Hi all

During 2019 I unfortunately found myself at the hospital after a motorcycle accident, during my recovery time I got bored of sitting around watching daytime tv and movies.

This time got me thinking back to the ‘good ol days’ when I was younger spending weeks at my Nan and grandads. In particular those warm sunny days in the summer spending time with my gramp in his summer house and garage building model boats. My gramp used to be a toolmaker back in the day so over the years passed on a fair bit of his practical skills and knowledge to me. With this in mind I thought to myself ‘why don’t I have a go at building a boat’.

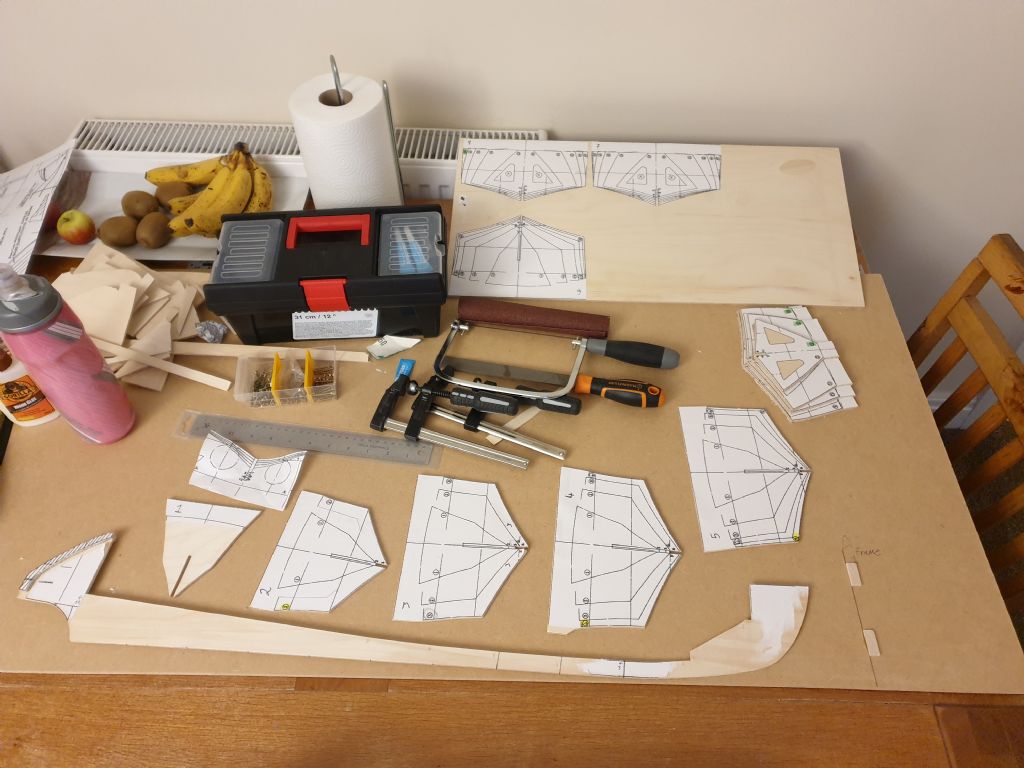

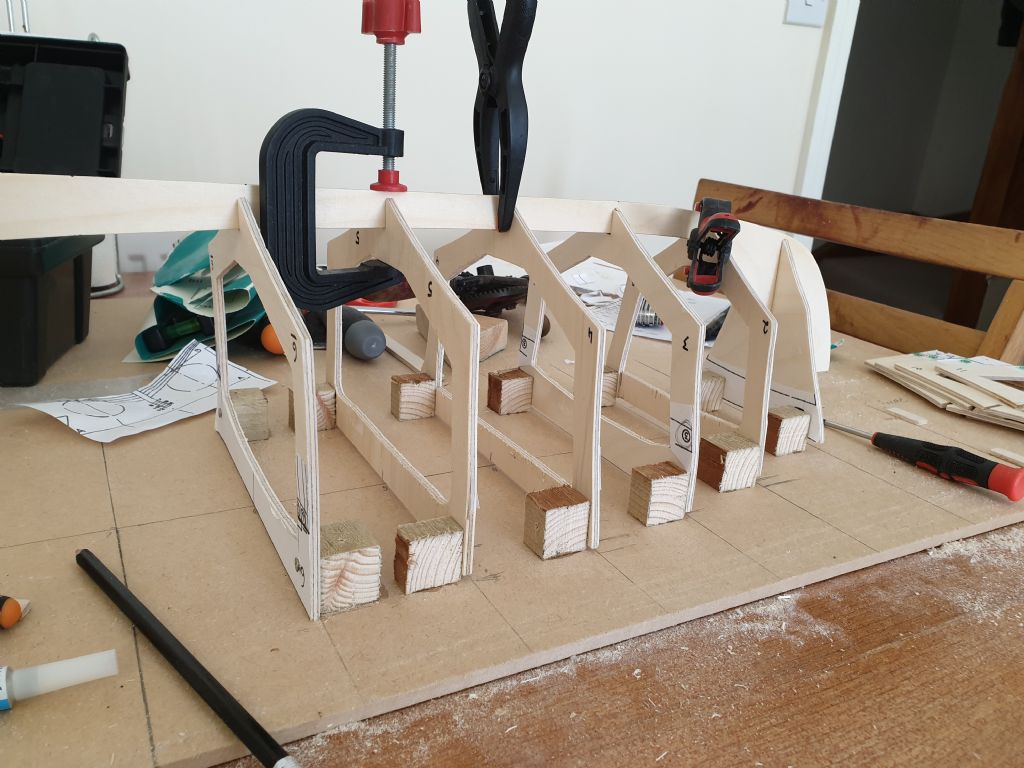

And so the hunt began, the first choice to make was do I go for a kit or do I go down the route of scratch building from a plan. After weeks trawling the internet all I had accomplished by way of a decision was knowing that I wanted something slightly unusual. Then I came across a plan which seemed to stand out, Nouveau. I believe it was originally designed by Peter Massey and featured as a free plan in Marine Modelling back in 2002. The model itself is a high speed commuter launch with sleek flowing lines and a canoe style stern. Its shape alone caught my attention, and after a bit of online digging I couldn’t find a lot of information about this model having been built many times. And so that was that, my decision had been made and I was going to go for it. The plans were purchased from Cornwall Model Boats and after a few days studying the plans and build article the build was to begin.

All this was a few years ago now and as life does it took a few twists so from time to time the build got put on hold, but I’m almost approaching a stage now where she is close to getting ready for her first bath test (hopefully later this year with some more progress) and I thought now would be about the right time to document and share the process (including some of the mistakes) of the journey.

I hope the story so far and everything that follows is of an interesting read, and please do go easy on some of my embarrassing mistakes as I go through the build process as this was my first solo scratch build. Overall though I’ve enjoyed the whole thing and even though this model is not yet fully finished I do have another set of plans sat waiting for me to begin the next one…… my fiancée will be overjoyed when I tell her I need to put up another shelf for another boat!😂