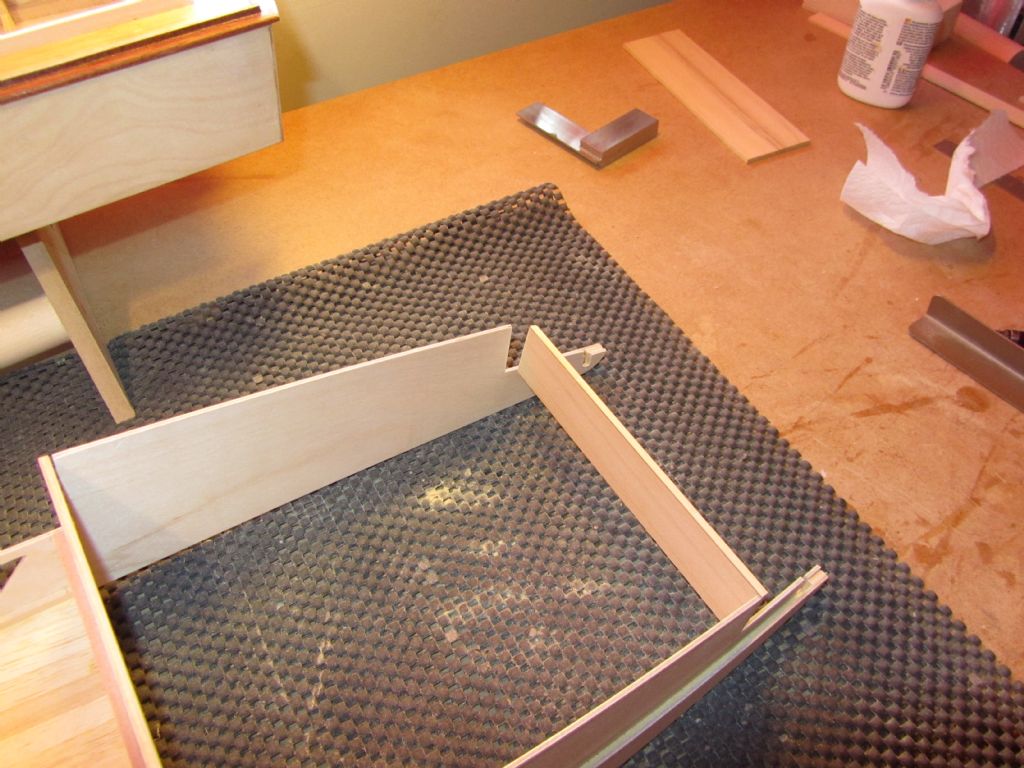

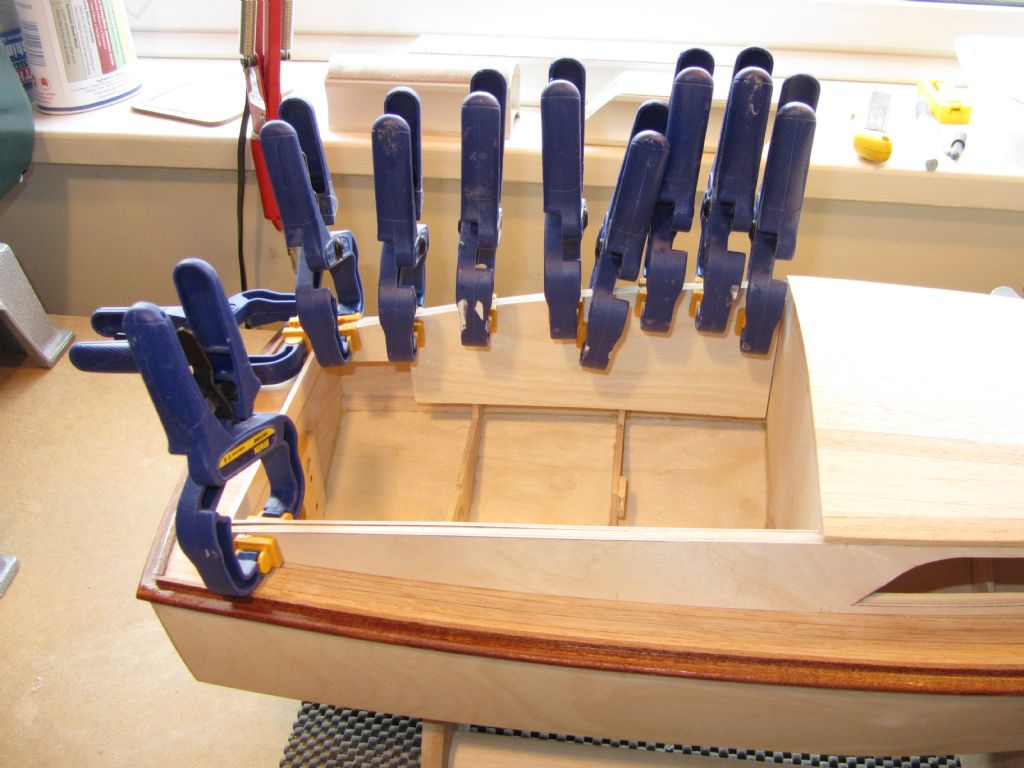

Added some more 2mm bass strip towards the bottom of the outer coamings to provide more support and glue area for the inner coamings, again with saw cuts so that it bent easily.

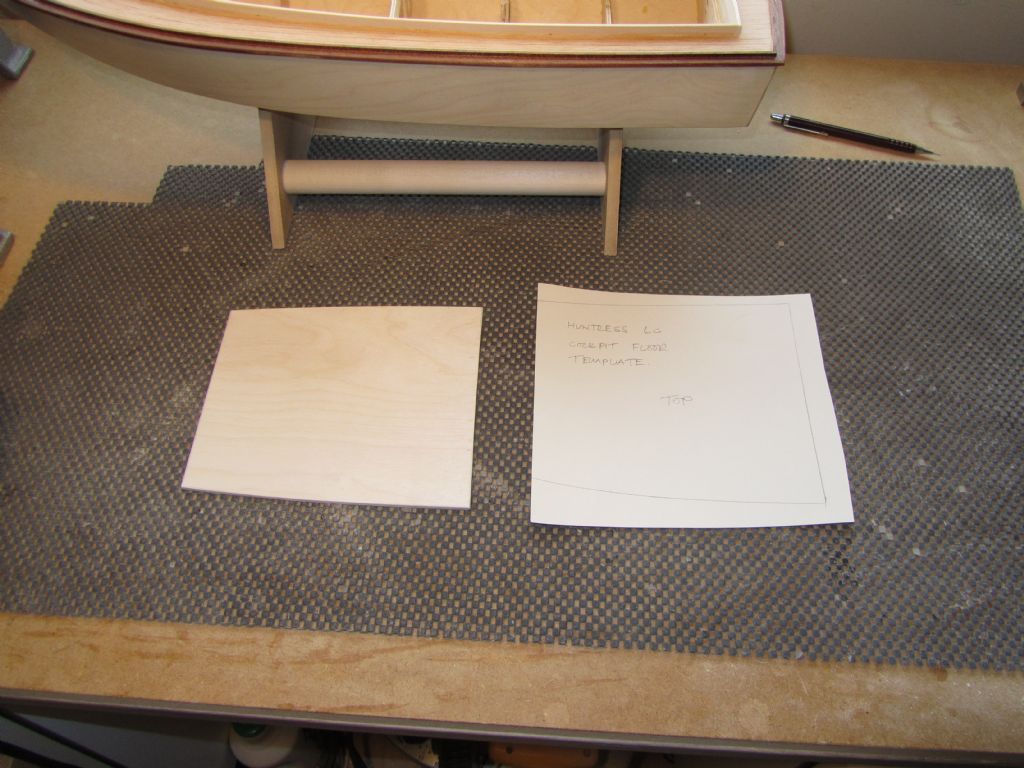

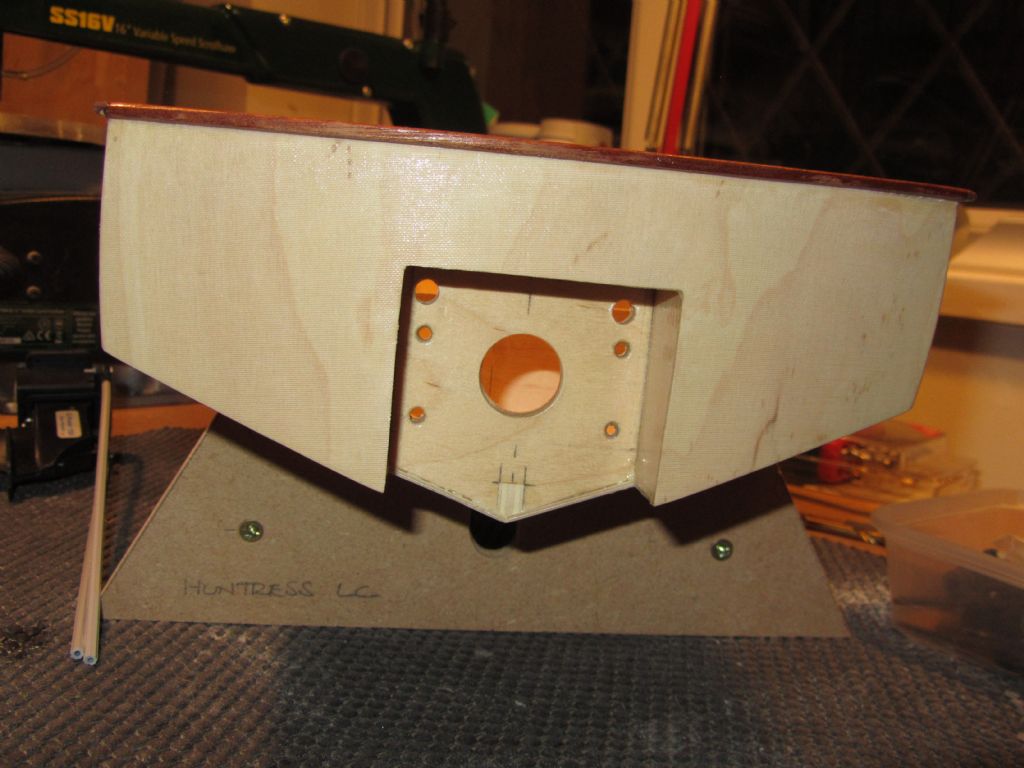

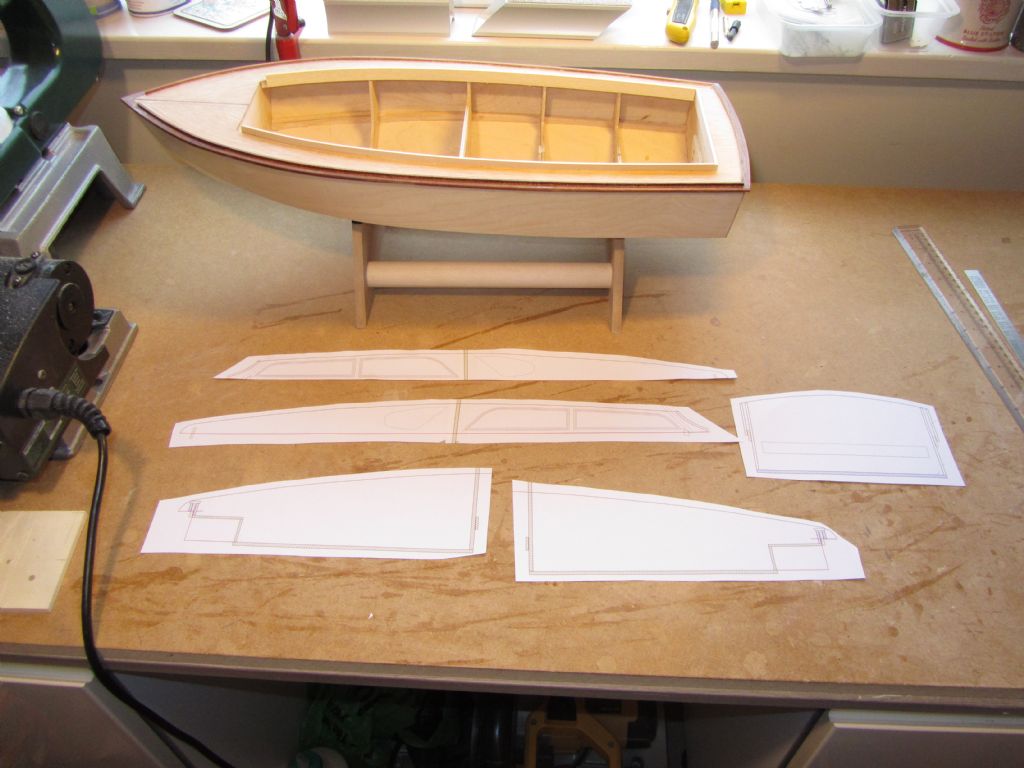

When I built the Huntsman 28, which is a similar build and very much like a longer Huntress Long Cabin (but without the stern-drive) I began the build of the cockpit area by gluing the inner coamings and floor together first. Whilst it worked out fine it is tricky in the that the floor has to be a good fit inside the upstand and allow for the thickness of the coamings, which due to the curve need to be glued to the outside of the floor. Also it was difficult to ensure that the rear of the coamings was tight to the deck. So with the Huntress I decided to glue the inner coamings in place first and the floor afterwards.

It's usually annoying when you find that your ply has warped but in the case of the inner coamings the 2mm warped piece that I selected was almost the perfect curve required! With the Huntsman 28 (it may been thicker ply as well) I put some saw cuts in the inner coamings to bend them more easily and reduce the stress on the outer coamings and the effect of trying to straighten them.

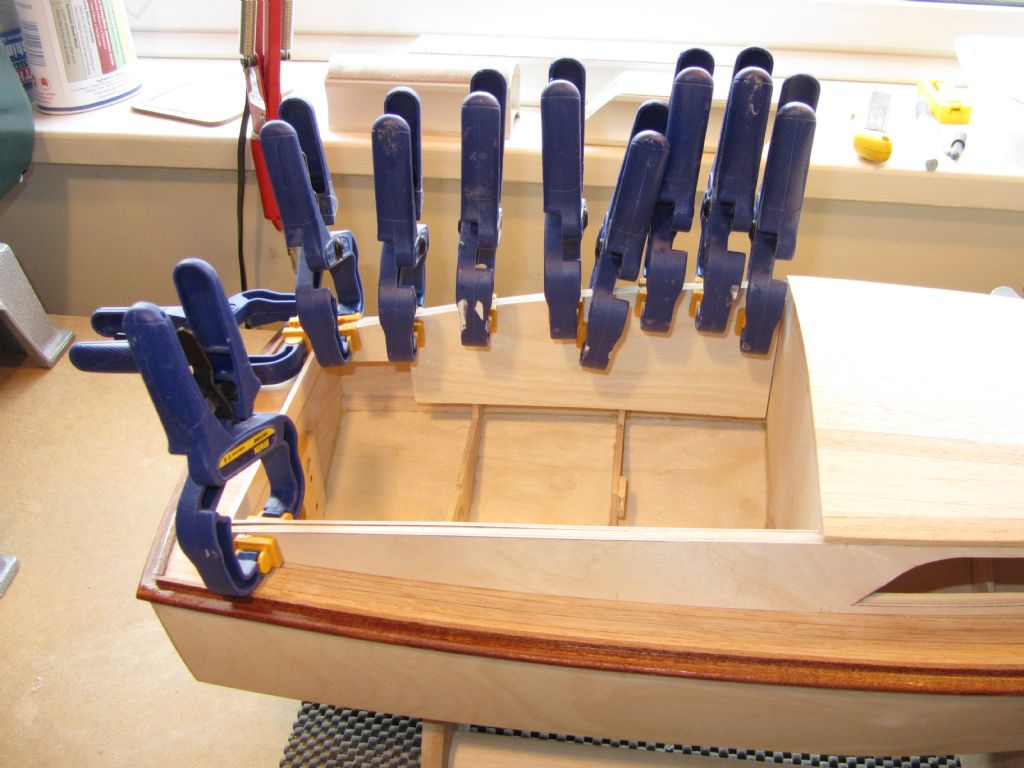

When I took the clamps off after gluing the bass to the top of the outer coamings, I was a bit dismayed to see a bit of daylight under the coamings. However I thought that once the superstructure was clamped down again and the inner coamings glued in place that the problem would be rectified and indeed once one side had been done and left overnight it was found still to be tight to the deck in the morning. It can't be stressed enough that when building a lift off superstructure that it has to be kept clamped down until the glue has completely dried, and with a/resin this means overnight, otherwise twist will be introduced – as I found out to my cost on a previous build even though it had been left for a few hours!

This morning the other inner coaming was glued in place and clamped and will be left until tomorrow. This does result in slow progress (yeah, slower than usual!  ) but it's not worth the risk of removing the clamps sooner.

) but it's not worth the risk of removing the clamps sooner.

I've got some additional shelves to put in a couple of the kitchen cupboards, so I'm multi-tasking anyway!

Chris

Edited By Chris Fellows on 16/03/2021 12:10:12

Chris Fellows.

Chris Fellows.

you must have nerves of steel not to put Clingfilm over the coaming, I always dread the moment when it should not have stuck to that bit !!!

you must have nerves of steel not to put Clingfilm over the coaming, I always dread the moment when it should not have stuck to that bit !!!