The usual cause of tangling with a drum is lack of tension. When it unwinds, tension is needed to keep the line tidy. With good wind, the pressure from the sail "might" do the job quite often. Any other time it is a certainty that the line will hop off the drum and make friends with almost anything.

There are several cures.

Easiest is an elastic line above deck that pulls the line out from below. Has the minor disadvantage that the elastic has to be regarded as an expendable spare part. Since all of the power generated by the sails goes through it and the arm develops quite a considerable twisting force, a really solid mount is advisable. As is ensuring the the arm does have room to swing. ( A club member ran one with a transmitter with not quite the right settings. When it got to the travel limit determined by a frame, it tried to mash through the frame, but managed to mash the splines instead..)

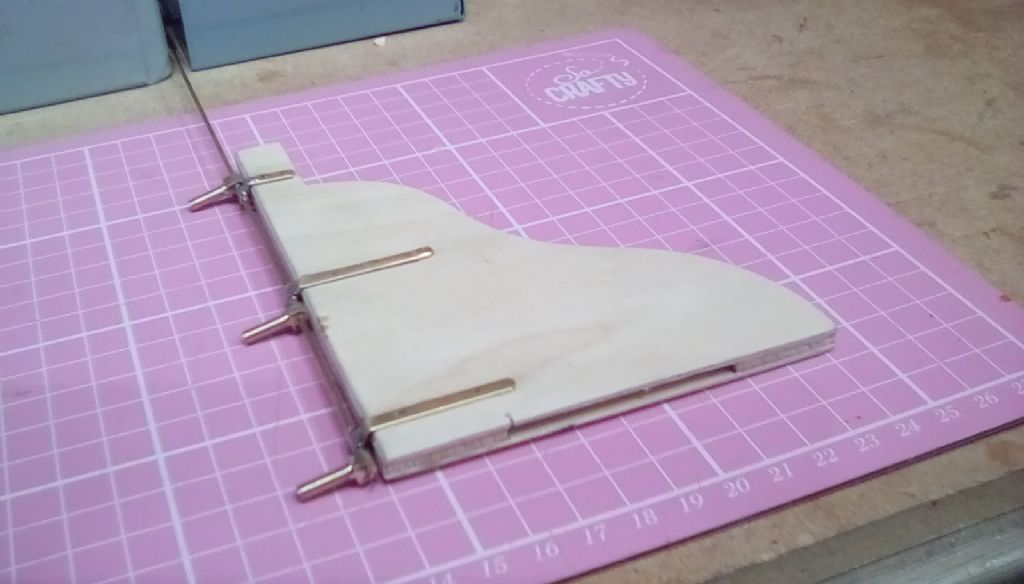

Next is the continuous loop. Most winch drums have two layers. The loop starts with windings on the lower spool, heads off to a turn point, goes over a straight run long enough for the required travel, turns and comes back to the upper spool. As it feeds out of one, the slack is taken up by the other. Zero chance of a tangle. The take-off for the sails happens on the straight run, which can be above or below deck, builders choice. A 6 turn drum winch needs about 17". The shroud that you get with some winches is helpful, but by no means totally foolproof with a single ended setup, but this might depend on the type of line used. Since the pull is linear and always in just one direction, mounting is vastly simplified.

It doesn't matter which system is used, you don't want potentially slack line below deck, while practically nobody can design a machine that can tie knots, mother nature does it for fun. I can vouch for this having had the slack line from an arm tie itself round the slide switch and turn it off when pulling the sails in. That was in a Victoria done as per the instruction book.

for now until I work out the steering servo mount and linkages…

for now until I work out the steering servo mount and linkages…