Hi All

My intention at some point was to build my own Huntress, but not just yet as I own one of DM's lovely creations and thoughts were it being on a Captain's Boat version, but other builds were going to come first.

Whilst my goal is to build all of the classic Faireys; Huntsman 31, Swordsman 33 etc. all at 1:12 scale, I do like to have a go at the more unusual, hence the River Cruiser and the Fisherman 27 – the latter being planned for a winter start.

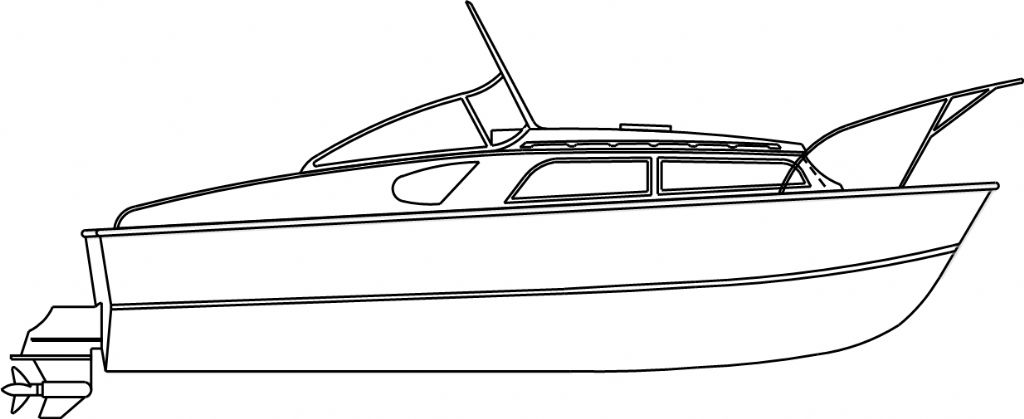

Anyway a discussion on Alan Bell's Huntsman 28 thread on stern-drives had me looking at my Fairey Marine book and I came across a preliminary design by Alan Burnard, Faireys' designer, for a longer cabin Huntress (still using the 23 foot hull) with twin stern-drives. Some Huntresses were fitted with stern-drives for particular customers, particularly where hulls were supplied for completion by other yards, but most were traditional prop shaft.

Along with the longer cabin there were longer and deeper side windows which look more modern and I reckon the overall look is very nice. It was penned (or should I say pencilled) in the early 1960s, so alongside other designs, and it was a pity that it never went into production. I guess that being the early days of stern-drives was part of the reason.

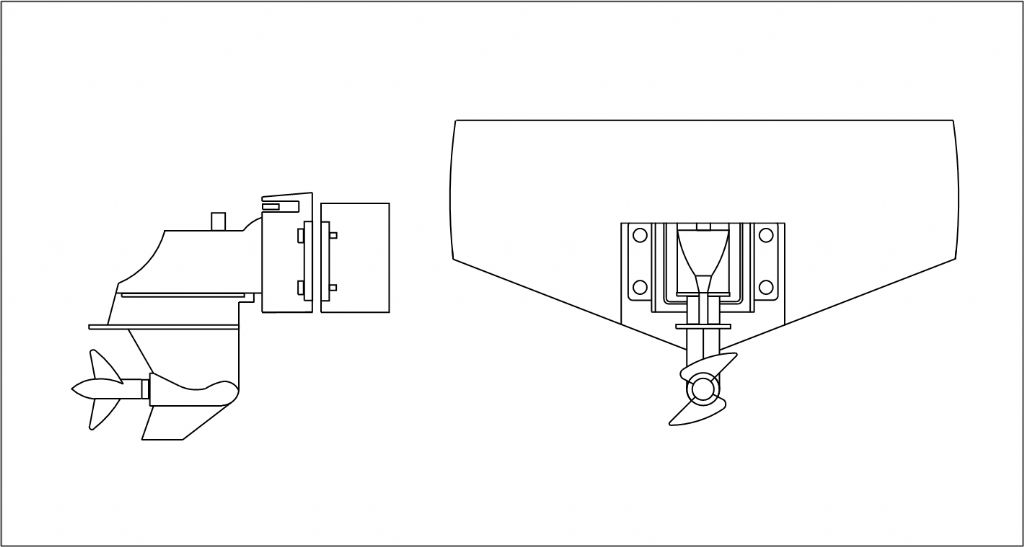

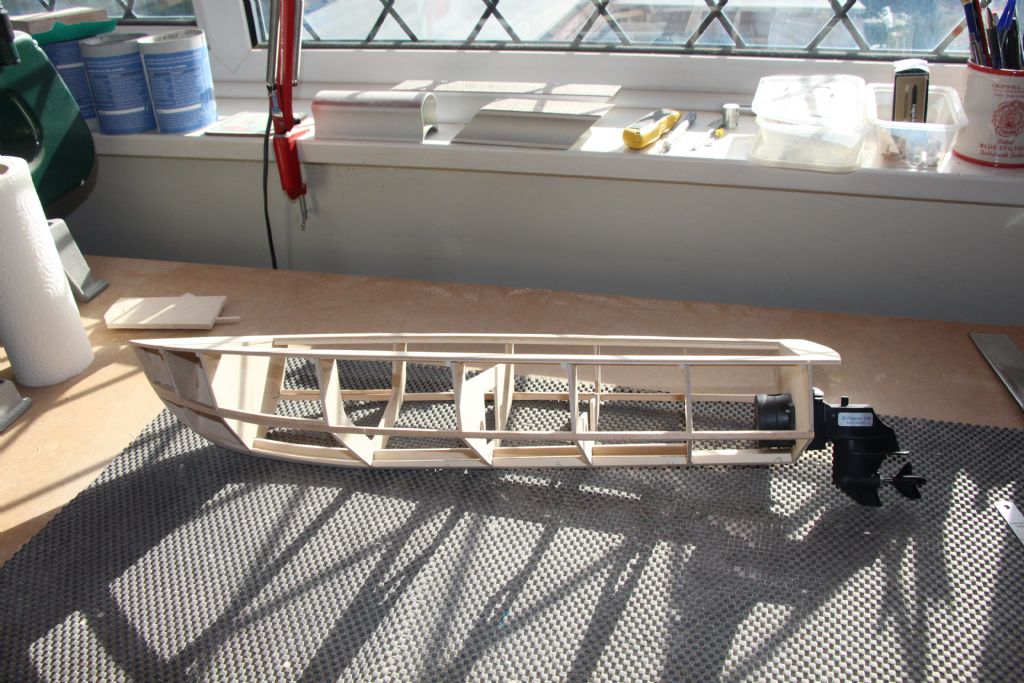

Upshot is that I decided I had to build one. First thing to look at was the availability of stern/Z-Drives to suit a small boat at 1:12. Not much out there really, well I found one at Bauer-Modelles in Germany which is slightly bulkier than ideal but it fits the bill and has a 36mm prop. It's made from plastic but it will have to do. The alloy ones are too big but are works of art with prices to match!

So with a suitable drive found and winging its way here the build is a goer. I've bought the motor as well, my usual choice of Overlander, whilst still in stock.

I need to wait until the drive arrives, but this particular one has quite a large piece where it fixes to the transom and initial thoughts are to recess it into the transom, we shall see.

Forgot to mention, due to the relatively small size of the model and the added complication and weight particularly of drives and motors etc. I've decided on one rather than two. It was only a preliminary design afterall!

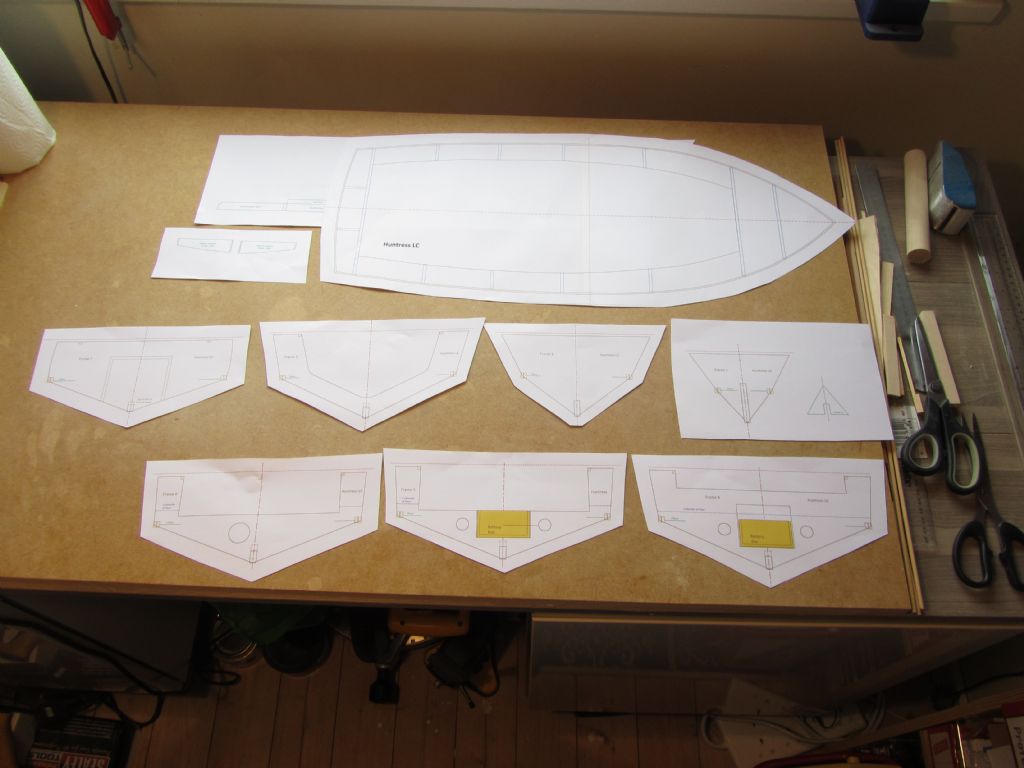

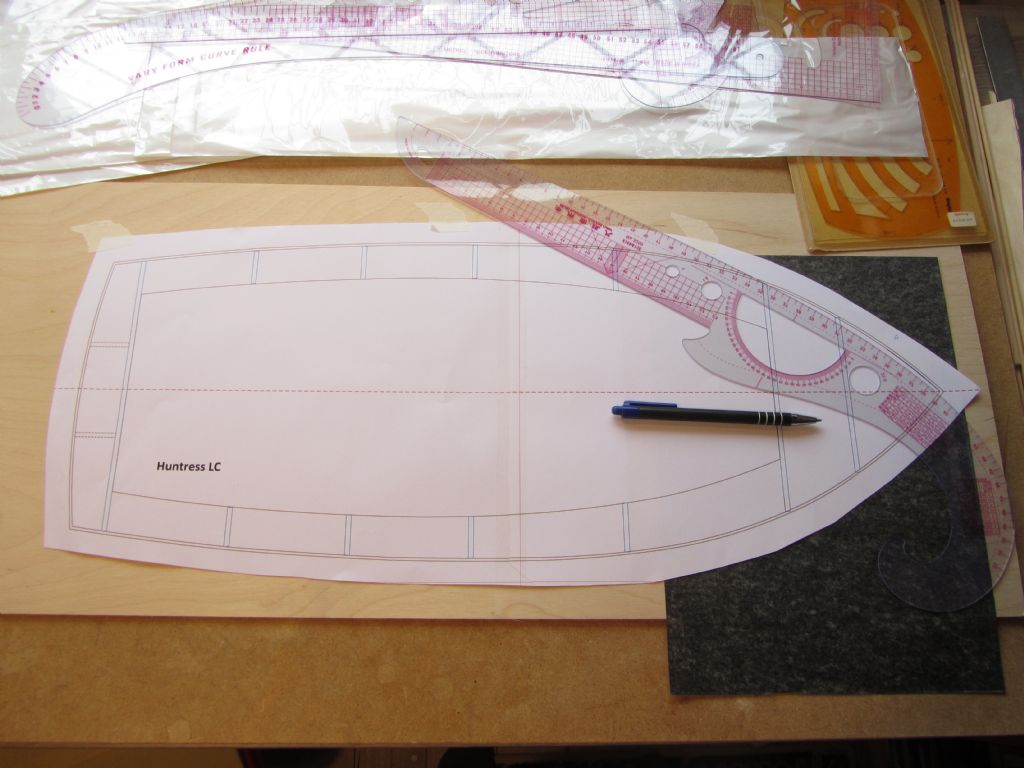

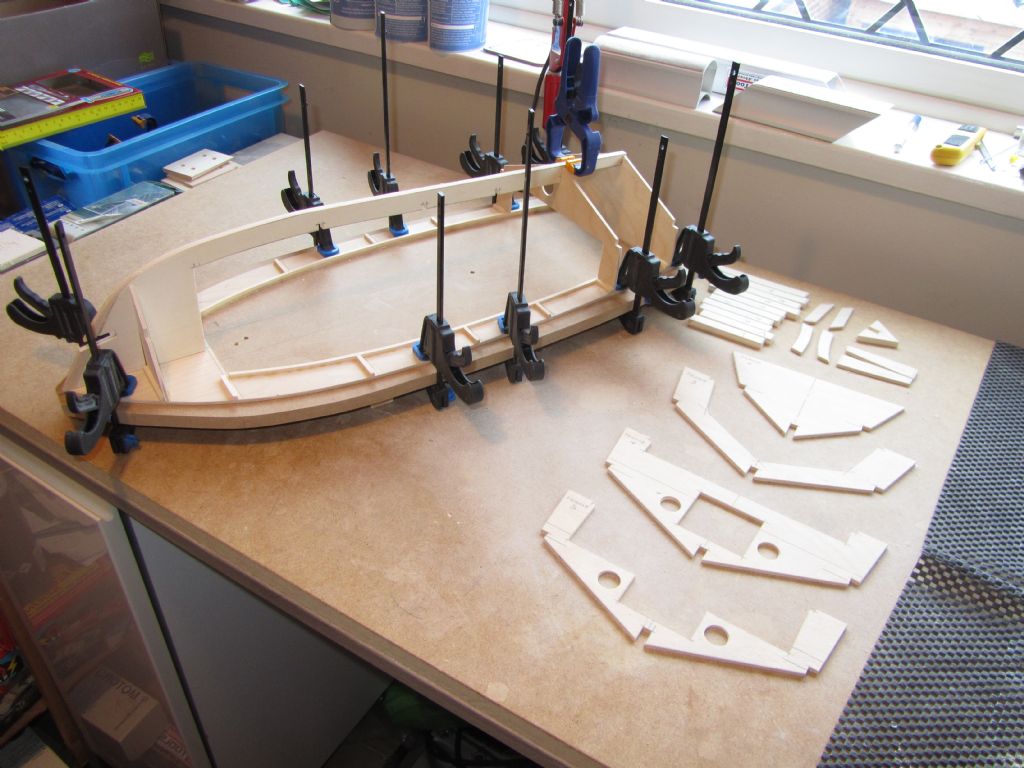

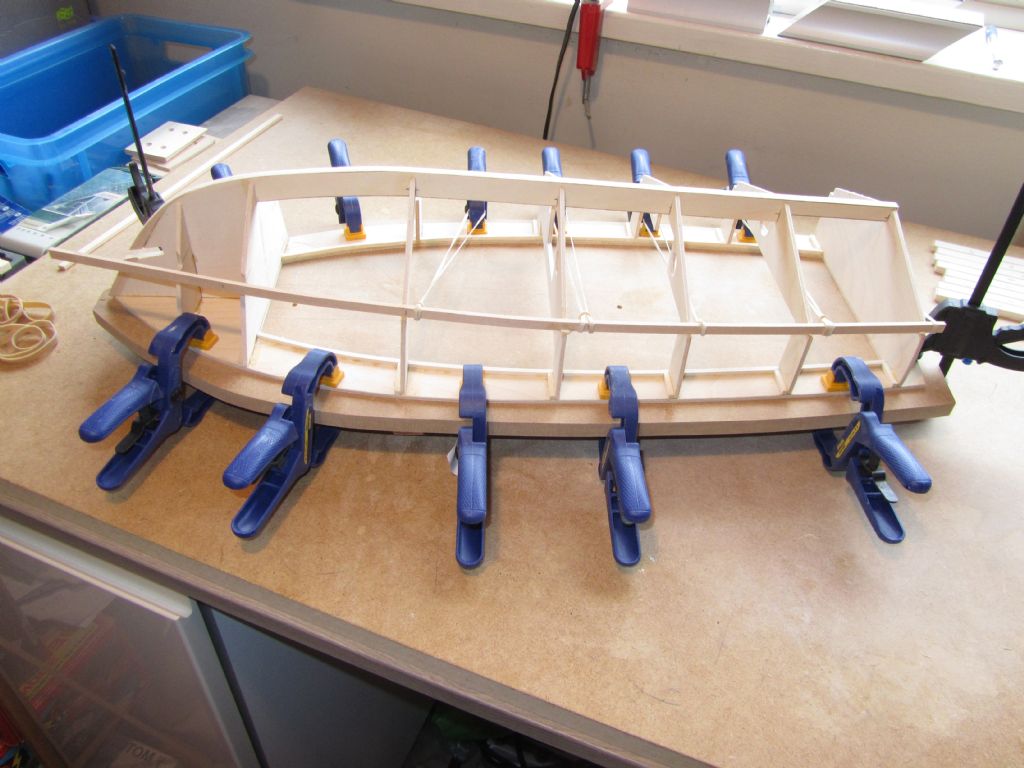

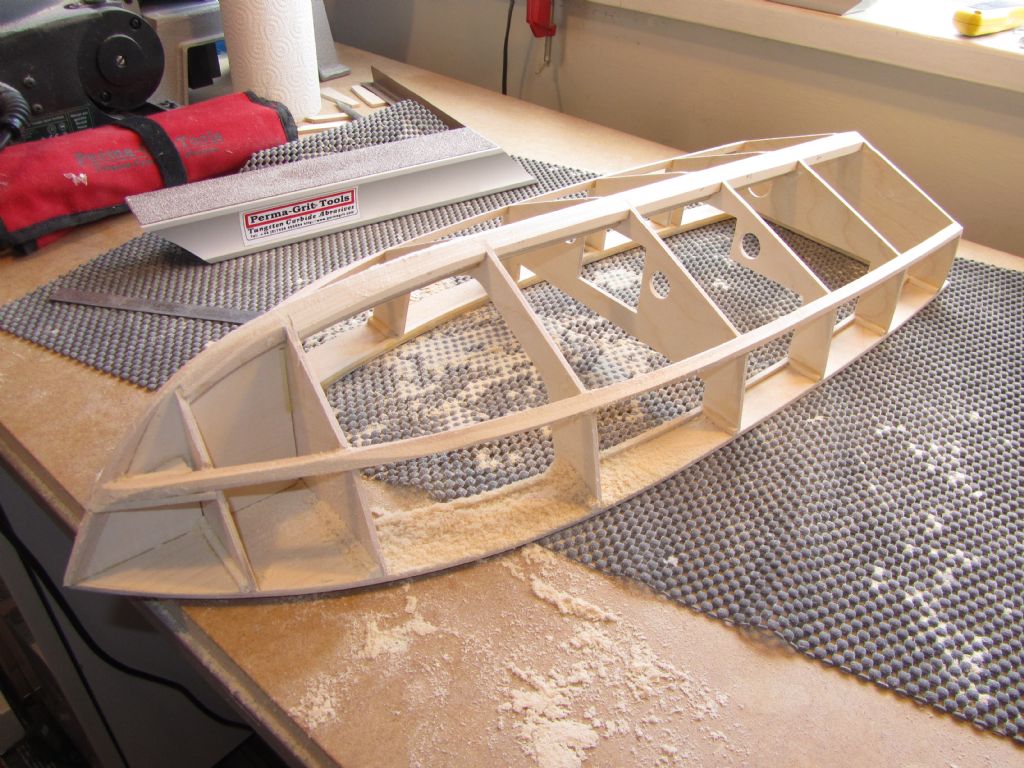

When the drive arrives I can make the necessary tweaks to the Huntress drawings and start on the hull build. Well, after sorting out my work room again!

Chris

Chris Fellows.

Chris Fellows.