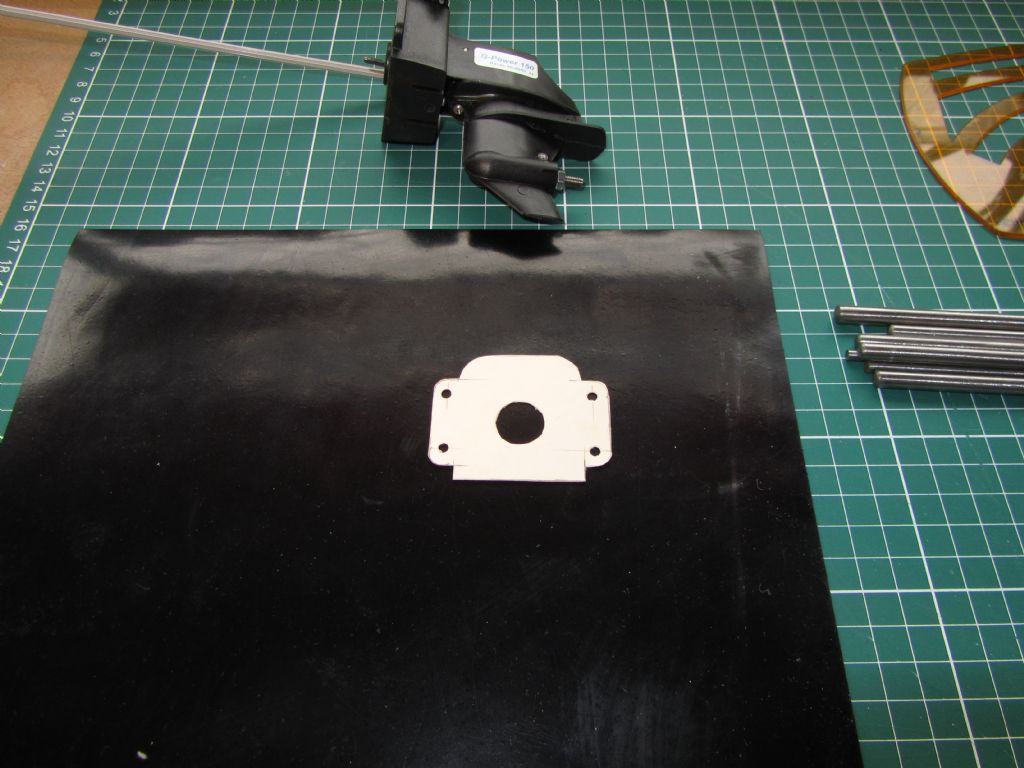

I don't have any old inner tubes and my pushbike ones are probably too small anyway. Not really thick enough for this job either.

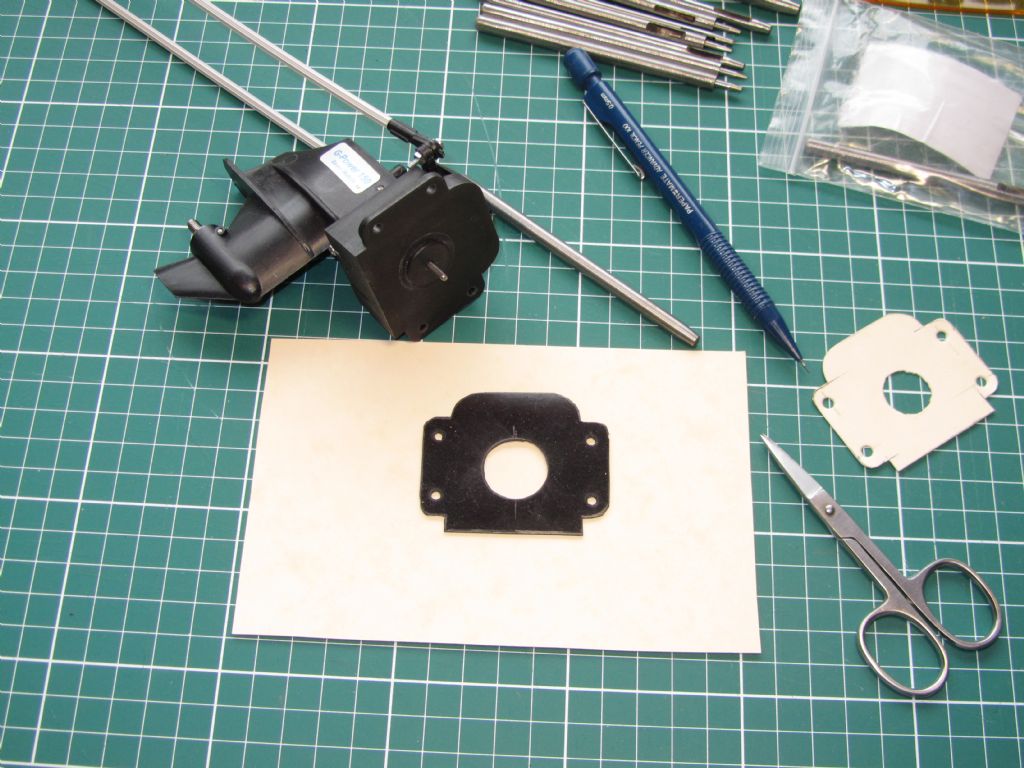

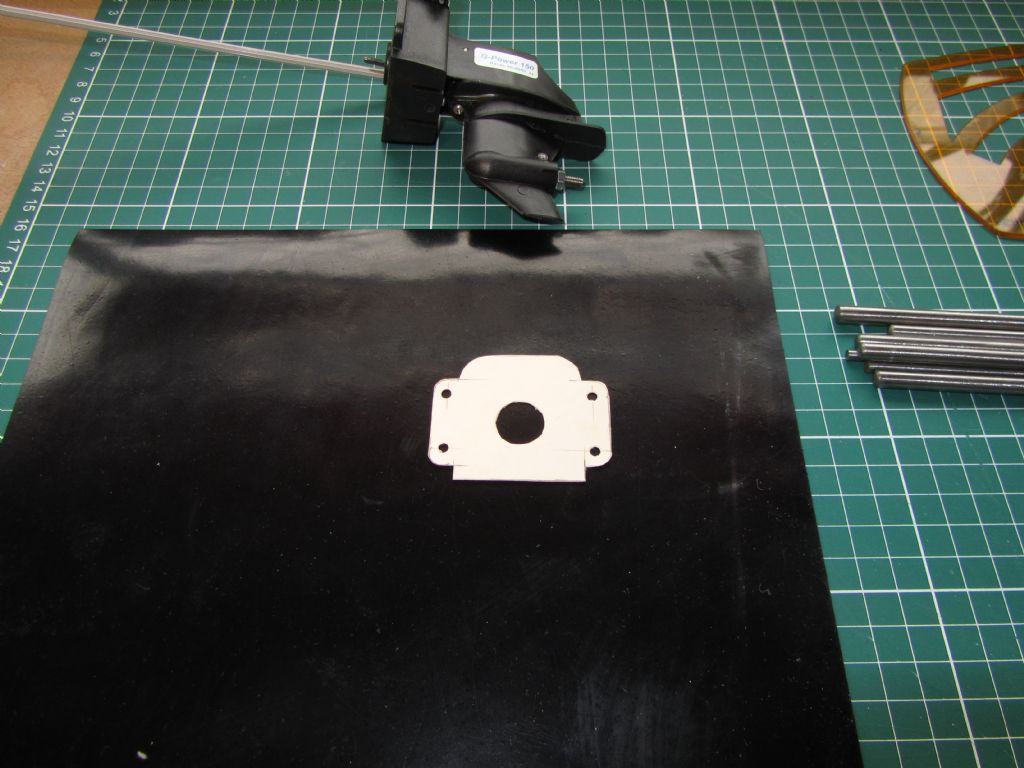

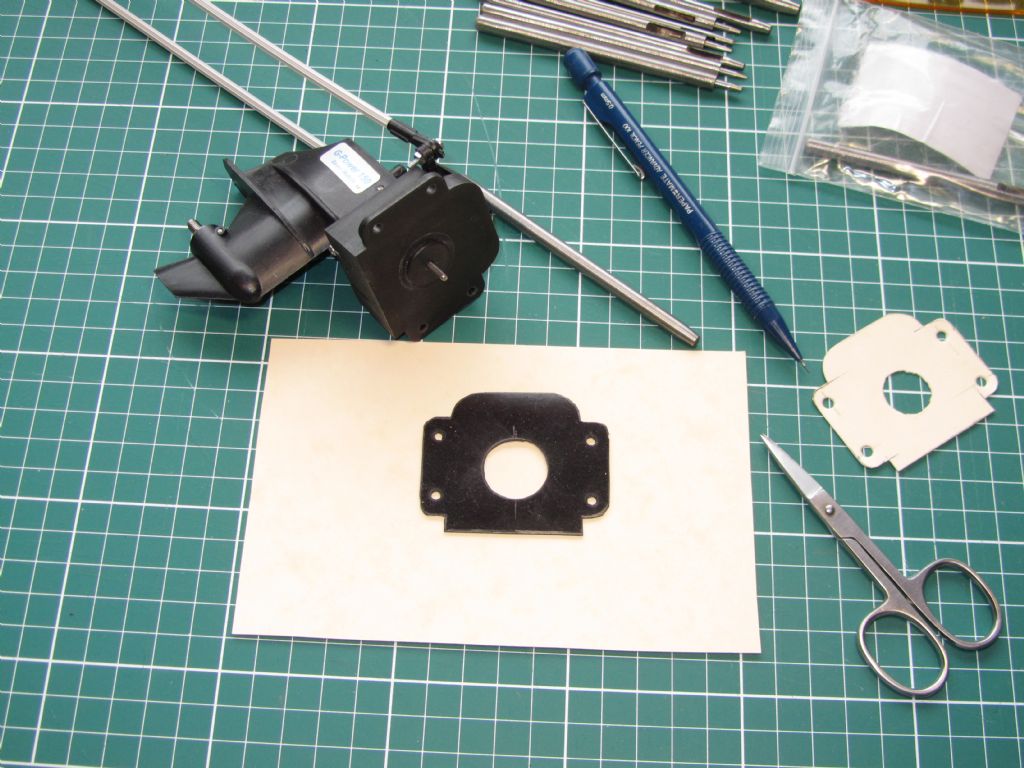

Decided that the 1mm was about right and made a cardboard template which I traced around on the rubber sheet. Cut out the hole and around the perimeter with a pair of nail scissors. I'd bought a set of hole punches not long ago for adjusting a belt and other jobs and this was one of those, so punched out the bolt holes, just the job!

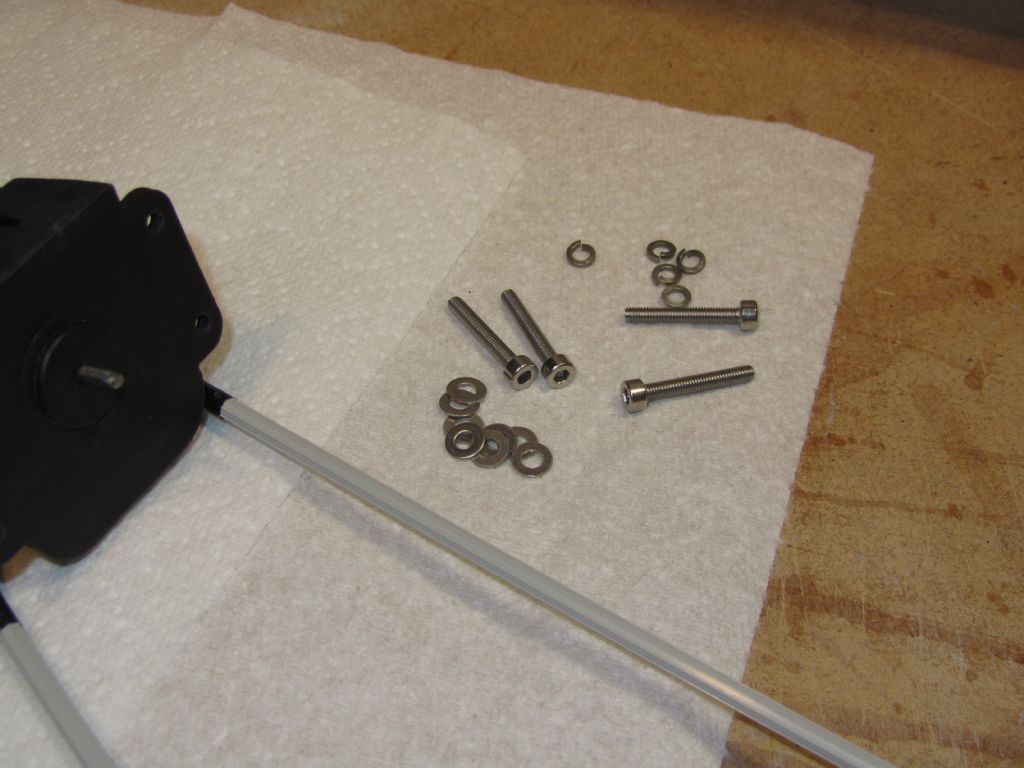

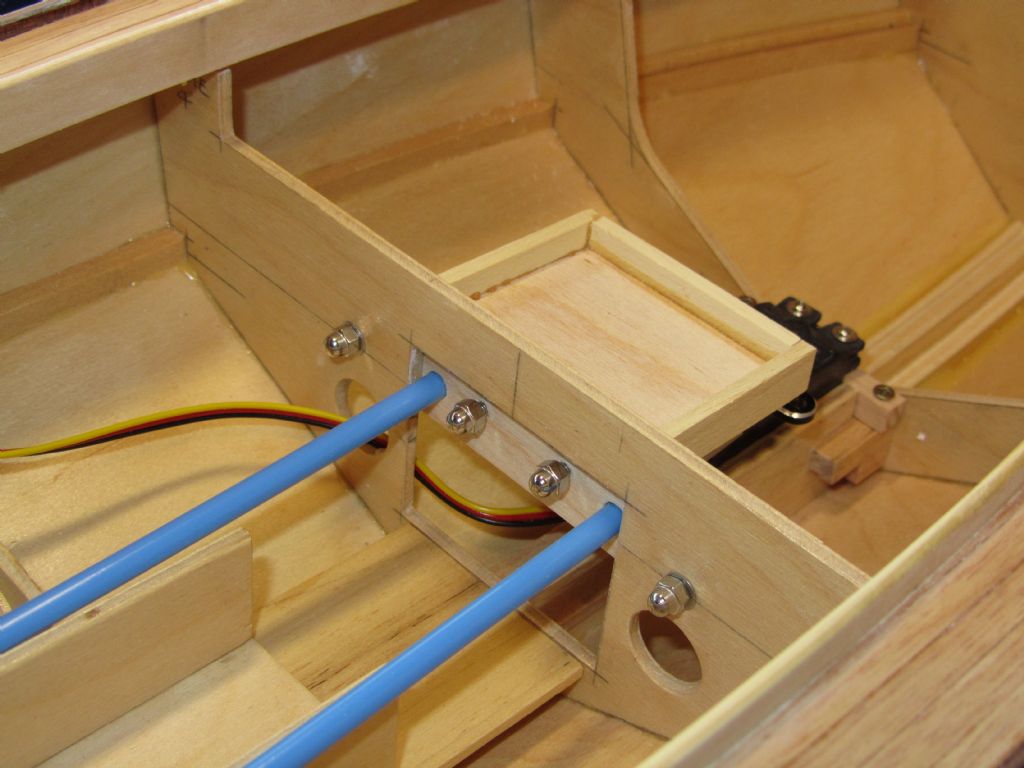

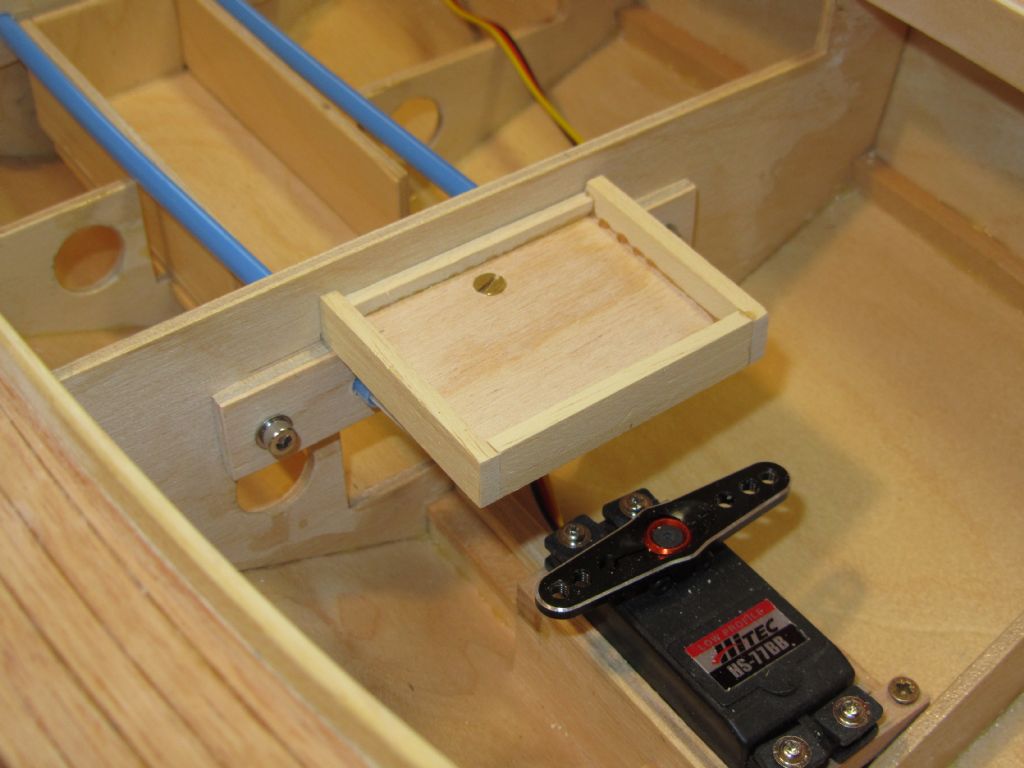

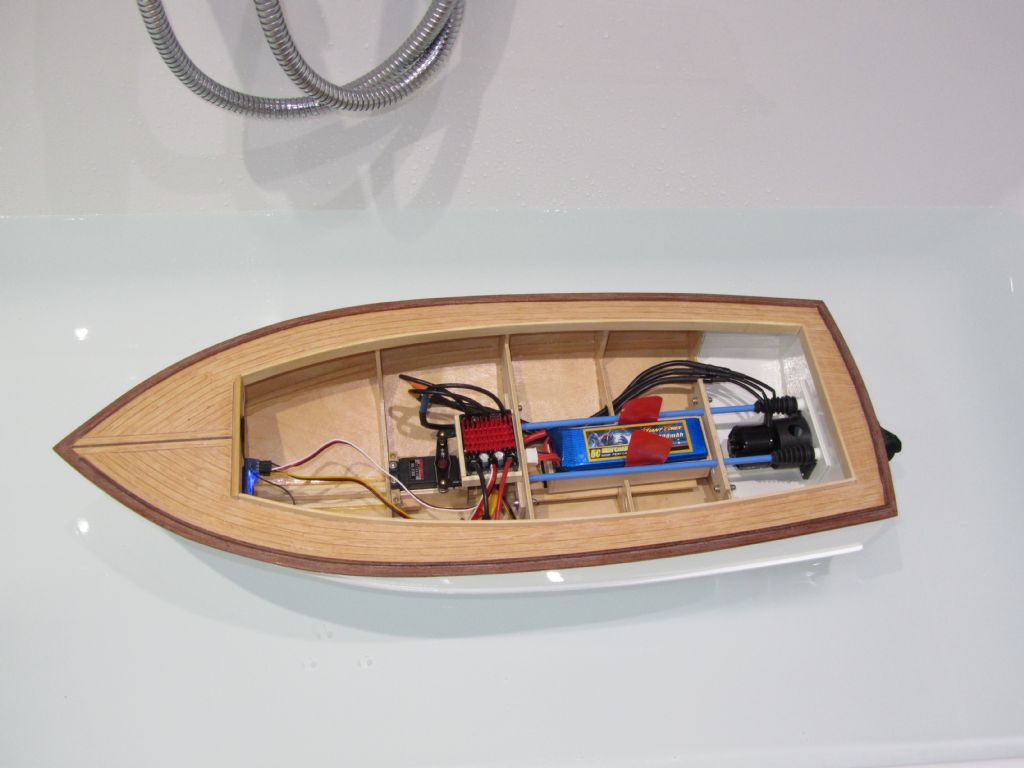

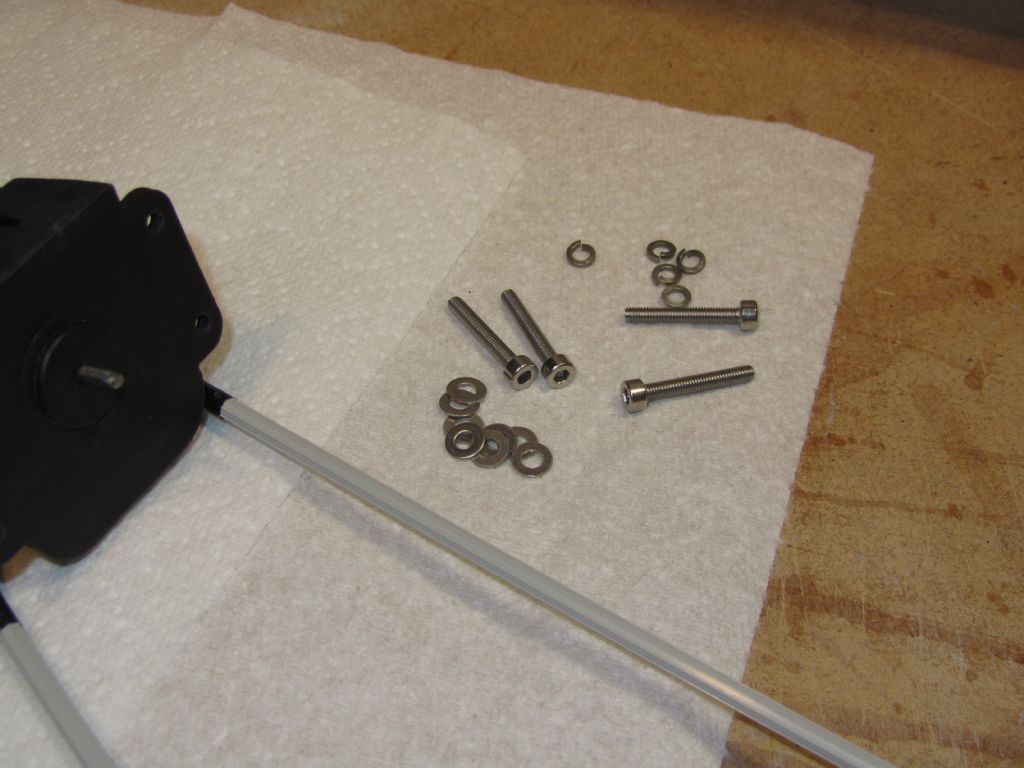

Fitted the motor to the housing using stainless allen head bolts, washer and a spring washer. Access is inside the housing so you don't want them coming loose as the whole installation would have to come out. I then fitted the stern-drive to the transom, having replaced the cross-head screws with more allen head bolts and bolted it to the housing. Easier said than done as access was tight with the snakes in the way and I had difficulty getting the bolts into the threaded holes in the housing. Also the solid coupling inside the housing has to positioned to allow installation and then pushed along onto the flexi-drive – all done through a small hole!.

Stood back to admire my work and noticed that I hadn't installed the rubber bellows, doh!! That was it for that night!

Didn't do anything yesterday as was out but this morning I took it all out again. Originally I wasn't going to use the outers of the snakes, and hence the bellows, but having decided to use the outers to avoid rubbing on anything I could have dispensed with the bellows and taped the outers to the plastic tubes going through the transom. But as I'd gone to the trouble of fitting flanges to the tubes and the bellows would be a neater solution then bellows it was! The small hole in the bellows was too small to go over the outer casing and so I enlarged it by cutting the end off with a knife. This was a failure and the hole was too big. Then I remembered the punches, chose one to give a nice snug fit and hey-presto.

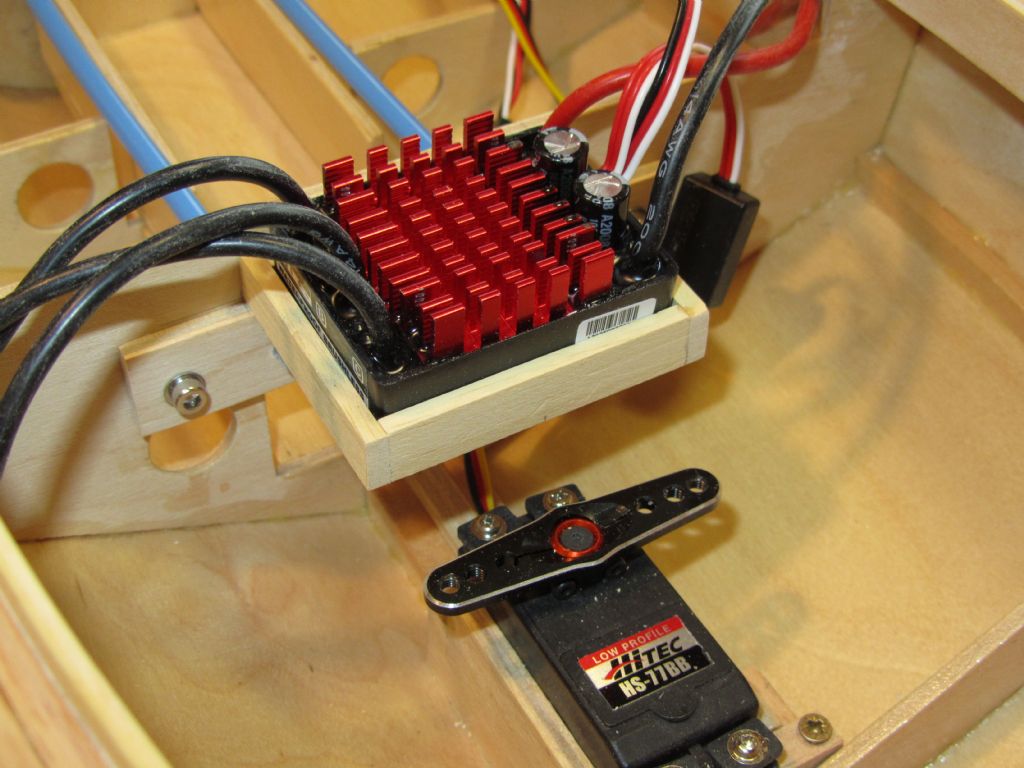

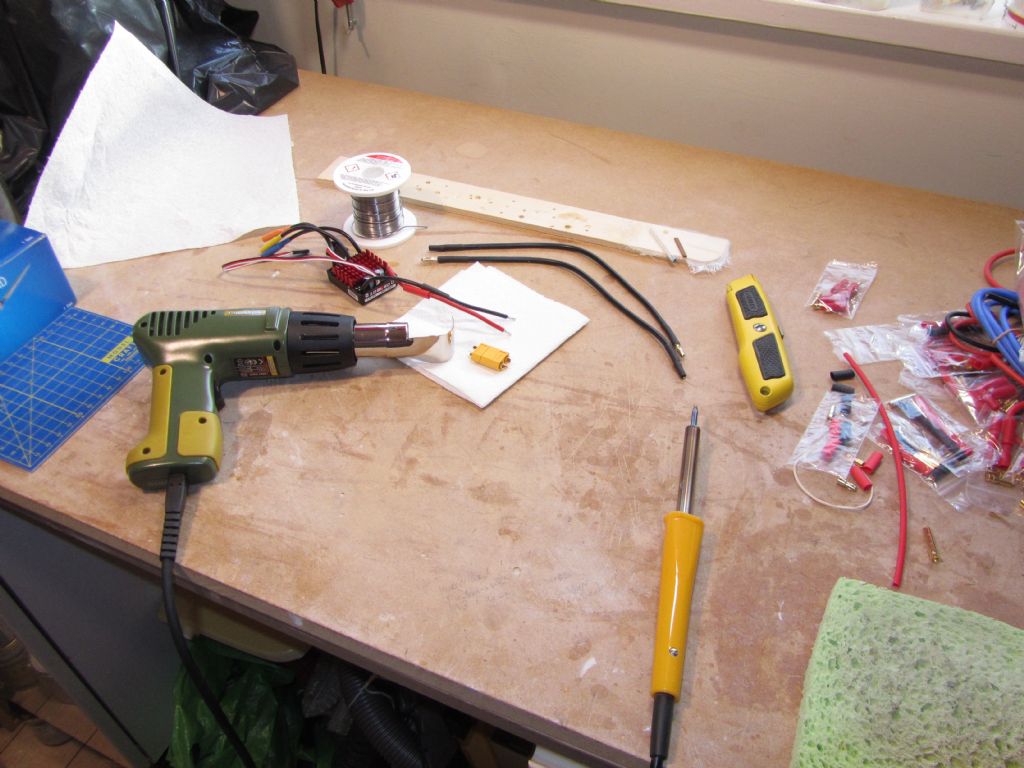

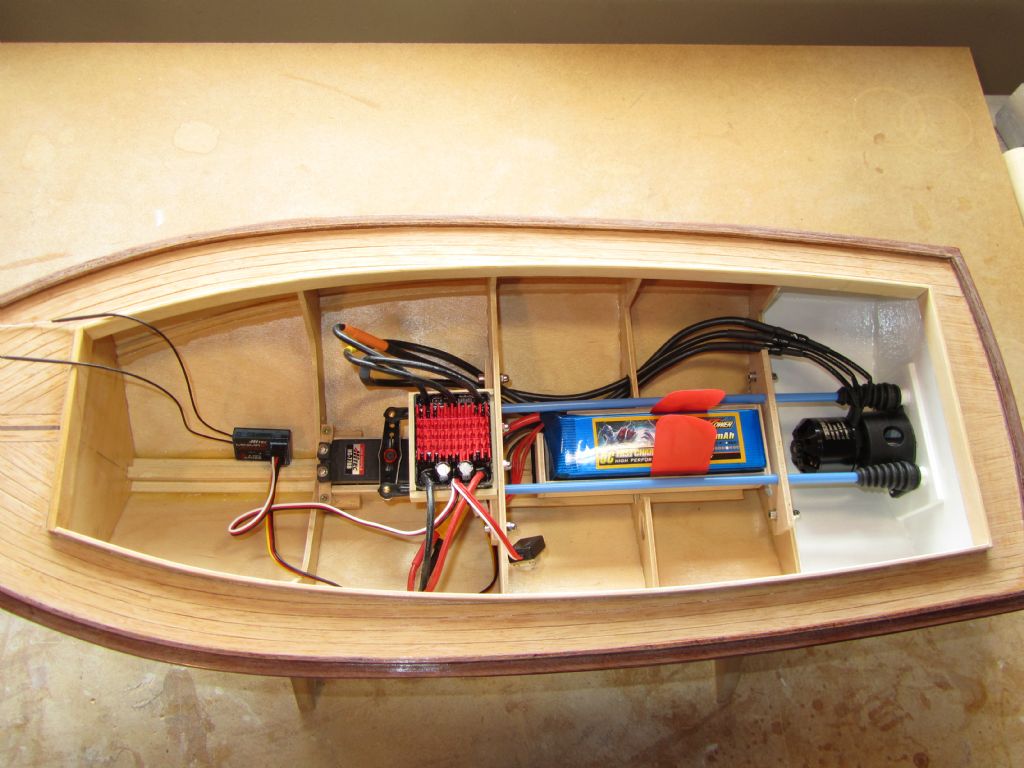

Reinstalling was even fiddler now with the bellows fitted but at least the bolts went in easier this time. Had to refer to photos again to remind me which servo and horn I was using and that was it. Battery box had been made previously so that can go in and then onto the ESC and wiring etc. My first!

Chris

Edited By Chris Fellows on 07/04/2023 20:27:46

Chris Fellows.

Chris Fellows.