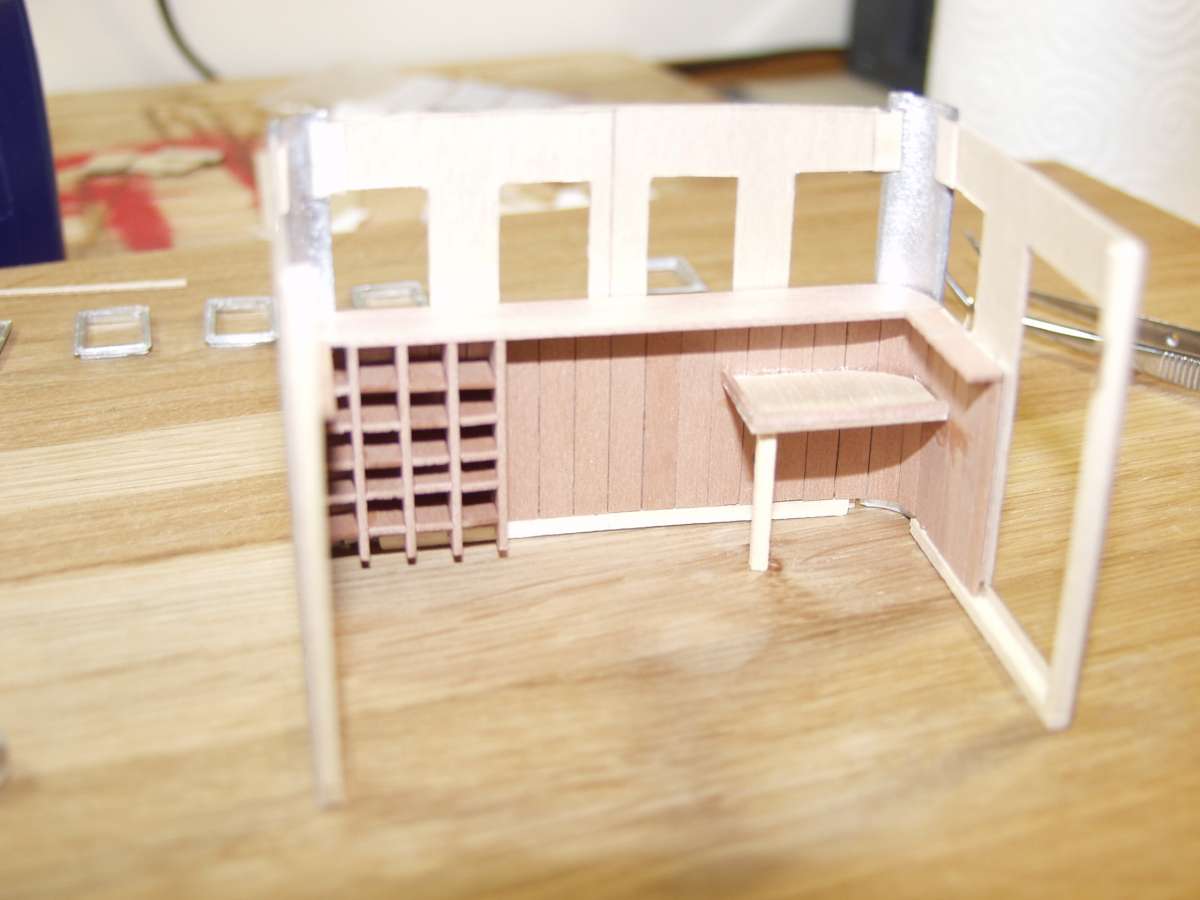

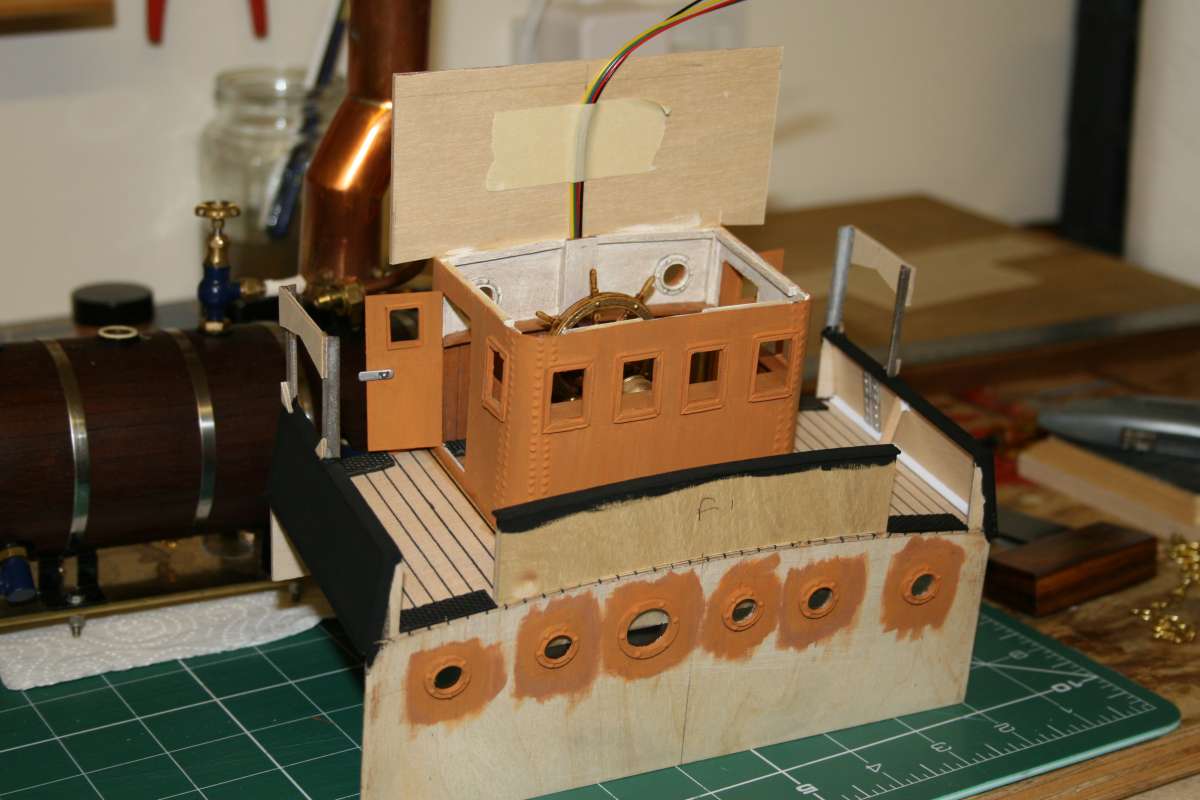

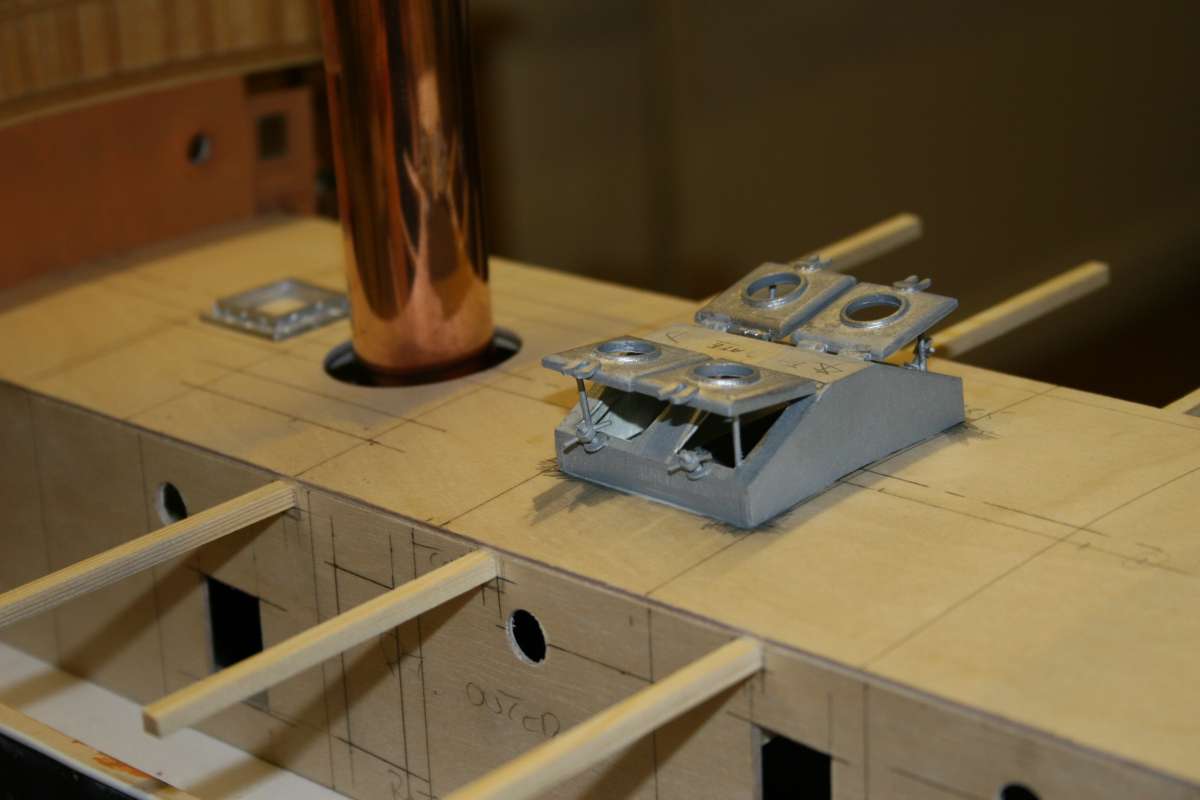

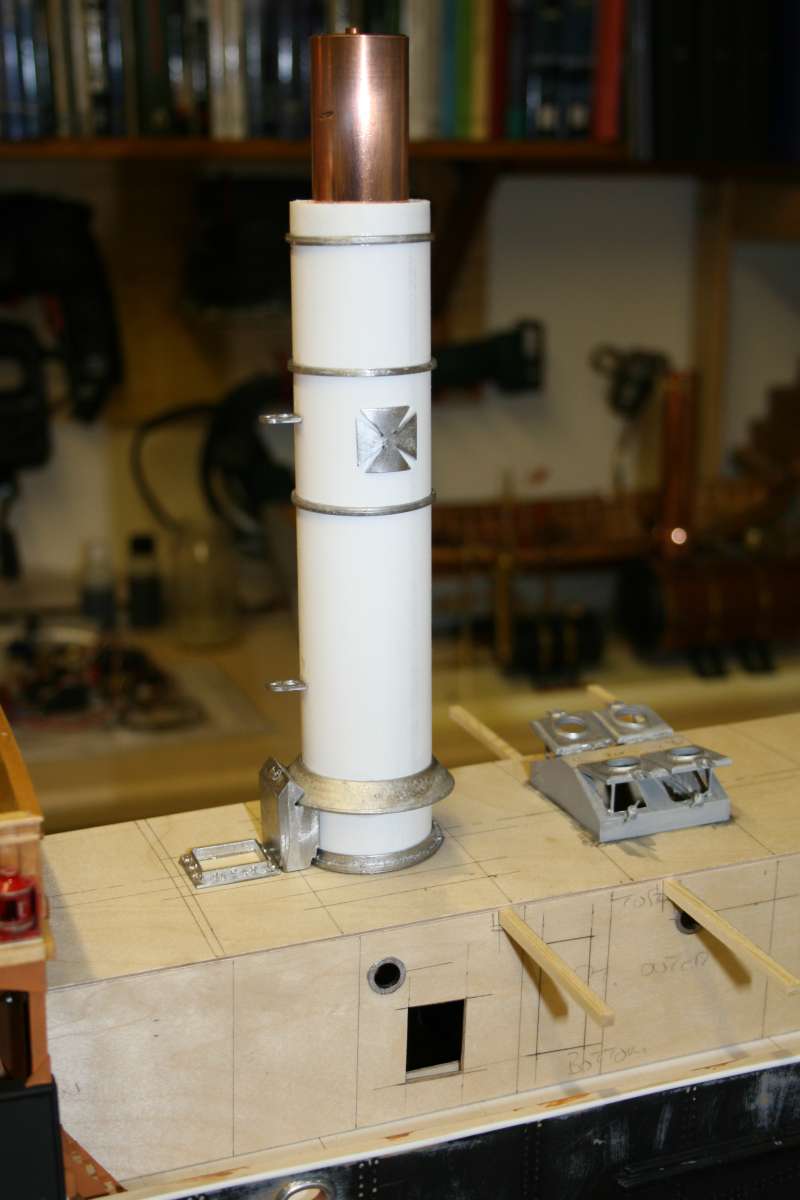

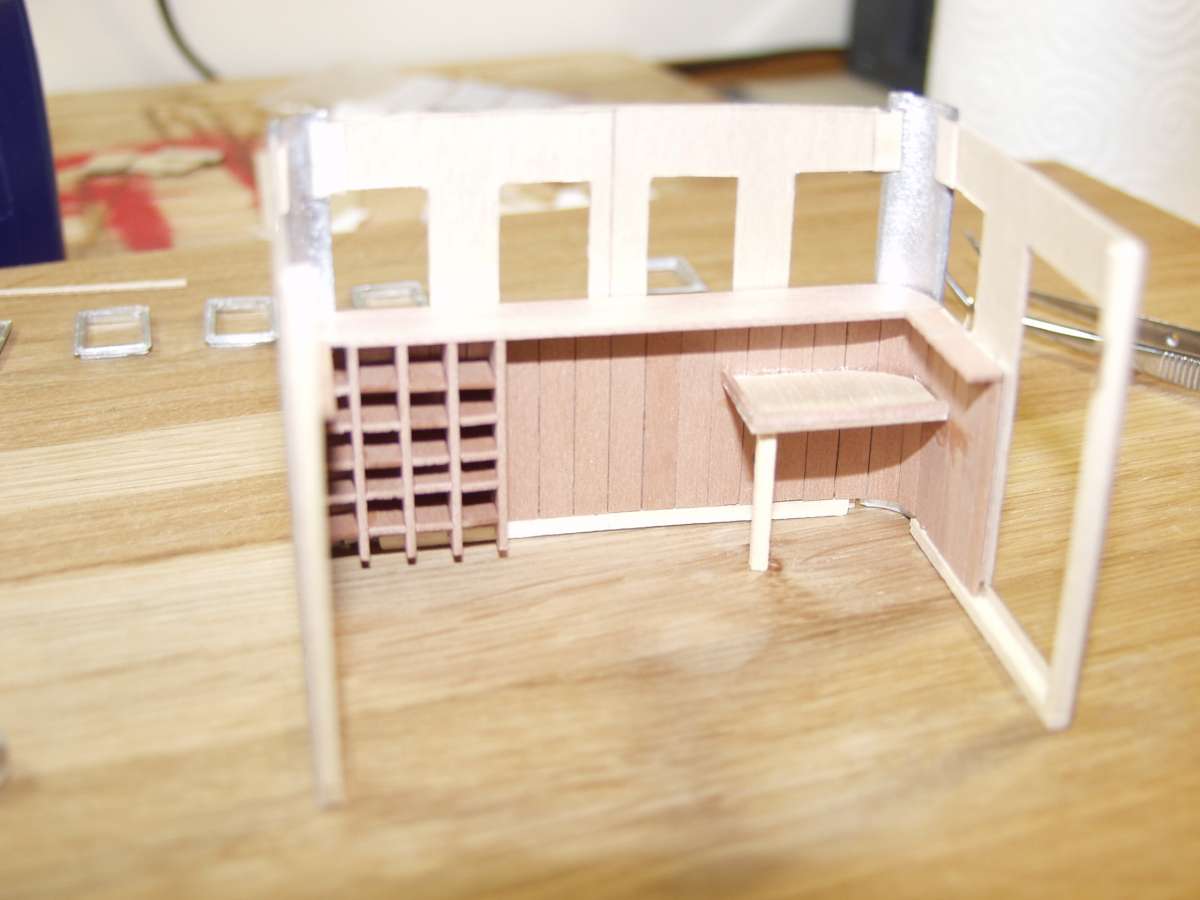

Probably the biggest deviation from the kit design was the fact that I wanted the bridge section to be removeable to give the best possible access to the steam plant. I consequently had to completely rethink how the bridge was going to be attached.

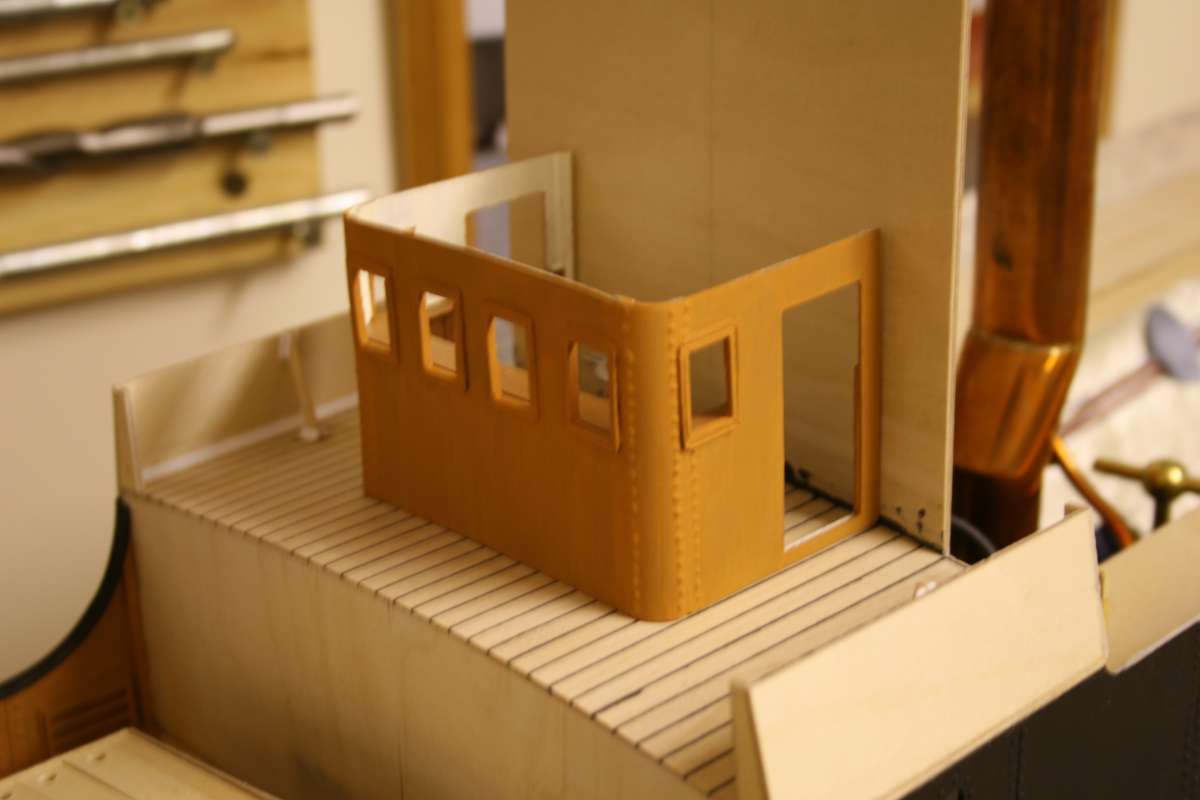

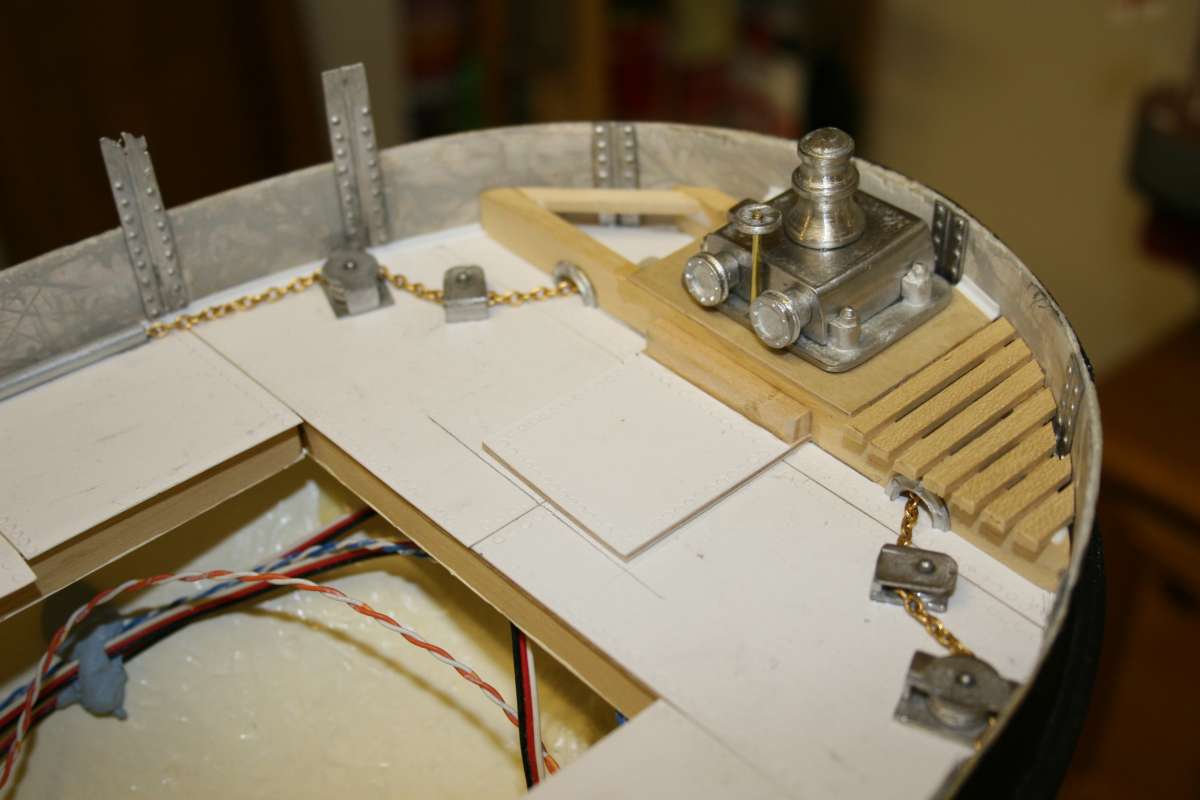

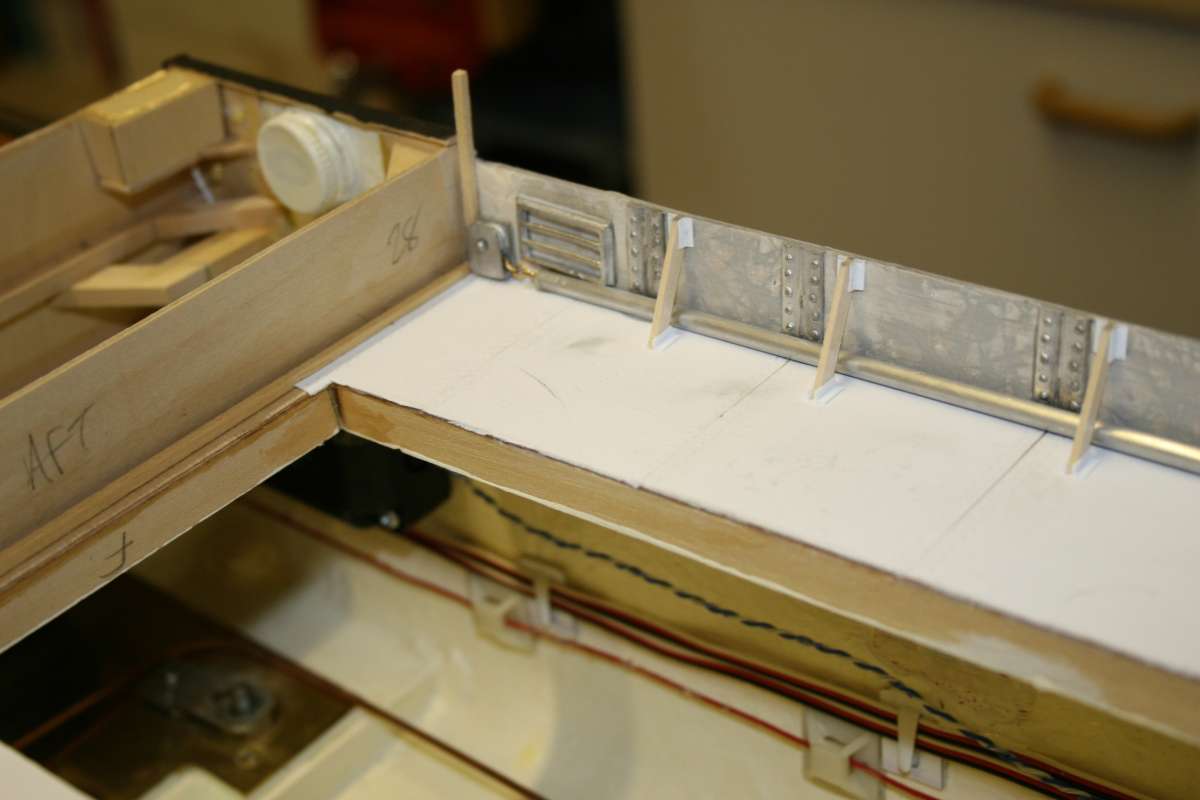

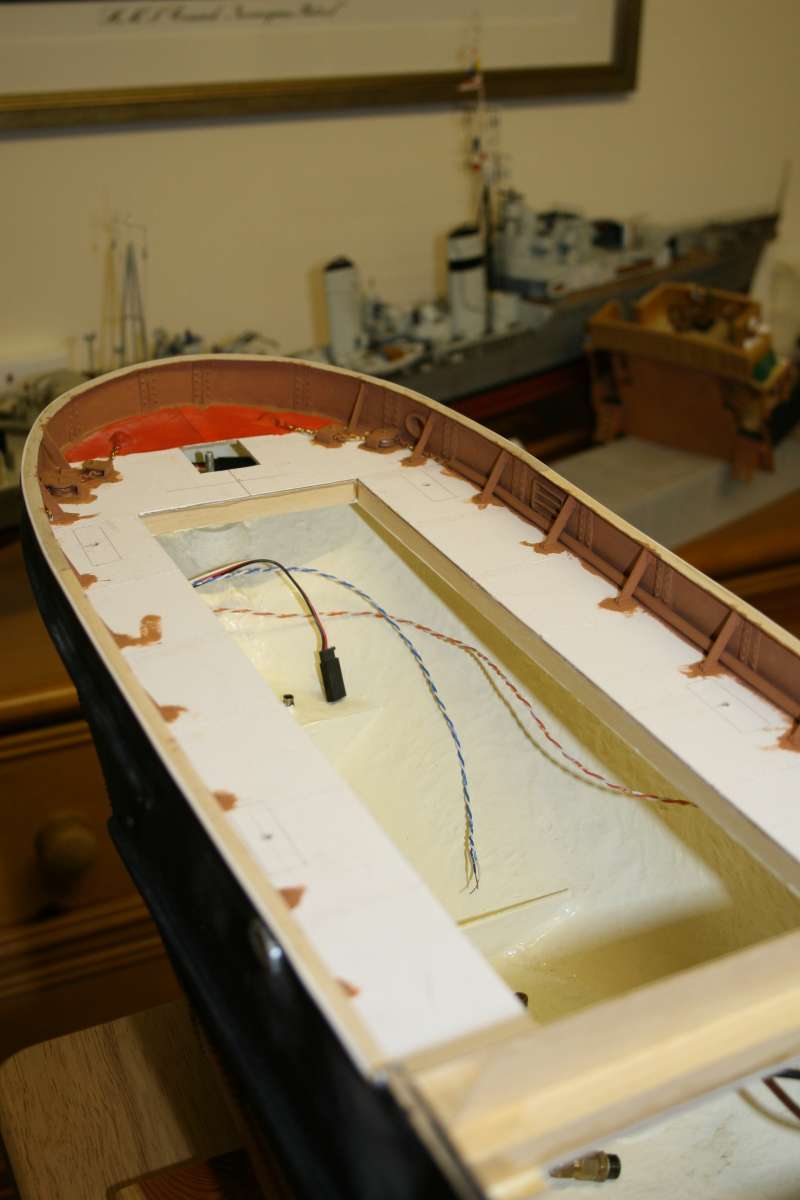

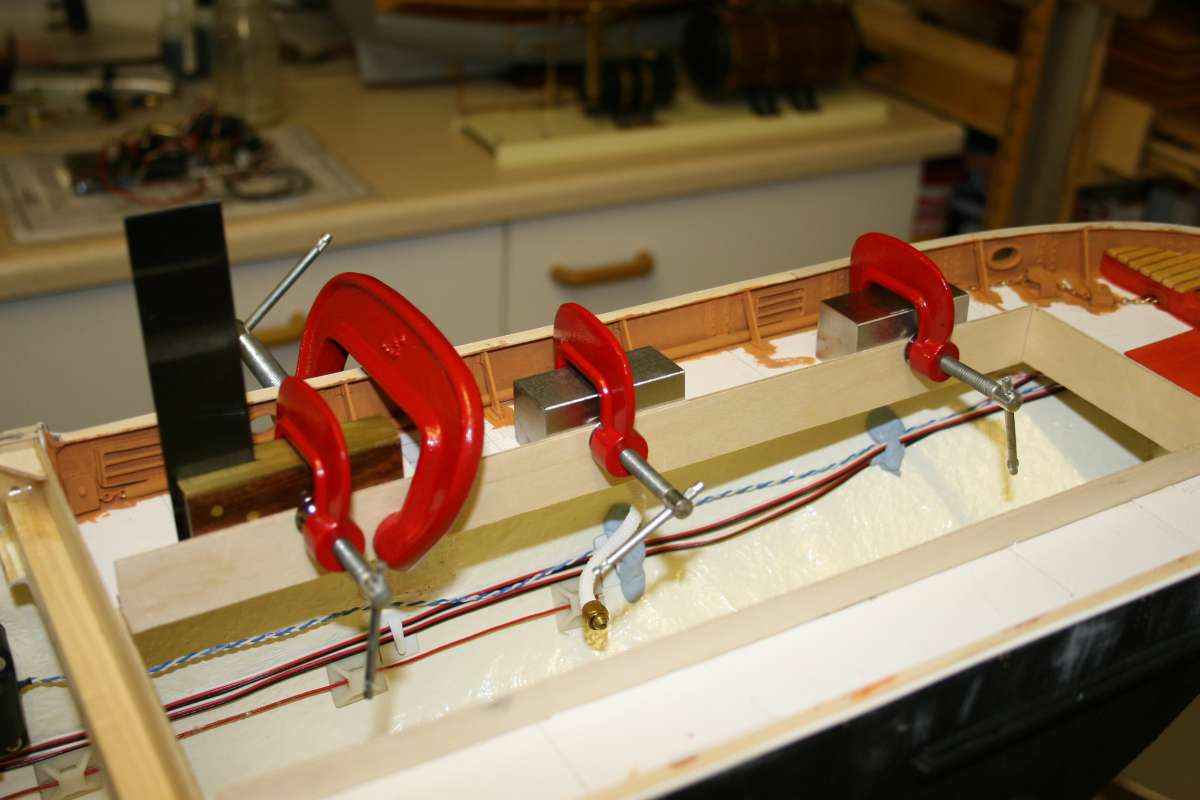

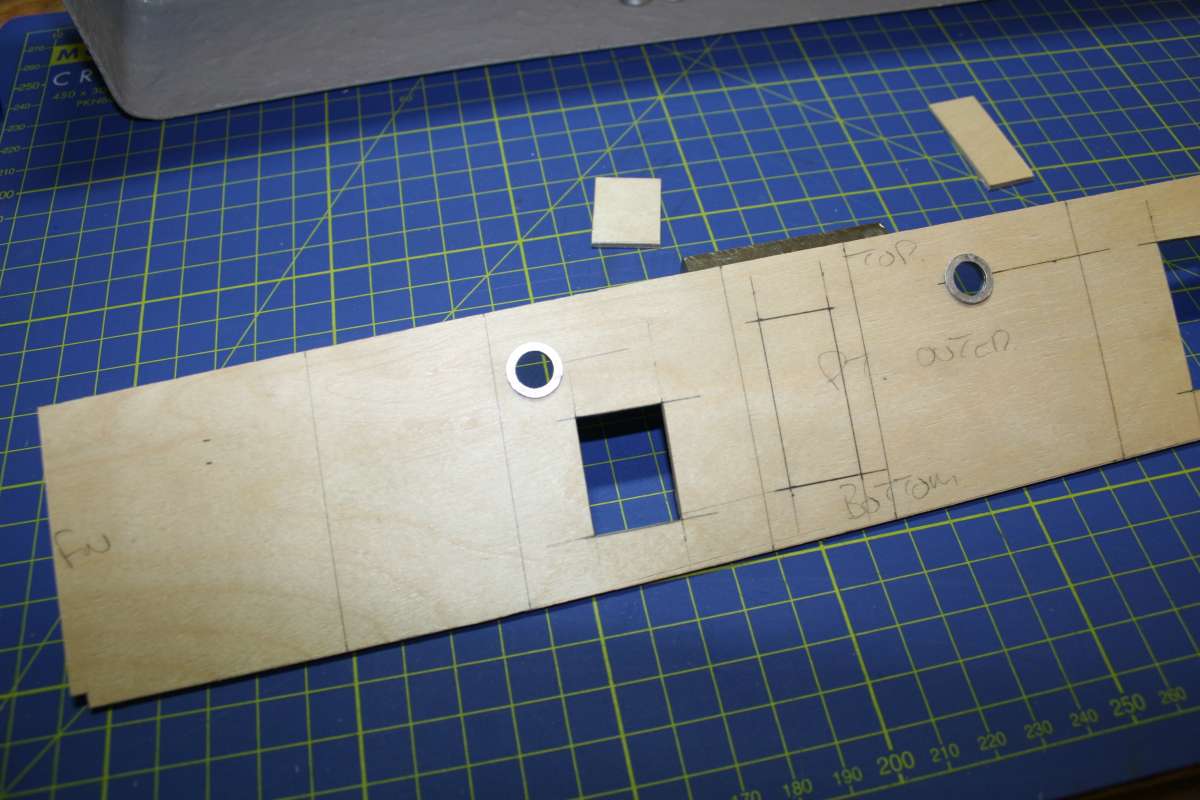

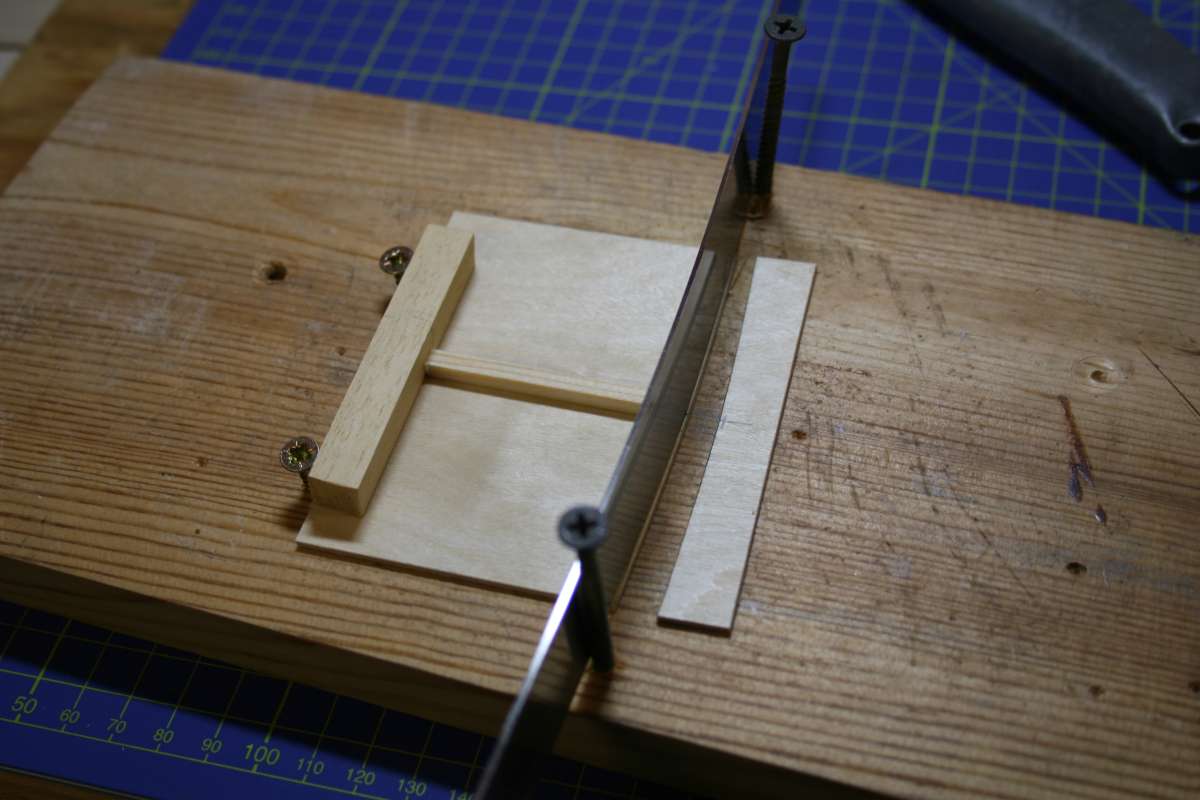

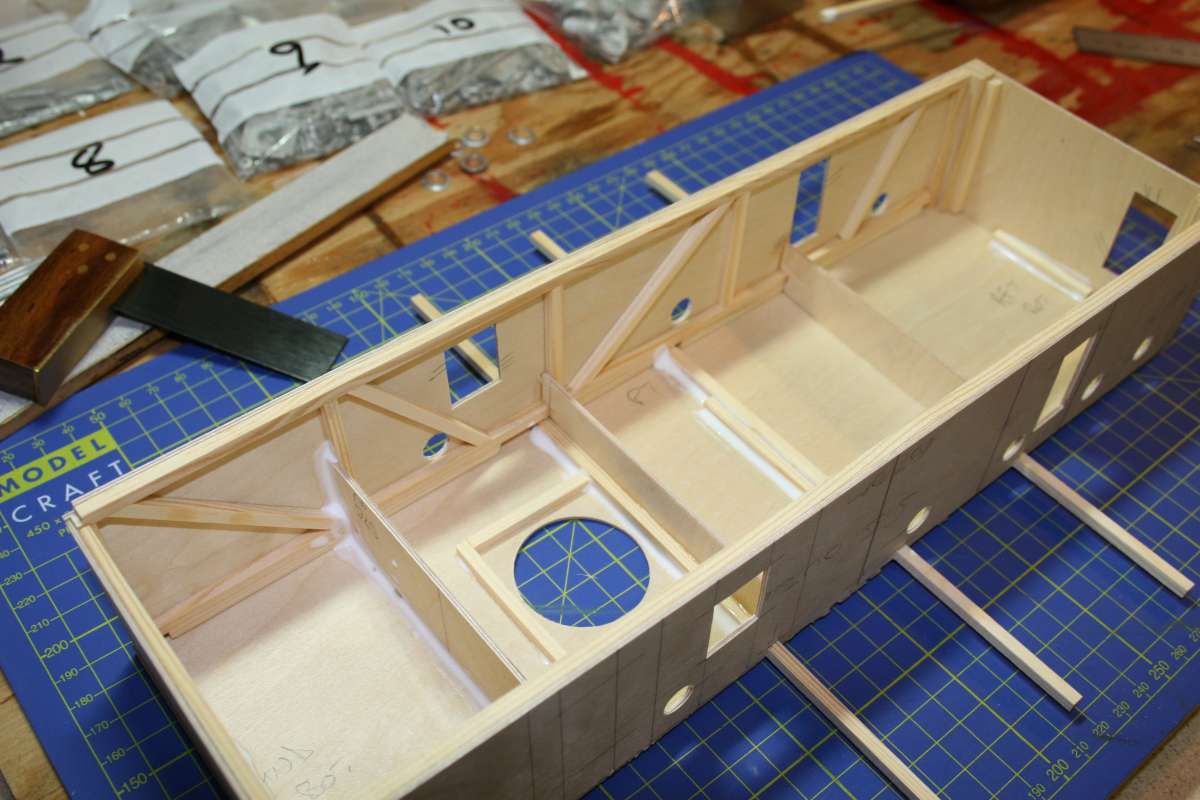

I decided the best way was to have a forward bulkhead and an aft bulkhead that slid into guides, with the bridge built between the two. The first job then was to create the guides and supports and fit the two bulkheads.

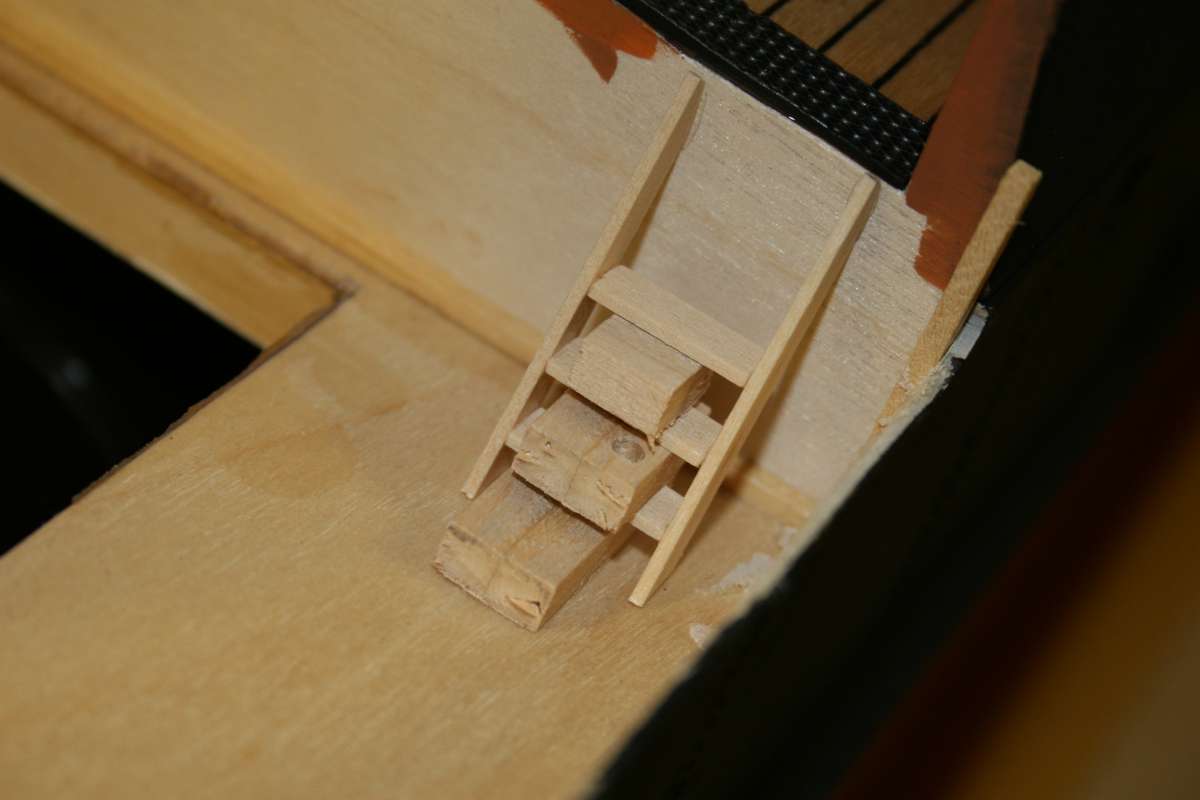

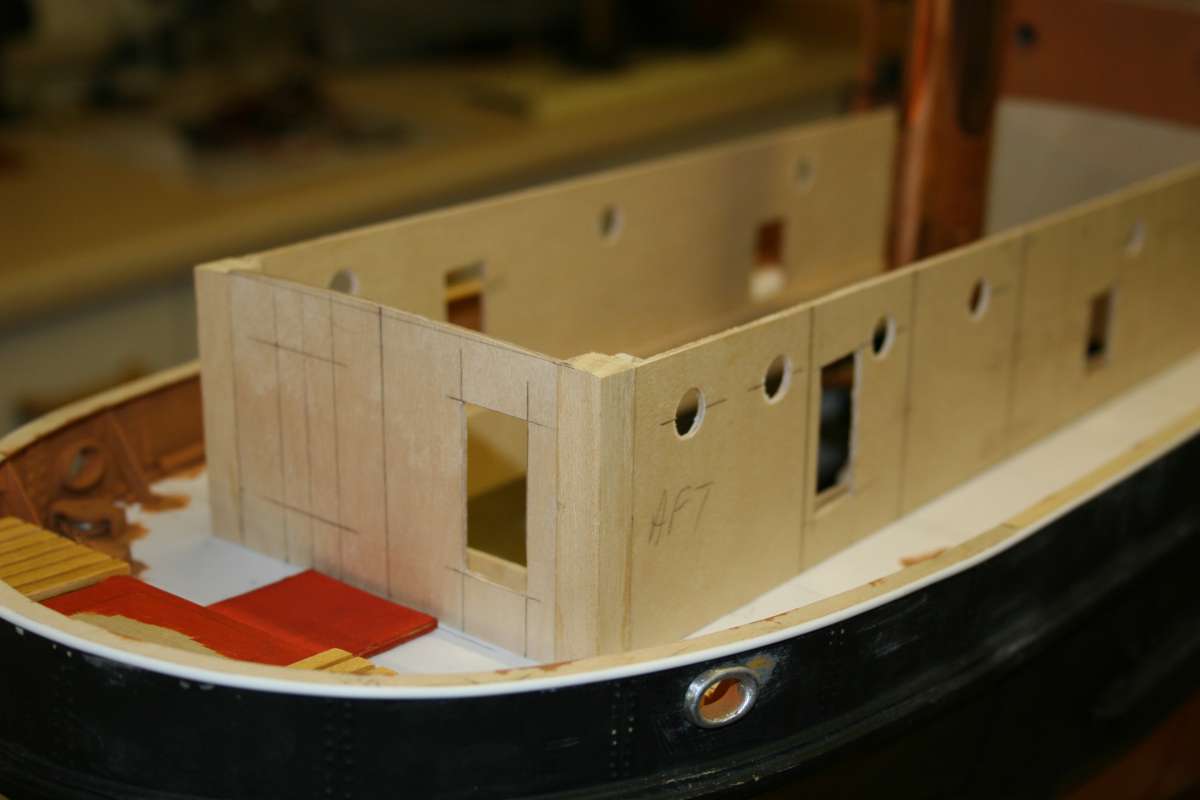

When they were in place I could fit the deck between them and build the bridge upwards from that. Additional stiffening was required to ensure the complete unit was rigid enough to be handled as a seperate peice and maintain its shape.

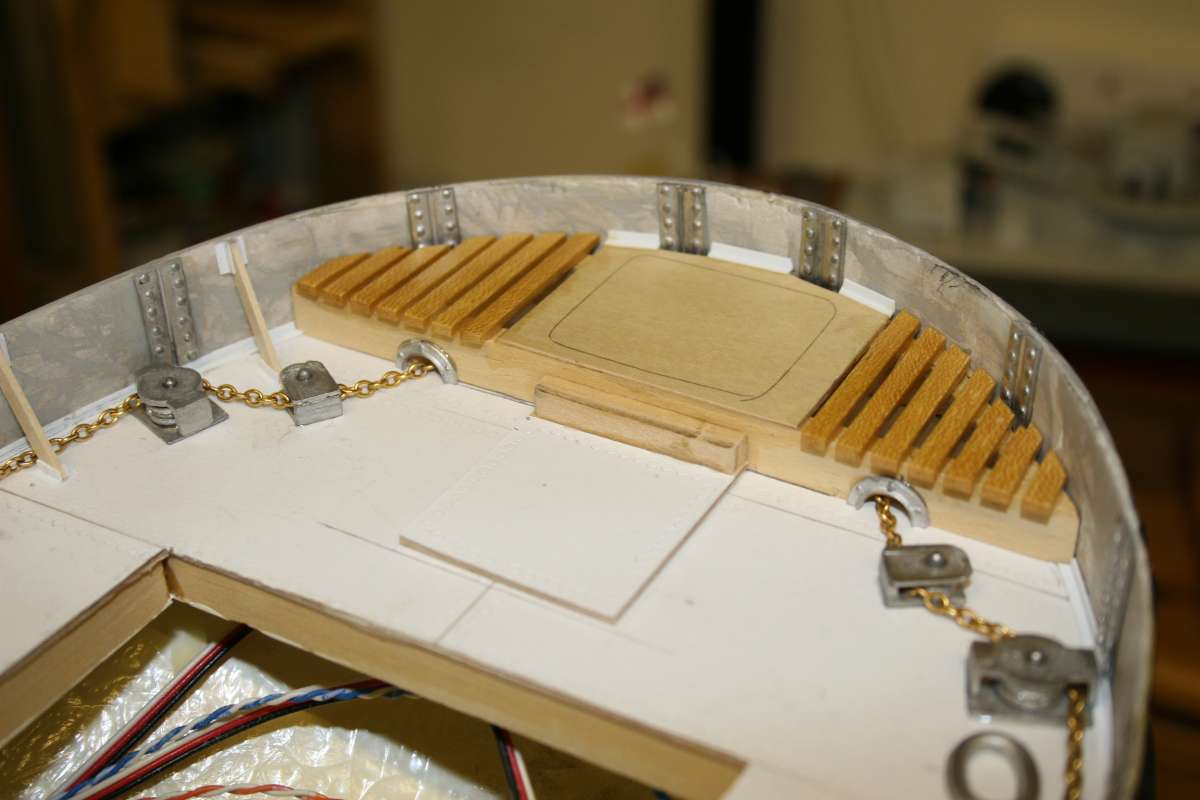

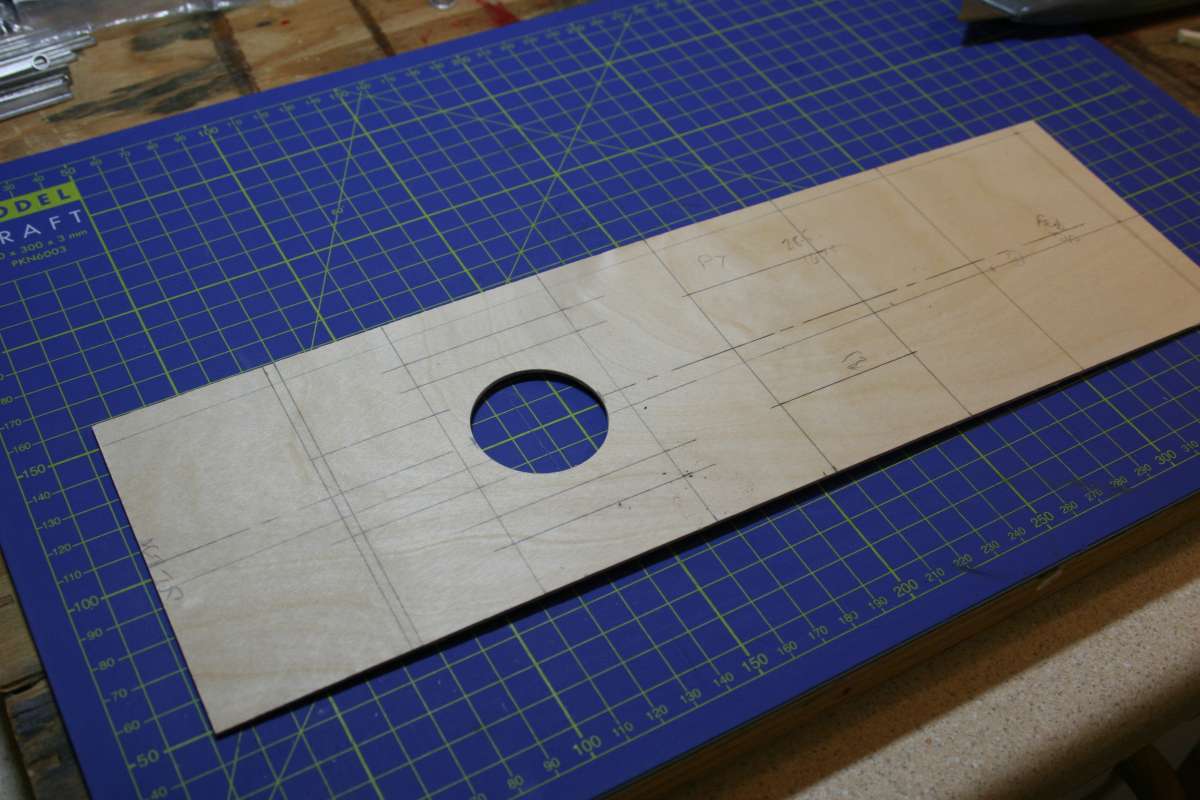

Then the deck was planked over a light play overlay.

To give me a solid structure that simply slid into the guides.

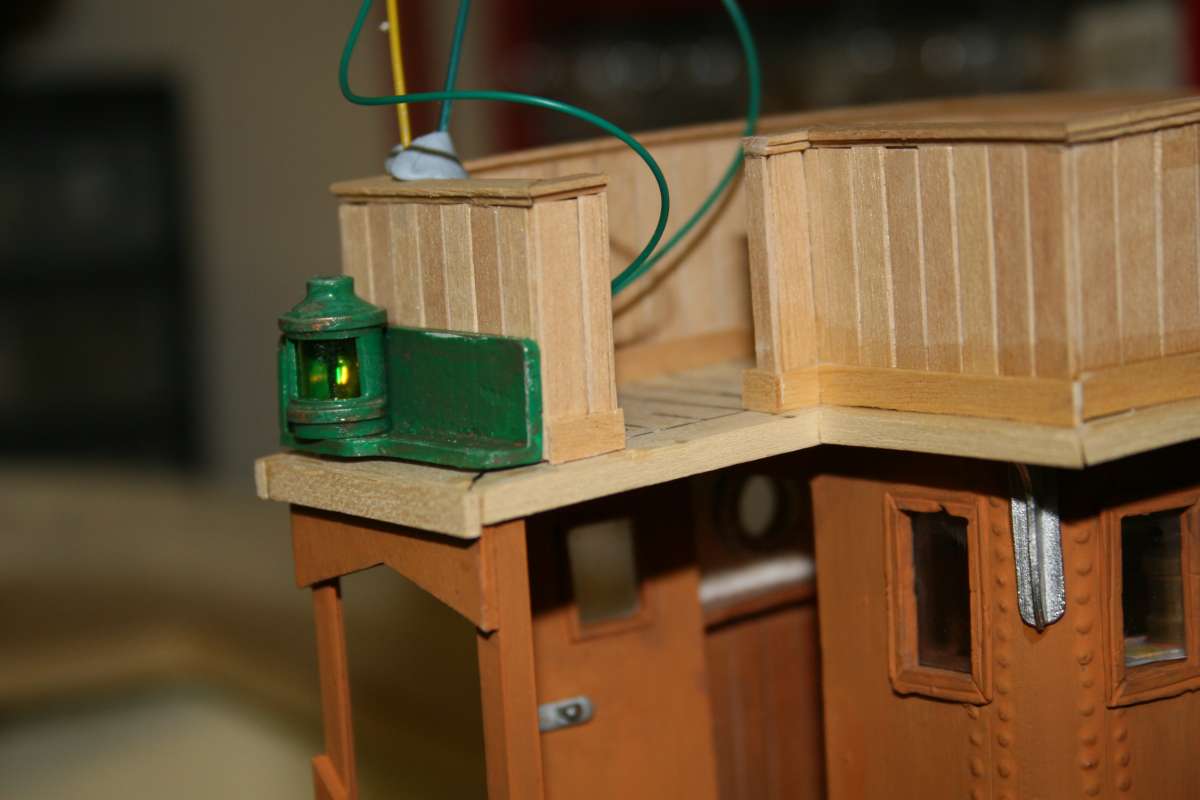

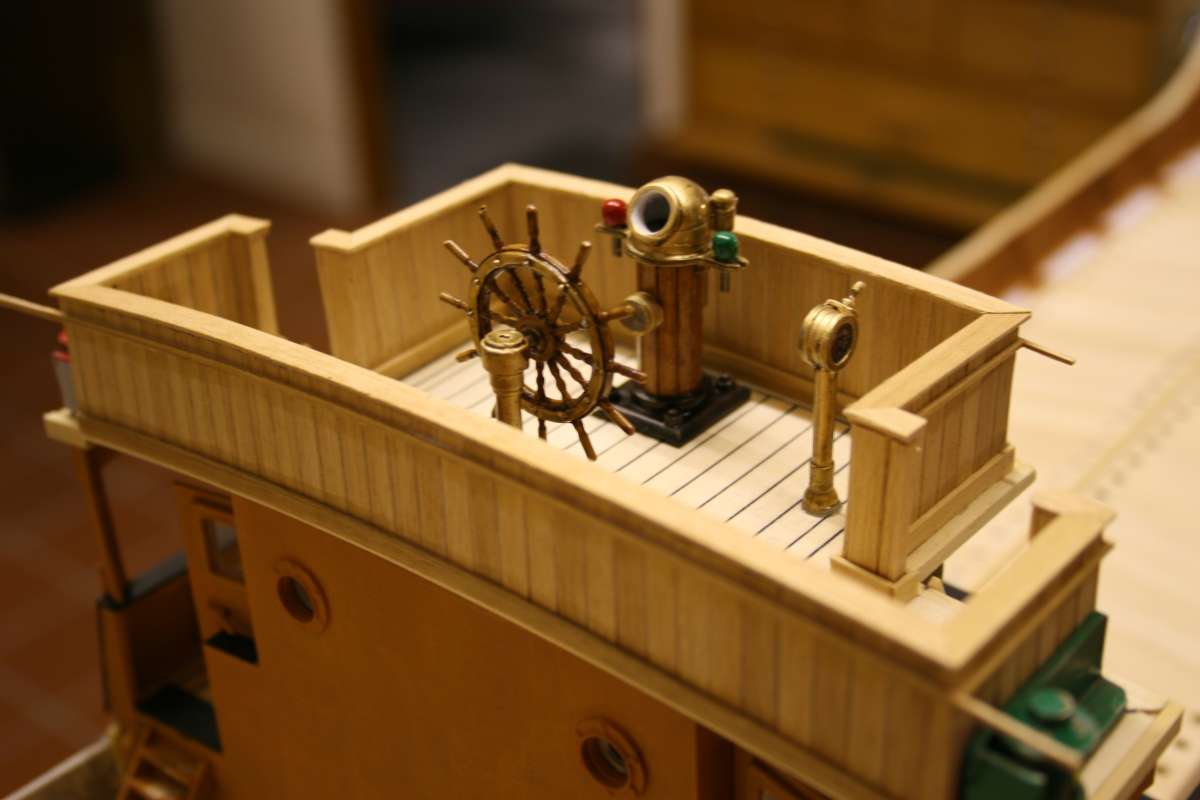

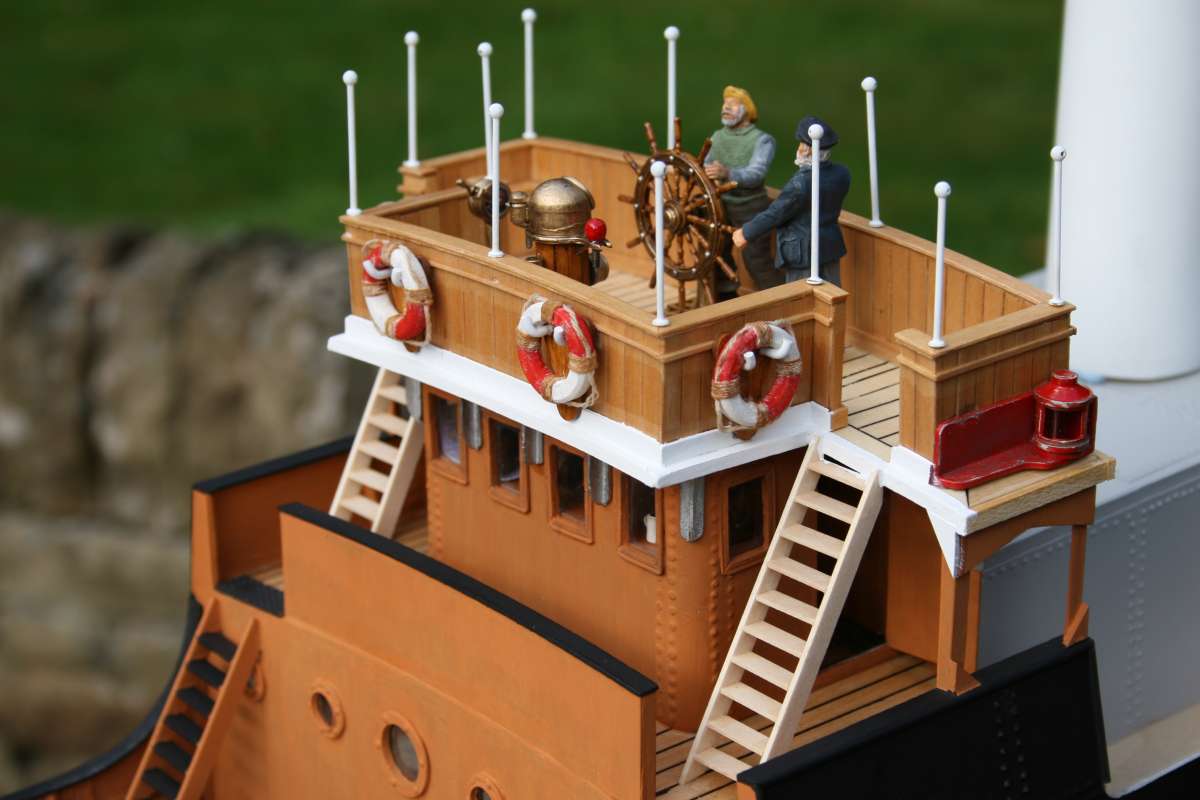

The remaining bridge structure was simply built onto this peice. I wanted the rear bulkhead to be one continuous peice right up through the monkey island and the aft bridge sidings for maximum strength and alignment.

Richard Simpson.

Richard Simpson.