As per the Swordsman thread I've taken time out to build a Robin's nest box and an unplanned job of having to buy and install a new tumble drier.

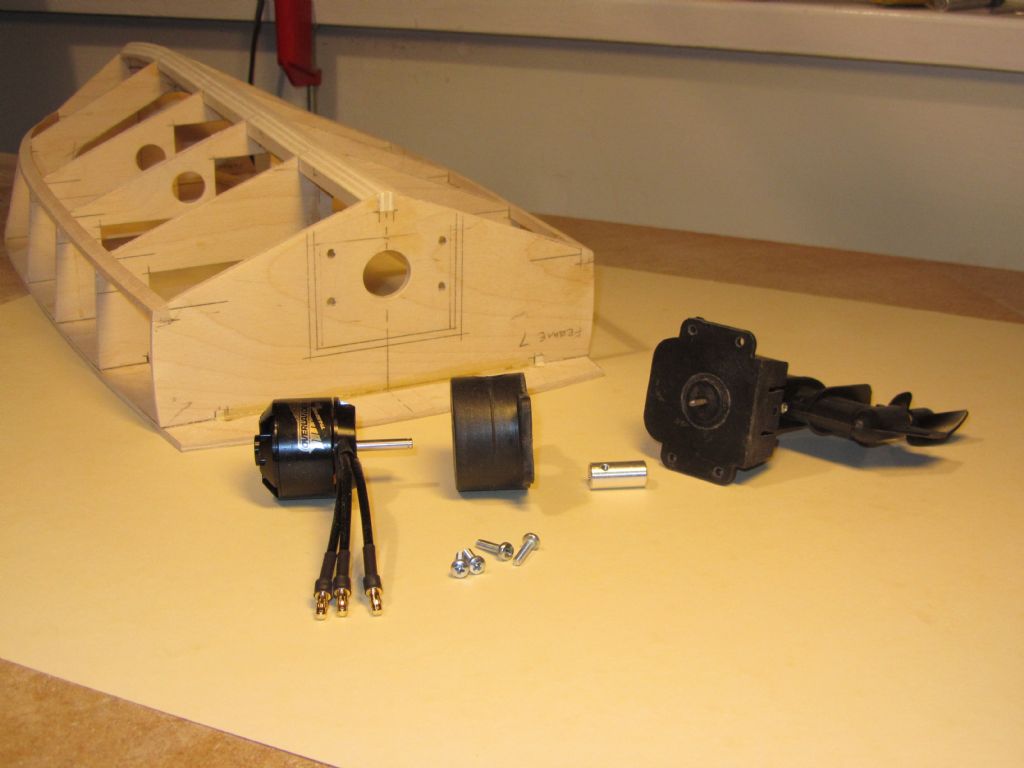

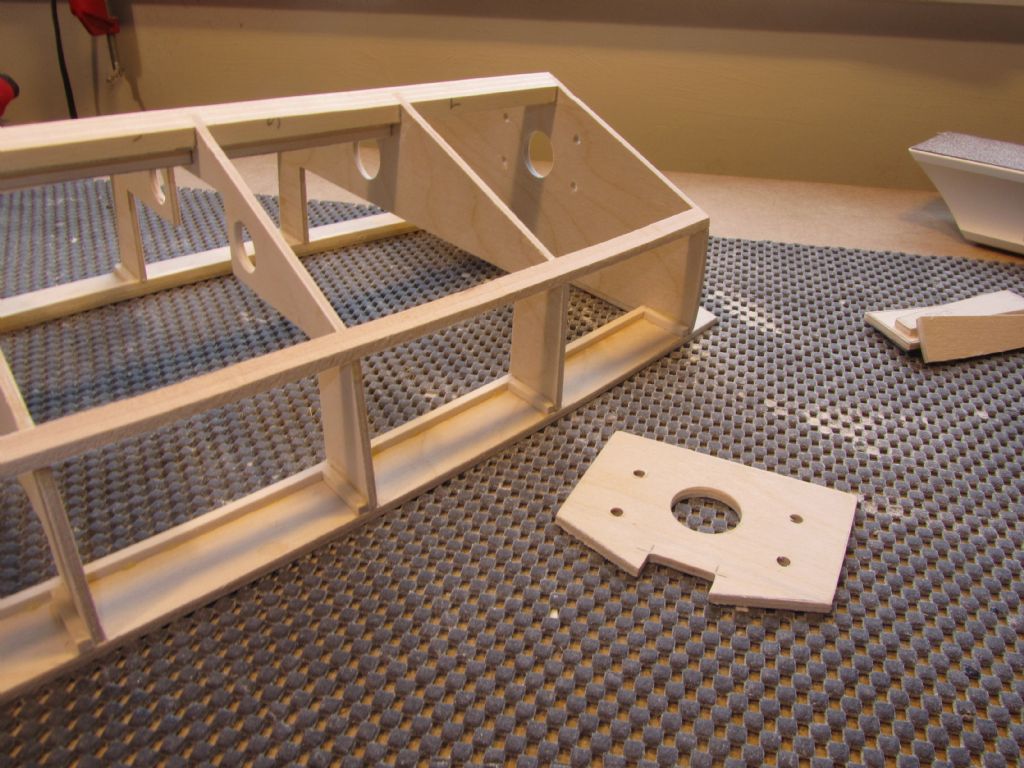

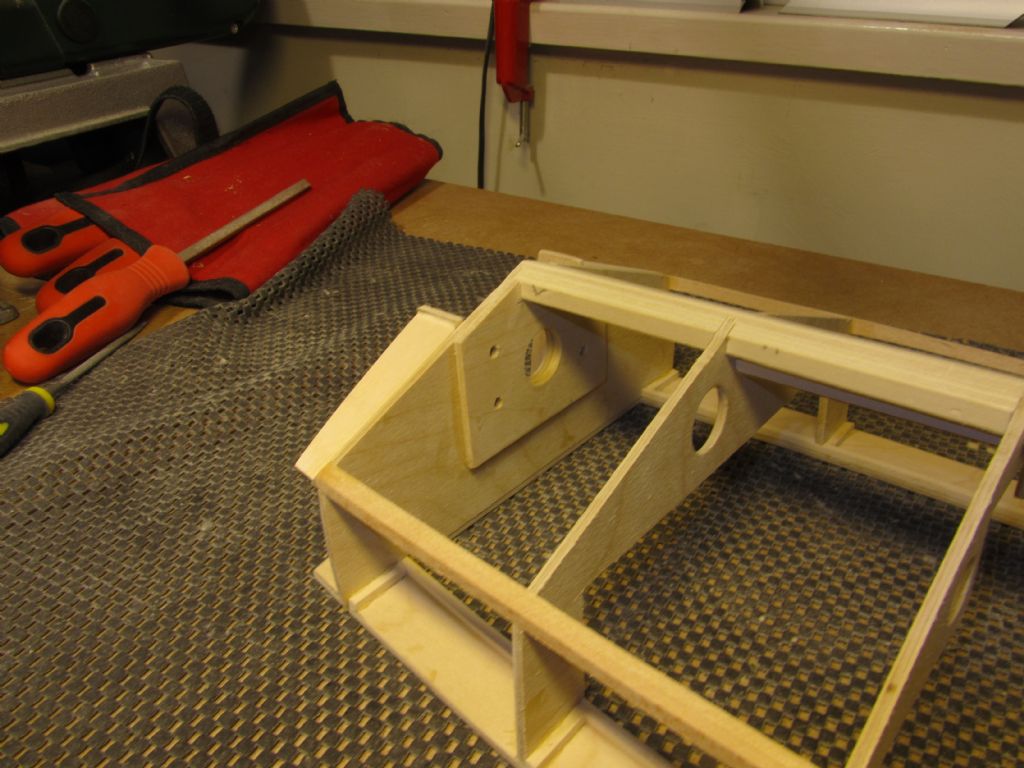

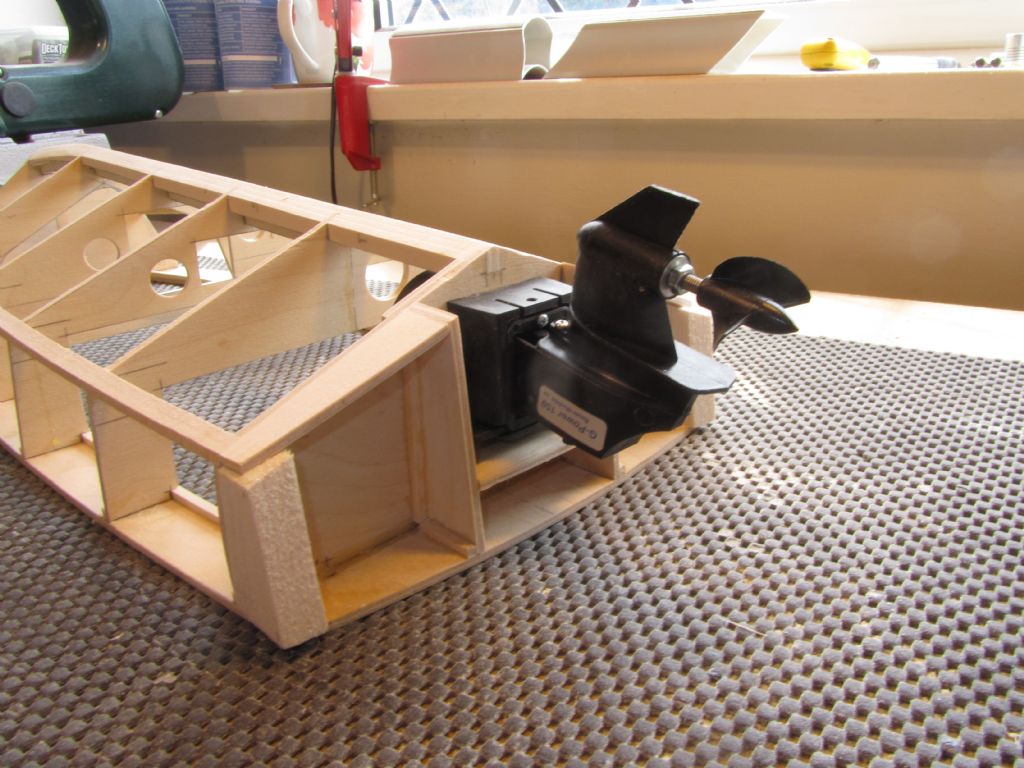

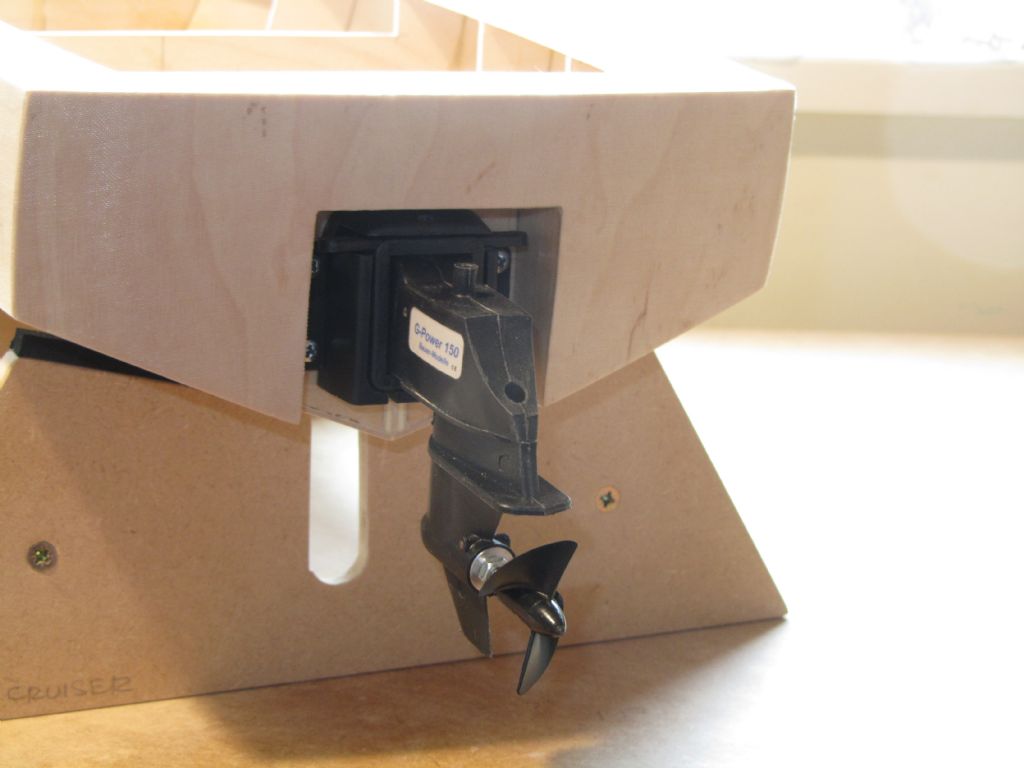

Have now returned to the Huntress and the first job was having a look at how I'm going to move the stern-drive for steering. Space is tight and hindered by the position of the motor and so I think I'm going to have to use snakes, so I've bought a cable one and a nylon one to see which would be best suited – the cable is looking favourite at the moment. I've also bought a couple each of single, double and triple rudder arms to give me options in linking to the servo.

Space is also tight where I need to connect onto the stern-drive and first thought is to solder a connector onto the cable and so have taken the opportunity to buy a small butane torch and silver solder etc. to do the job – I need one anyway for when I solder the pulpit rails up on my builds. Once all the bits and pieces have arrived I can decide how to tackle it, which may or may not involve the snakes!

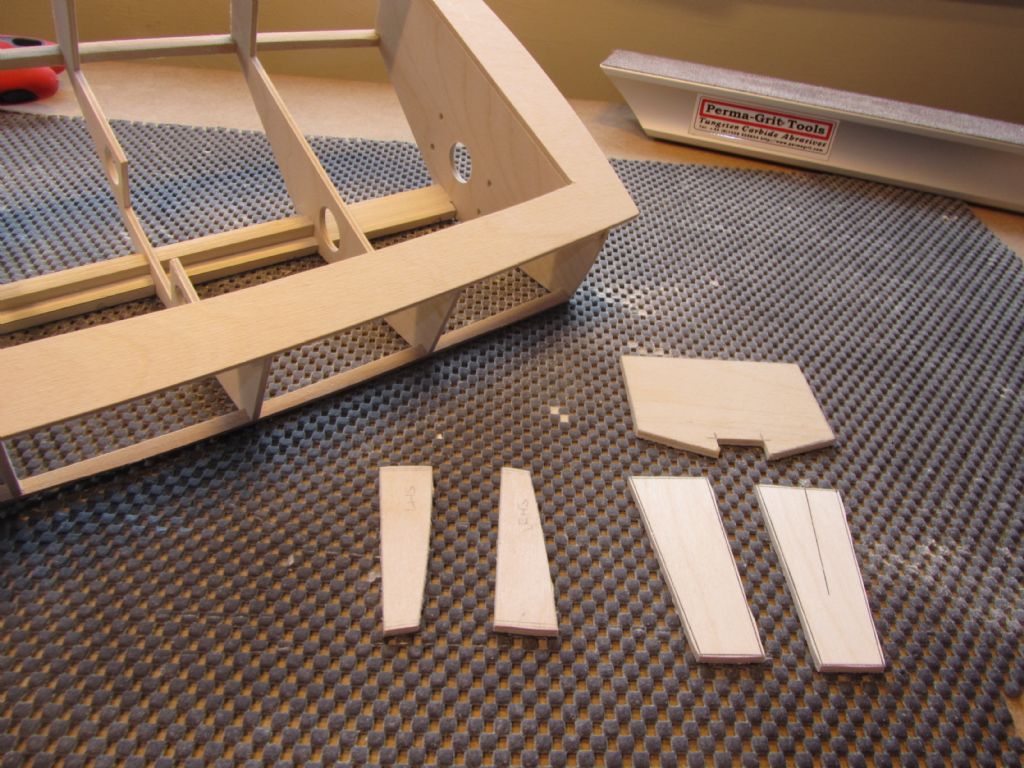

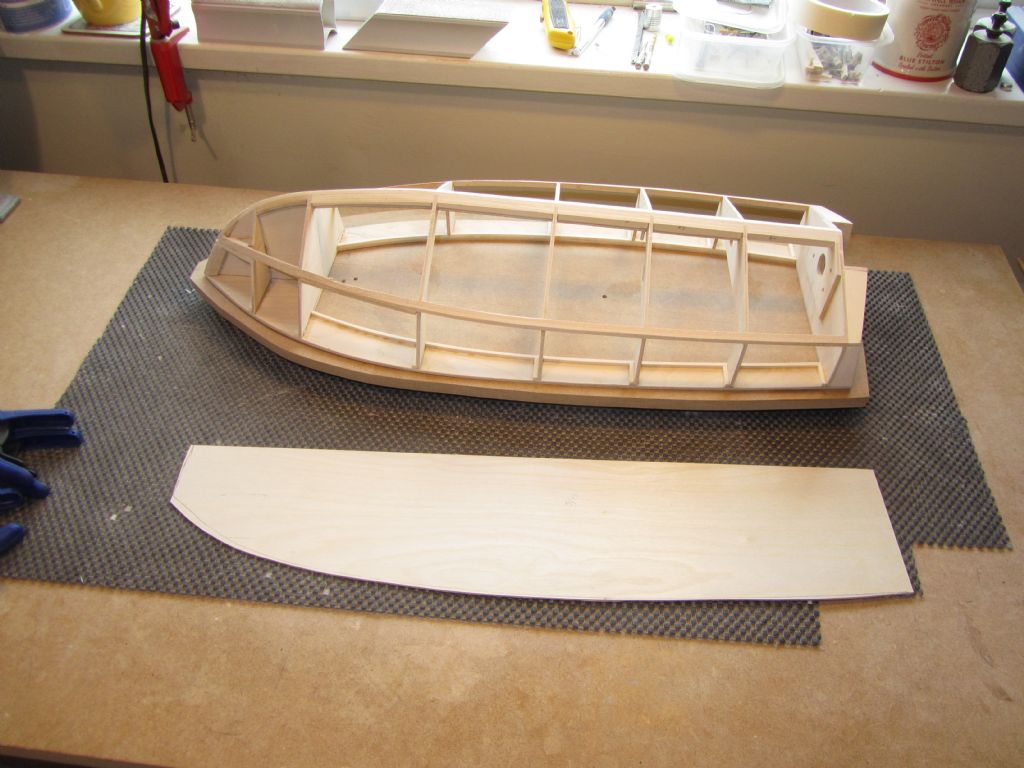

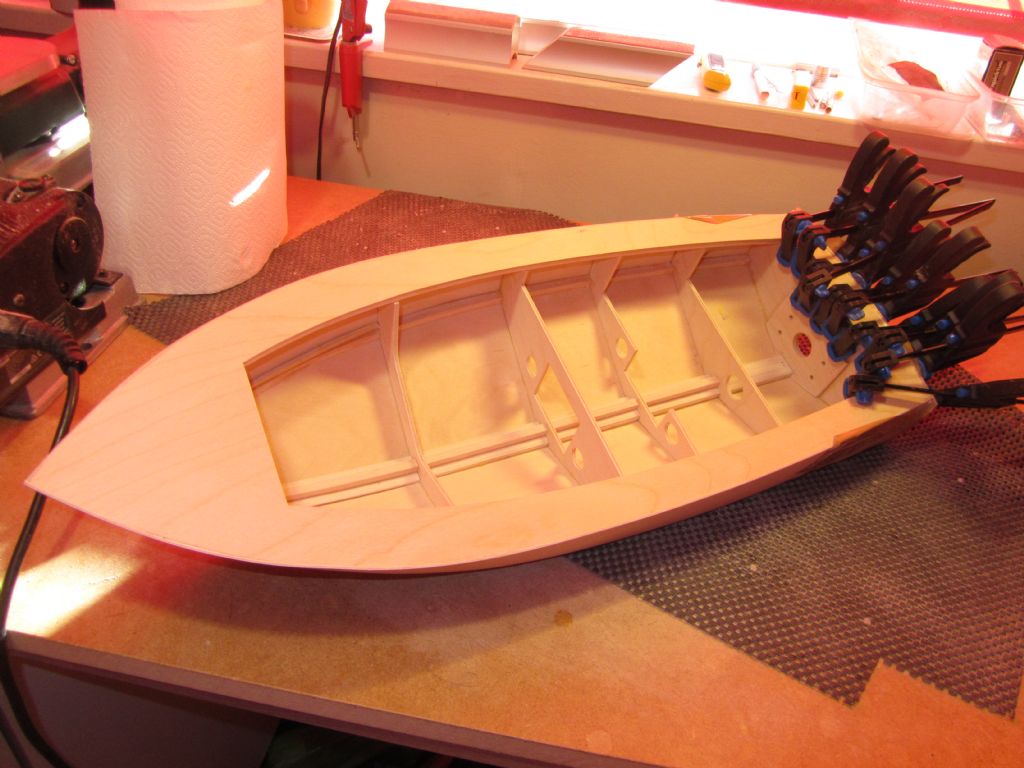

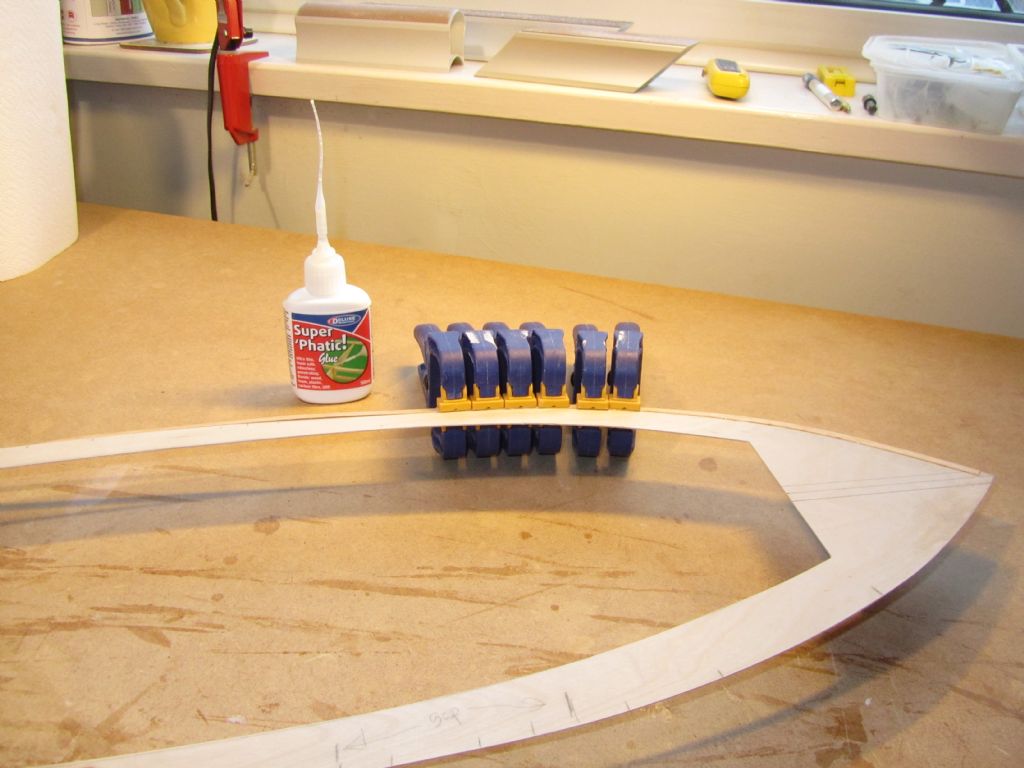

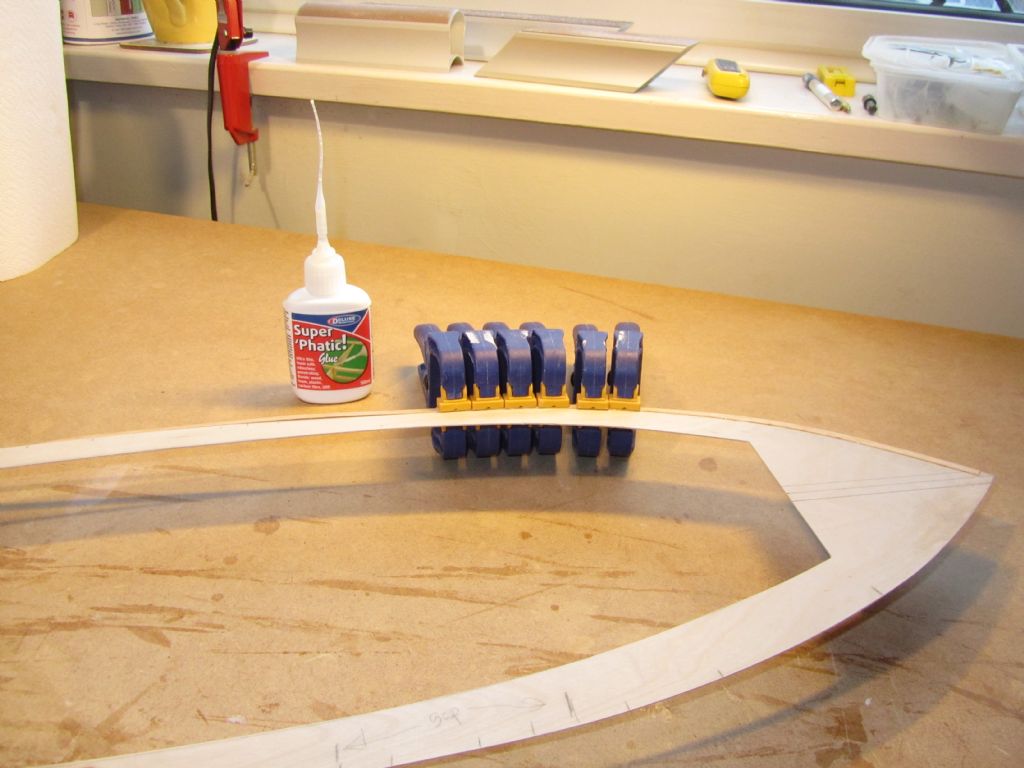

In the meantime, I've decided that I am going to have another go at planking the deck, especially having bought some more thin ply and planks. This time though, rather than using thin CA (as like others it affects me, causing my nose to run for a couple of days) I've taken up Colin's suggestion of using Super Phatic. This doesn't have the instant grab of CA and takes 10 to 20 minutes to dry and as well as taking longer I'm having to approach the job in a different way. Upside is that the glue dampens the planks so helping with bending and getting them to lay down and they can be clamped in place and best of all I'm not gluing my fingers to the planks! Only on the first plank at the moment but I'm much happier with the result, though it will take me somewhat longer.

Chris

Edited By Chris Fellows on 20/02/2021 16:48:15

Chris Fellows.

Chris Fellows.