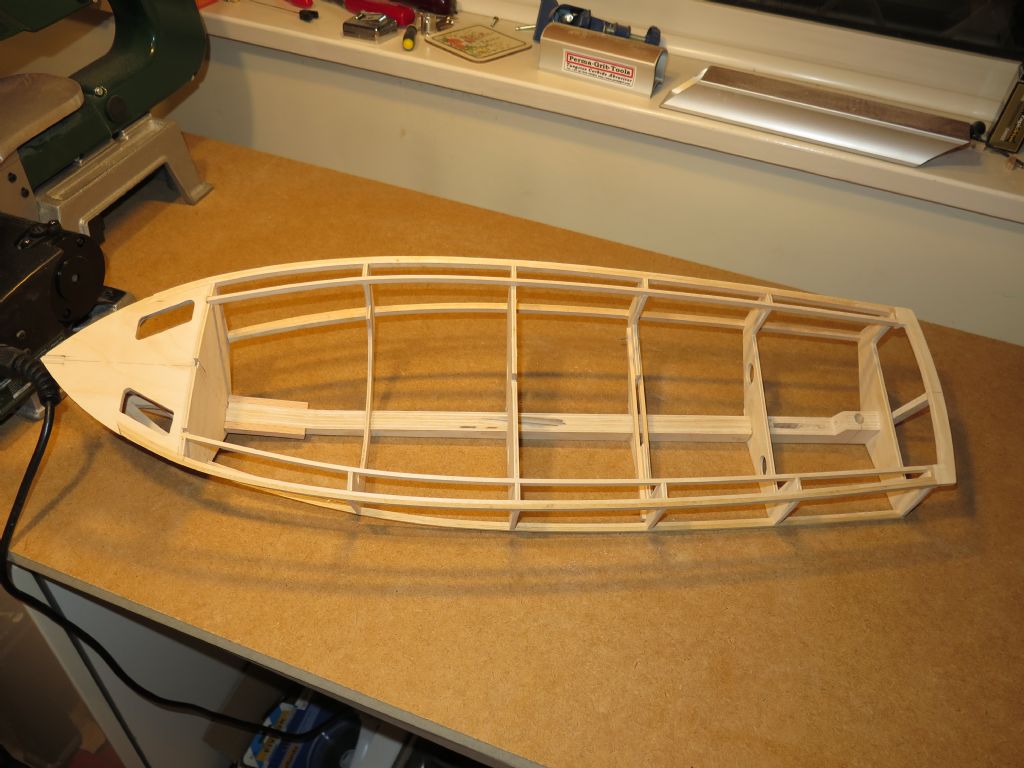

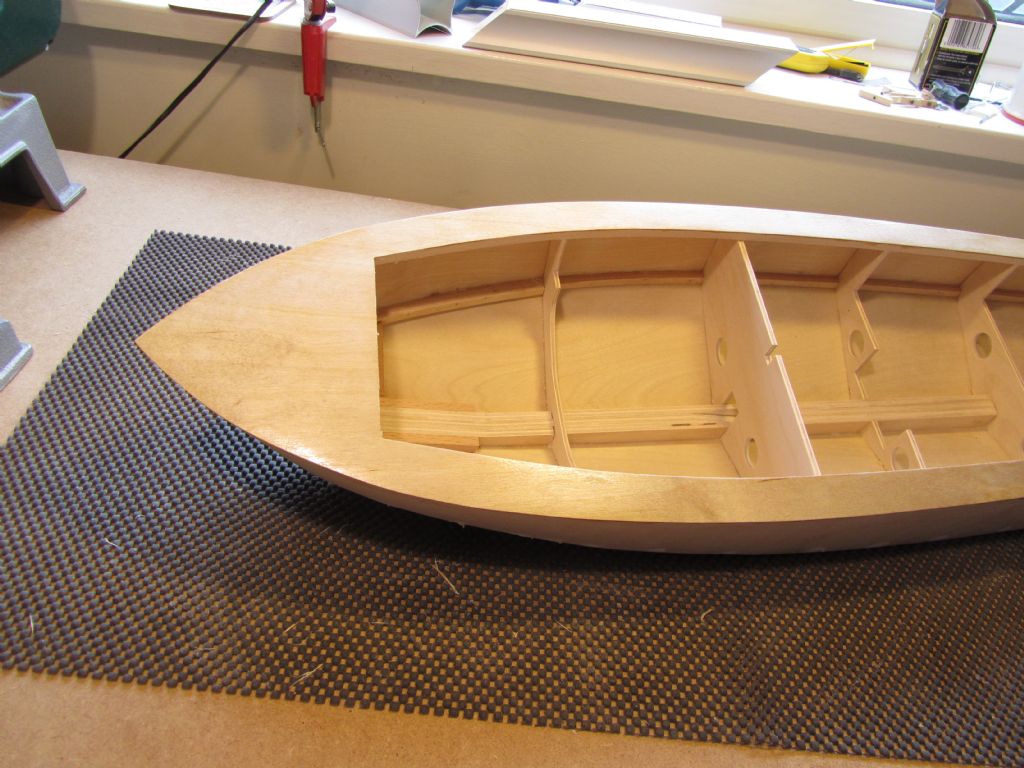

Back on he Huntsman now. Don't know why I said I'd be veneering the deck in my last post as what I intended to do and have now done is added the deck in birch ply so that I can varnish it. I'm not going to plank or draw lines on this model as the deck areas are fairly small and I'd never get it finished!

Another delivery of timber from SLEC duly arrived containing the 0.8mm birch ply I wanted so that I could fit it to the curved deck more easily that the 1.5mm that I used for the hull skins, or so I thought!

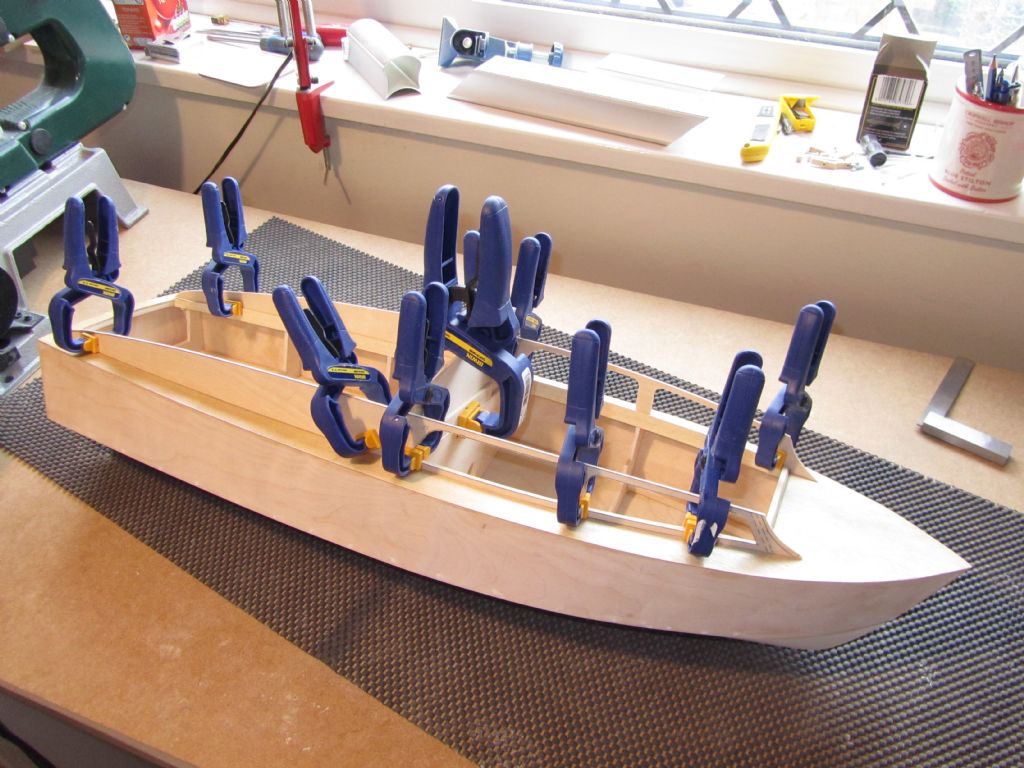

I cut out a card template for the whole of the deck and then cut out the 0.8mm ply. Laying it in place it certainly bent to the profile easily enough and so set to adding aliphatic resin to all the required areas. I positioned the ply, starting at the bow and it was like herding cats when I began adding the tape and clamps. By the time I'd got the bow area taped down good and tight the side and rear parts of the deck were curling up and the glue was drying. I wanted to finish it in one go really but I took stock and decided to just do the bow and part way down each side and finish it the next day. This worked well, but I did have to put a saw cut in above the transom as I couldn't get the ply to sit flat – this will hardly be noticeable though.

I have to say this has probably been the most tricky and fiddly (more than fitting the first hull skin on the first build) part of the builds so far, particularly as I had to be careful of not damaging the surface. There is the odd small mark and scratch but nothing of consequence.

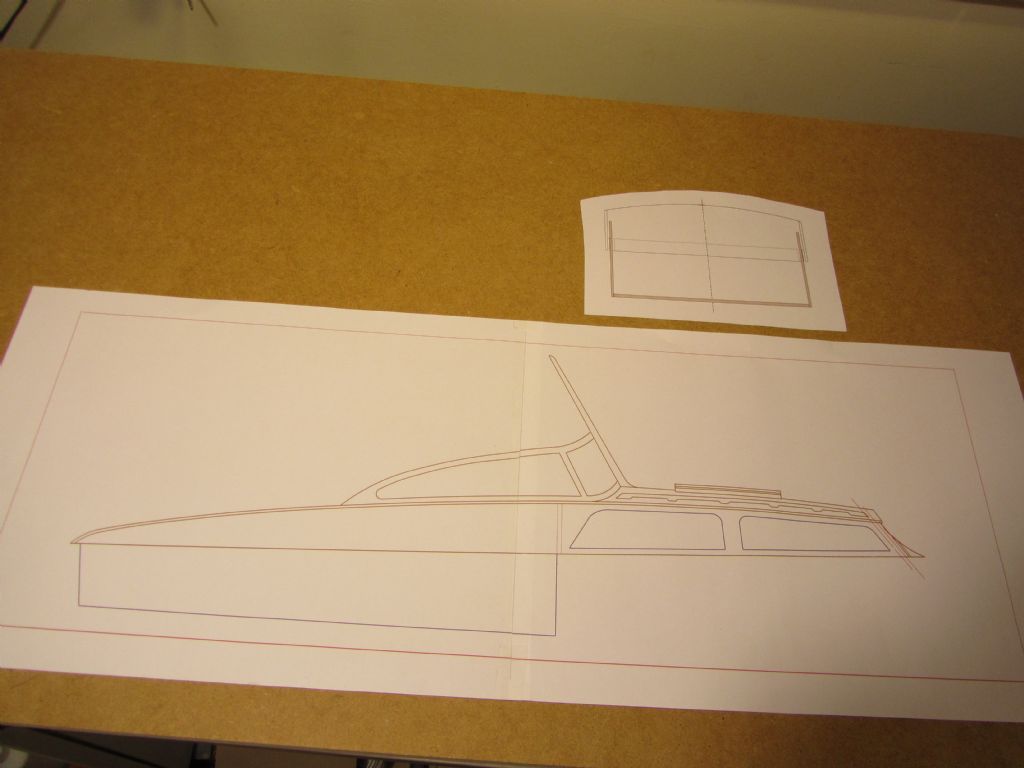

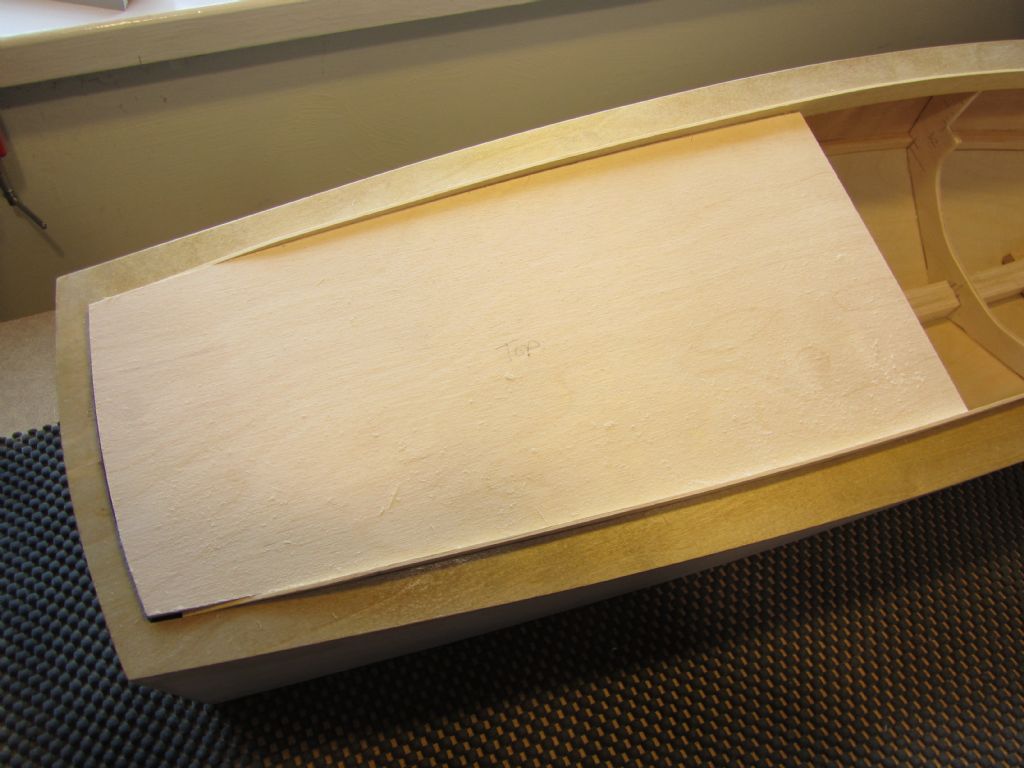

I'm pleased with the outcome though as I've got the fit pretty neat and tight. I shall apply a couple of coats of varnish to provide protection before I start on the superstructure – I need to do some more on the drawings though before I do that and in the meantime am back on the Swordsman.

Oh, almost forgot, before fitting the deck, I fitted the transom to finish off the hull skinning.

As ever the photos are out of sequence!

Chris