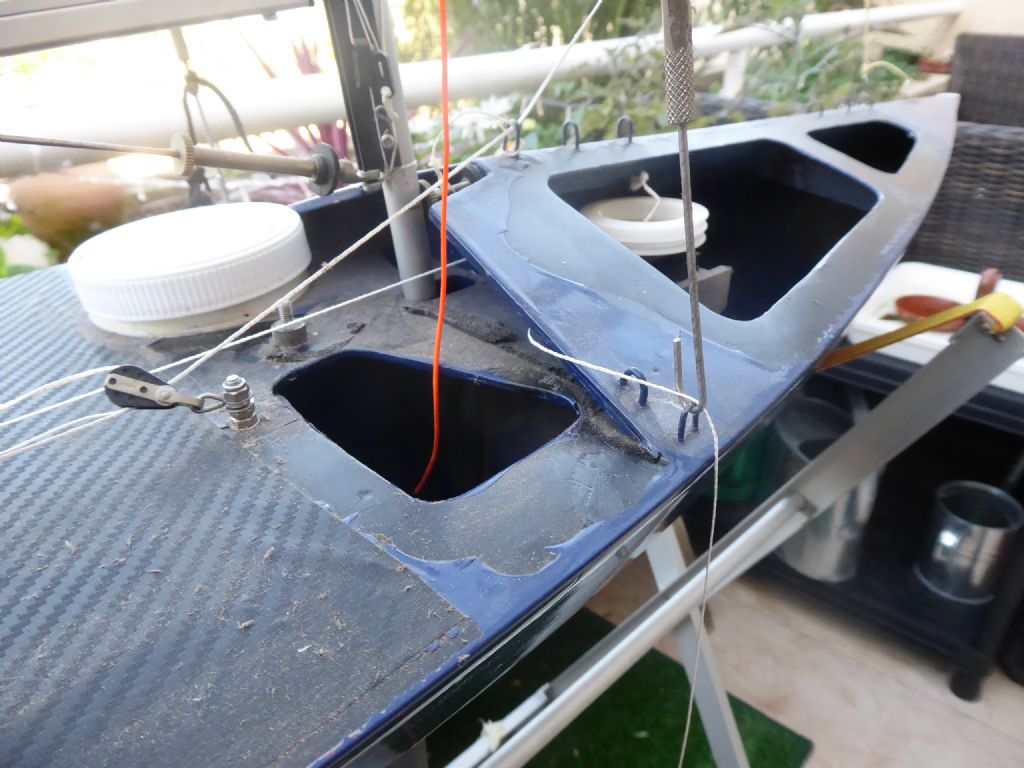

Getting there with the hull. Deck patches are the next job.

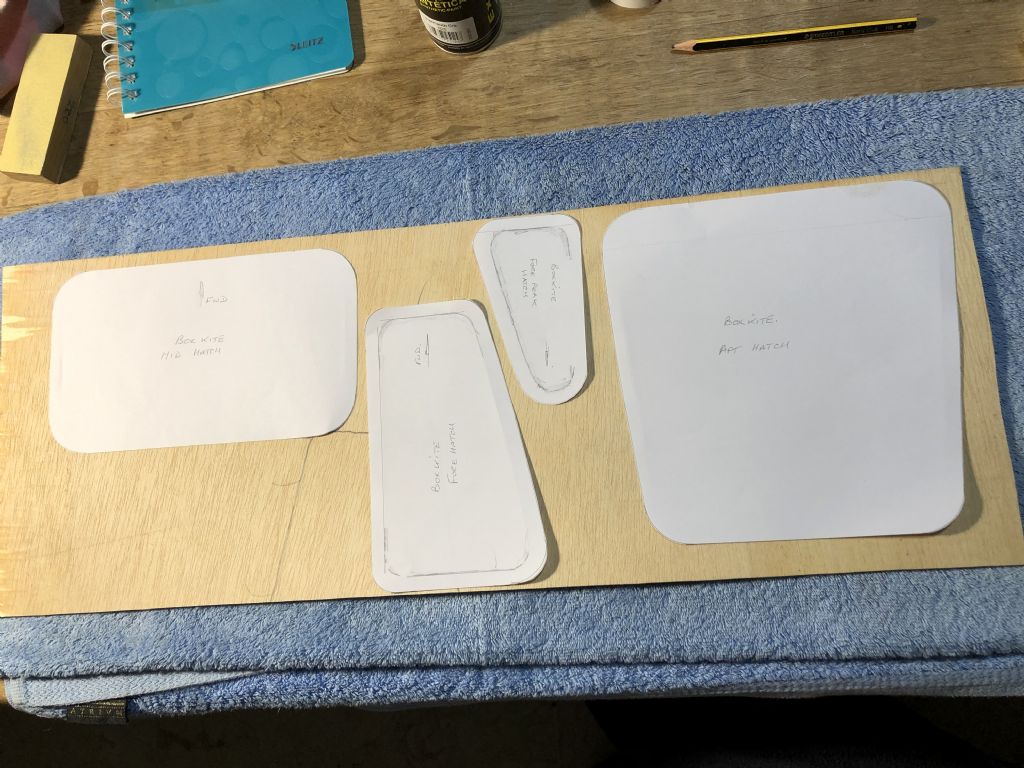

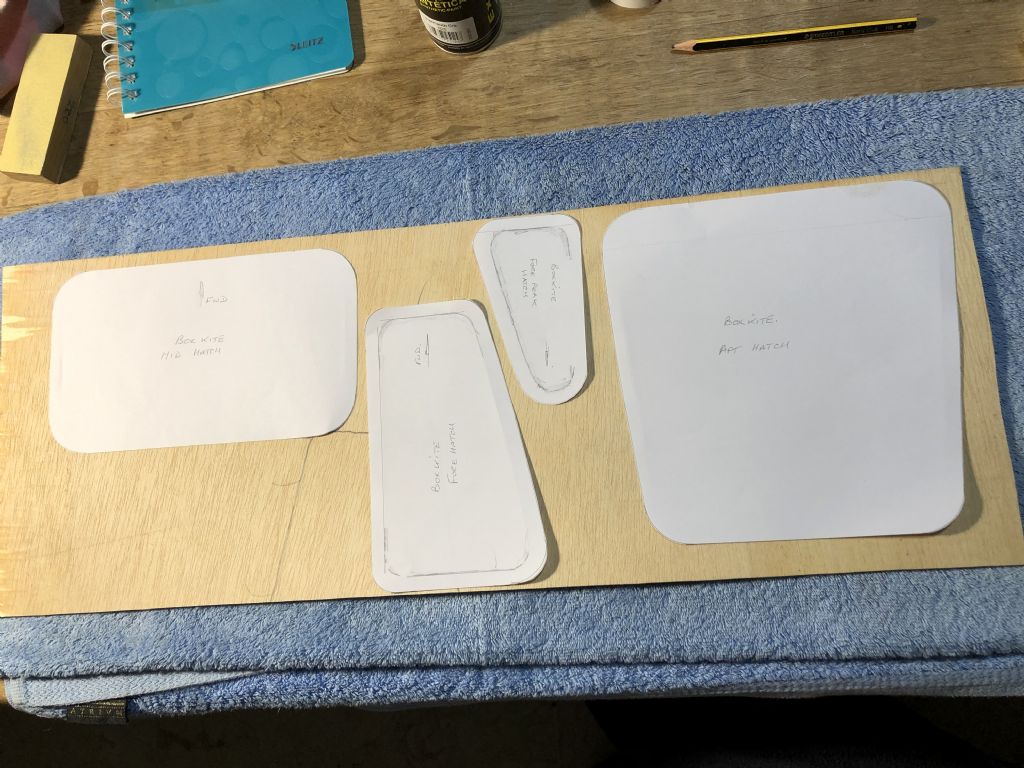

To make the paper templates I marked the edges of the apertures with the side of a pencil lead in the style of church Brass Rubbings. I then added 8mm all around for the patches to overlap. I read somewhere that 6mm was the minimum but that looked a bit skinny and I had 8mm space available to keep them all the same so that decided it. These were then stuck to some ply we use for templates (similar to Lite Ply but a lower quality and the offcuts are generally free) with my favourite method with Pritt Stick.

Here we have the complete set with the forward two doubling up as mirror images.

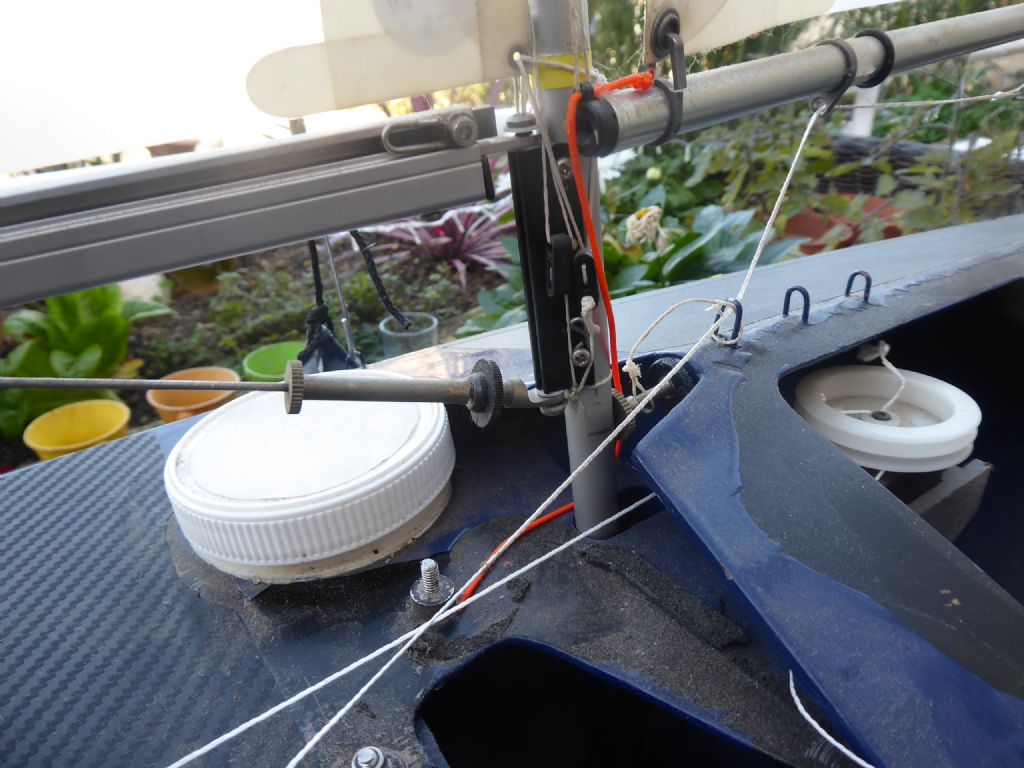

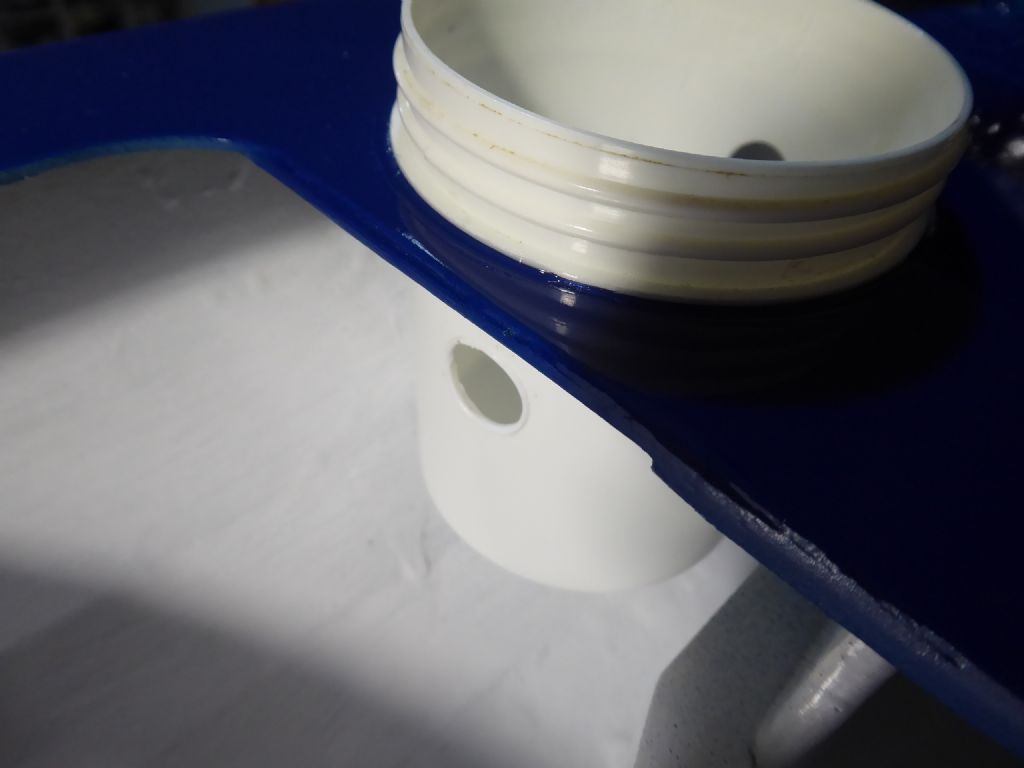

This is the midship patch template as an example. I told a slight fib as I had to make a small scallop to clear the radio pot.

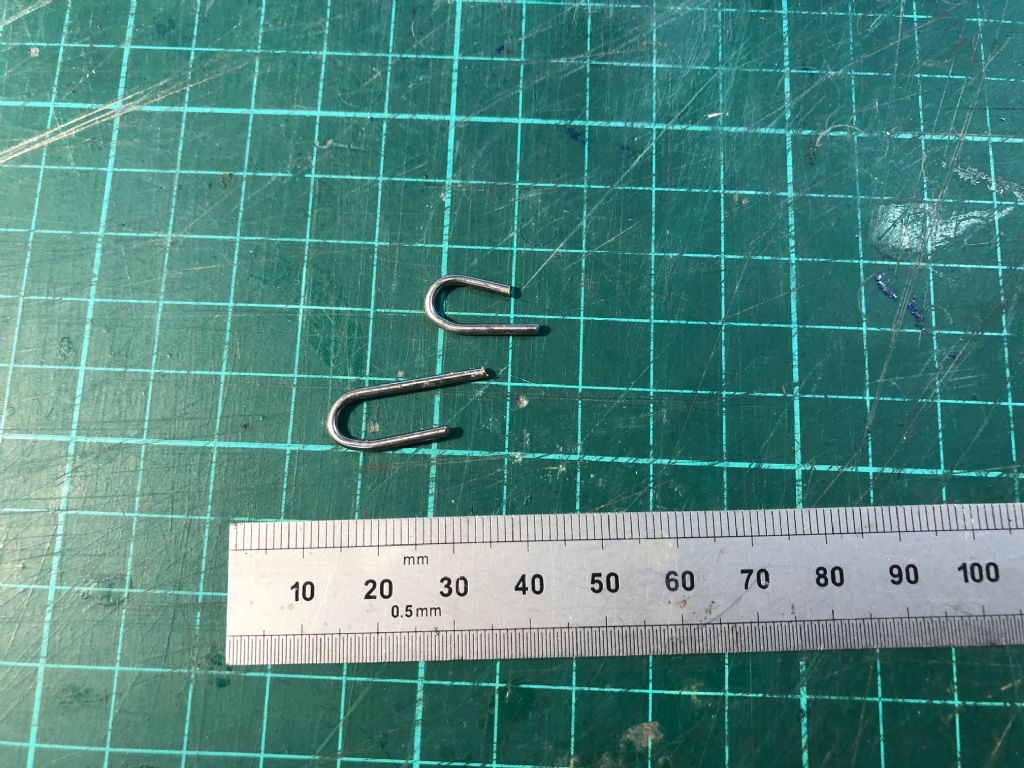

I am a big fan of making templates and jigs and furthermore have learnt the hard way to label them. I still have a small collections of things I have no idea what I made them for.

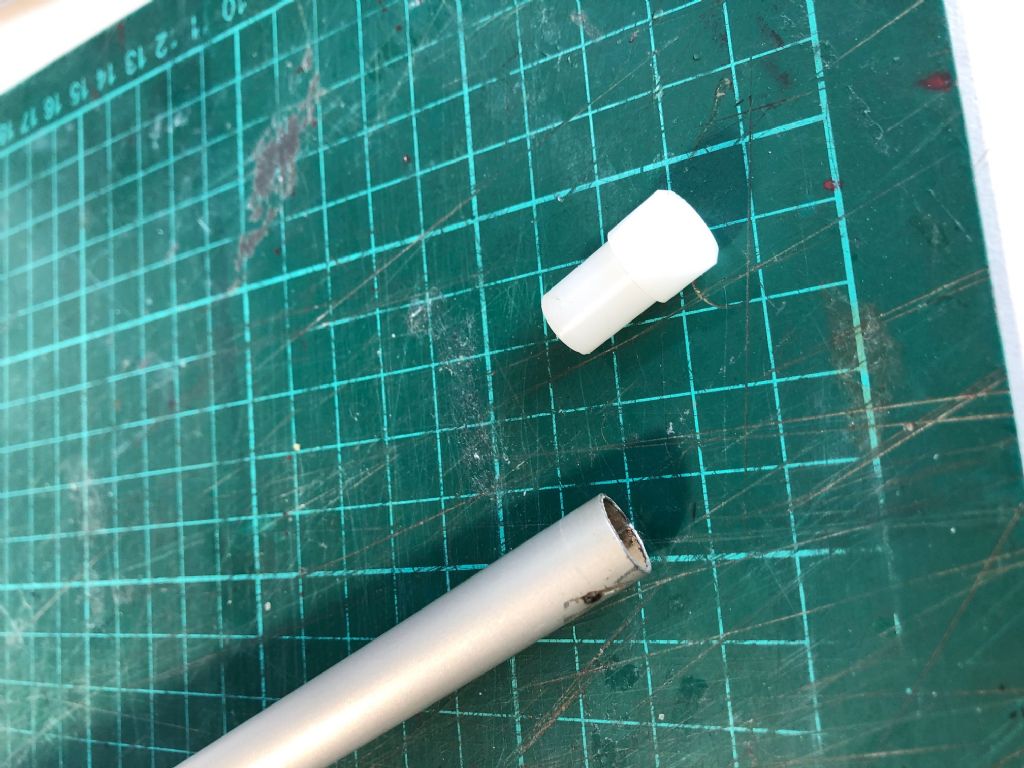

It is then dead easy to cut the patch around the ply using a very sharp scalpel. The patch material is woven, self adhesive and a selection of colours is available from SailsEtc where I got mine.

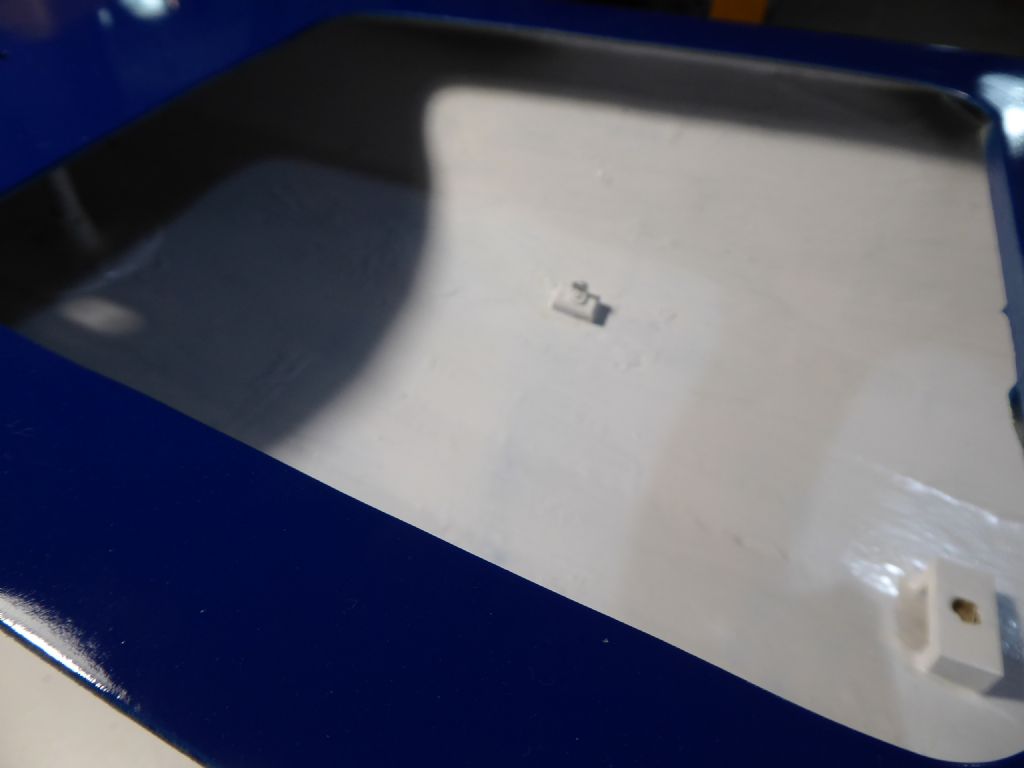

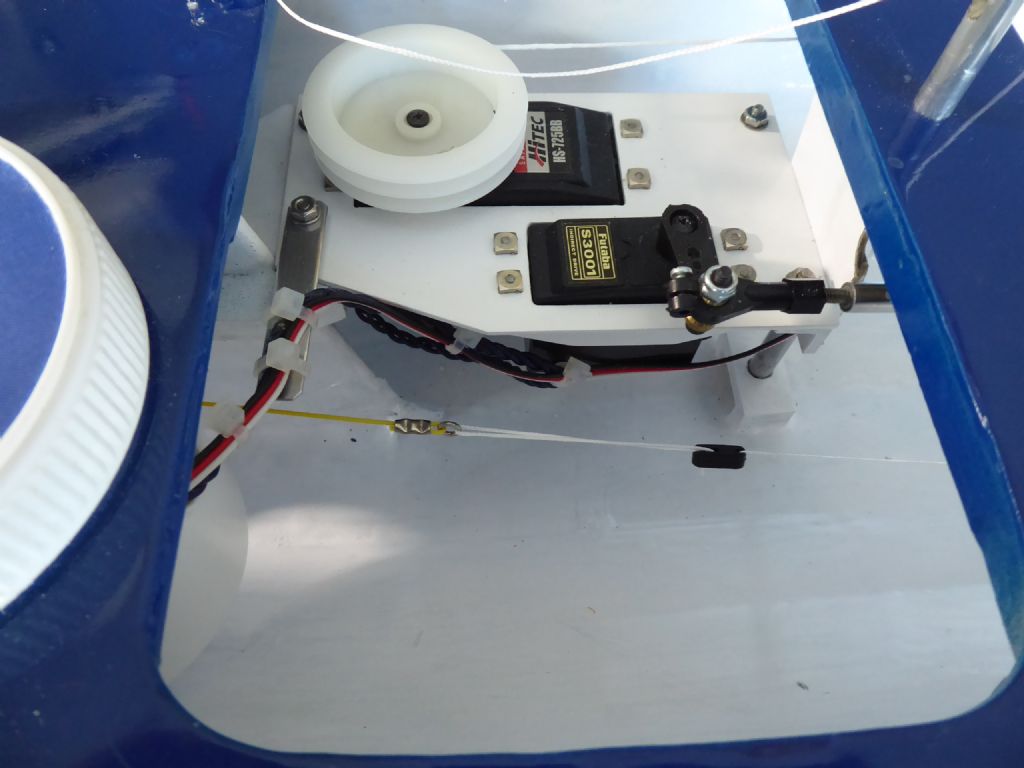

This centre patch is the one that is more likely to need removing periodically as that is where all the gubbins are. For that reason I made a tab to make it easier to start the peel. If you have to scratch away at an edge, the patch pretty soon becomes useless and the deck gets scratched.

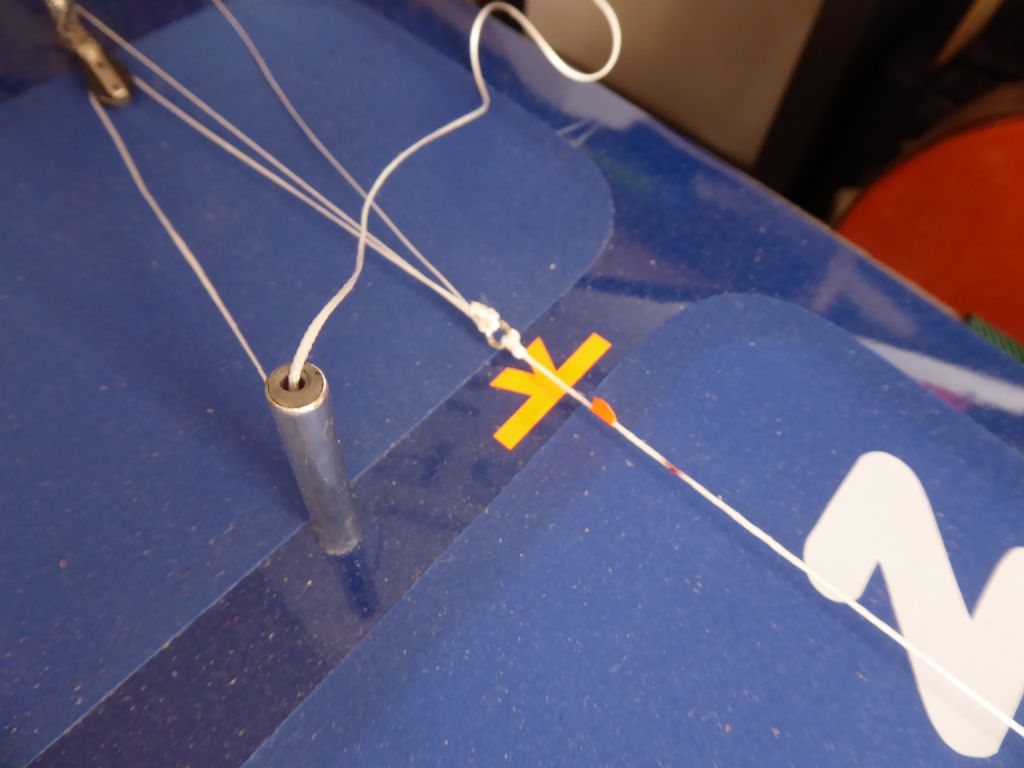

Before painting the final spray coat on the deck I lightly scribed the corners of each patch. This shows up in the top coat and means that the position and orientation of the patches can be found easily.

While the ply templates were out I made some paint screens from some cereal box card. These protected the inside while the deck was being painted.

I can now get on with the rig.

Tim R