Hi Len

First I am no good at drawing so sorry about this.

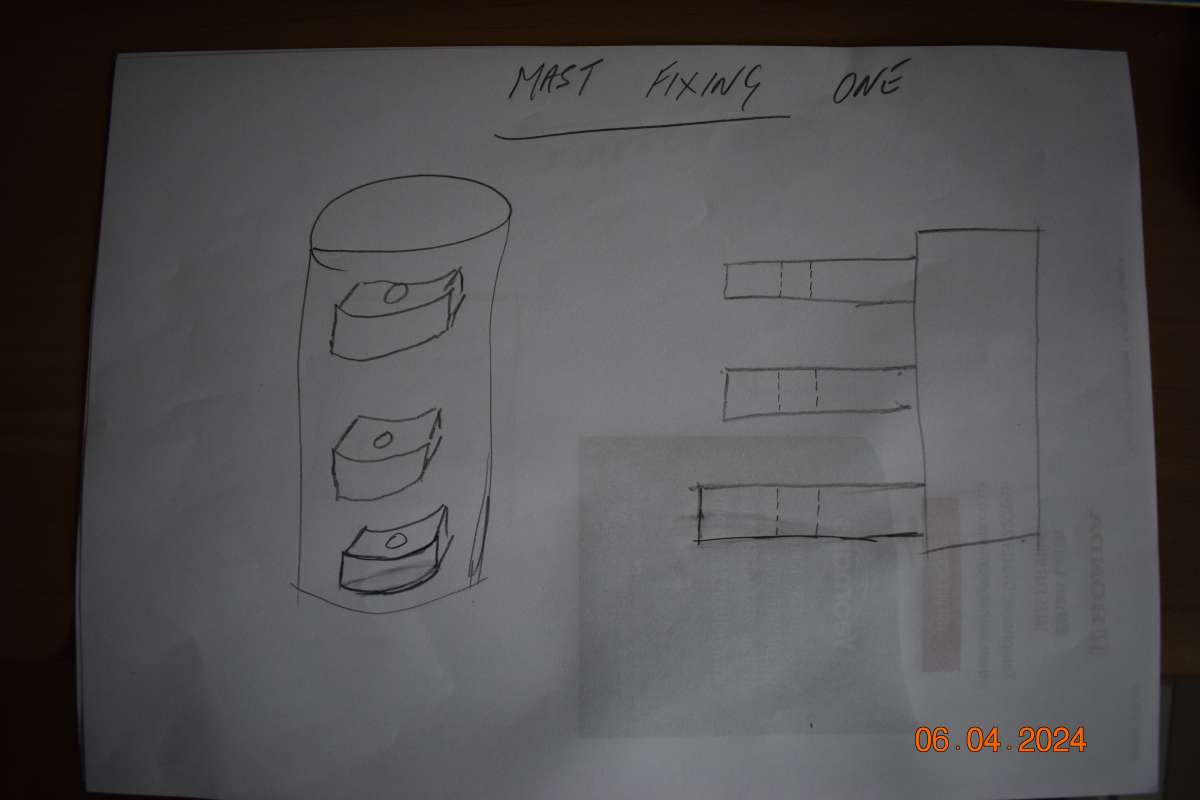

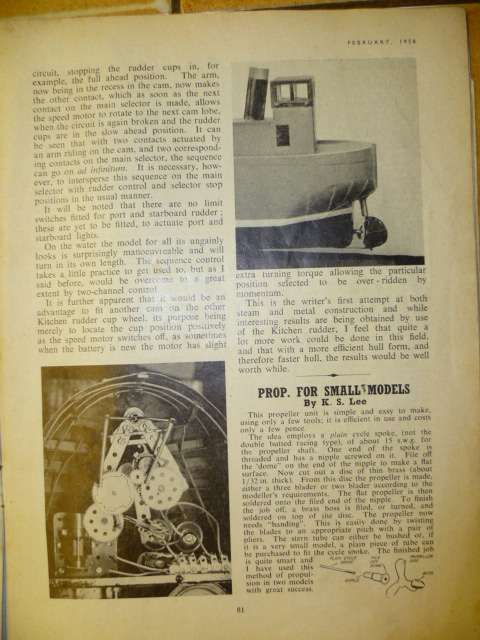

Mast fixing; I used some brass tubing that fitted the mast, to this I soldered some brass plate, before doing this you need to drill a hole in the plates for a fixing pin, the gap between the plates needs to be the same as the plate used in the Swivel plate, the ends of the plates need to be rounded.

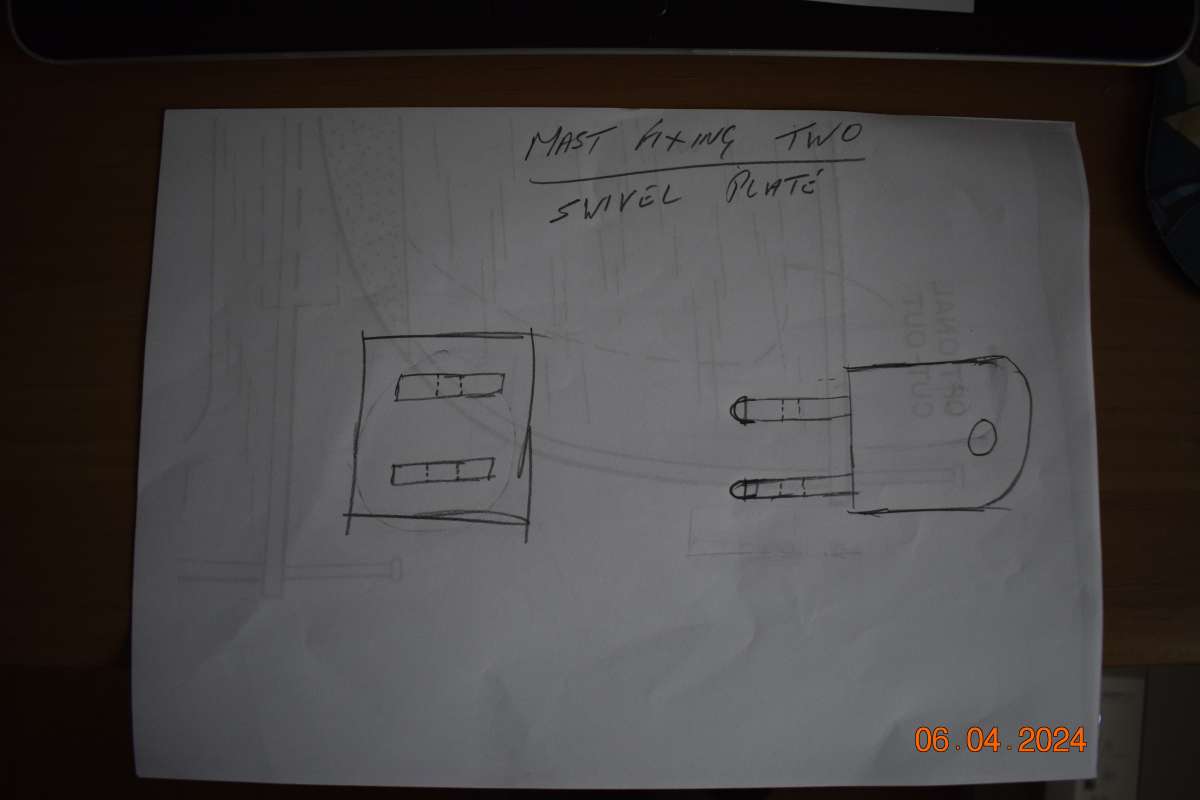

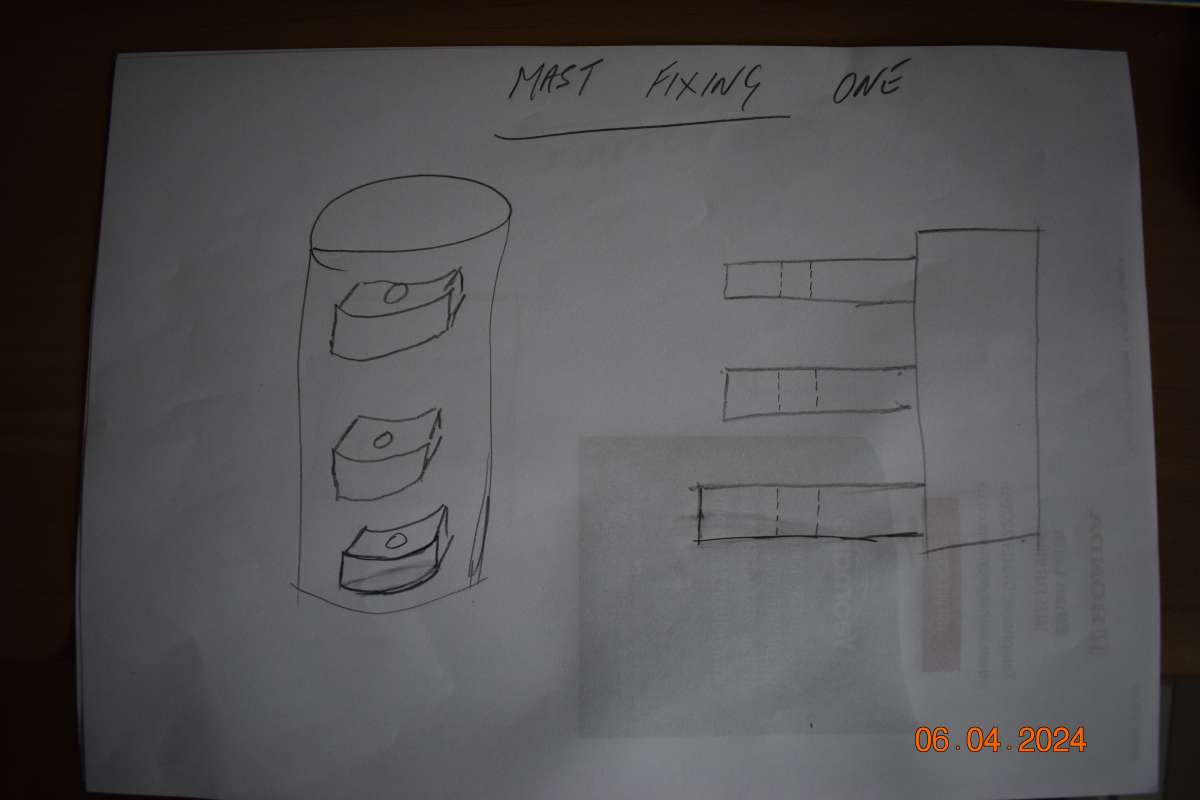

Swivel plate; I used some brass square, to this I soldered two plates again a hole has to be drilled in line with the holes in the mast fixing, also a hole needs to be drilled at right angles to the plates in the square part of the swivel plate, so that a fixing pin can fix the boom to the swivel plate, all ends to be rounded.

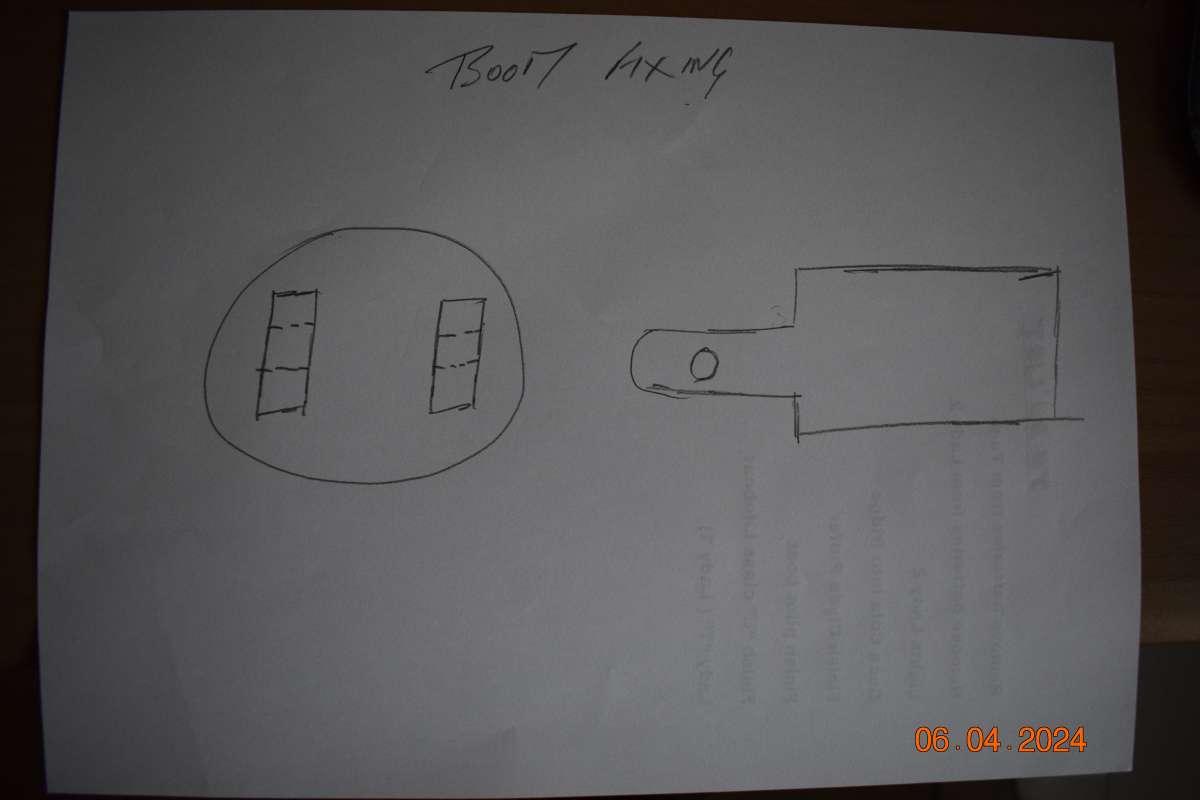

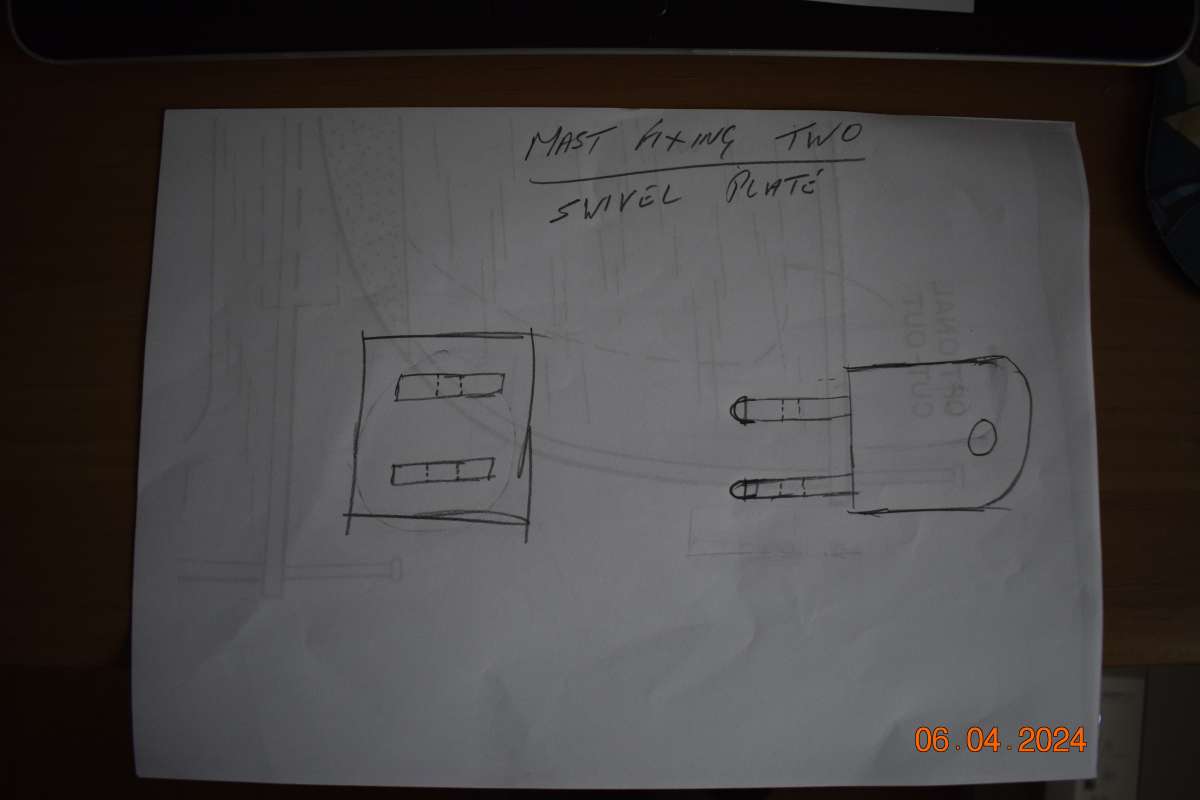

Boom fixing; Again I used brass tubing, I soldered an end cap to one end so that I could fix two plates, these plate need to be able to fix on the outside of the swivel plate, a hole to be drilled for a fixing pin, all ends to be rounded.

The swivel plate goes between the the plates of the mast fixing and fixed by the pin, the swivel plate must be able to move side ways, the boom plates to go on the outside of the square section of the swivel plate and fixed by a pin, this also must allow the boom to move up and down.

I do so hope that this as clear as water.

Fred

Len Morris 2.