Chris

Its difficult to provide the whole picture on the forum as there is no easy way I know of to display an Excel spreadsheet. If you would like a copy of the complete sheet with all the data I have collected, send me a PM with your email address and I will forward it to you. However a summary of the Springer data is as follows.

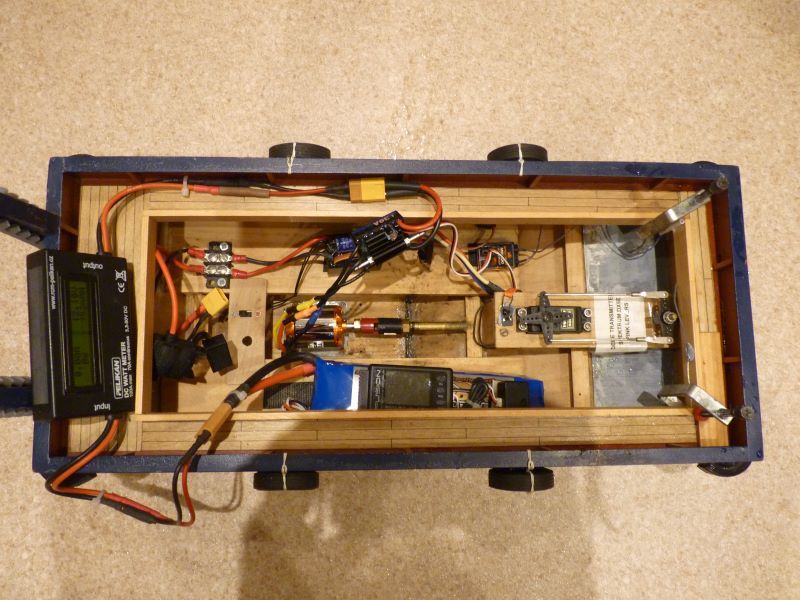

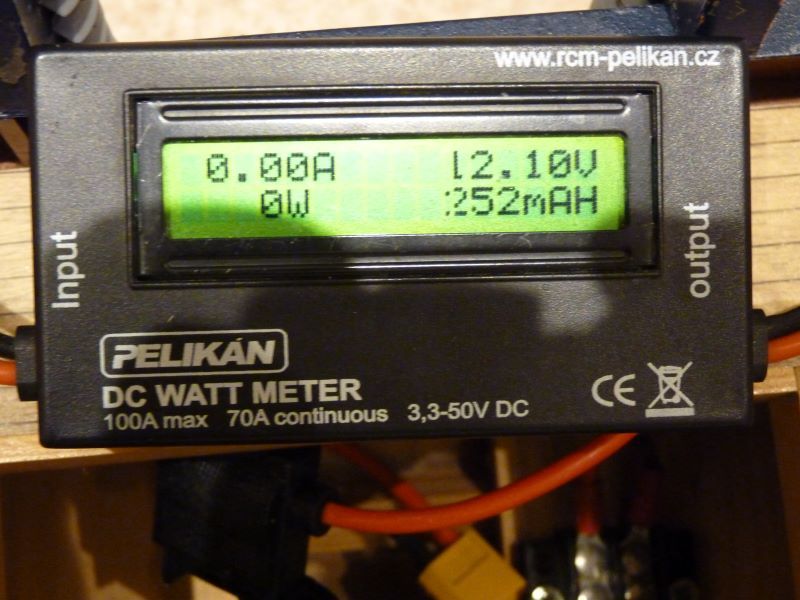

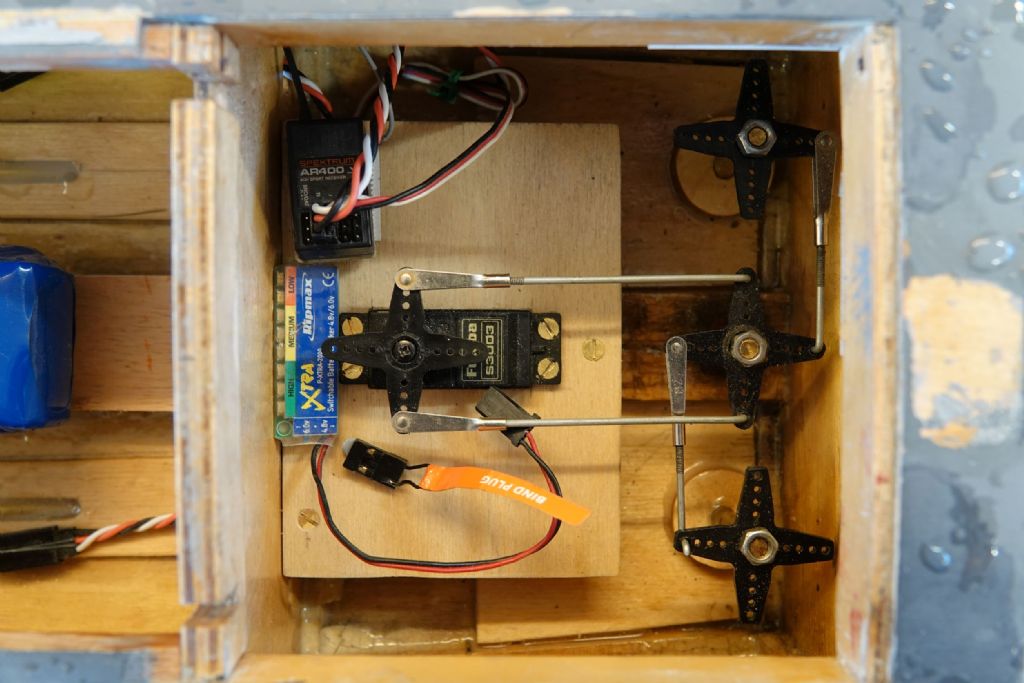

Graupner Speed 500E brushed motor, 7.2V NiMh 40 mm 3 blade prop driven at 3250 rpm (45% of unloaded speed) max load current 4.1 amps, This was the original configuration I used for the model, worked OK but a bit slow and the motor got hot with prolonged running at high power.

Turnigy D2836-8 1100KV brushless motor, 7.2 V NiMh 40 mm 3 blade prop driven at 5900 rpm (70% of unloaded speed) max current 12.2 amps. Not sailed in this configuration

Turnigy D2836-11 750 KV brushless motor 7,2 V NiMh 40 mm 3 blade prop driven at 4685 rpm (82% of unloaded speed) max current 5.5 amps.

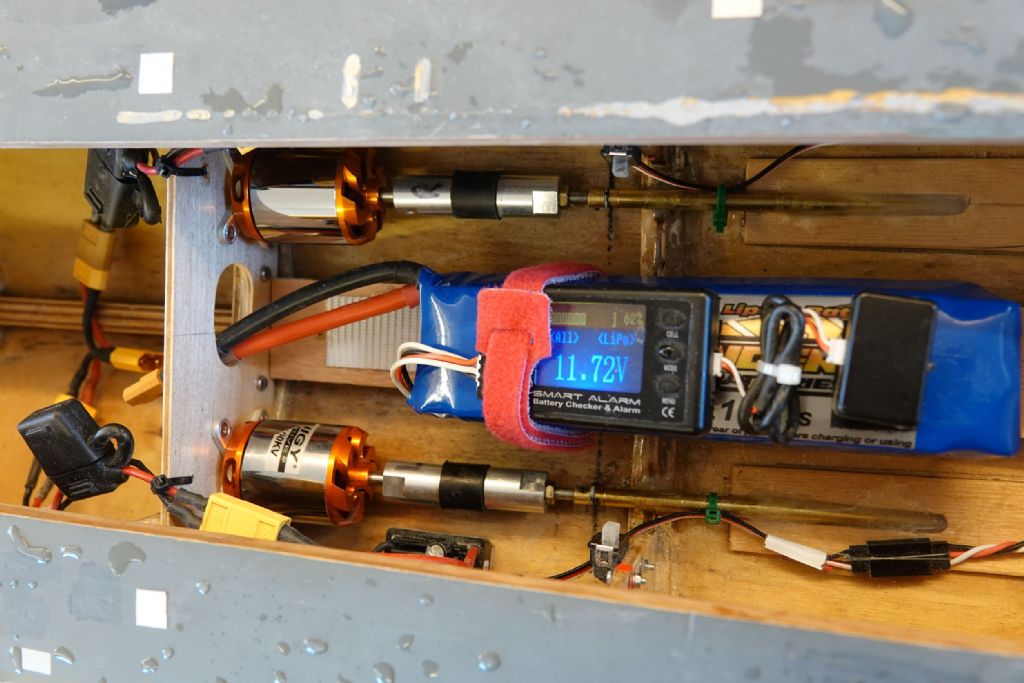

Turnigy D3536-9 910 KV brushless motor 7.2 V NiMh 40 mm 3 blade prop driven at 5710 rpm (80% of unloaded speed) max current 9.9 amps. Standard working configuration now, also used with 11.1 V LiPo occasionally

Turnigy D3536-9 910 KV brushless motor 11.1 V LiPo 30 mm 3 blade prop driven at 10740 rpm (89% of unloaded speed) max current 9.4 amps Not sailed in this configuration

Turnigy D3548-4 1100 KV brushless motor 11.1 V LiPo, 40 mm 3 blade prop driven at 9540 rpm (76% of unloaded speed) max current 35.1 amps Not sailed in this configuration

Turnigy D3548-4 1100 KV brushless motor 11.1 V LiPo, 30 mm 3 bladed prop driven at 11630 rpm (89% pf unloaded speed) max current 17.5 amps Not sailed in this configuration

As a guide I work on the basis that provided the max loaded speed is at least 75% of the unloaded speed there is a good match of motor and propeller. Between 45 and 75% the combination is usable with care, i.e. provided the model does not need to spend long periods at high powers, eg a model narrow boat. Below 45% the motor is running too inefficiently and will quickly overheat if high powers are used.

I have sailed the Springer with a D3548-6 790 KV brushless motor on an 11.1 V LiPo but not measured its performance. However I did produce a rather blurred video of its performance and there is a link here supercharged springer

Gareth