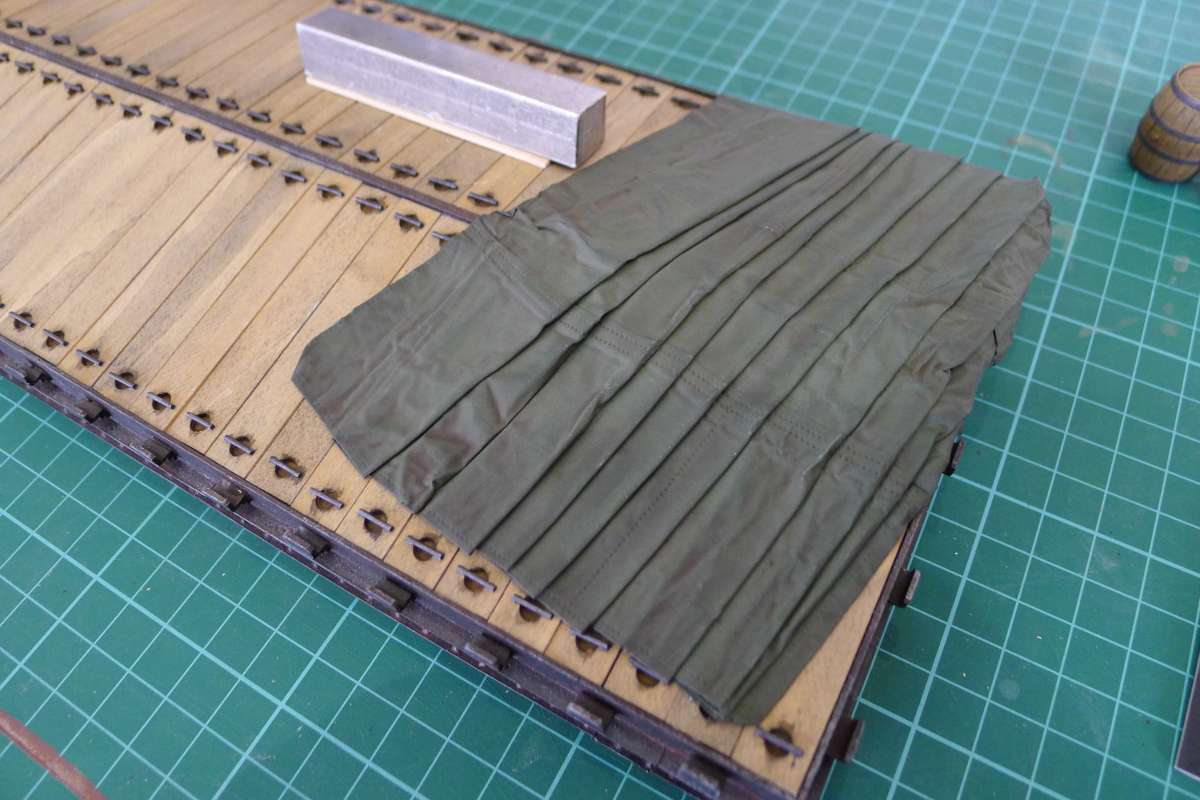

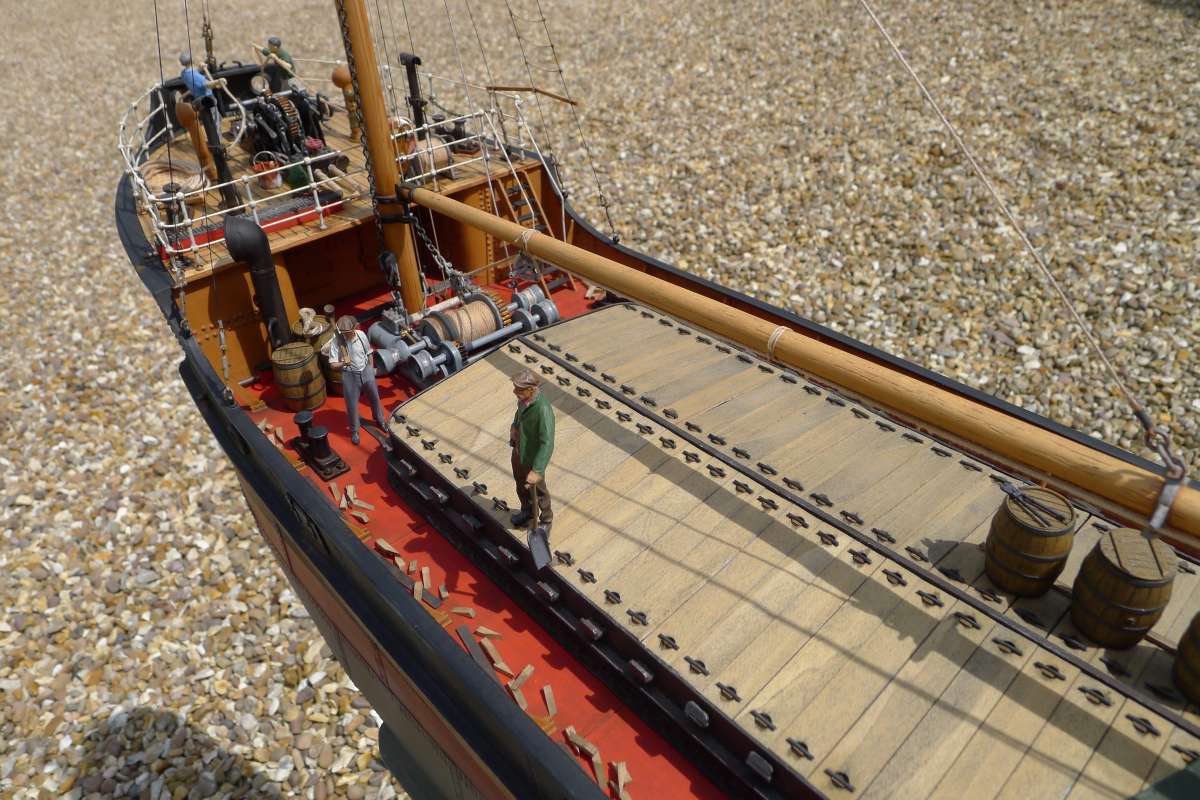

The final stage of this build, apart from adding an ensign to the aft mast, was always going to be the weathering job on the hull. The big challenge with this was always going to be that vessels of this type and age were always worked incredibly hard. Consequently there was frequently little time for maintenance nor money for materials so usually only the bare minimum was done. I have studied many pictures of this ship and others of the same era working similar passages and can see very clearly that many of them are what could best be described as heavily weathered. The challenge is transferring this to a model without it looking a mess! So very tentative steps were taken in an attempt to remain in control. As mentioned above before anything the entire hull was given a watered down wash with a dark brown enamel wash. Everything was done on one half of the model with it sat at around 45 degrees before turning it around and doing the other side.

One of the best shots I have of the ship is along side in Douglas harbour sat on the sand so the whole hull is visible. What can clearly be seen is not only the bleached and salt streaked upper paintworks but also how the barnacles form below lightship water line and how different loaded waterlines are visible in the salt stains. I wanted to try to catch some of these effects but first was to introduce some rust streaking. I didn’t want it to look over done so I added some around the bow plating and the anchors and then some below the freeing ports and mooring chocks or hawseholes. The method was to place a piece of masking tape on the edge of the plate and then stipple some oil paint on the edge of the masking tape with a small tatty old brush. The paint was random light and dark rust colours and ochre. A large flat wide brush was then dipped in thinners and almost dried before dragging it vertically downwards through the paint. This was then cleaned off the brush and the stroke repeated until the right amount of streaked paint was left.

After that had thoroughly dried a very light grey pigment was streaked lightly downwards in a random manner, concentrating on fittings but using enough to create a bleached and salt streaked effect over the entire black part of the hull.

When I was happy with that it was time to have a go at below the waterline. I set the model up on a base in exactly the same way as I would when drawing a waterline but this time the model was set at a light ship level. Basically the stern was pretty much a similar level but the bow was much higher out of the water. I drew the new water line, masked off the line and covered the model with bin bags to protect it. Below the masking tape was then given a very light dusting with a dark green acrylic paint from a rattle can. Holding the can a good distance from the model and trying to get a bit of random shading. Once that had dried I again dragged some very light grey pigment powder down over the edge of the masking tape. All the masking was removed to reveal the shaded lower hull. I then wanted to create another salt stain shadow at another level so again the waterline was marked out at an intermediate load level, masked up and this time further pigment only was dragged down over the edge of the making tape.

At the end of the process I already wish I had done some things a little differently but this is the first time I have tried to recreate such an effect and, overall, I’m reasonably pleased with it. I just need an ensign for it now then some final pictures outside.

Richard Simpson.

Richard Simpson.