I use Z-Poxy all the time Colin, but just saw the Devcon whilst searching last night, and as it's 4.25 oz in each tube as opposed to 4oz in z-poxy for virtually the same price, I would try it again.

see what its like on the shafts and rudder tubes when it comes………..

which brings me to Rudders, part 3 lol.

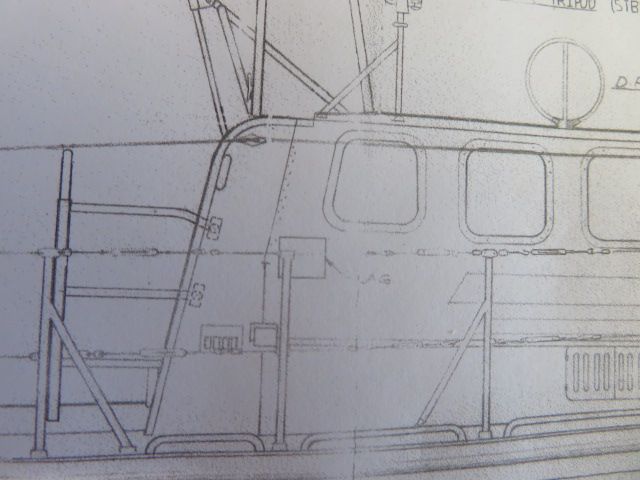

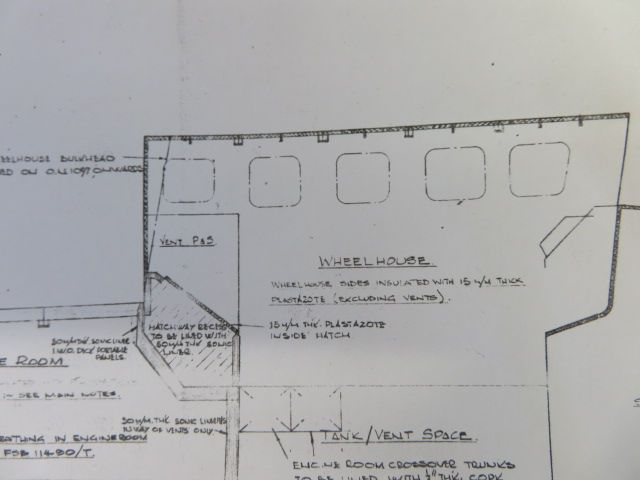

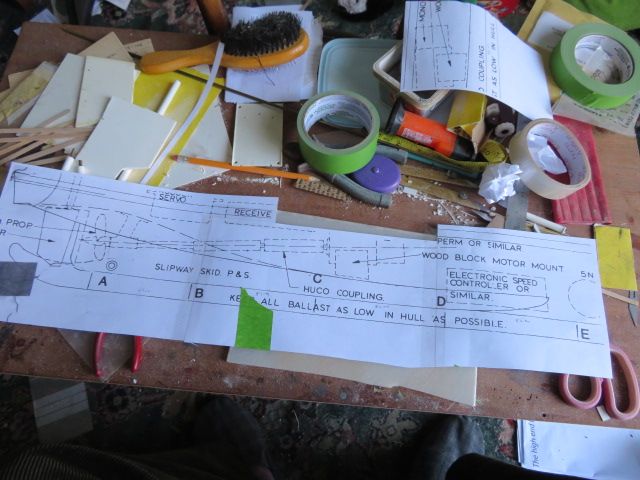

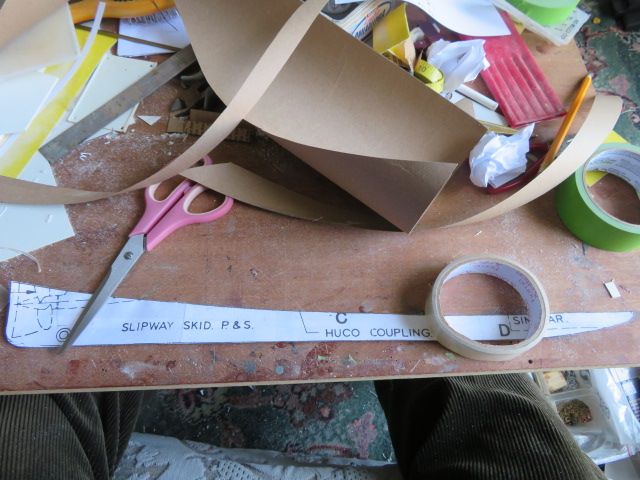

Part 3 of my rudder construction for the Tyne.

I like to make my models as maintenance free as possible.

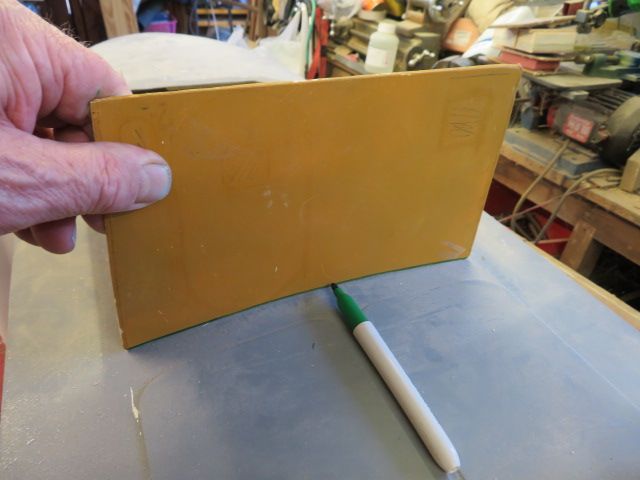

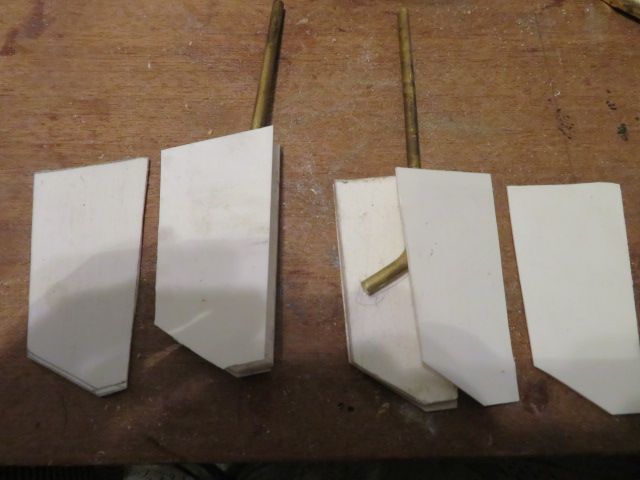

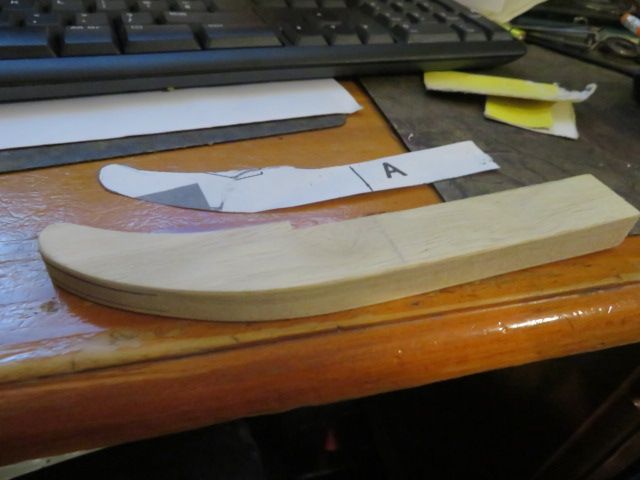

and so, after sanding and trimming the rudders to shape and cleaning them up. I thought I would use my normal method and take some thick walled plastic tubing from plastikard, Matlock for the rudder tubes.

tough, strong and perfect for threading some brass rod through………no reaction between plastic and brass, self lubricating and normally the brass would just fit, with very fine tolerances………..

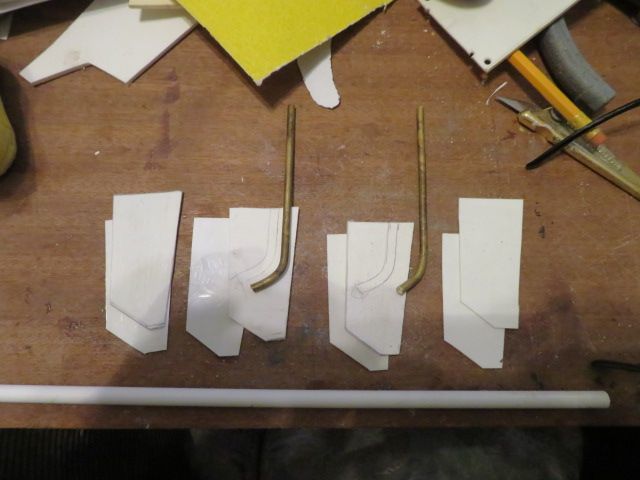

ahh, there came the problem. I had run out of my old internal diameter plastic tube for the brass rod of the rudder shaft………….and the plastic tube I had was of a bigger diameter.

not to worry, I found some brass tube with internal diameter perfect for rudder shaft to fit in, but just too large outside diameter for the brass to fit into the plastic tube.

found a drill bit the same dia. as he brass tube outside, found my larger mandrel and reamed out about 10mm of the plastic tube to take some small lengths of the brass tube to act as bearings.

took the bits and pieces to the workshop, and using my small engineers vice as a bearing press, inserted the "bearings" into the plastic tubes…voila' Two bearing tubes to take the rudder shafts!……..scratch building brings out all sorts of creative thoughts.

Edited By neil howard-pritchard on 26/05/2020 22:57:45

Edited By neil howard-pritchard on 26/05/2020 22:58:11