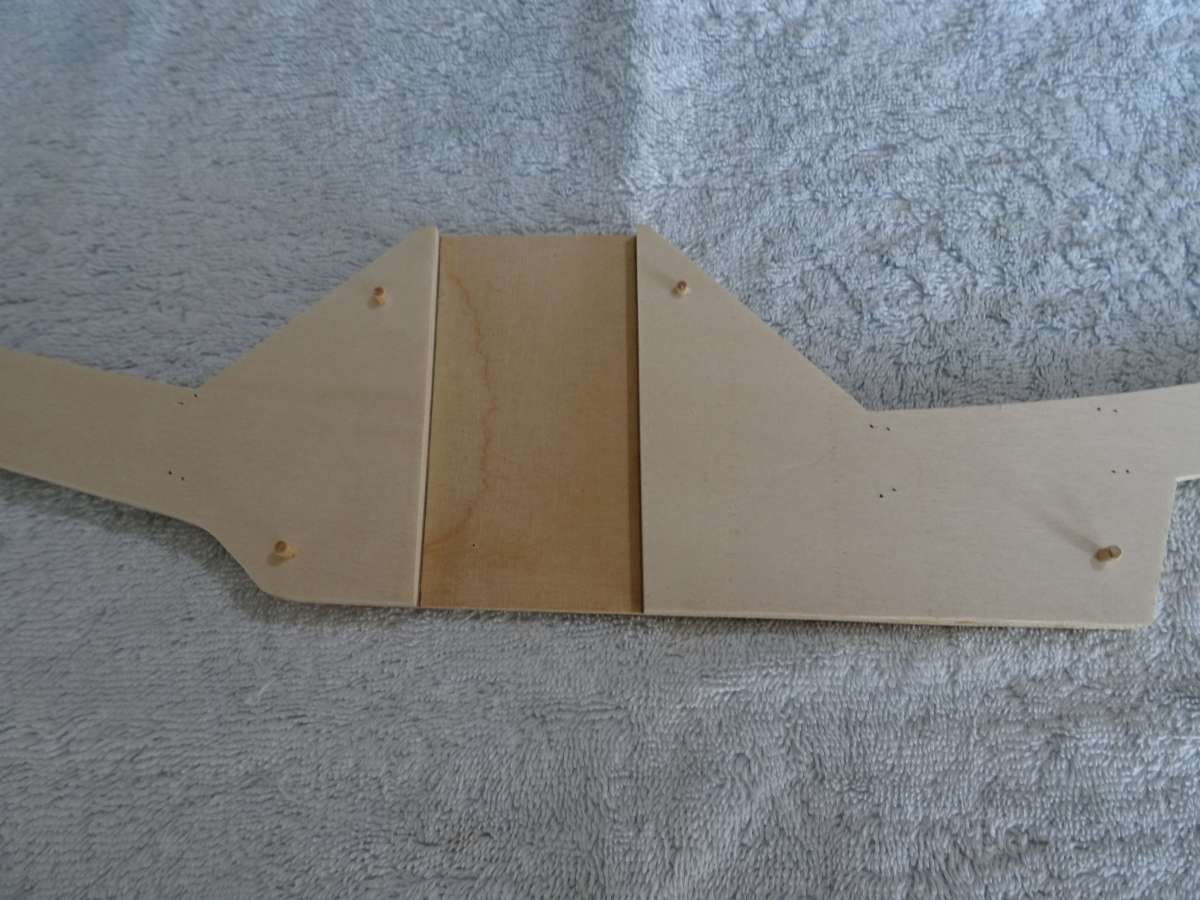

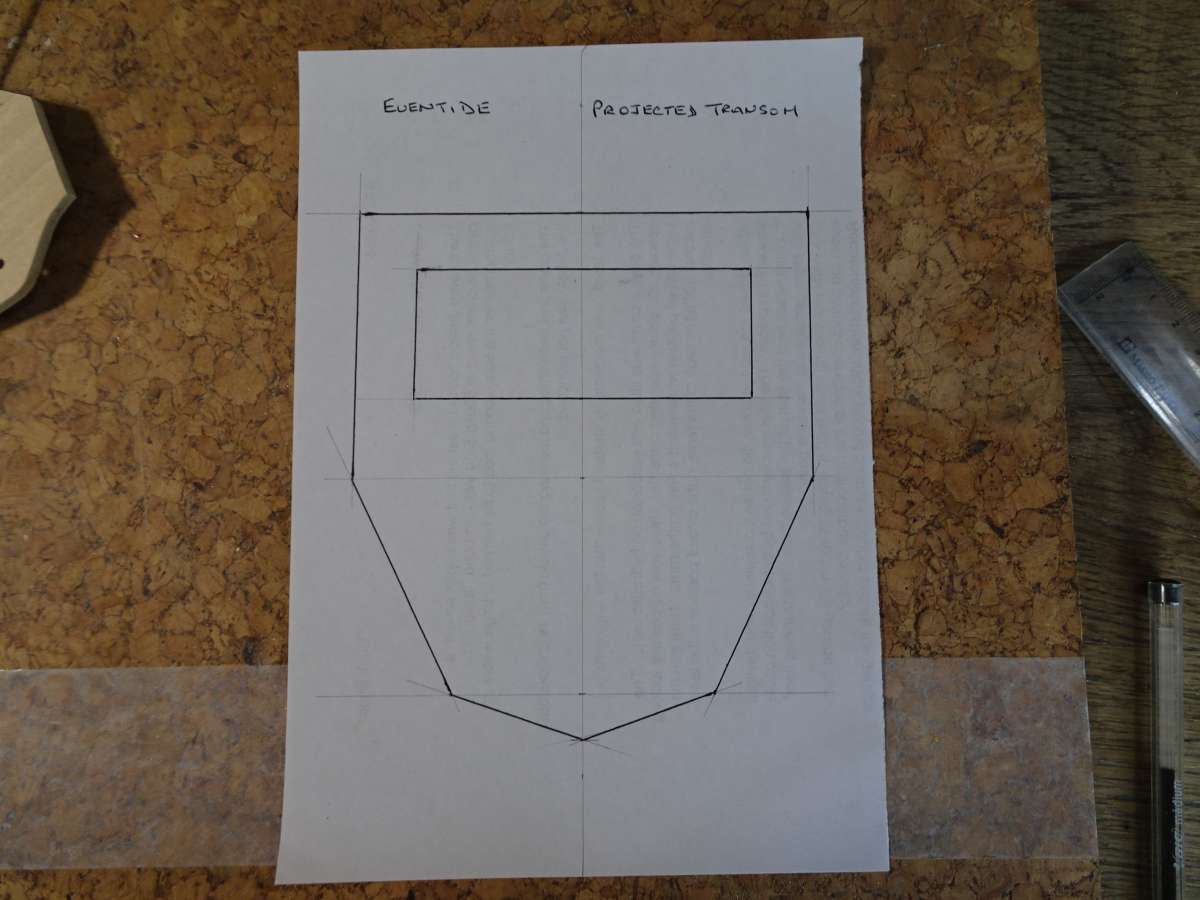

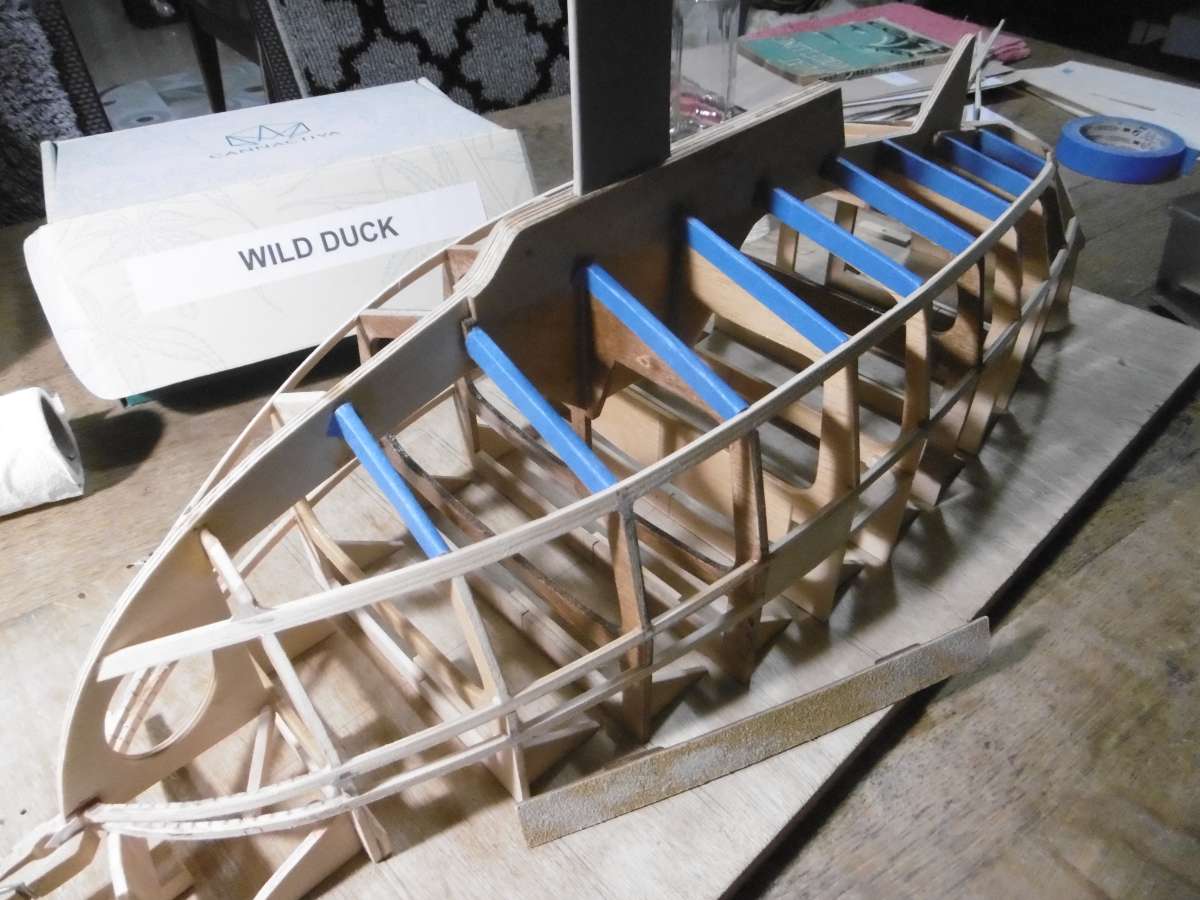

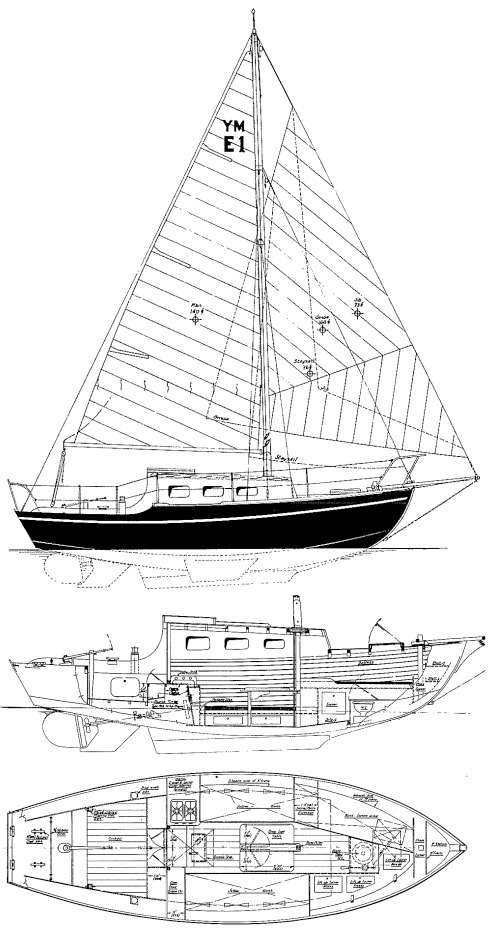

On with the build and to set up the frames on the building board. Ray’s method of extending the frames up / or down (whichever was you look at it) to a common datum helps a lot. He did leave out the transom and seeing as that was pretty important to support the aft end of the keel, it had to be worked out. Actually it was a fairly simple piece of projection as we both made the transom flat and then curved it by adding a balsa sheet to sand to shape.

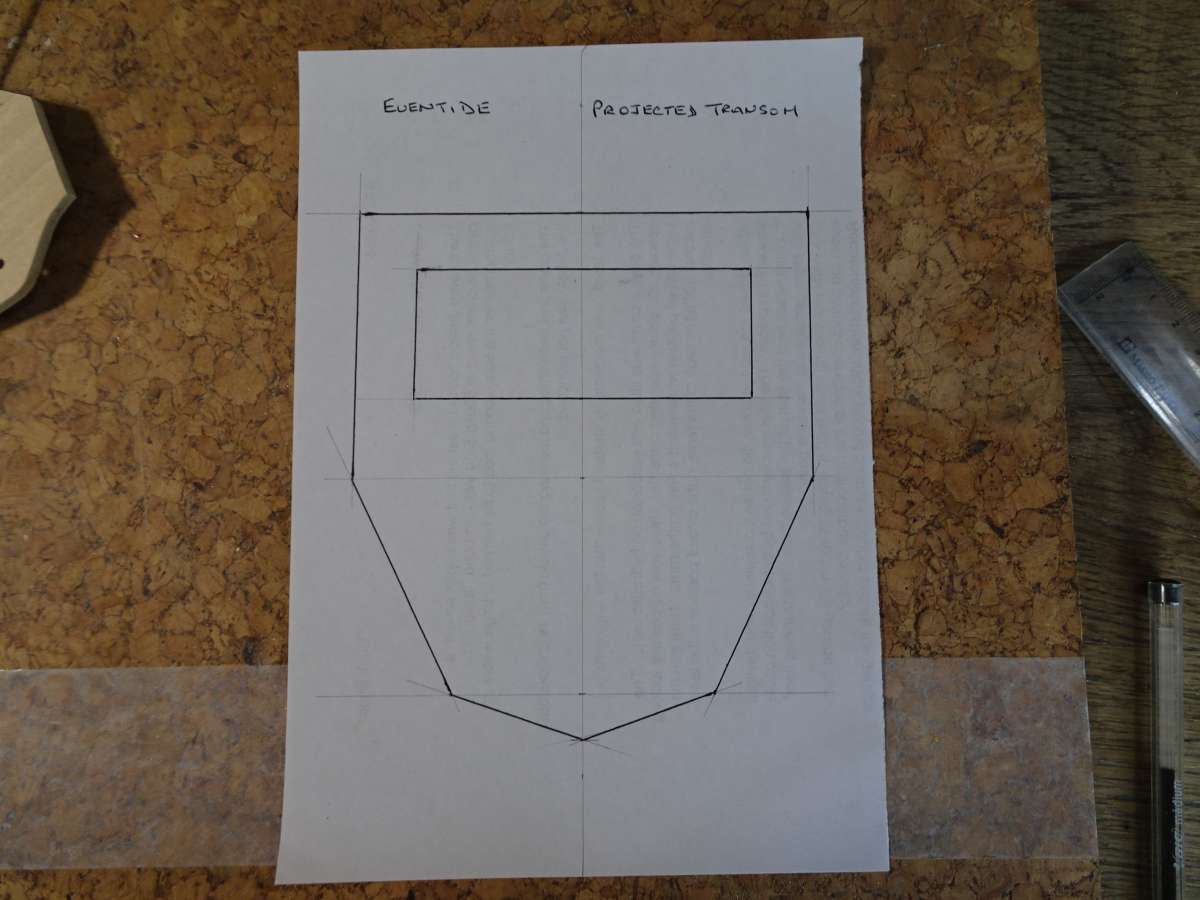

Here is the projected transom and if anyone else fancies building Eventide I can send the drawing as a pdf with a scale for reference. It did work out more or less spot on.

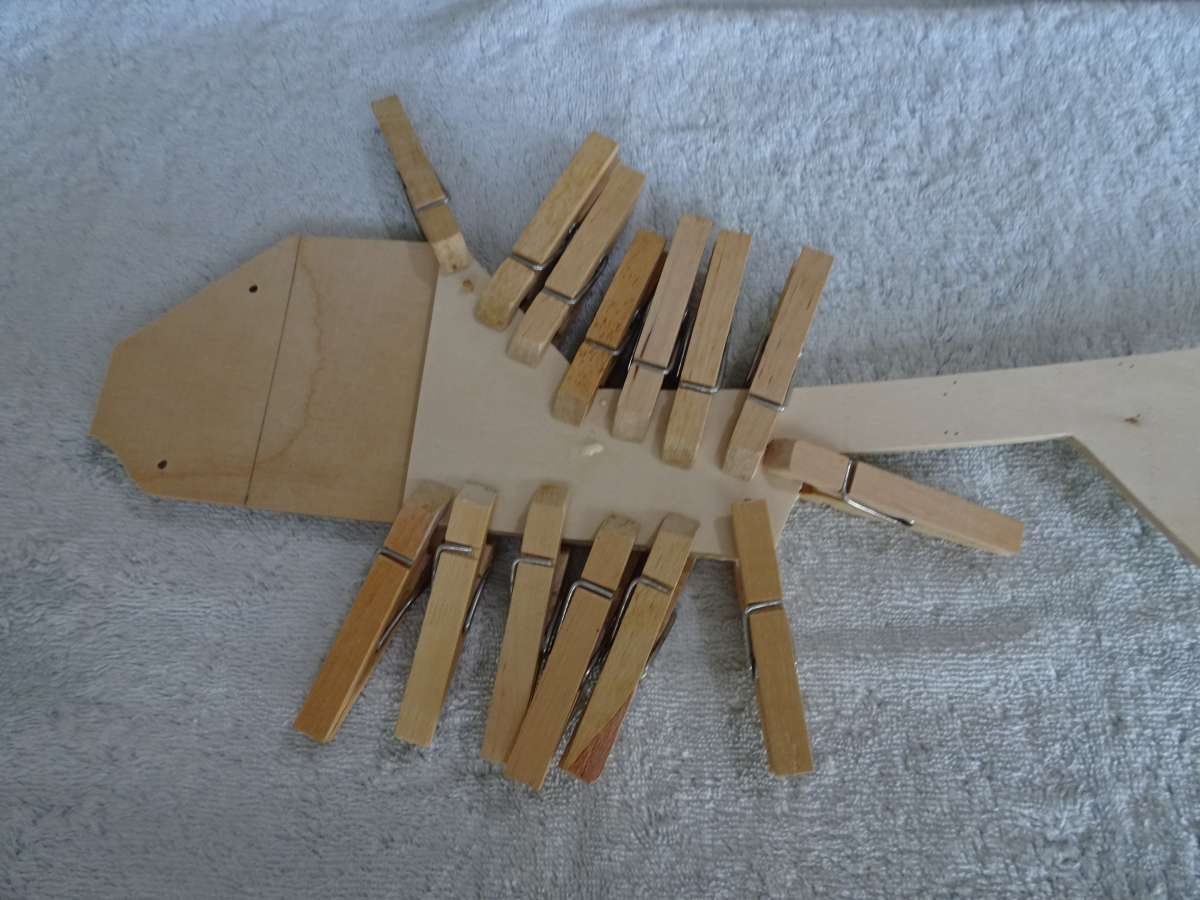

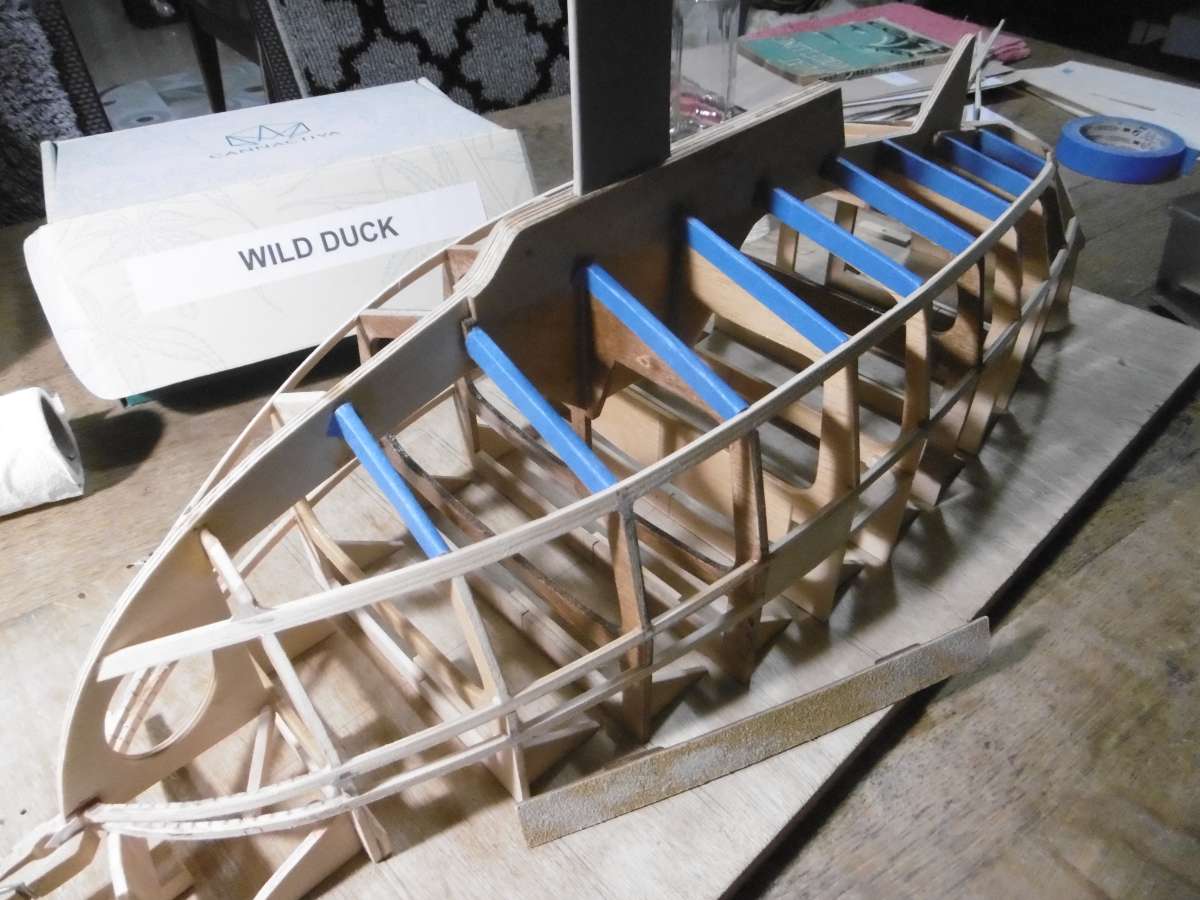

Some people glue pieces of wood to the frames to screw to the building board. I am a wood miser so mine are glued direct with aliphatic. Being Lite PLy they broke off very easily when the came came to release and some quick sanding of the glue spots restored the board like new.

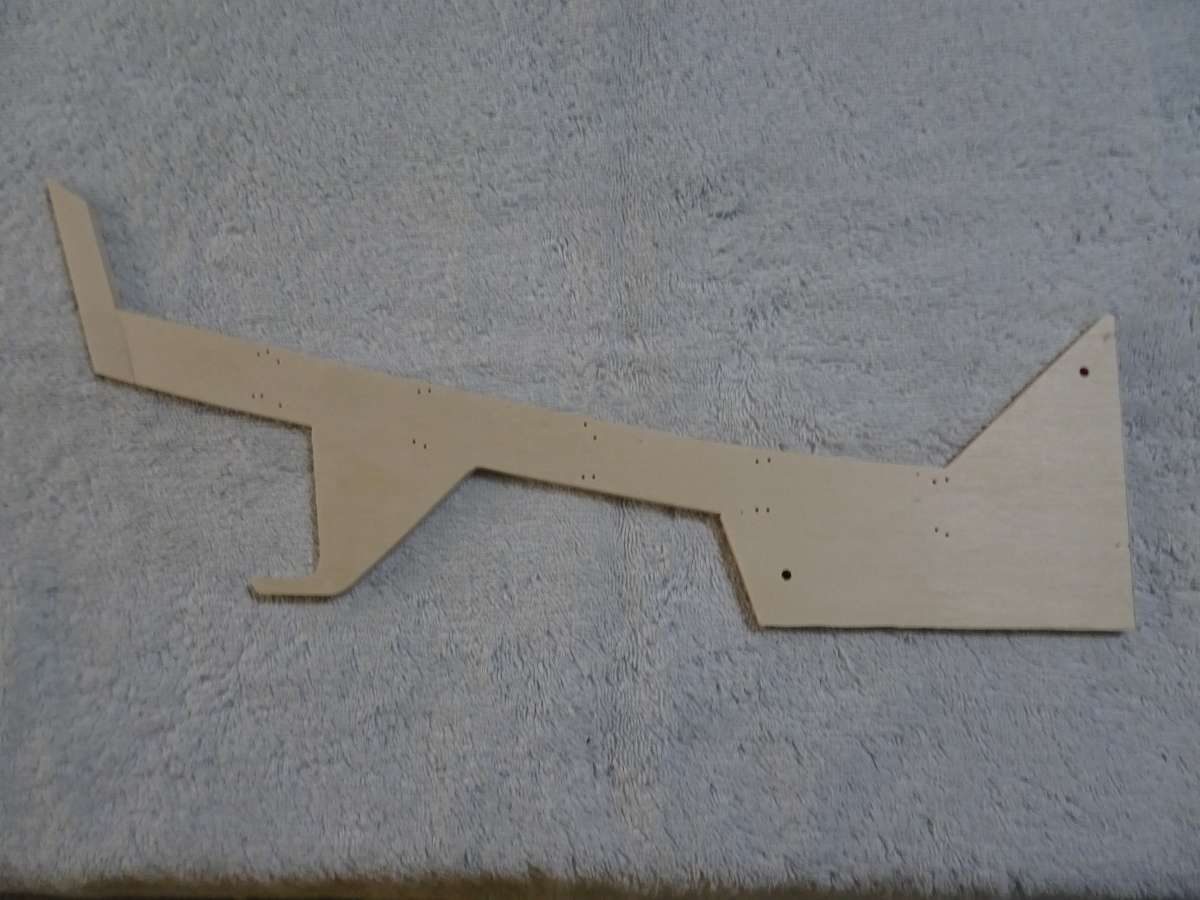

You can see the station marks drawn on the board to get everything lined up. The marker holes in the keel where the other points of reference and the little right angled brackets held the frames up square to the board. In this way all the warps in the ply were taken out and everything went into place quite well.

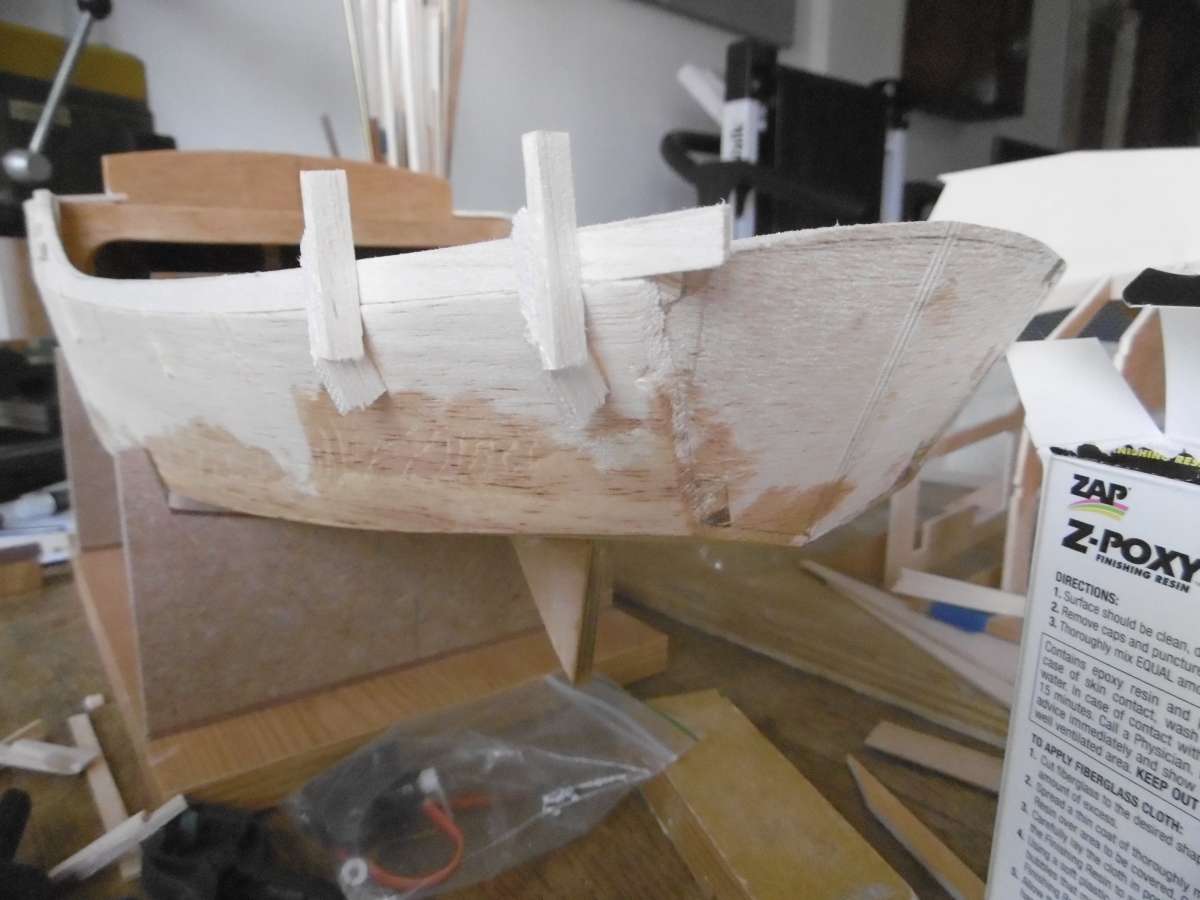

Inevitably there was a bit of fairing up to do. I really think it is worth taking some tine over the fairing. It make everything much easier when applying the skins. Also important to keep everything symmetrical. A waterline marker is very useful for checking the chine heights are the same both sides and it is easy to measure out from the keel to make sure the width is the same.

A trick I learned from building model aircraft and sanding the wing ribs was to protect the parts you don’t want sanded.

Here you can see I have started at the bow and all the other frames are protected. When you start to rub into the tape you know it is time to stop!

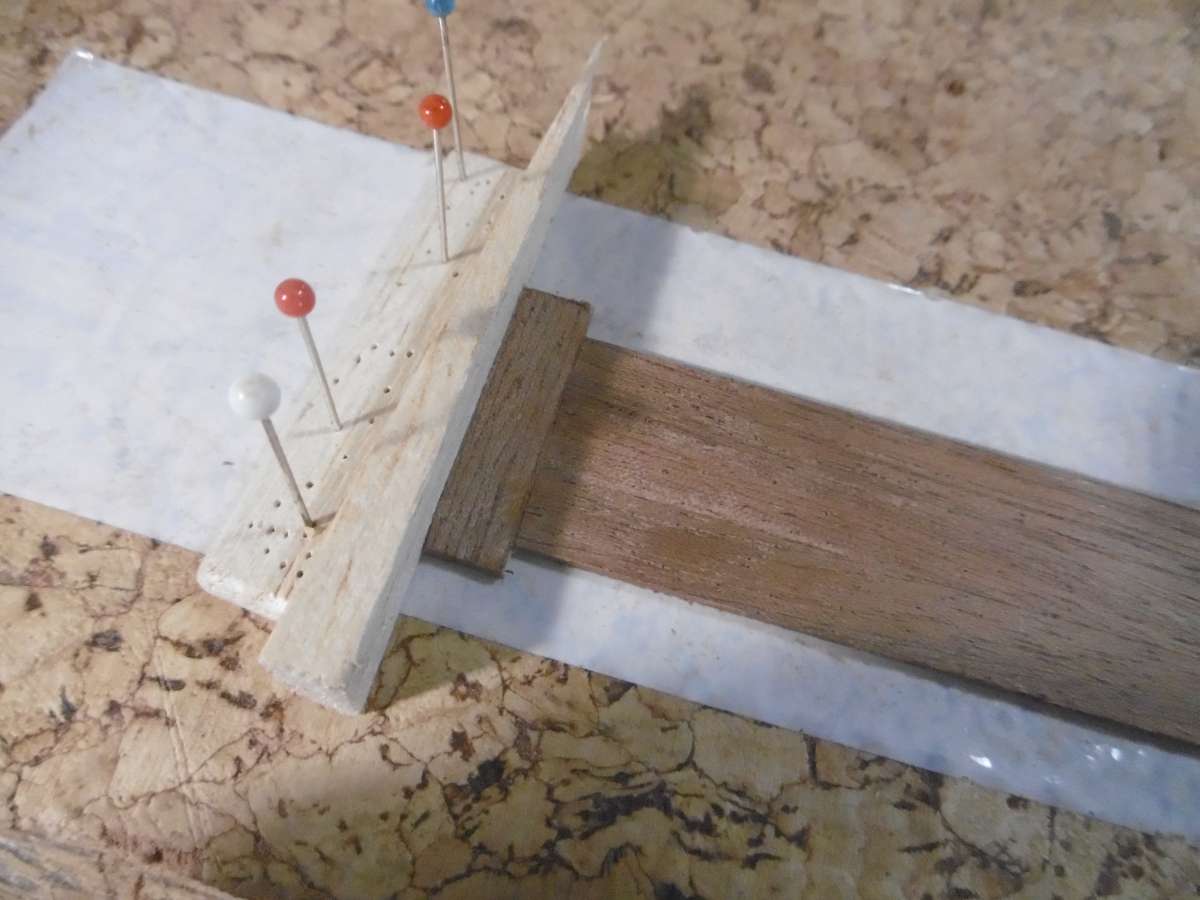

The deck stringers wouldn’t go round the tight curve at the bow and so had to be persuaded by making the saw cuts. It is best to make the saw cuts progressively deeper as you move away from the bulkhead. If you don’t you get a sharp bend at the bulkhead and the rest tends to be straight. It is quite easy to fine tune this by gradually deepening the cuts and seeing how it bends by pulling in at the bow. If there is a tendency to go straight cut a fraction deeper. It sounds like a lot of work but it is probably only two of three trial cuts and I think it is worth it.

Nearly ready for skinning which is a great moment turning the skeleton into a boat.

Tim

Tim Rowe.