There has been a bit of talk on Carl's threads about bow bumpers.

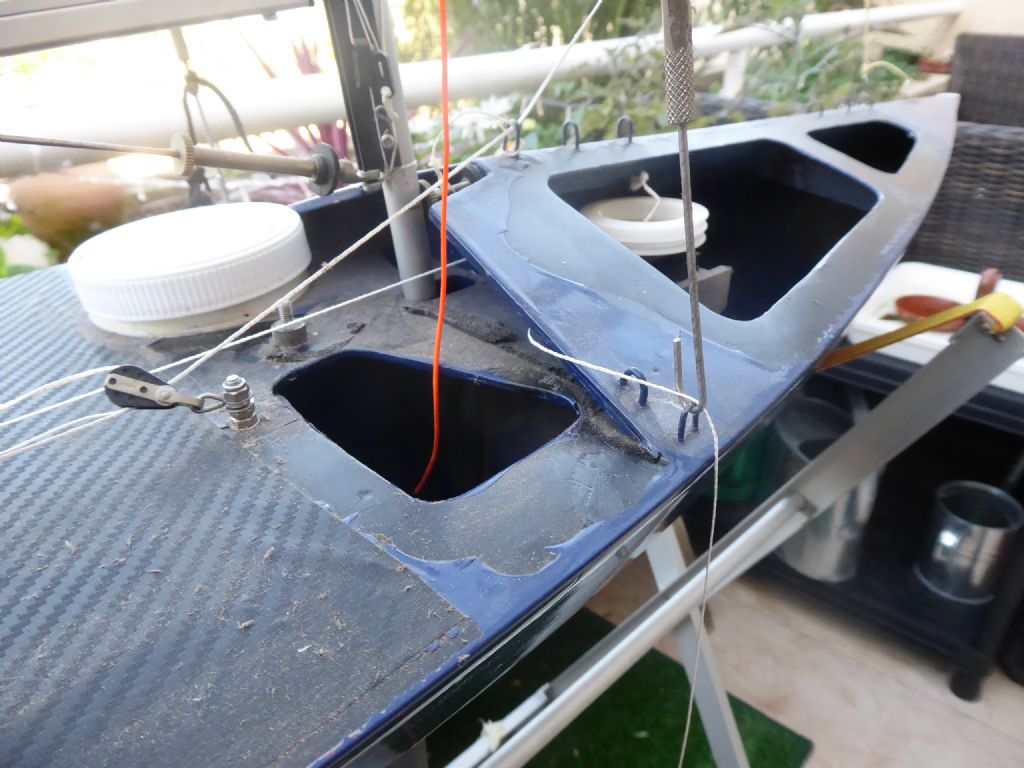

This is a reminder of what the original foam version looked like and it had been used in anger with a permanent dent half-way down. It definitely had to go and this is what I did:

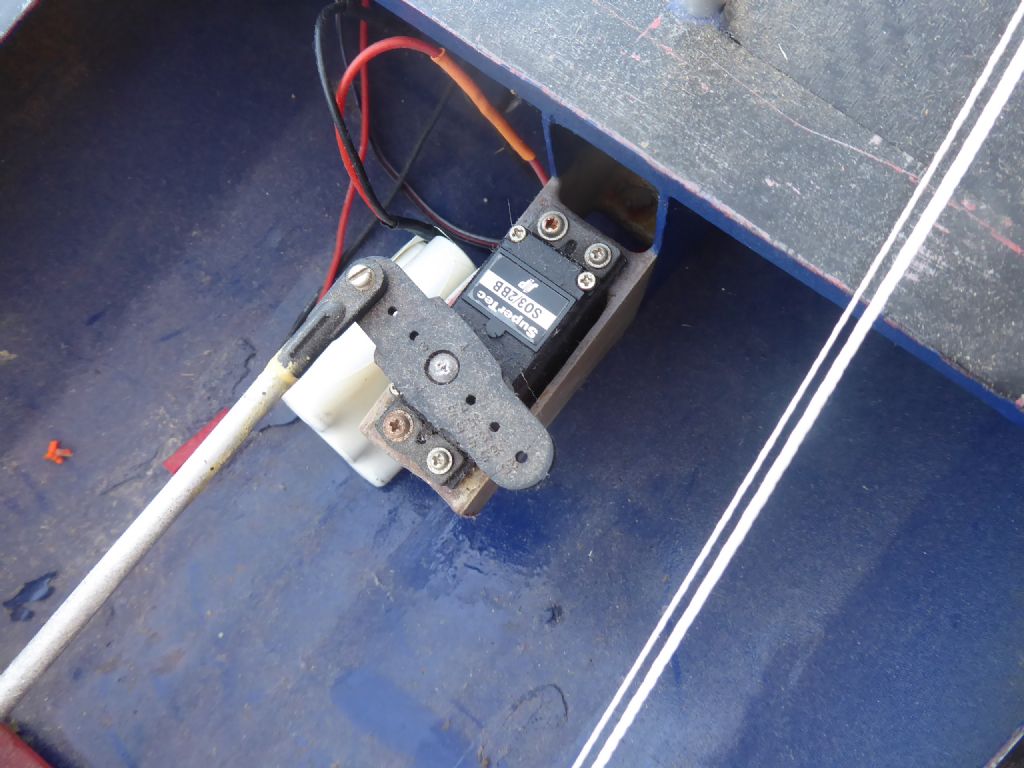

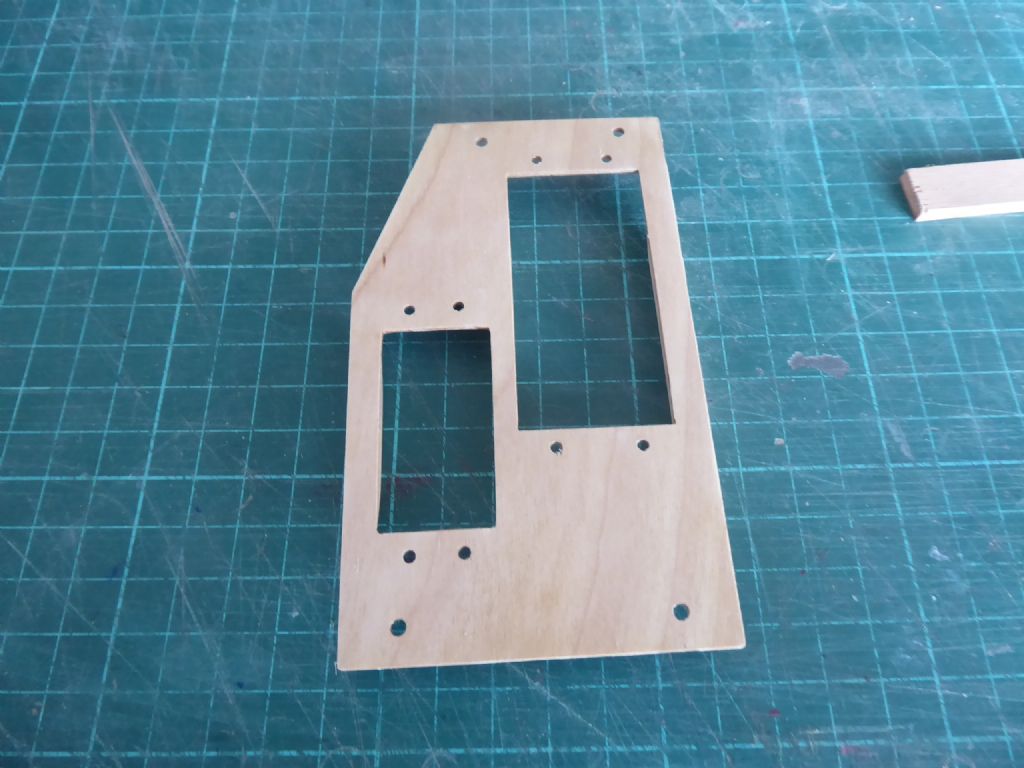

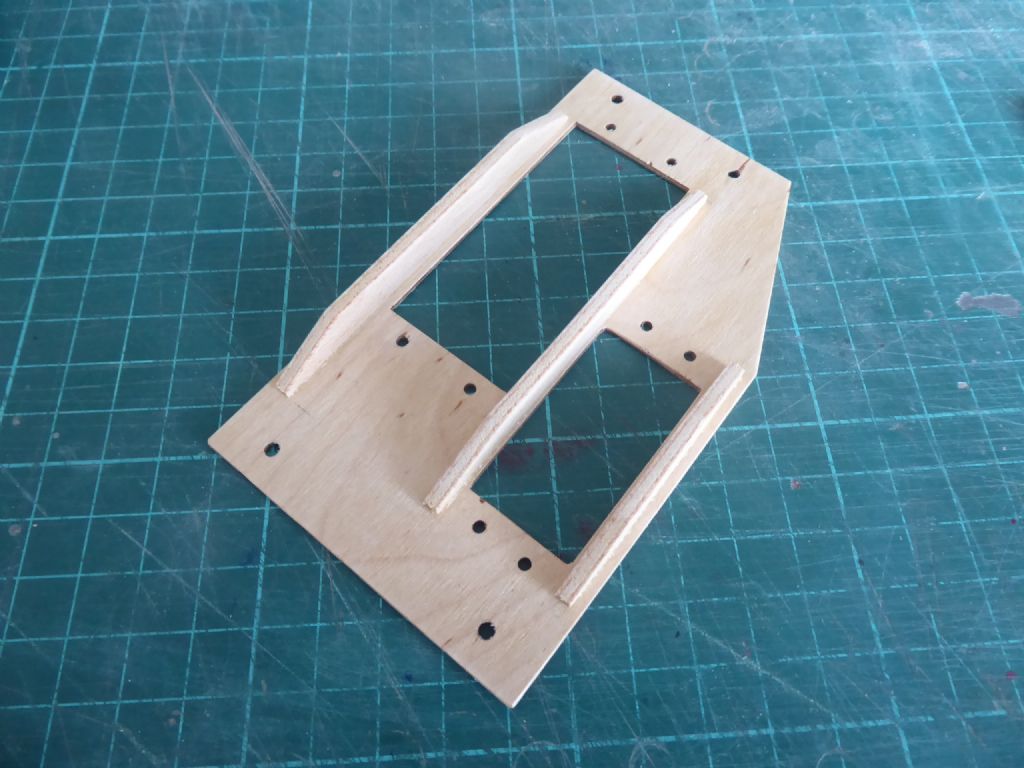

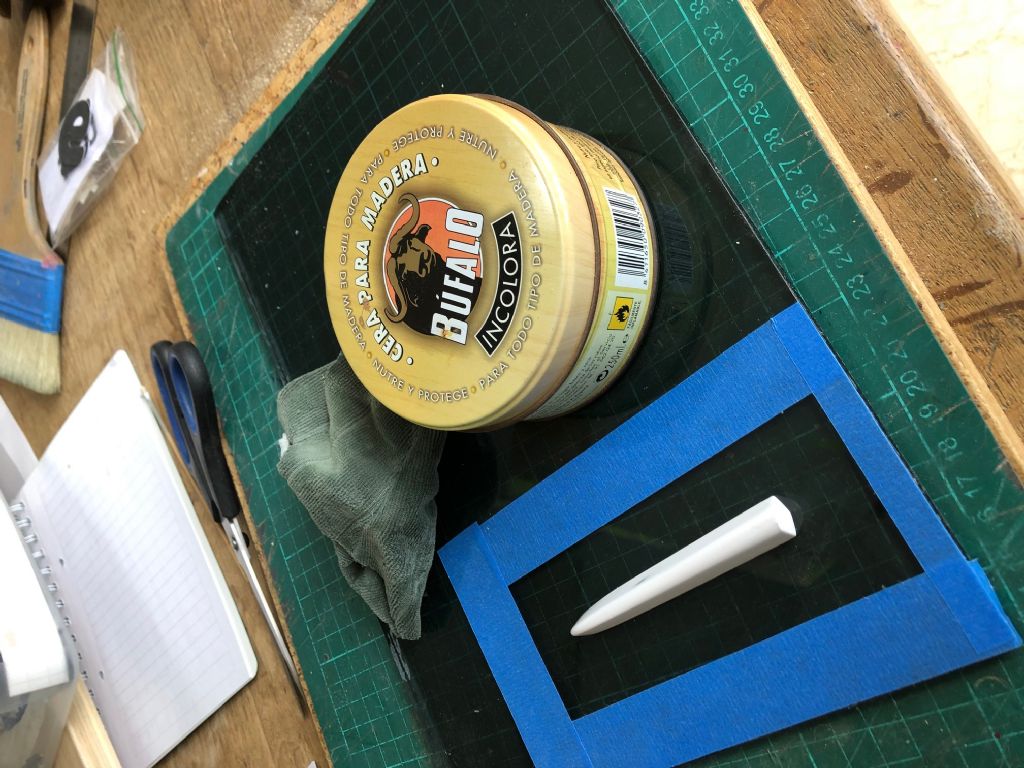

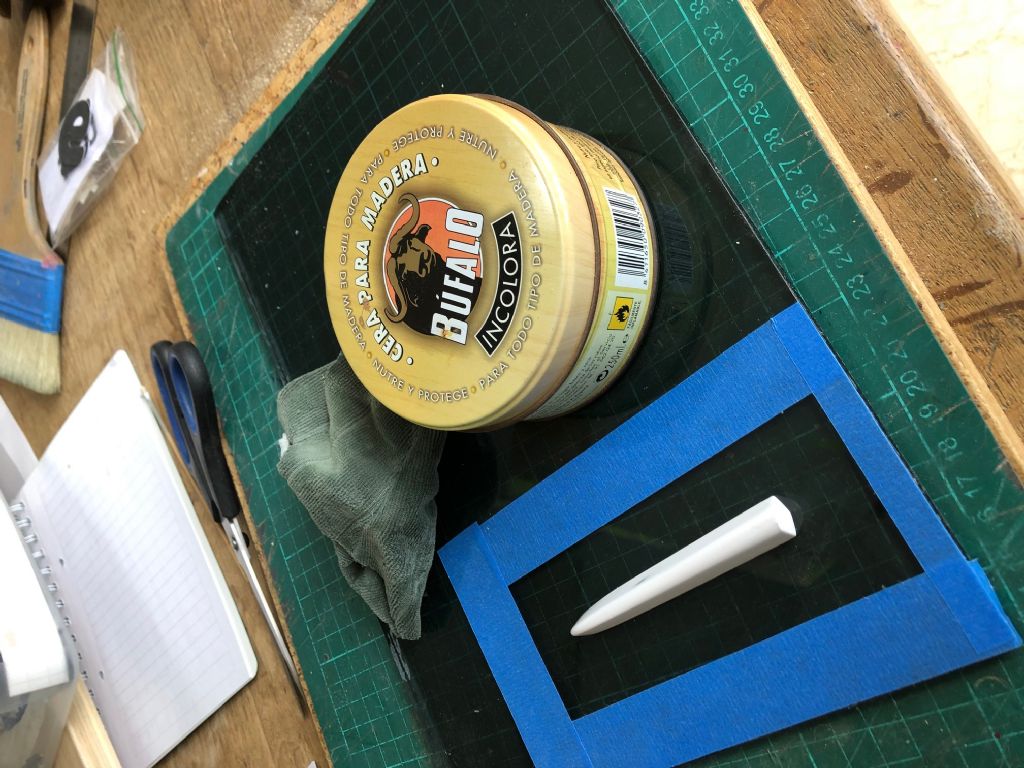

I carved and profiled a piece of medium hard balsa that was stuck temporarily to the bow with double sided tape. After fairing and painting, the pattern was stuck to a piece of glass plate (again with double sided tape) and then given multiple coats of wax.

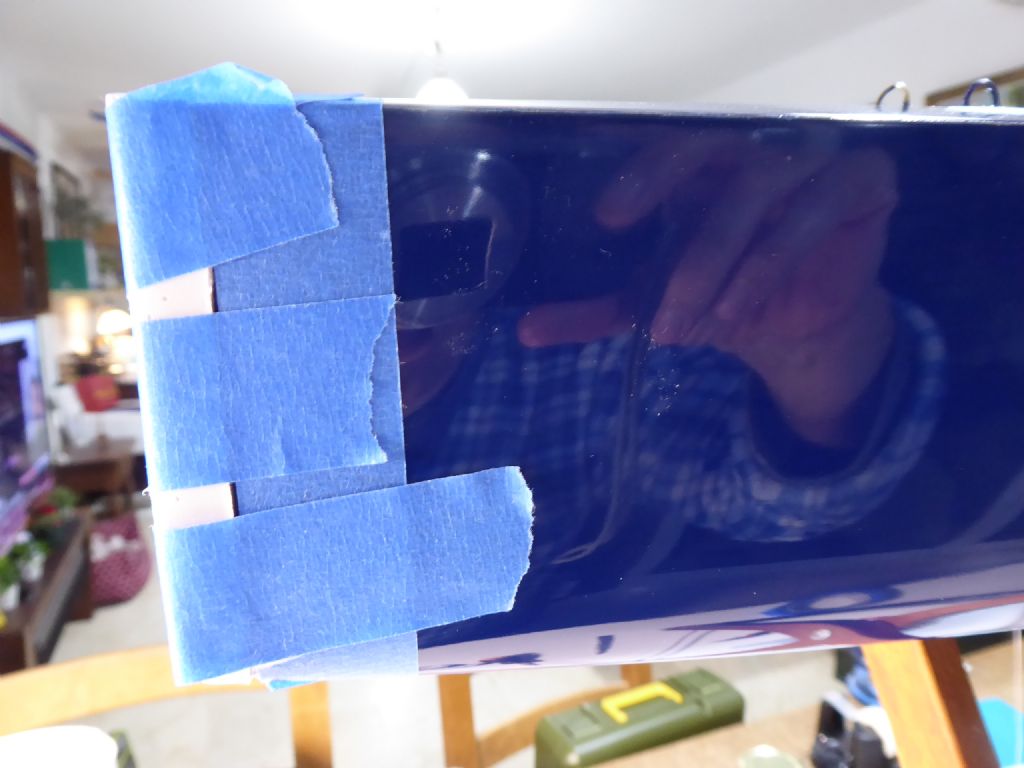

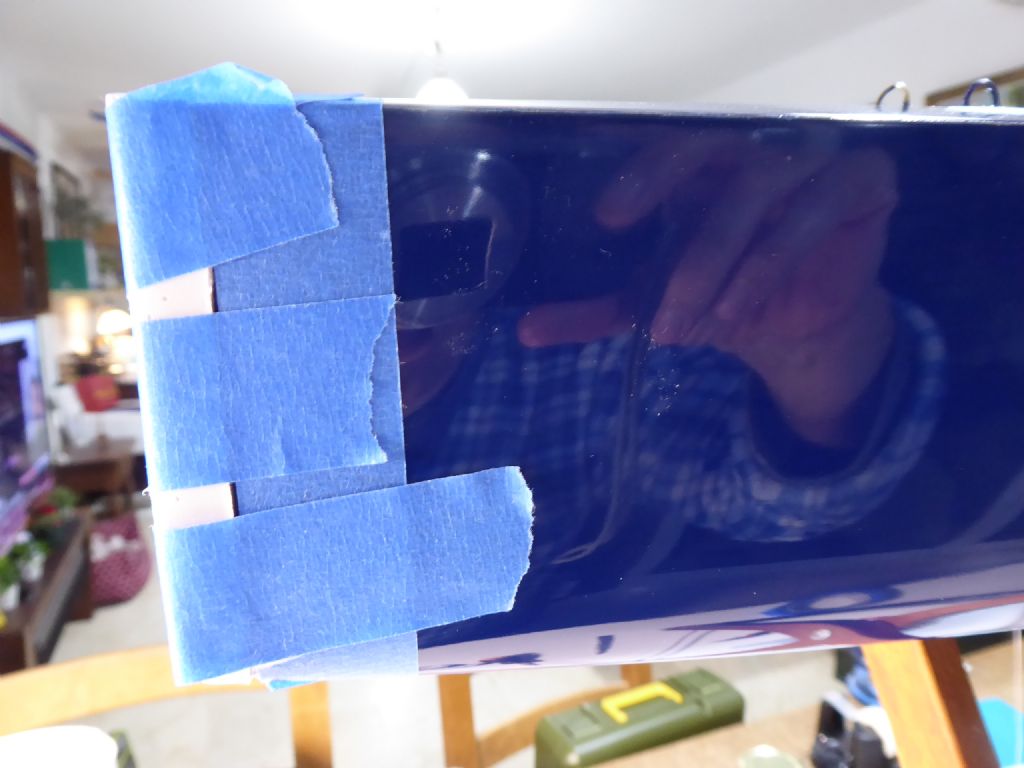

The blue tape creates a trim line for the completed mould and facilitates releasing from the glass.

A fairly stiff mix of epoxy and micro-ballons was pasted over the pattern and glass and allowed to gel. The rest of the mould was then made up with odd bits of glass cloth and rovings inside a balsa frame. When the mould was finished and thoroughly cured, out came the pattern. Not in one piece however which was a bit too much to hope for. The mould surface though was good.

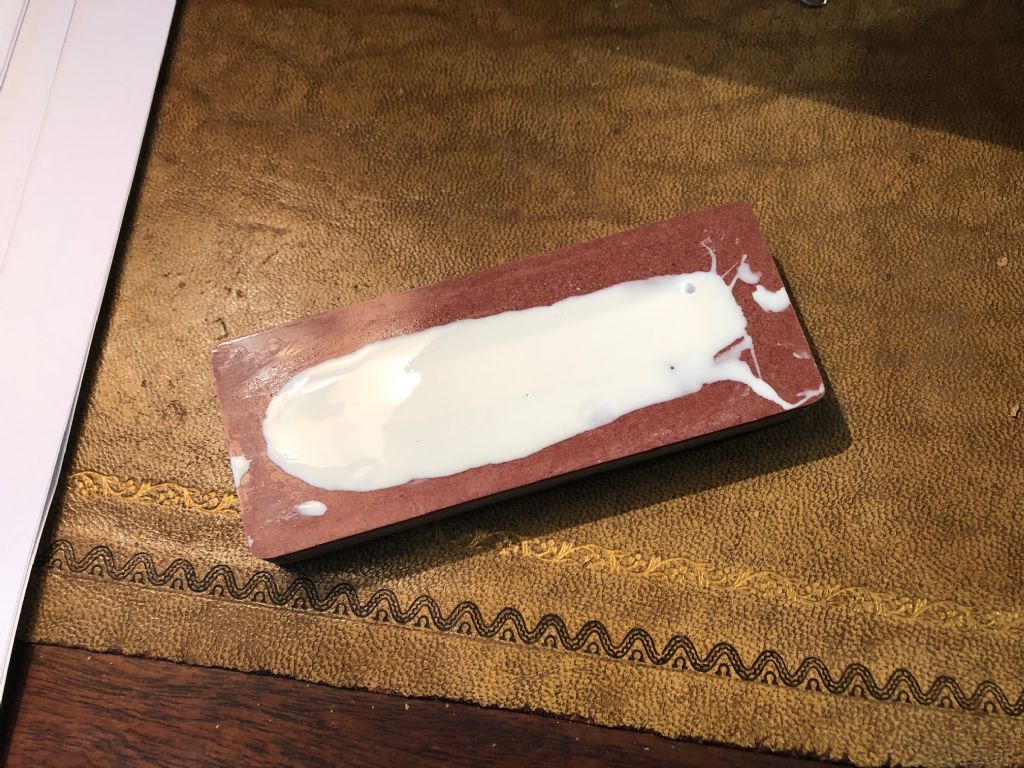

The mould was then filled with liquid silicone catalysed at 5%. Although I mixed carefully and gently I did manage to introduce some air and you can see some bubbles rising in the liquid mix. The lesson for next time is that there is no rush as the silicone is very slow curing. There were a few bubbles in the final moulding and I should have let the mix stand for probably 1/2 hour before pouring.

This time though, using a very light smear of Vaseline in the mould, the bumper release very easily. Before doing that however, the top (mating) surface was carefully trimmed with a brand new traditional razor blade.

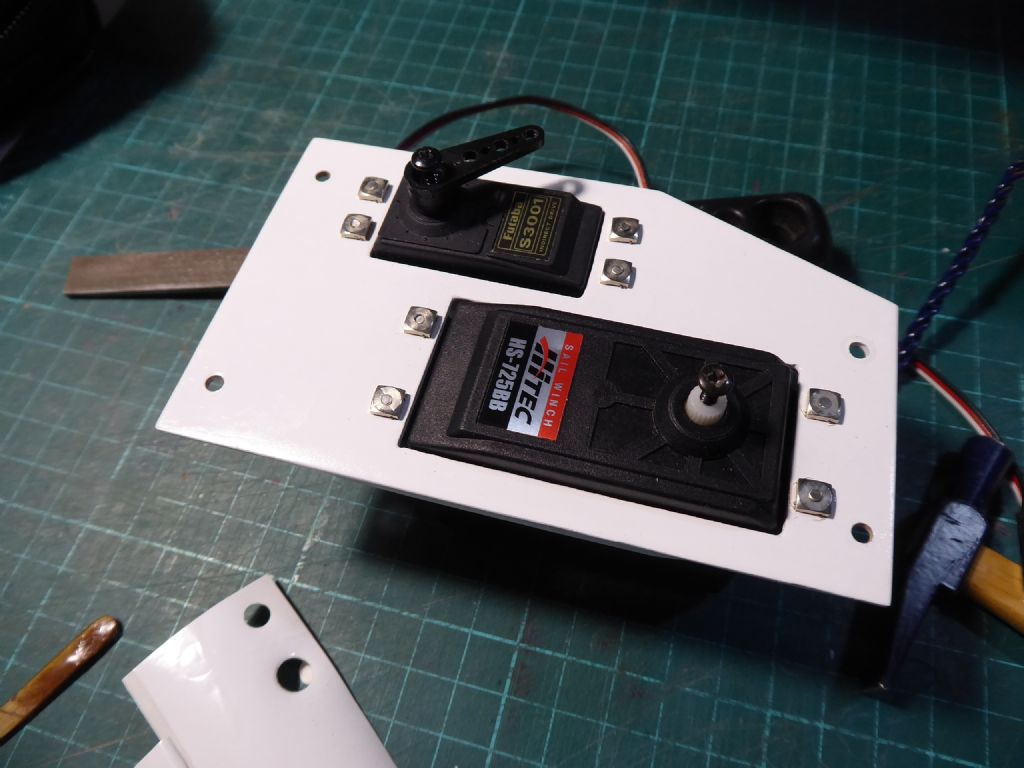

Here you have a better view of the mould construction.

For the technically minded the Shore hardness for this silicone was stated at 25. On the IOM the hardness is not stated but usually is limited at 70 otherwise it starts to take on battering ram characteristics and you quickly lose popularity with your racing mates. 25 is quite nicely squidgy.

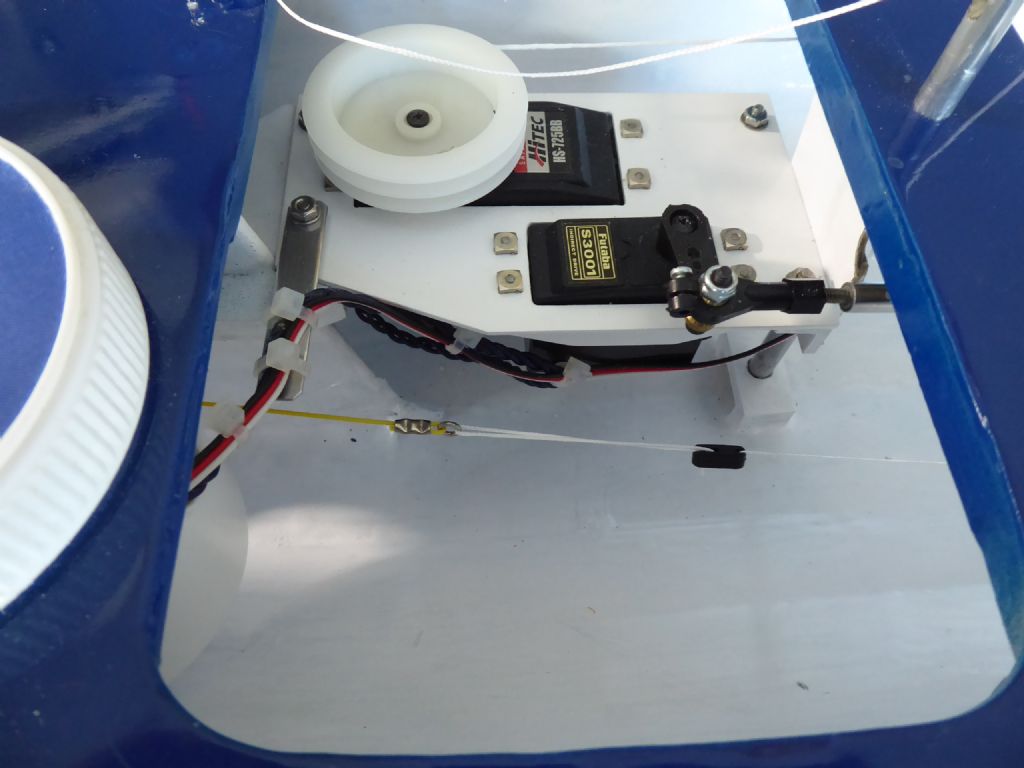

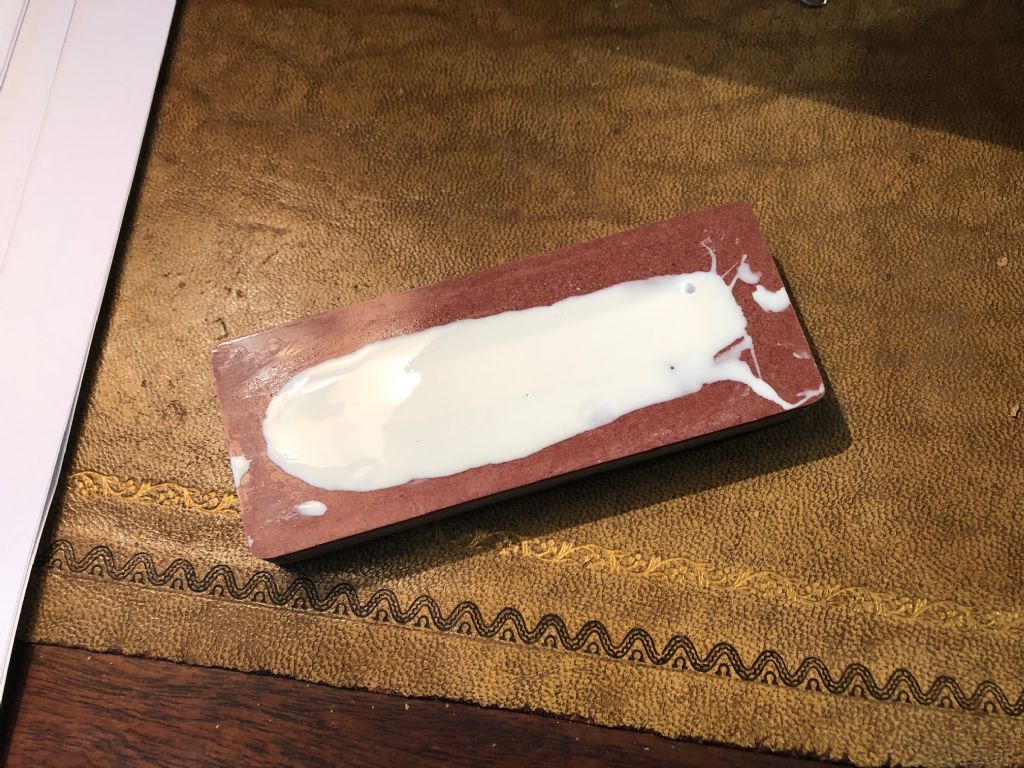

The bow area was then masked off to keep the bonding silicone off the paint.

And the bumper taped in places while the moisture curing bathroom type white silicone did its stuff. The bow bumper now matches the hull profile accurately and it now looks the part.

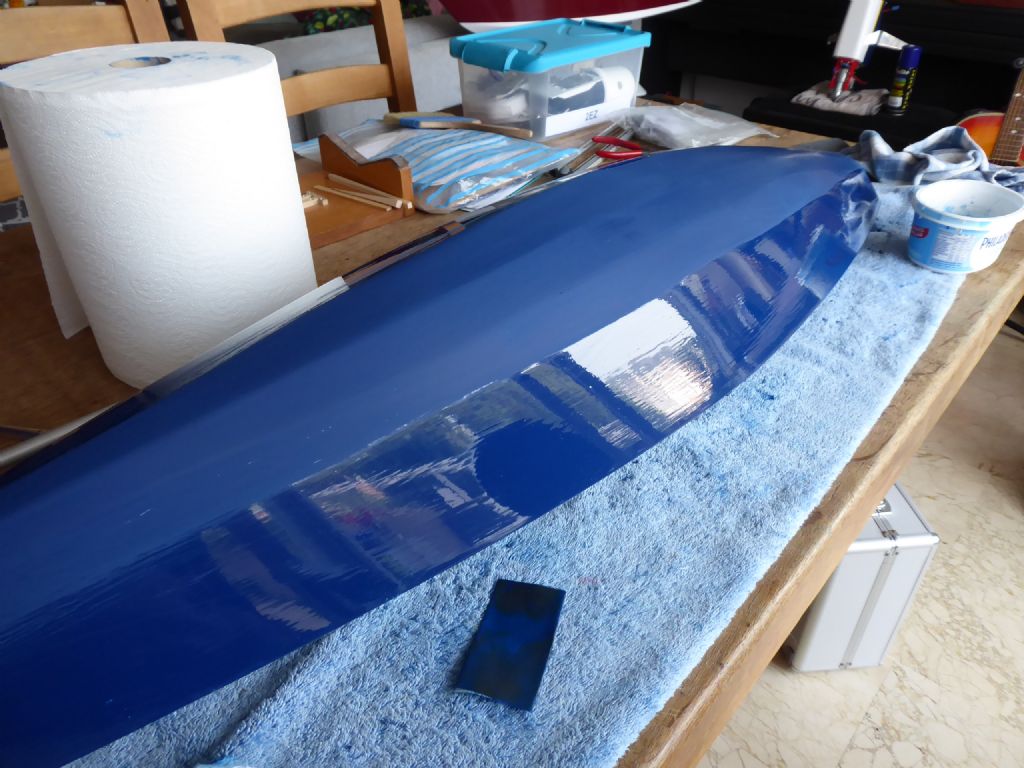

Just to note that the hull has now had its primary polish and the deep gloss is starting to develop.

Tim R