As Ray mentioned, gluing in thin triangular pieces is probably the only way to get rid of gaps between the deck and superstructure due to twist in the later. I had quite a good fit until I fitted the roof planks which as the glue dried introduced a bit of twist which resulted in a gap at the front, righthand side of around 1.5mm.

As Ray mentioned, gluing in thin triangular pieces is probably the only way to get rid of gaps between the deck and superstructure due to twist in the later. I had quite a good fit until I fitted the roof planks which as the glue dried introduced a bit of twist which resulted in a gap at the front, righthand side of around 1.5mm.

I tried some judicious sanding along the sides but that didn't make much difference.

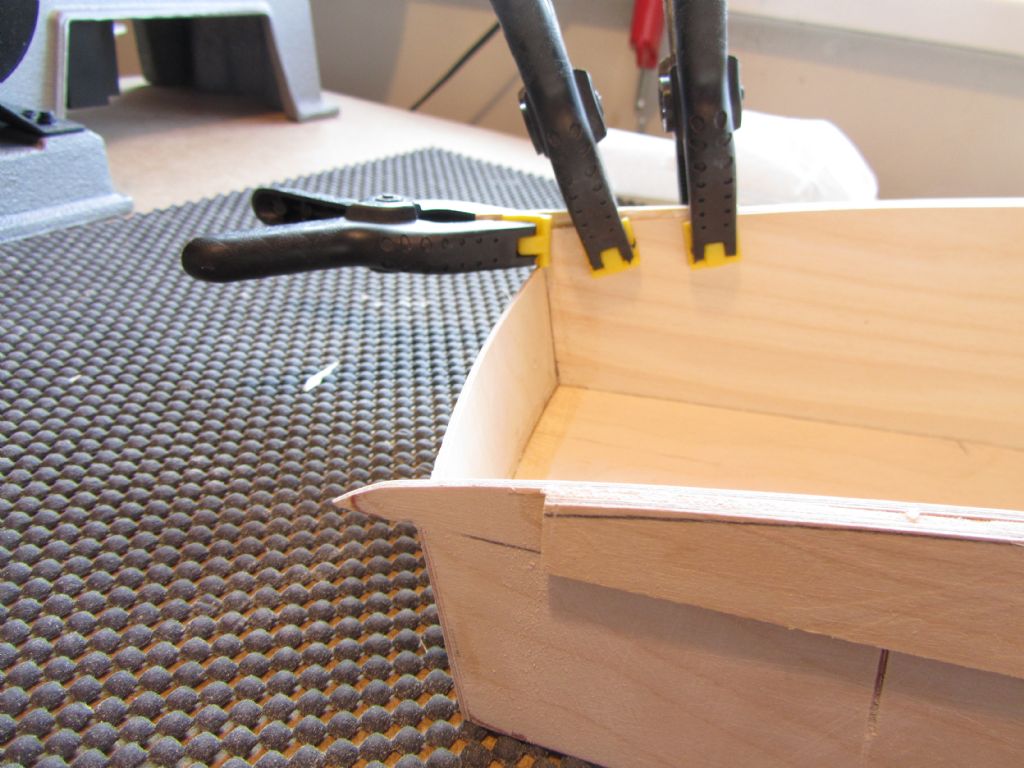

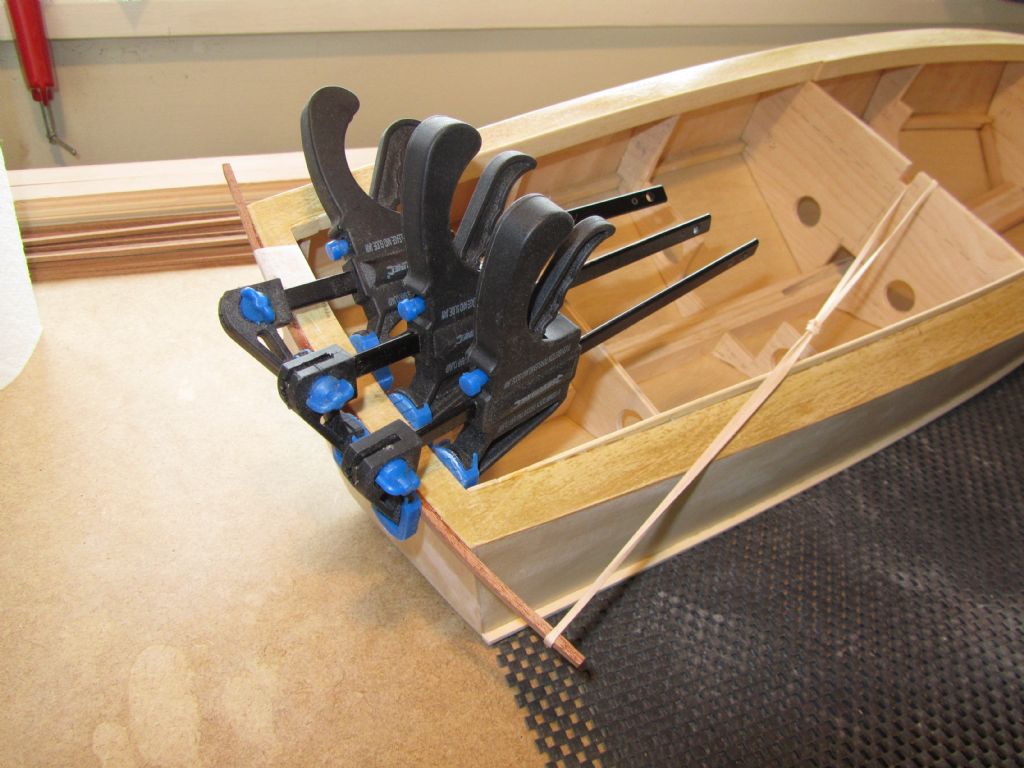

So I cut a long thin piece of 2mm ply, about 75mm long, with the Stanley knife, and glued them in place with cyano and bent them to the curve with my fingers, prising them away as they started to get stuck! The ply was left proud and then sanded to line with the faithful PermaGrit block.

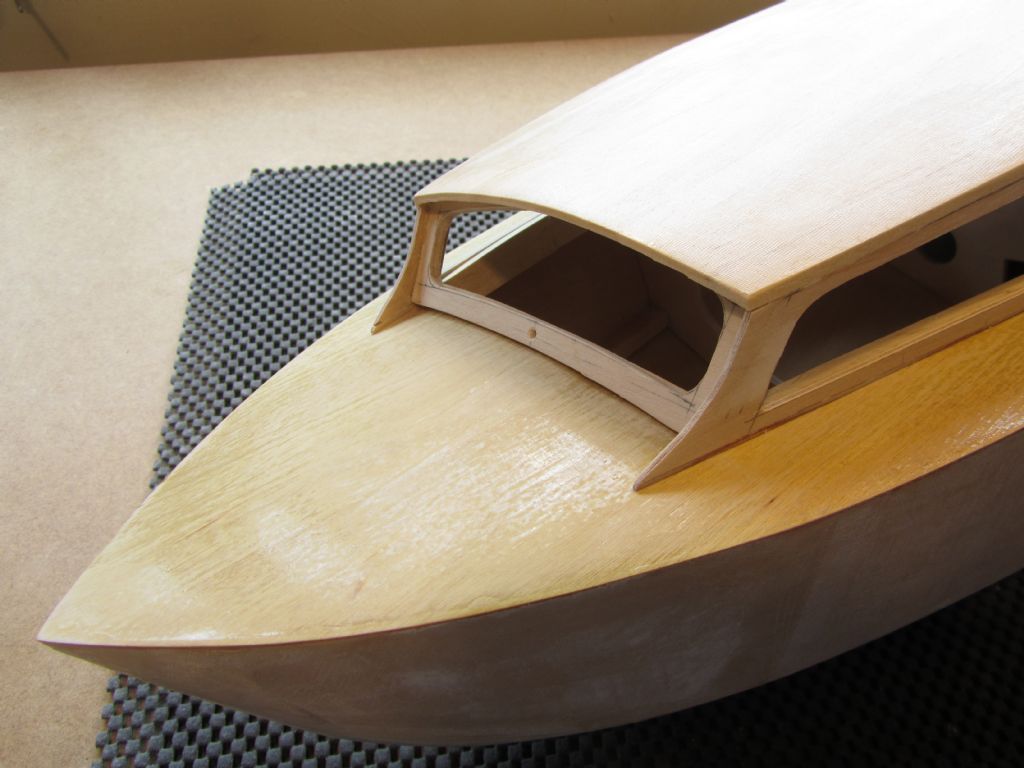

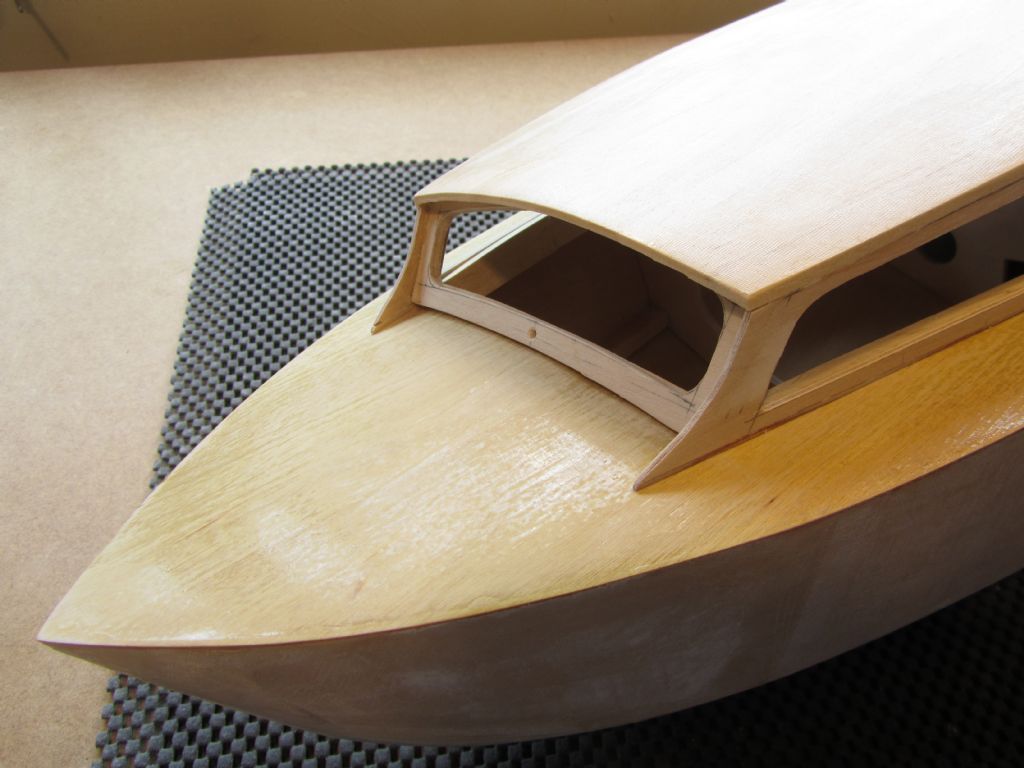

This remedied the gap but then caused some on the other side! This was no bad thing really as otherwise the bottom of the front window wouldn't have been parallel with the deck. So another piece of ply, about 50mm, was glued in place and sanded. As you can see from the photo this did the trick and I was happy with the result. This then though left a gap between the window and deck so a piece of 1.5mm bass was cut and glued in place and sanded to fit.

That's not the end of it though! Because of the extra ply at the sides the bottoms of the foremost side windows were now deeper and not parallel to the deck so some filing and sanding was required.

There was also a couple of small gaps at the rear of the coamings where I'd added the extension pieces which got the same treatment.

Fiddly and time consuming but worth the effort.

Chris

Chris Fellows.

Chris Fellows.