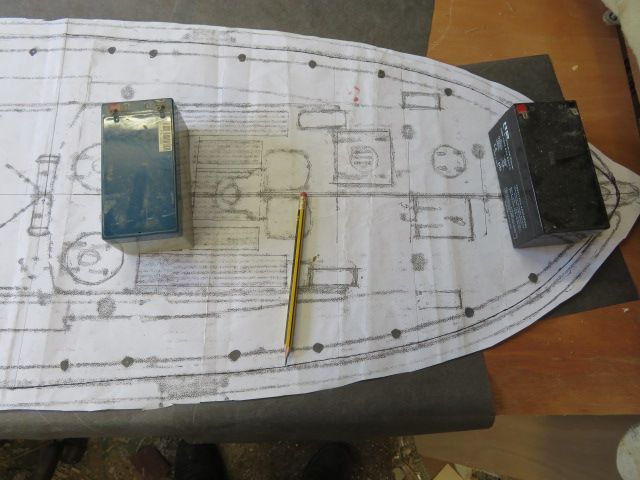

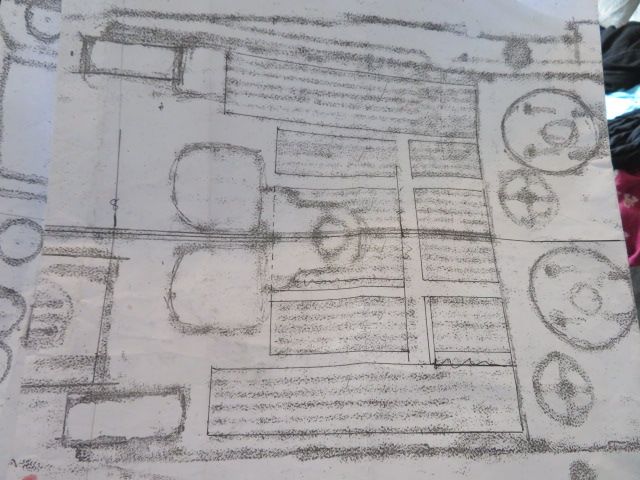

Everything seems to be bigger on this boat than on other classics that I have built in the past, other than the bigger Clyde that I built years ago, but am enjoying it very much.

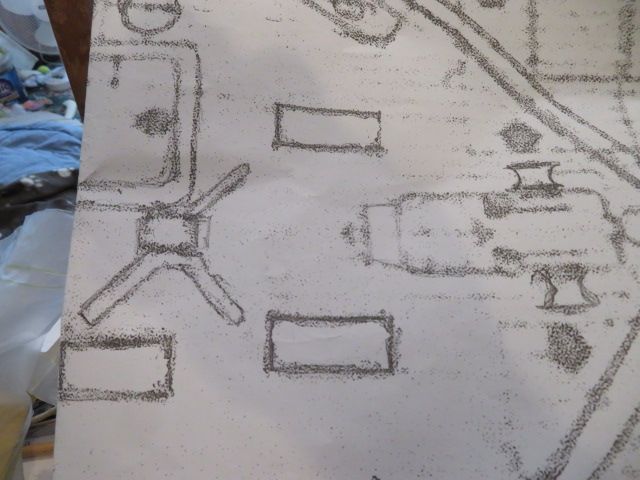

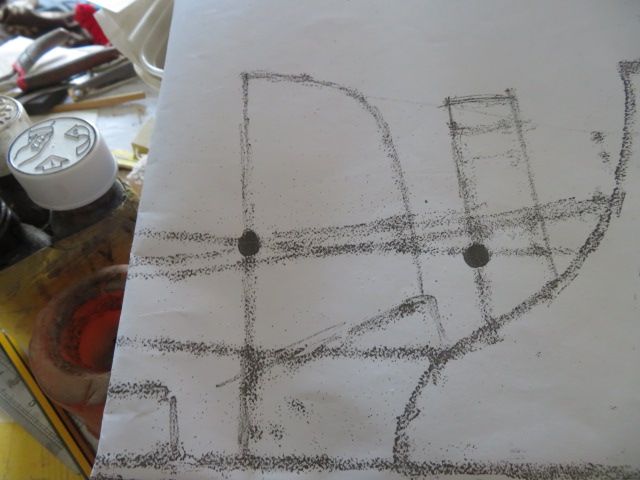

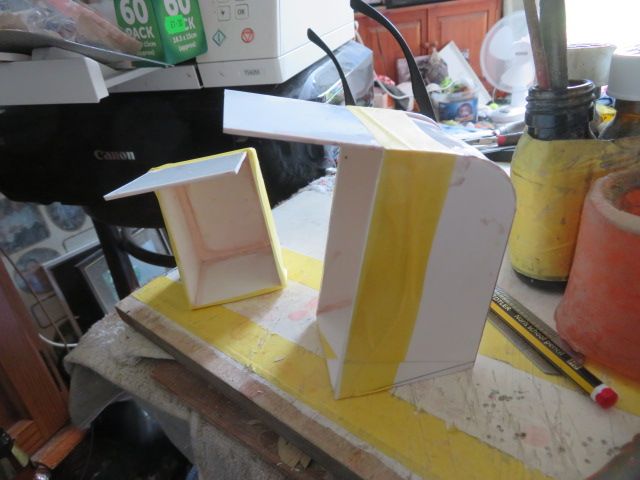

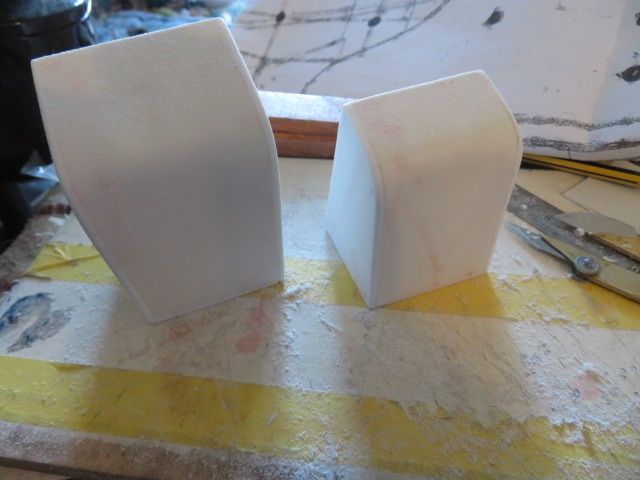

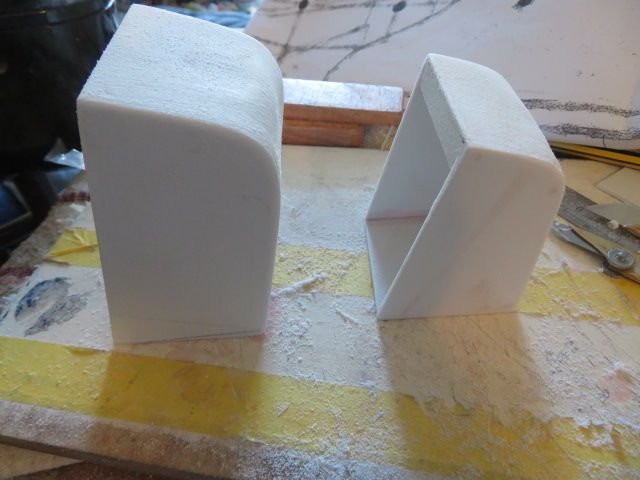

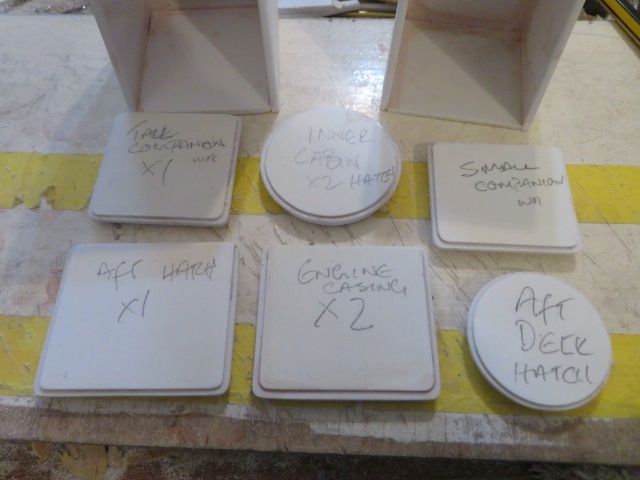

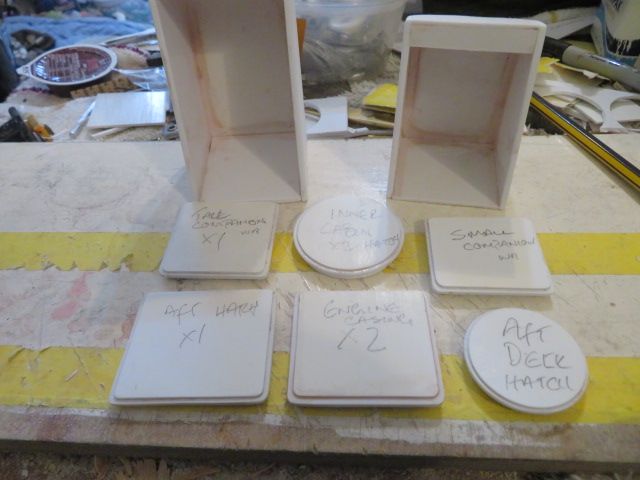

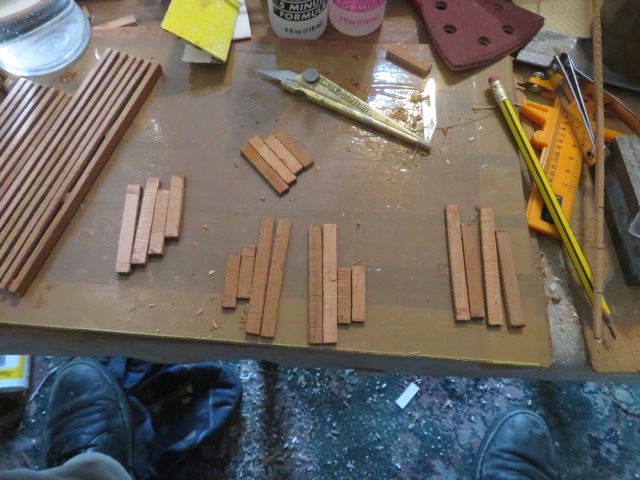

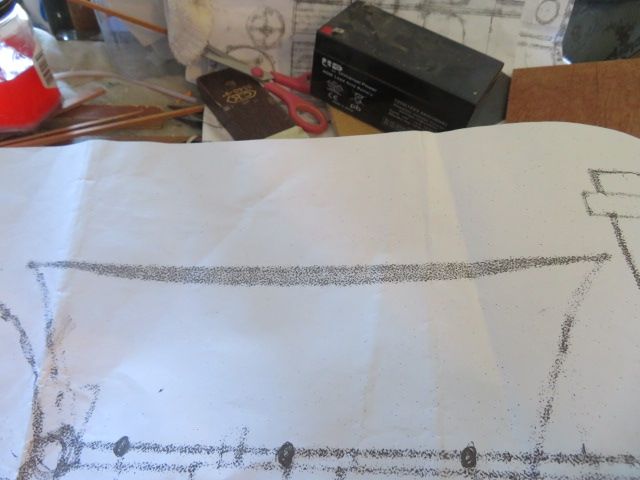

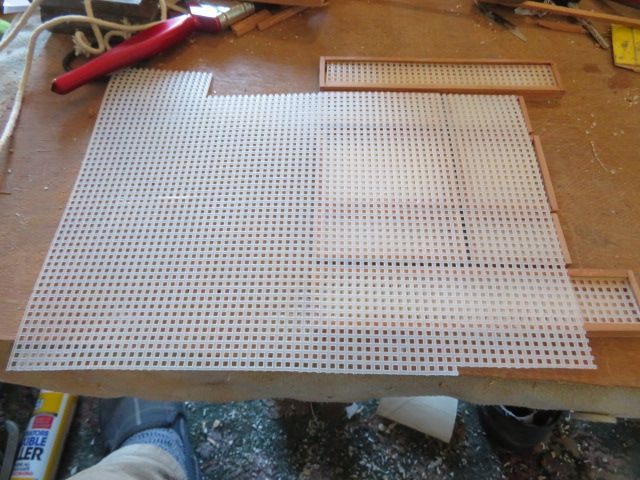

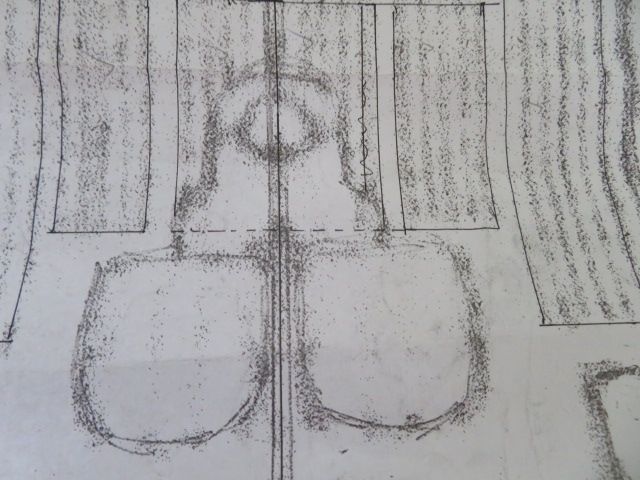

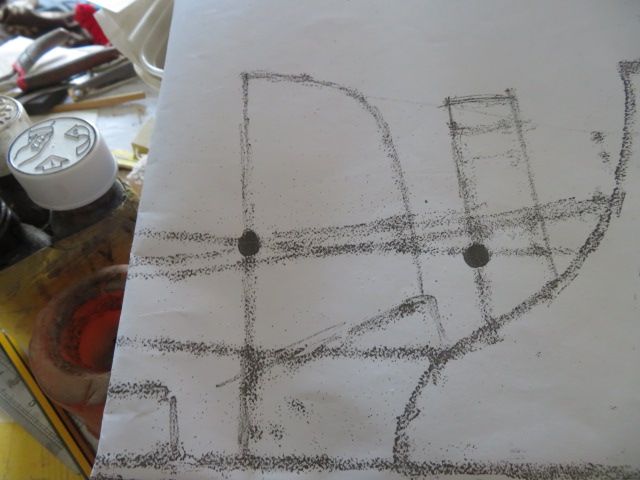

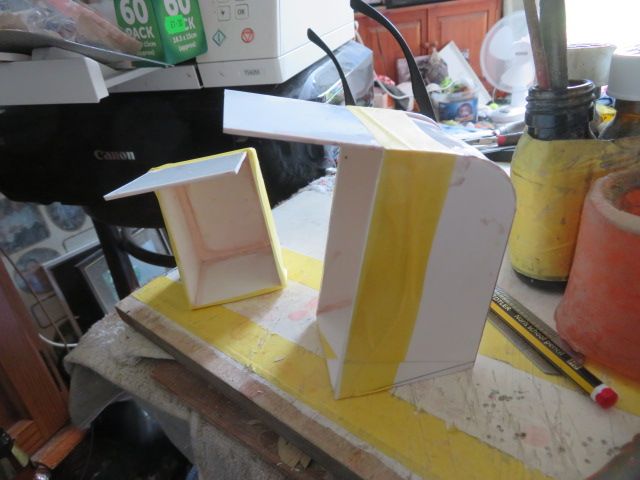

Last night I started cutting out and gluing the base and sides, and backs for the two different sized companionways, housing hatches to the insides of the boat, the fore and rear survivors cabins, but because of their sizes I chose to use 2mm thick plasticard, for all pieces.

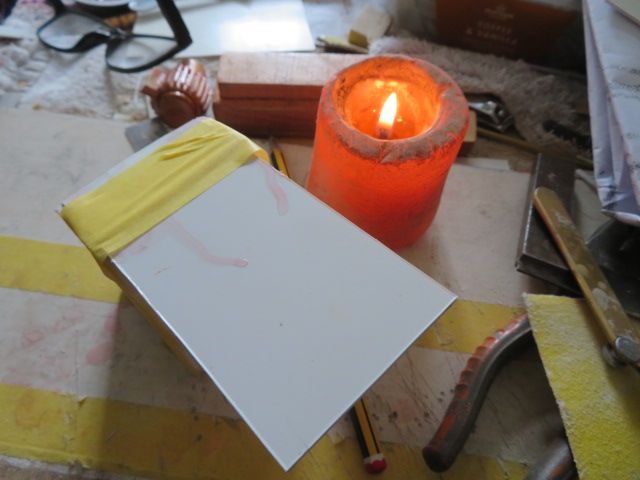

So last night I glued the bases, sides and half of the backs up to the start of the bends in the two companionways using EMA Plasticweld, and although it will bond within seconds to glue parts that no stress is put on to the joints, when under stress as the backs would be when I start to bend the thick sheet, the joints need to be left to fully bond the pieces together and harden up to full strength. As such I left what had been glued, over night.

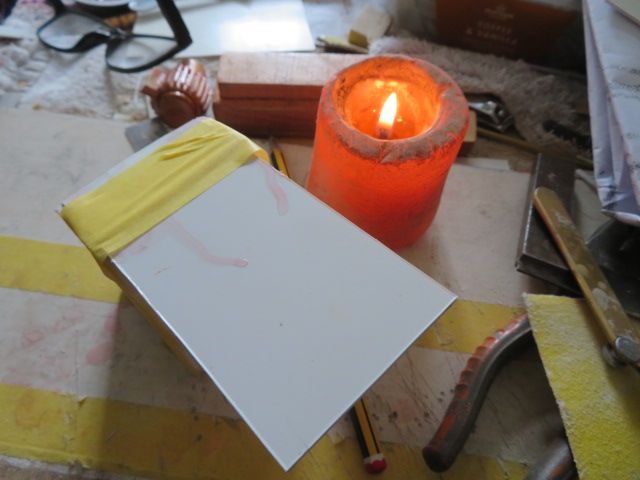

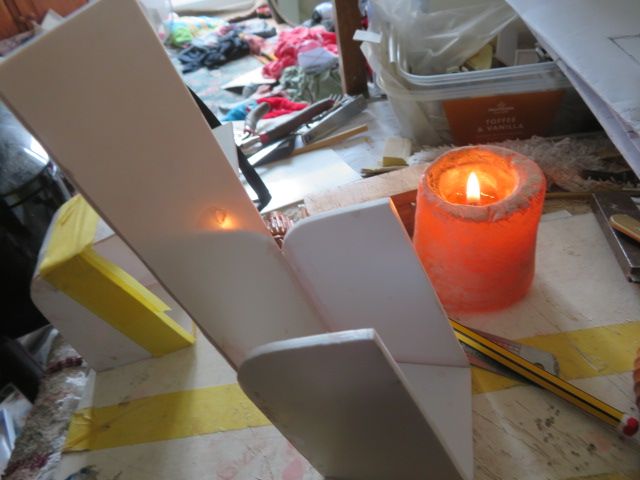

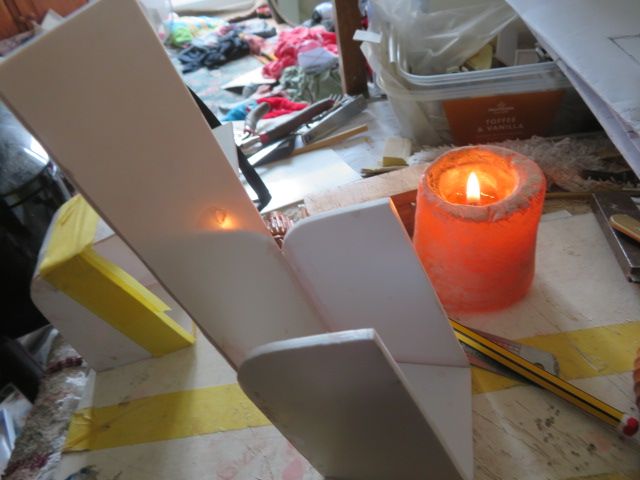

This morning I lit a candle, and with gentle heat to the plastic to be bent, I anealed the plastic to soften it in order to bend to shape.And then i glued it together and tape it up to maintain the bend and joints and left all to bond and set.

I am giving my 3 monthly pinta of O Neg this afternoon at the same hall that Dave Stavros Jones feels so much at home every October, the exibition hall of the Norbreck Castle, at 14.00 hours so will leave the companonways to set until I have had my 3 monthly ration of Bourbon creams and week orange squash. lol, before I carry out some cleaning up and trimming off.

Edited By neil howard-pritchard on 26/07/2022 11:49:05

neil hp.