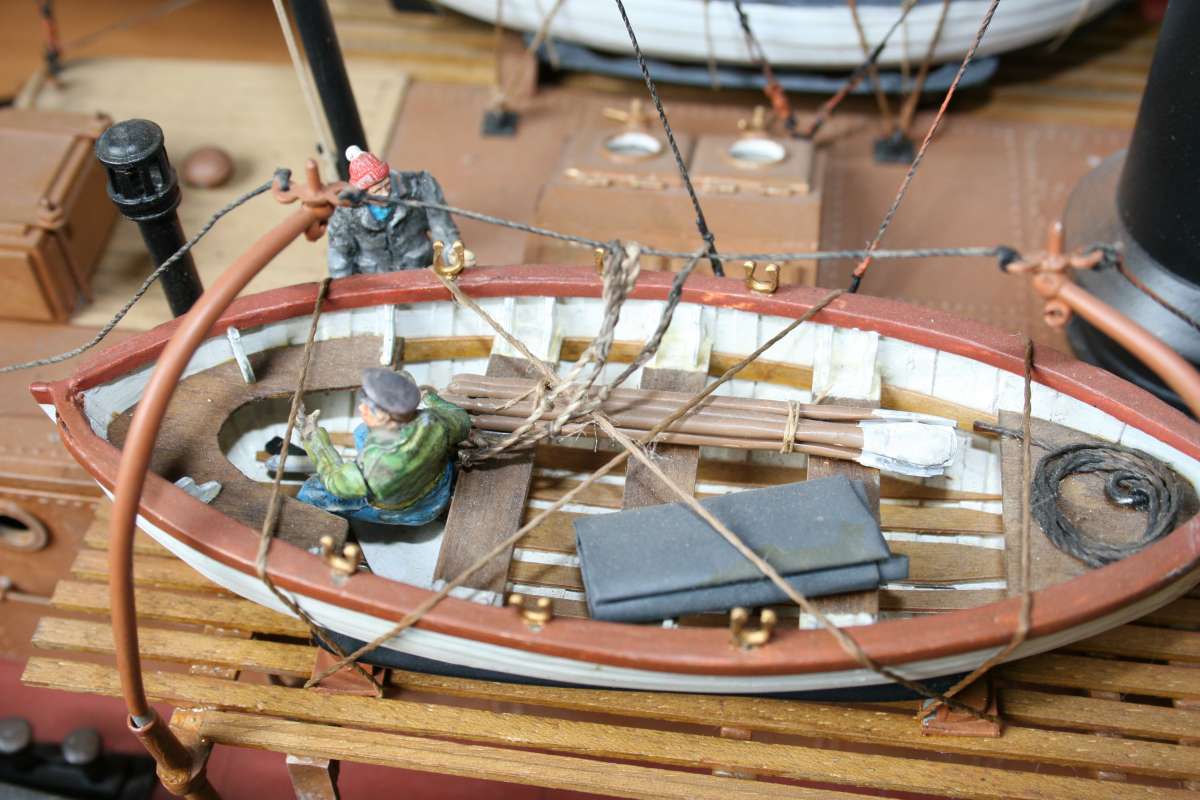

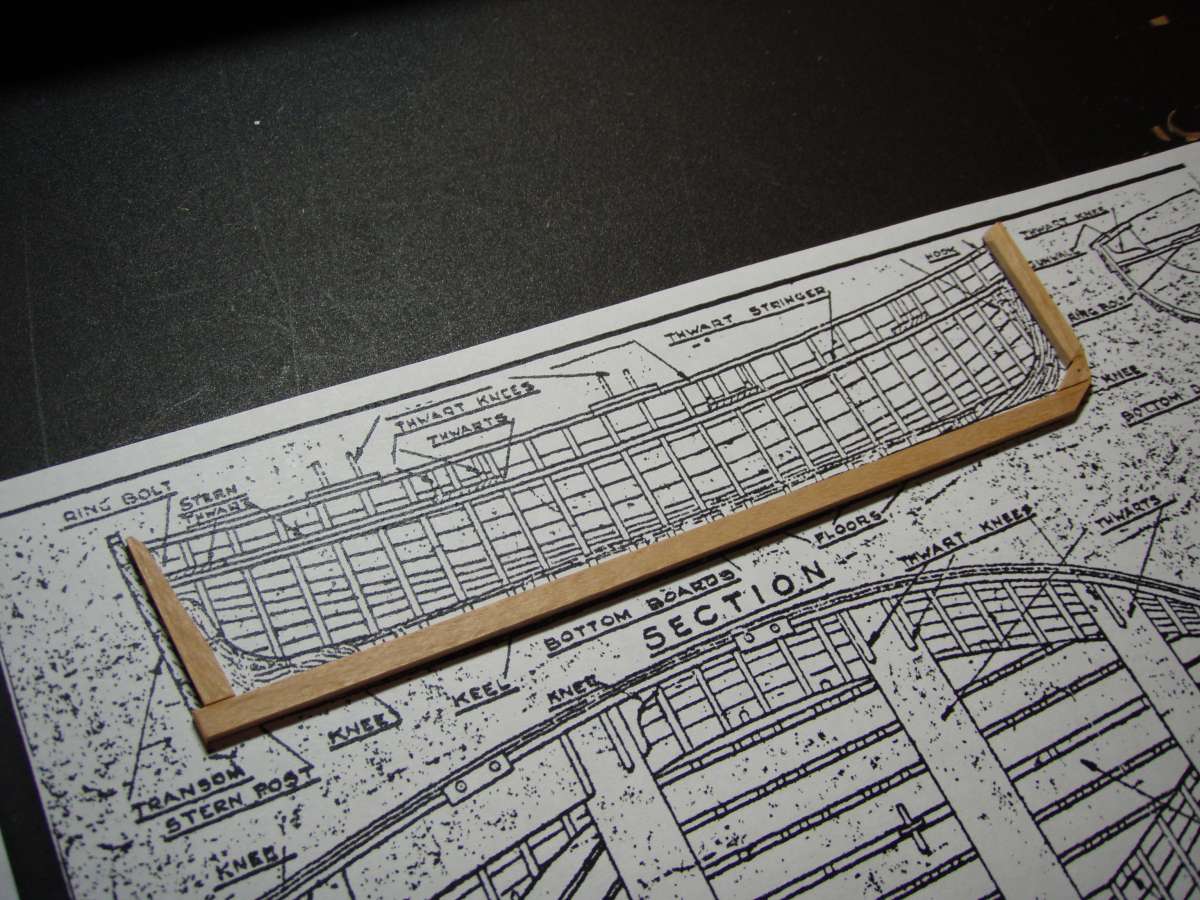

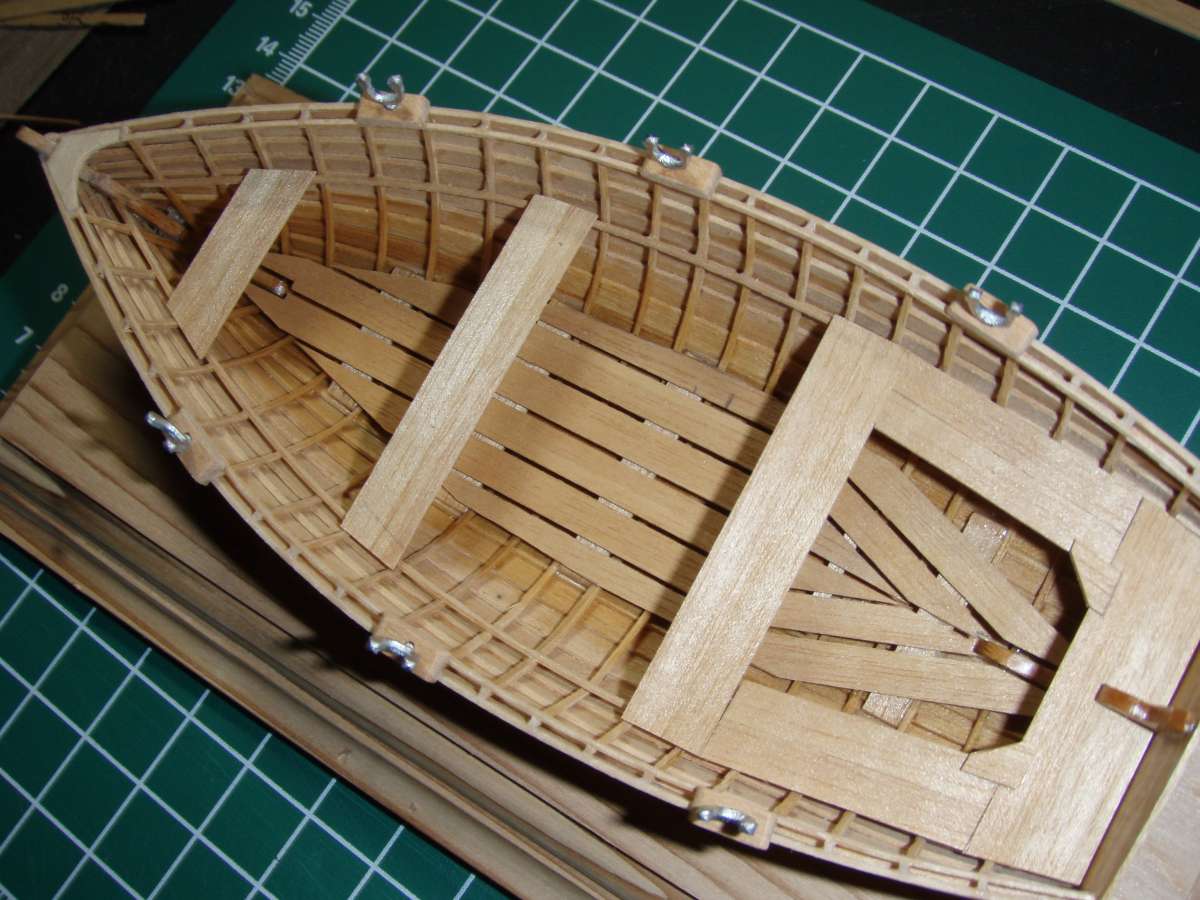

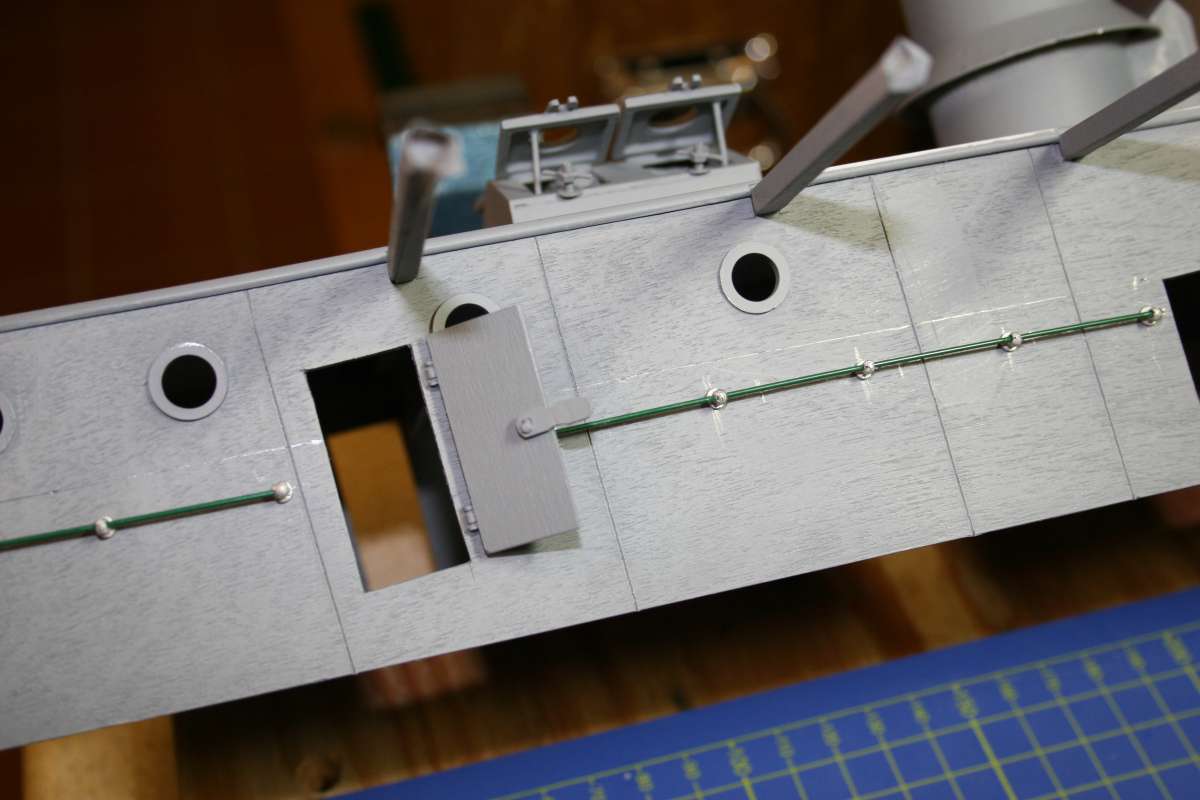

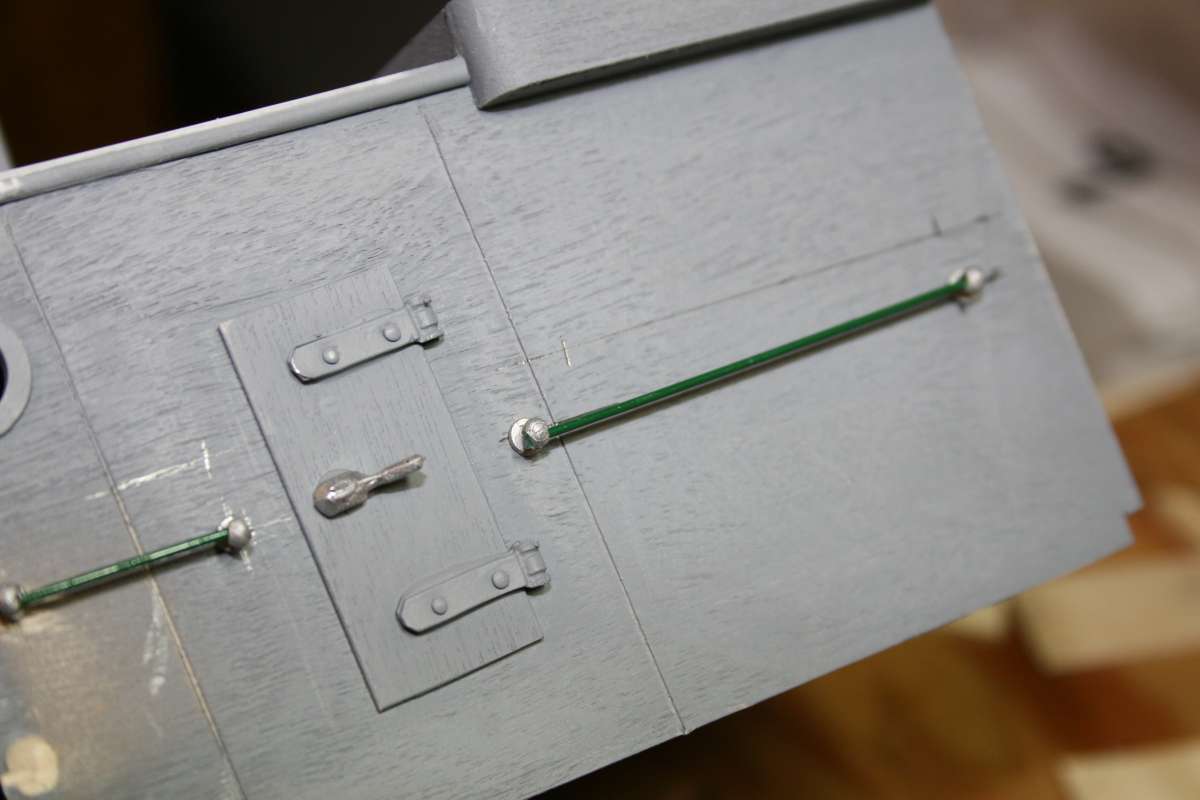

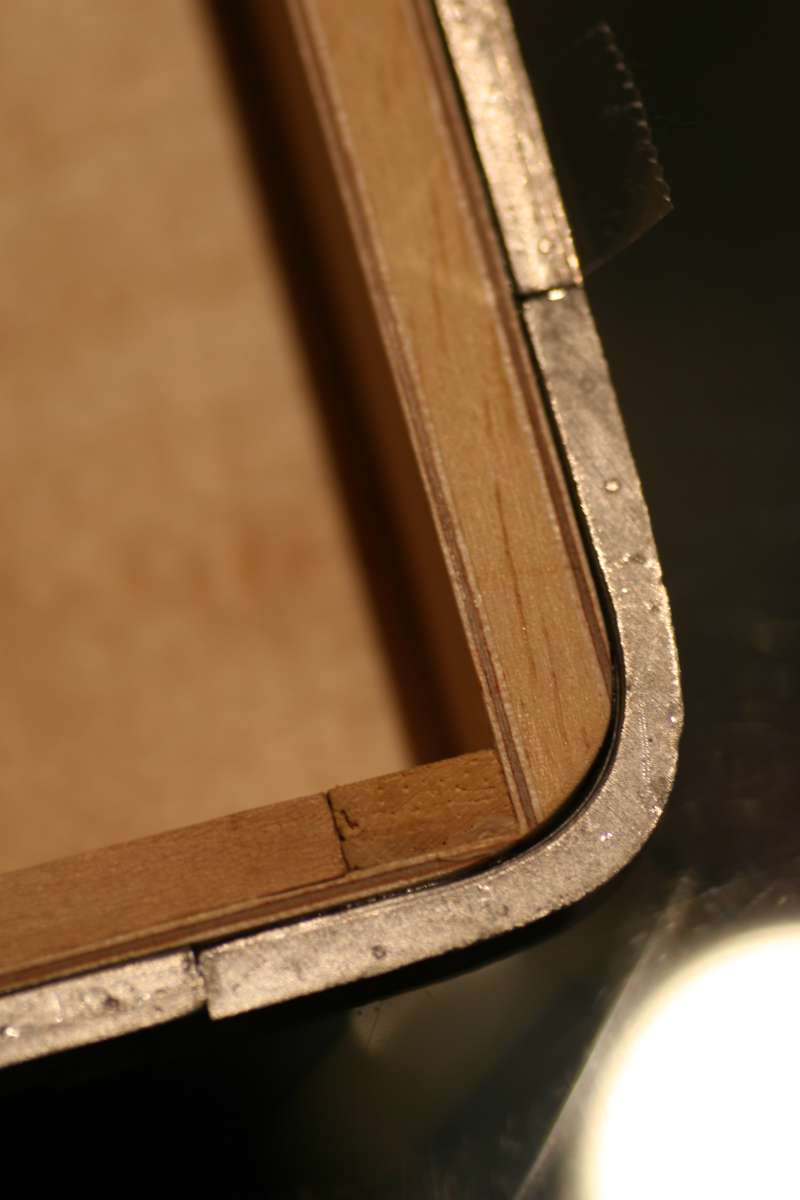

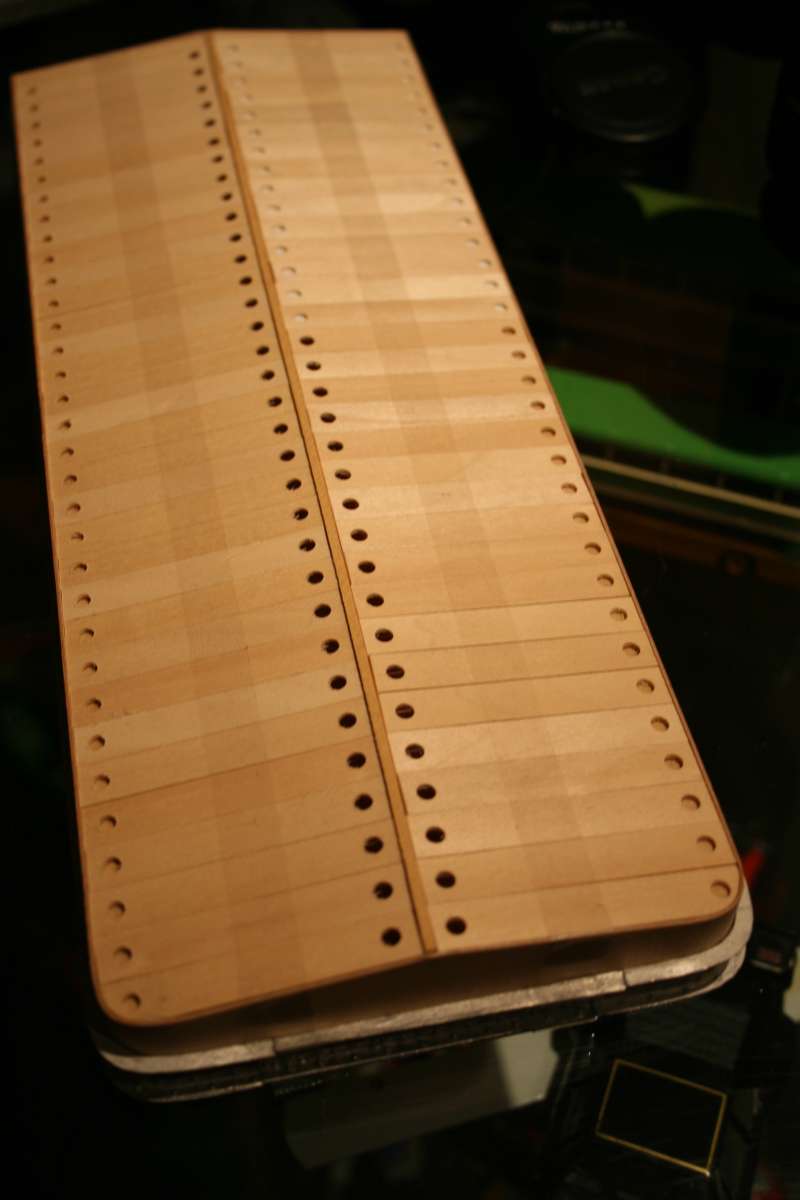

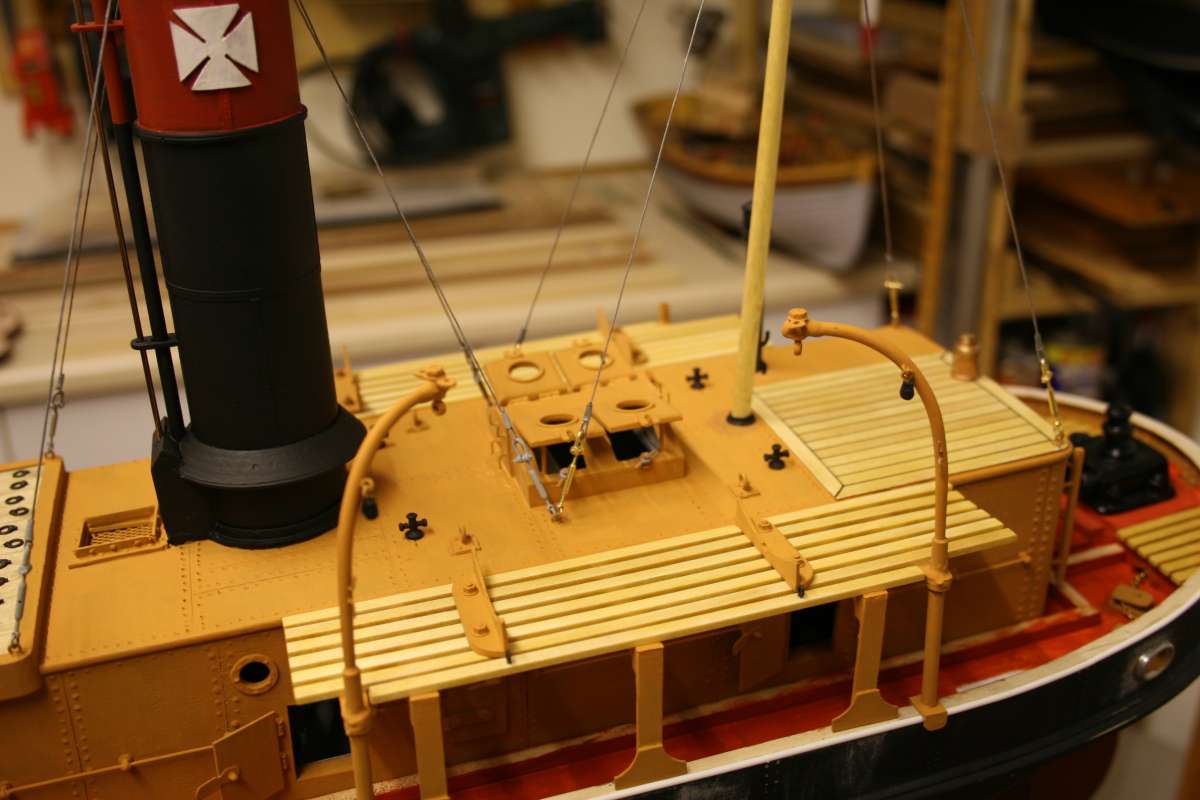

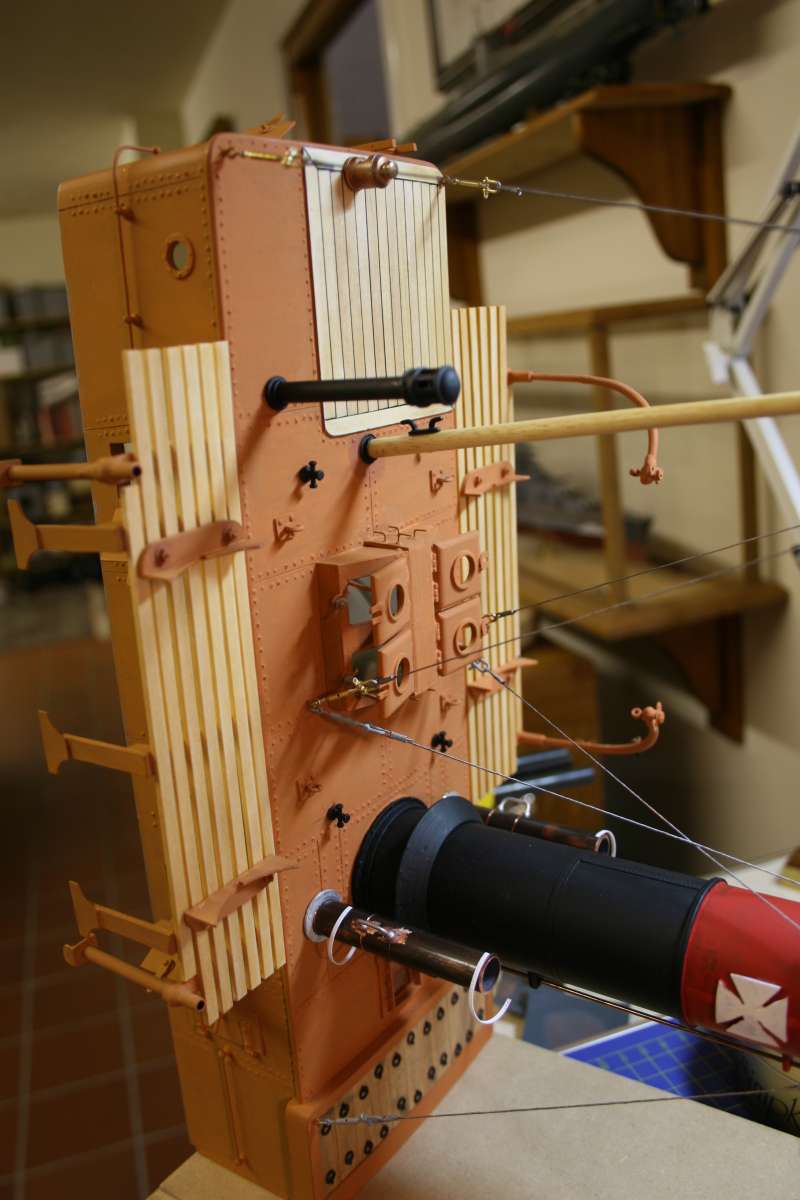

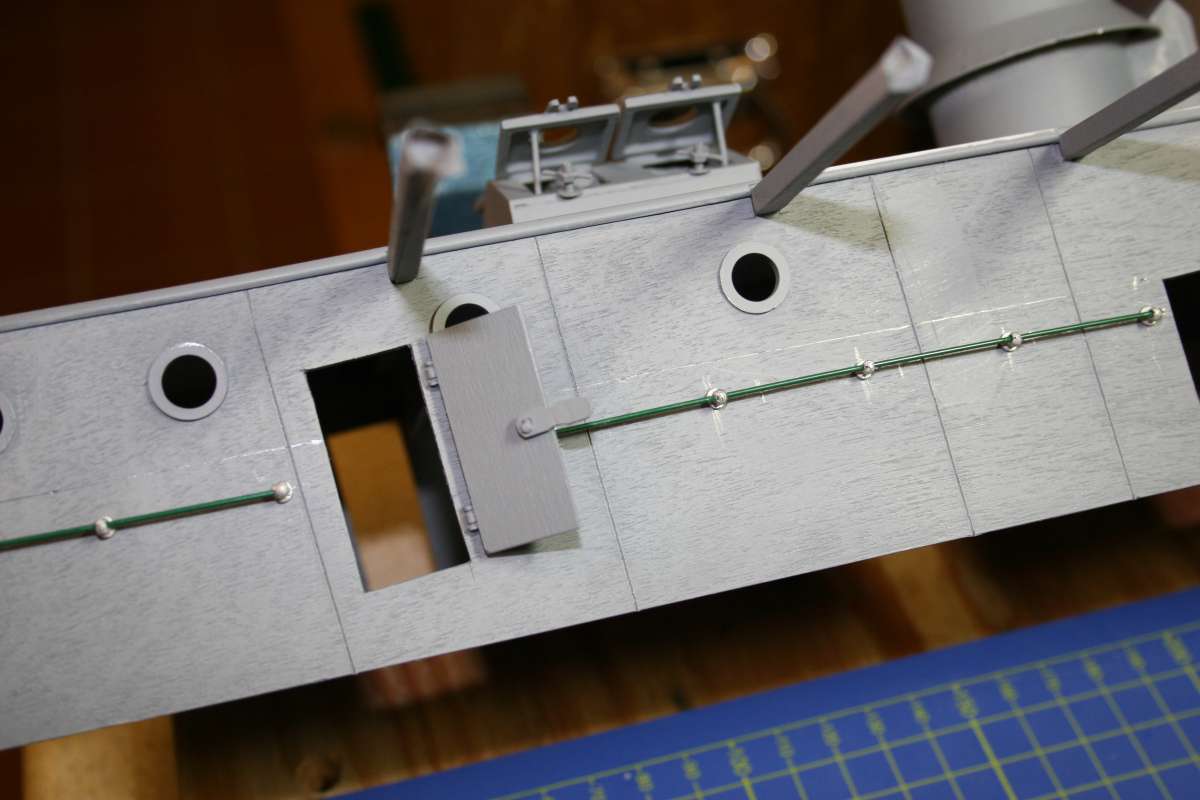

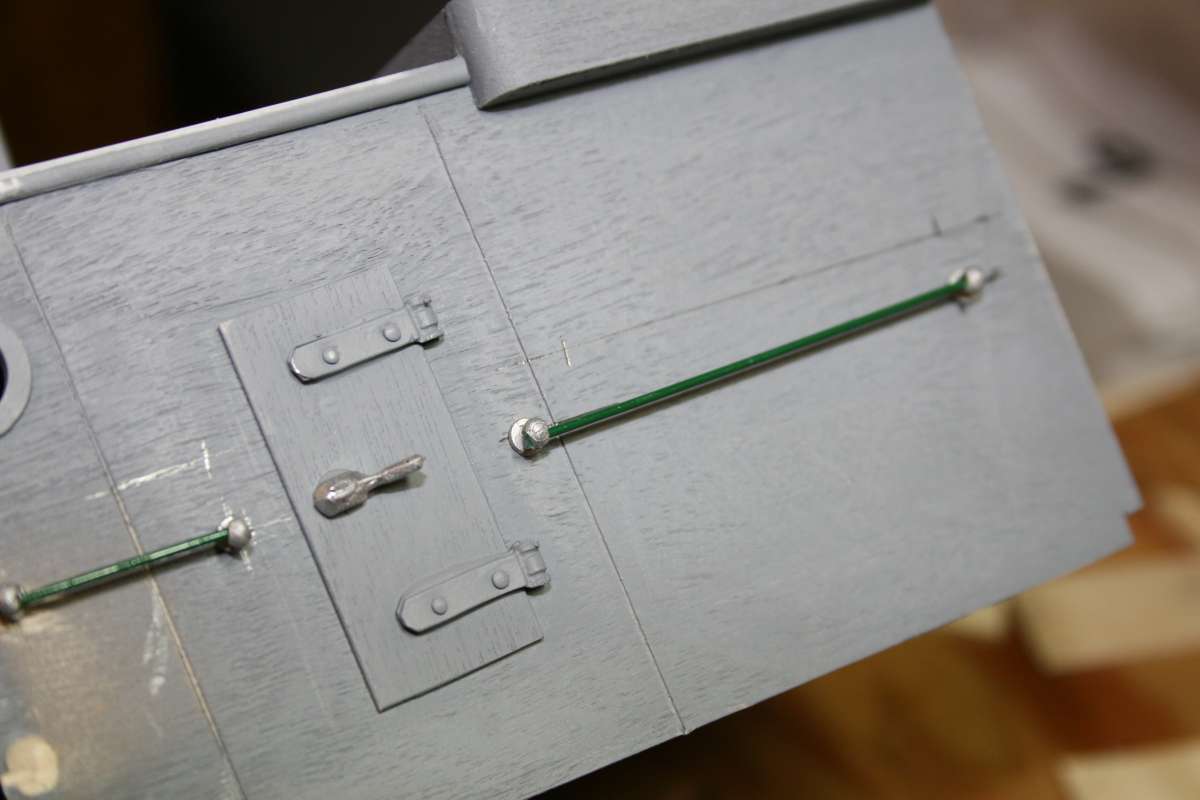

So with the two boats done it was time to turn attentions again to the quarterdeck accommodation unit. This was basically simply adding bits and peices to it until it was done. Some bits were from the kit parts, some bits were aftermarket items and, again, some bits were scratch built, usually for a higher level of realism. For instance the boat stands were fairly chunky cast white metal parts, which looked much better scratch built from stripwood and then bolted to the decking with small brass BA nuts, bolts and washers.

First up was an overall coat of Halfords primer to help identify areas that needed attention.

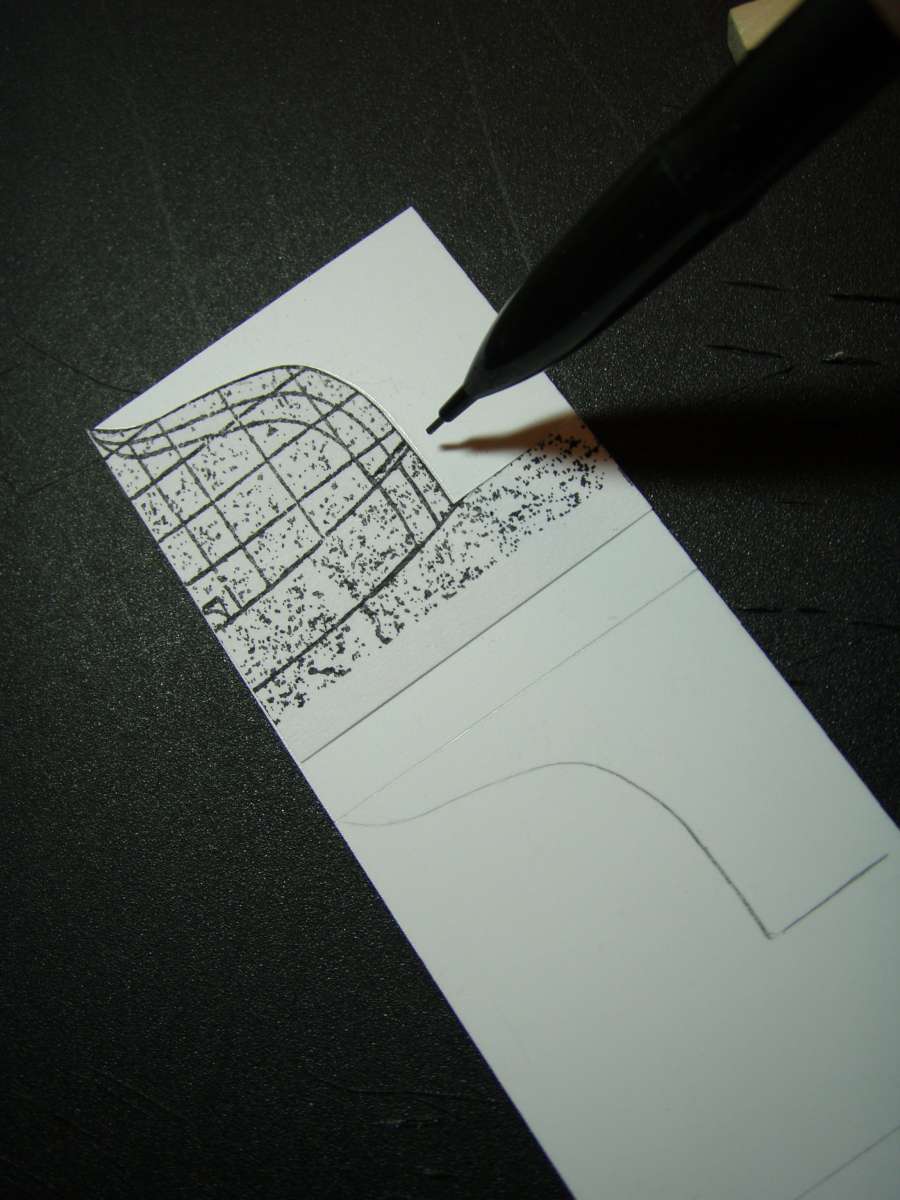

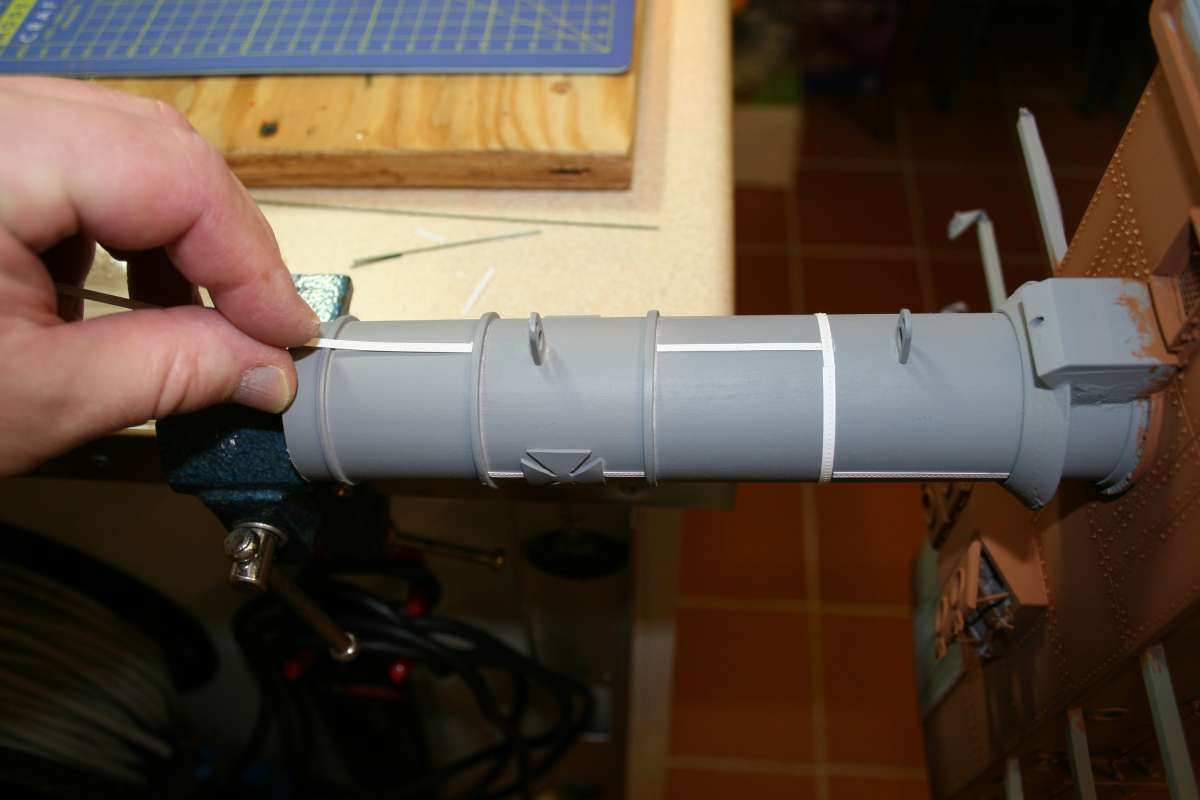

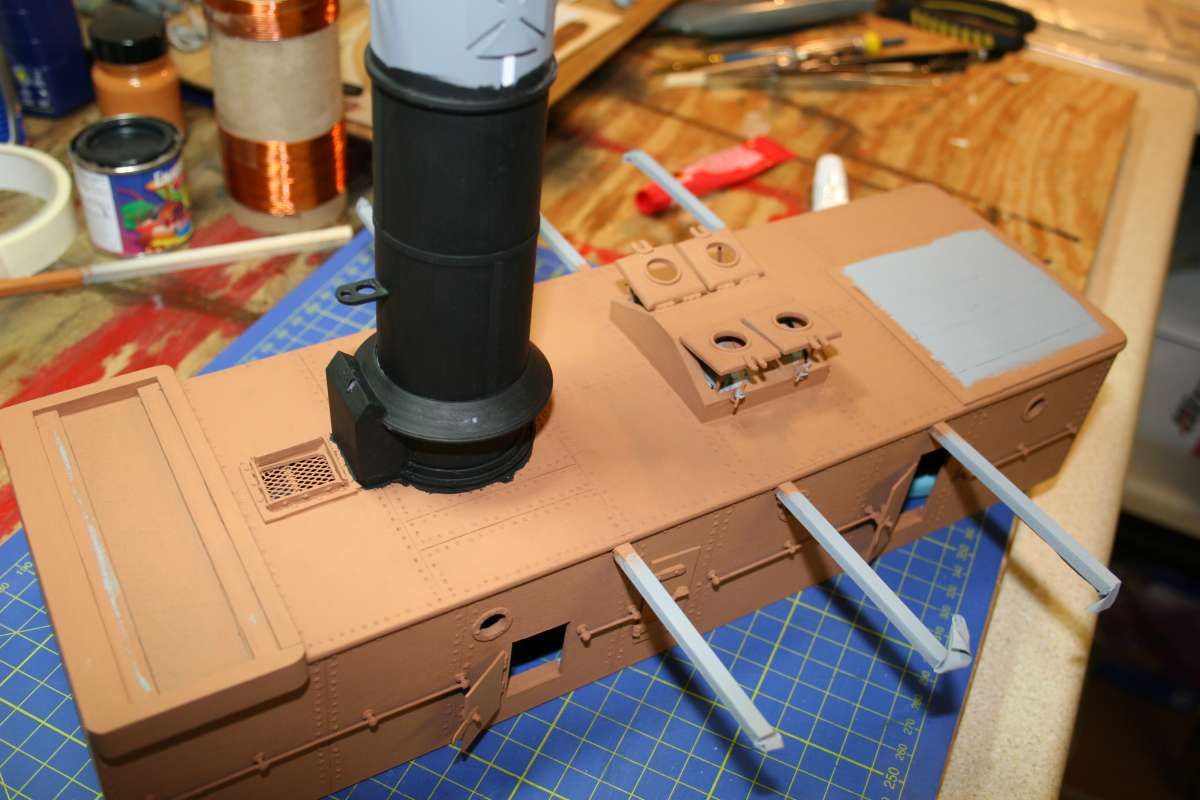

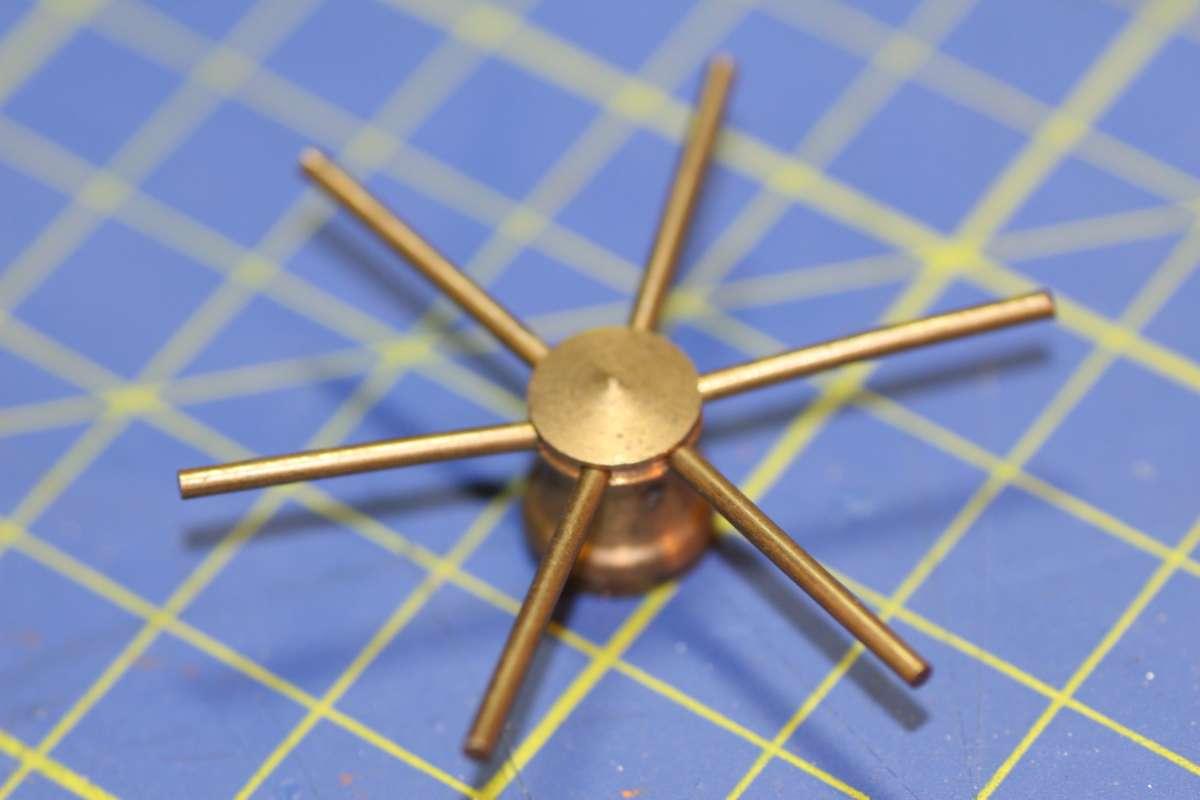

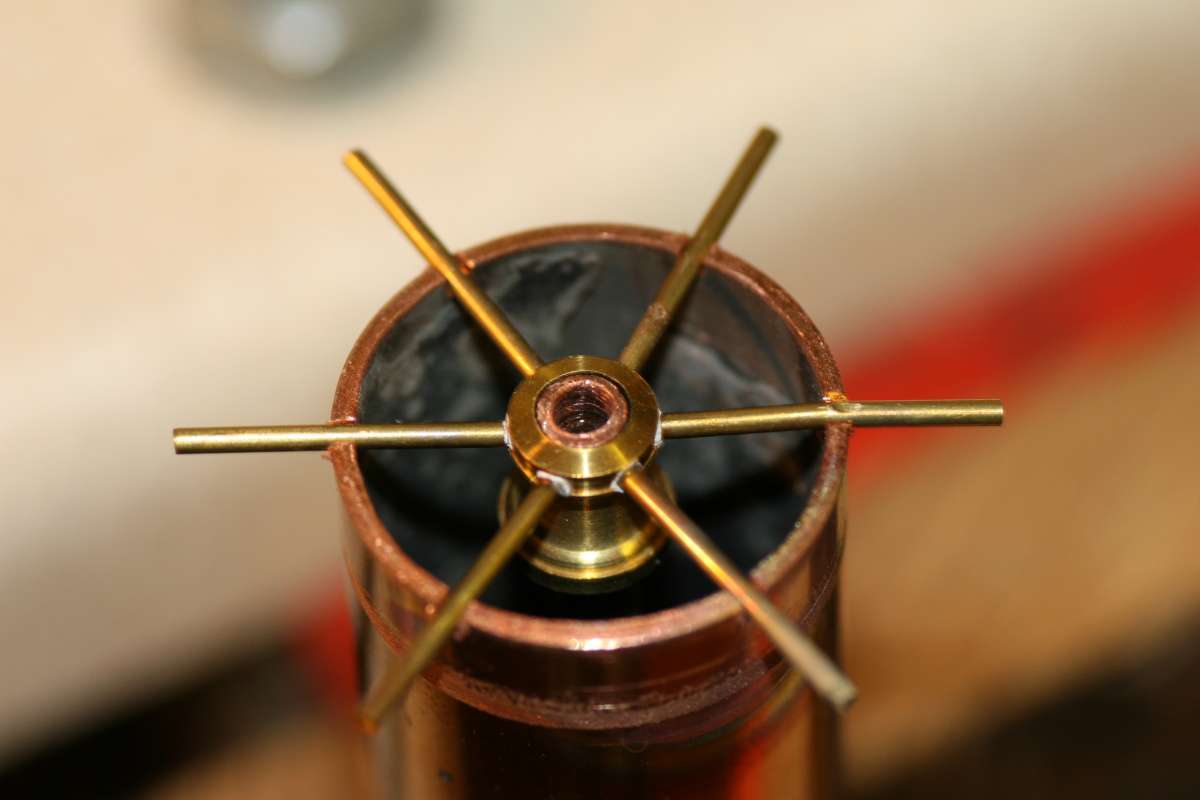

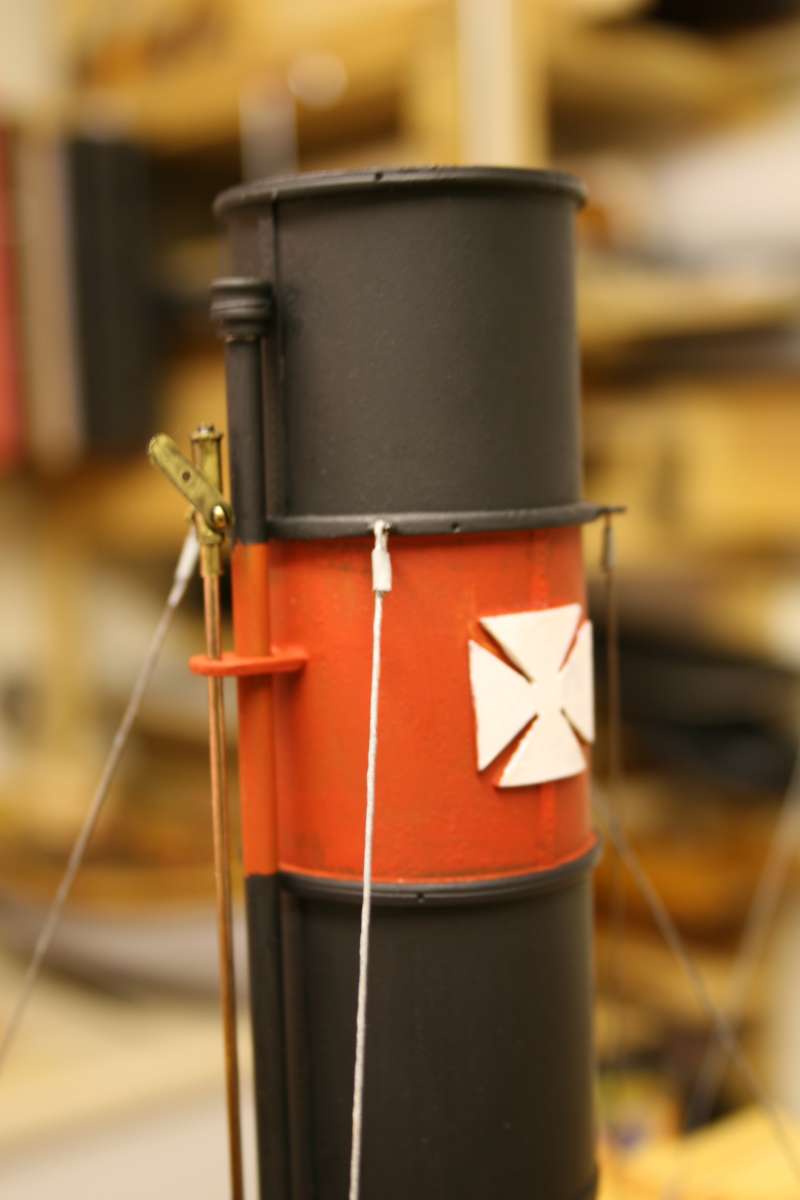

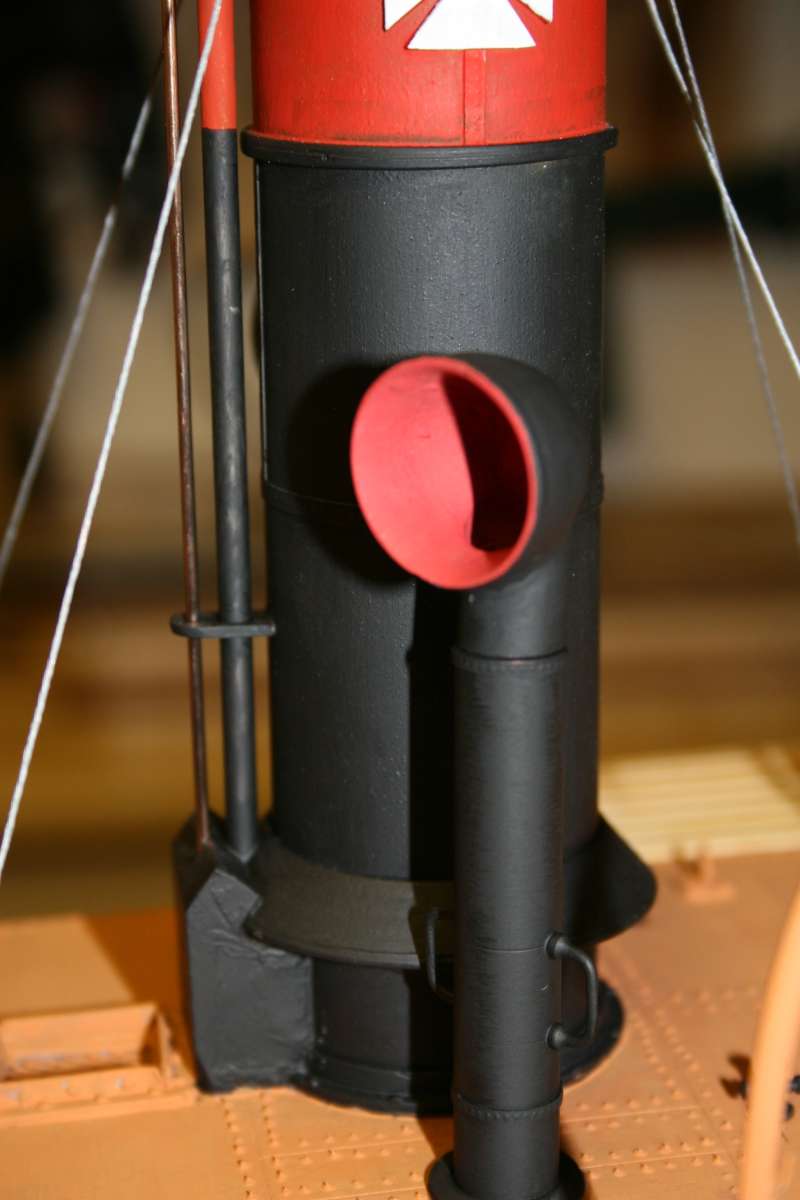

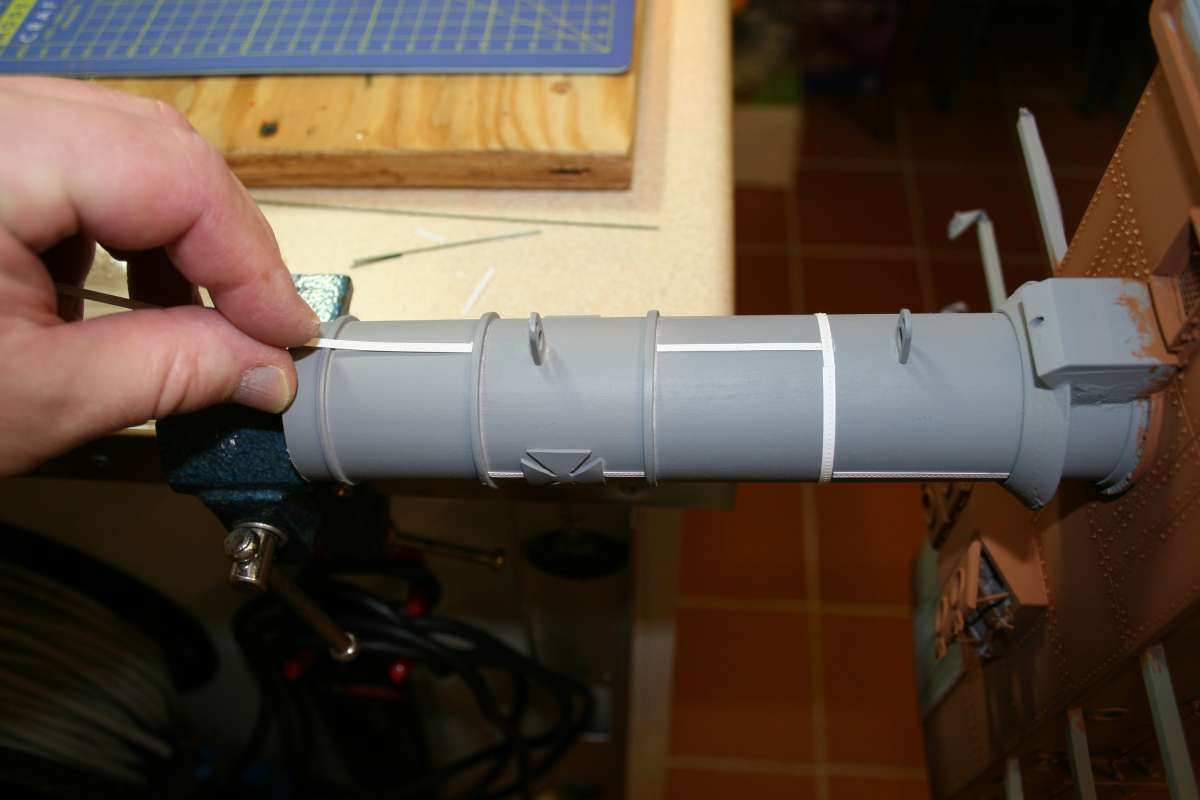

The funnel was enhanced with some butt straps made out of paper with the pounce wheel run over the back of it.

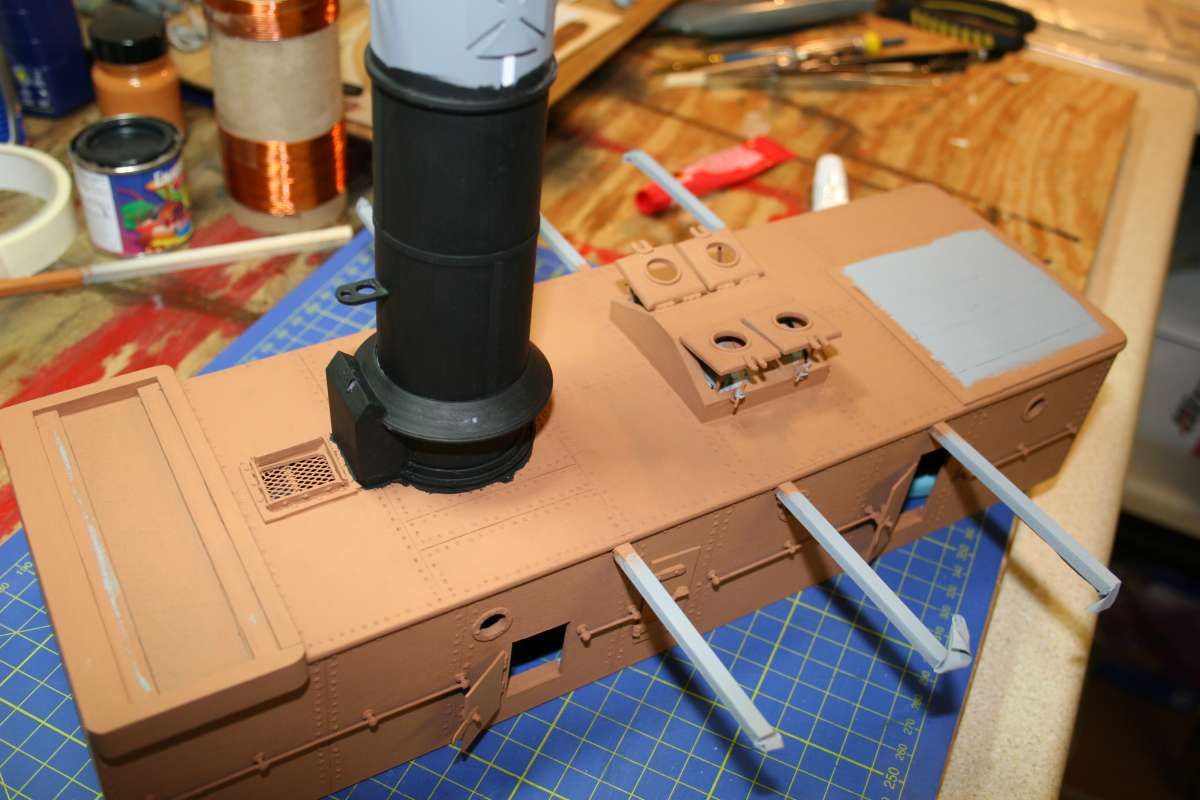

Then time to get some top colour on. The accommodation is a mix of Humbrol matt orange enamel and brown enamel, which can be very slightly varied to give some tonal differences. The funnel was a matt black enamel with slightly varying amounts of black satin added.

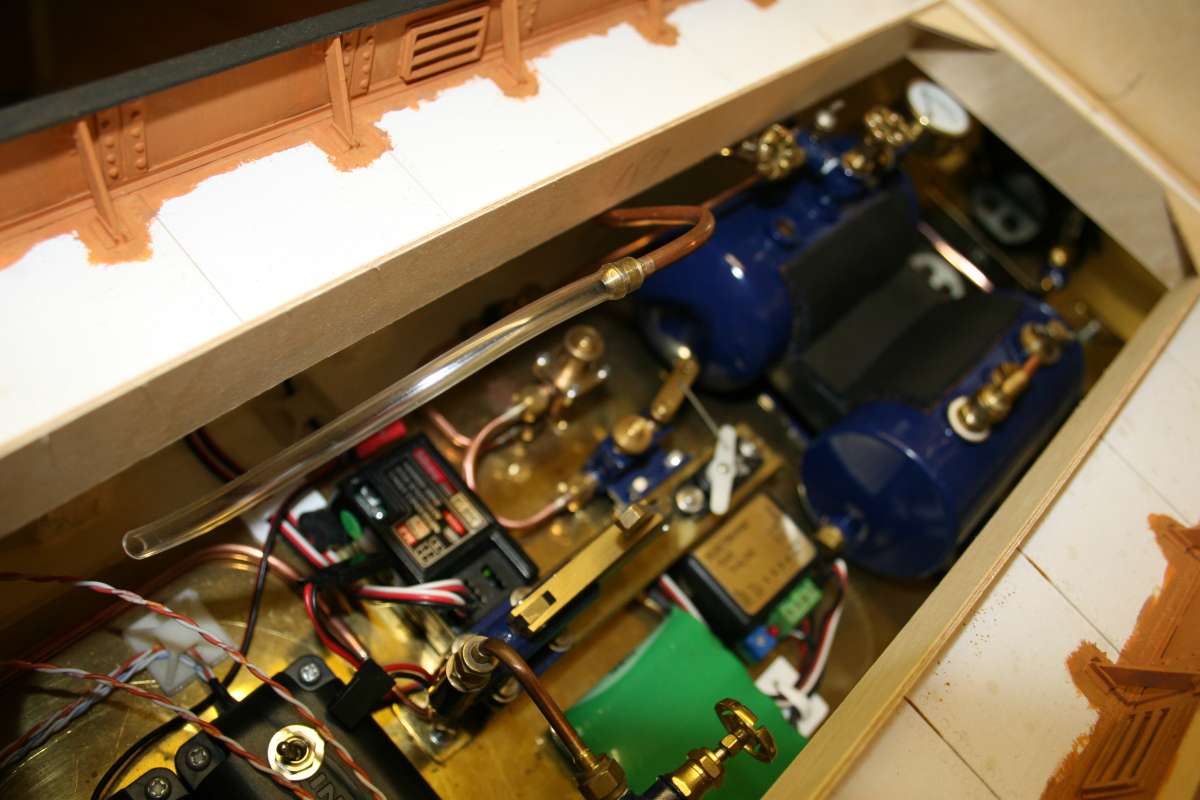

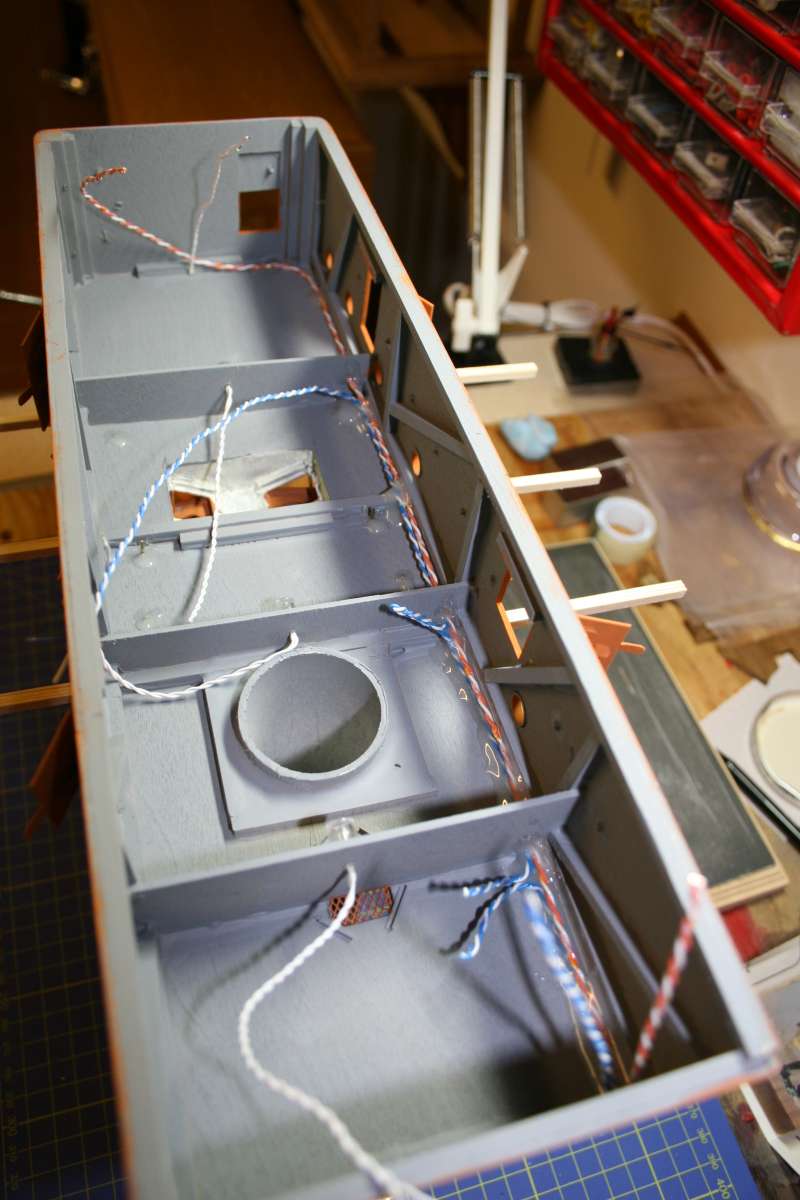

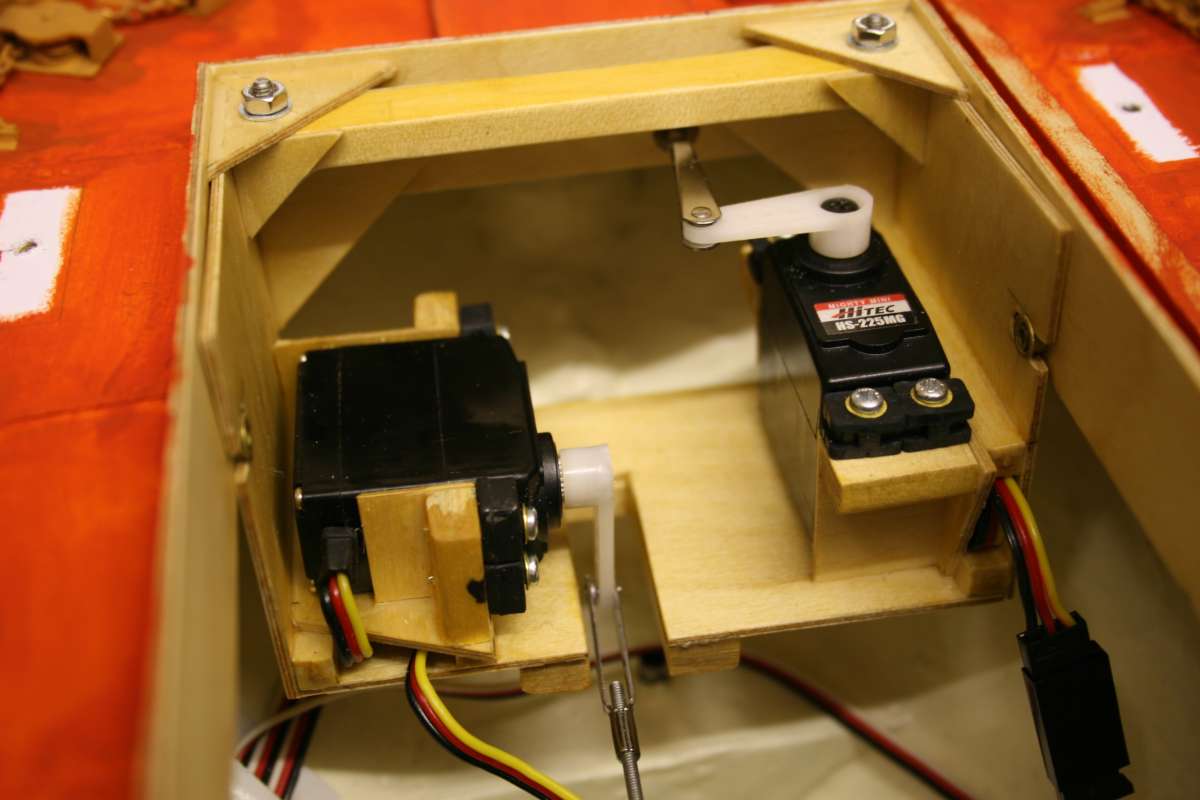

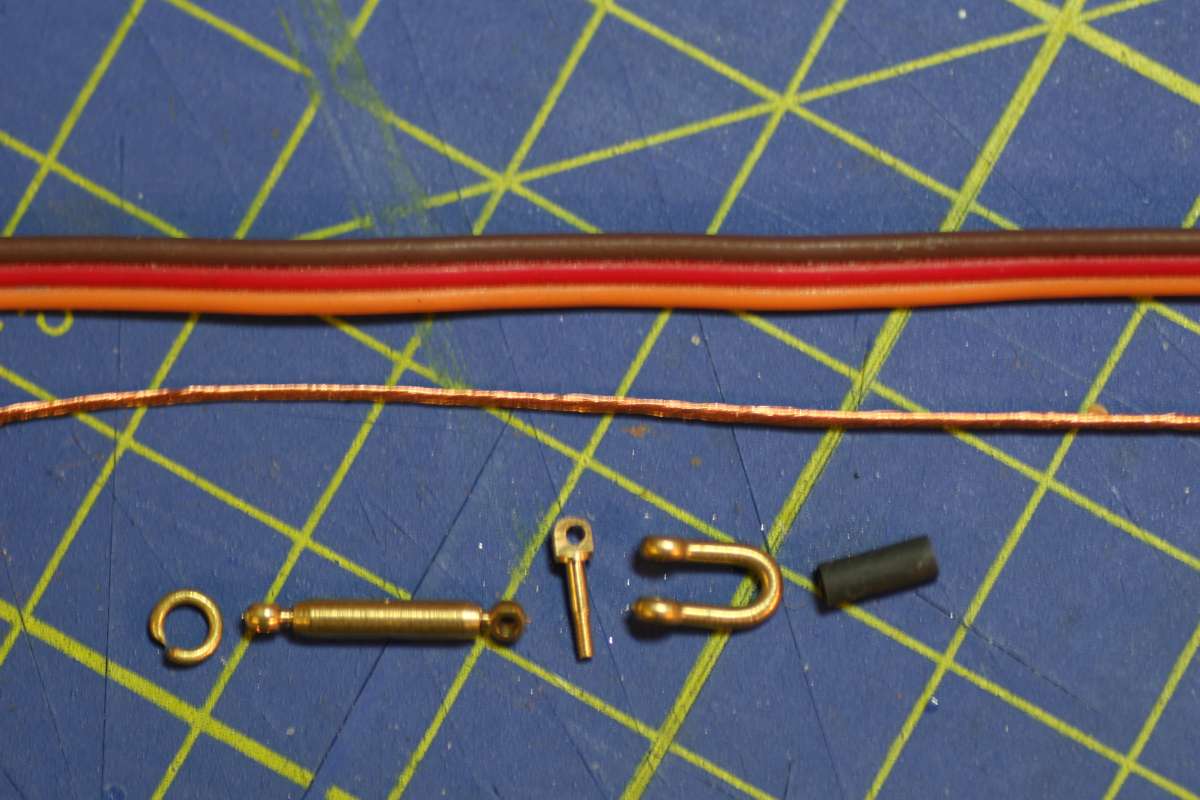

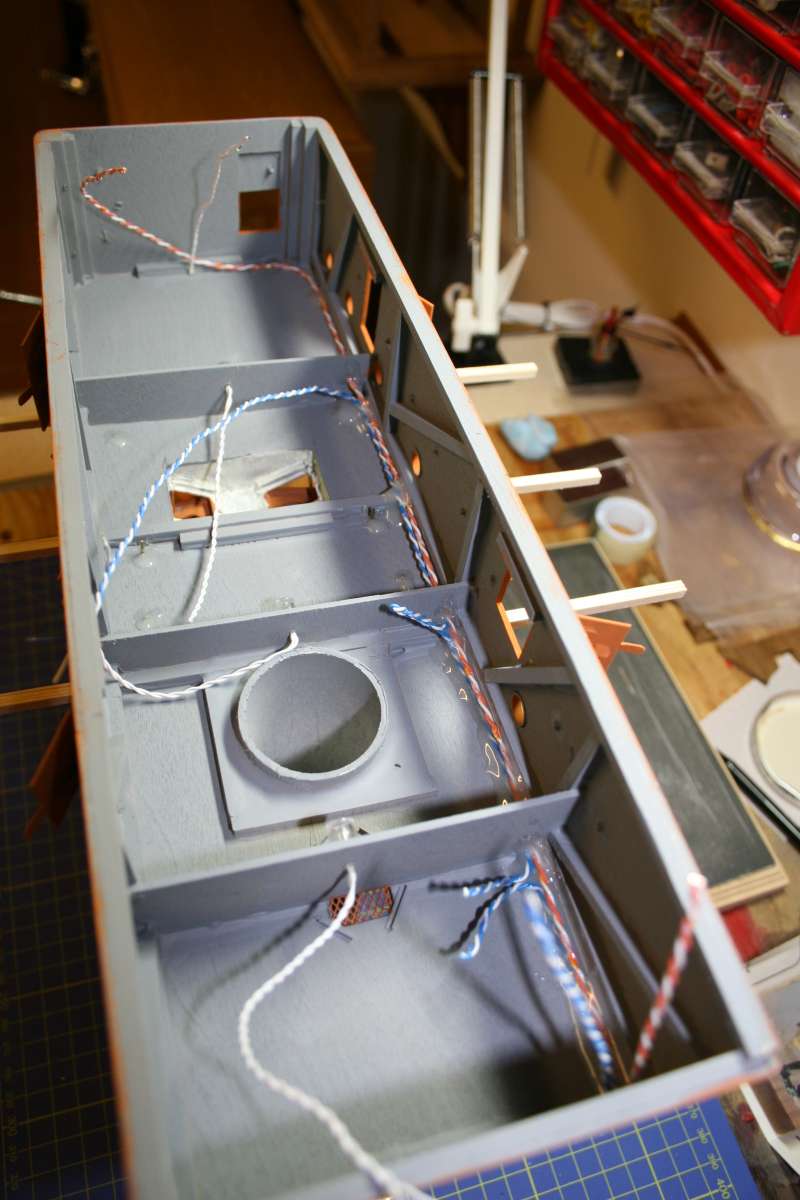

Meanwhile the wiring was fitted for the lights. There will be a stern light on the aft of the top deck and bulkhead lamps on the internal bulkheads. The internal surfaces were all given a coat of waterproof primer to protect it from condensation.

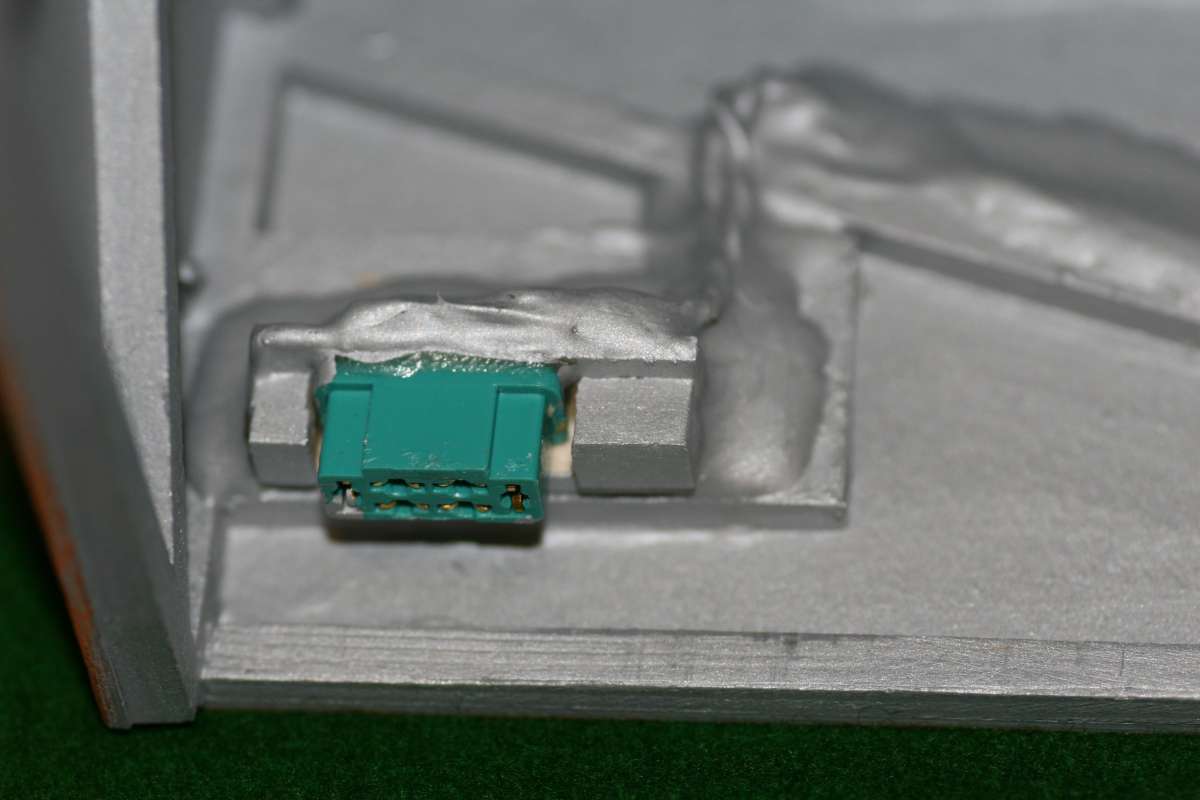

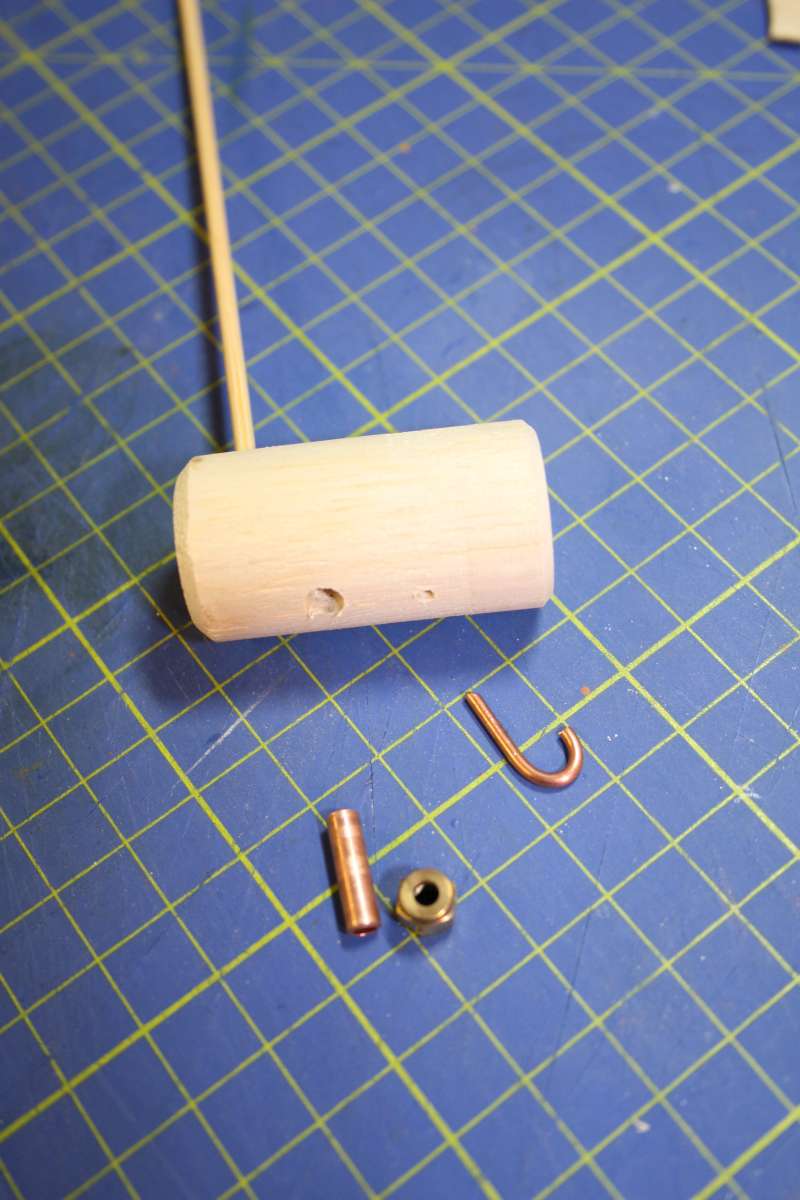

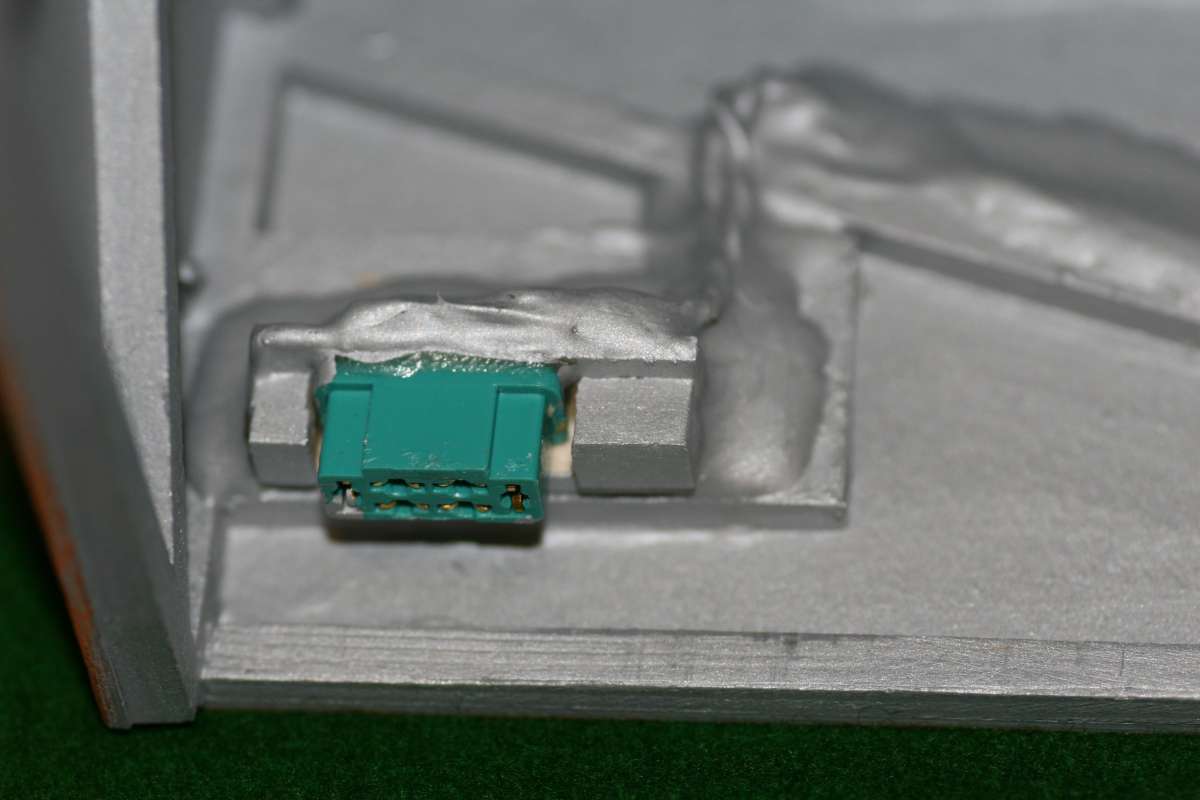

I decided to use a push plug to transmit the power into the peice. This was mounted in the unit, with the matching part mounted in the deck coaming so the two parts simply pushed together when the unit was fitted in place. It saves trailing wires when you lift the unit up that get in the way and prevent you putting the unit where you want when you lift it off. It is completely dependant on the accuracy of the fit but, get it right, and it seemed to work reliably.

Richard Simpson.

Richard Simpson.