Hello All,

Been Motoring slowly on this one, Just waiting on some bits n bobs to arrive before I get the Deck Firmly in place. these will be a speaker and 'Noisey Thing' from Action Electronics, These are being made up so it will be a while yet.

Anyhow here a few shots of progress, I need to Fathom out now how to curve the 0.08mm ply around the base of the wheel house. Should be fun!

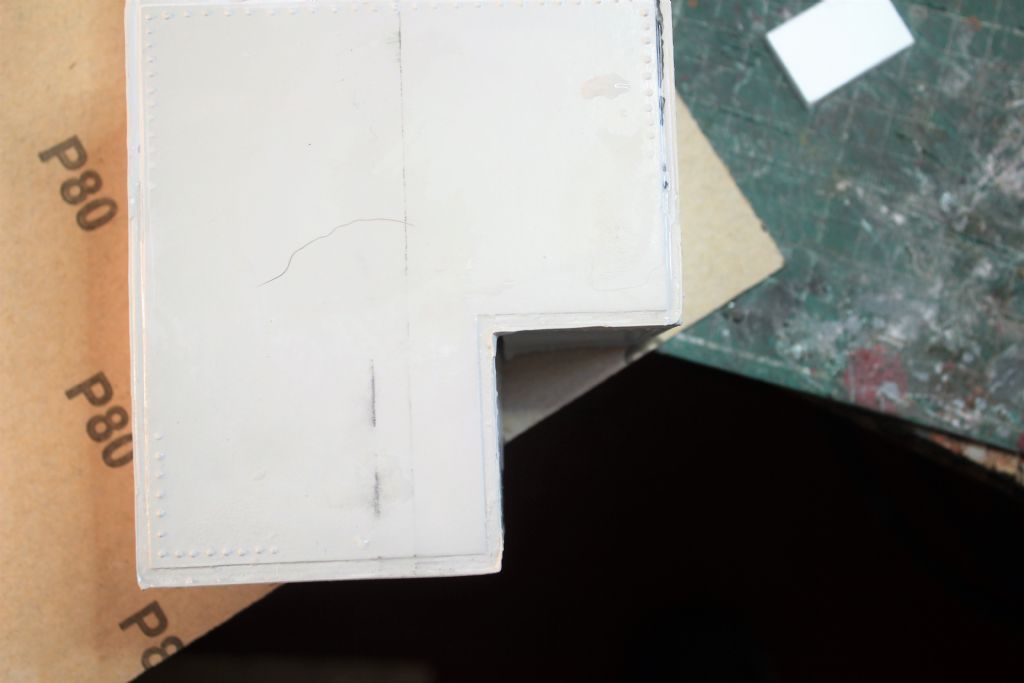

The Superstructure unit was pretty warped in many places. A right pain in the you know what, It still bows back after manytreatments of the hair dryer.

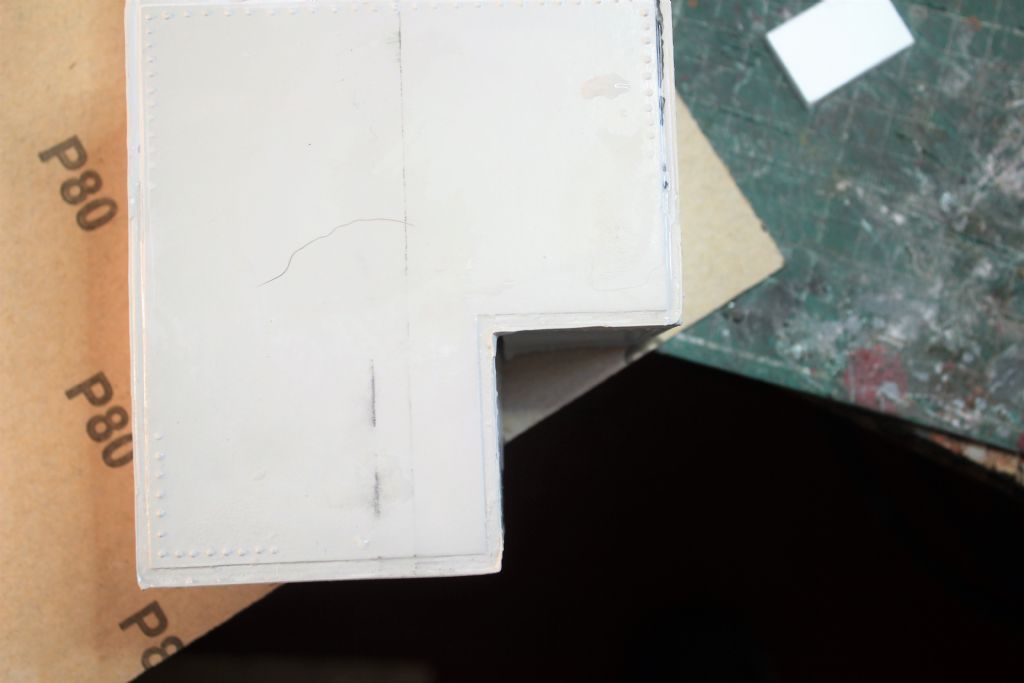

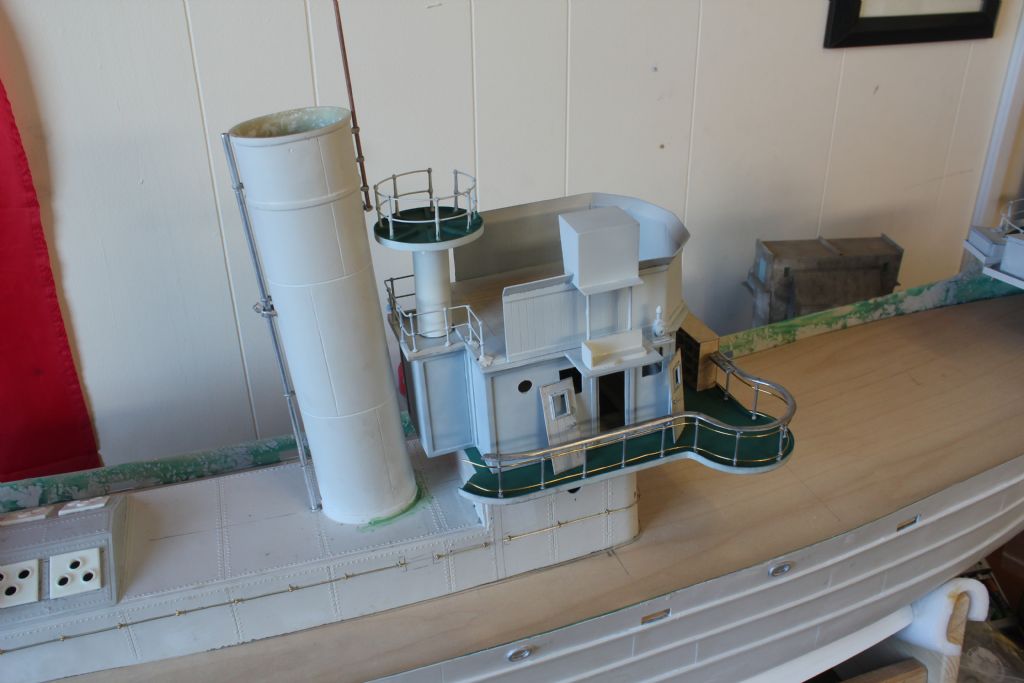

I had cut into the rear part as the part was not square and bugged me and the gap filled with P38, You can see in the first photo the parts re positioned and how nice a square it is now

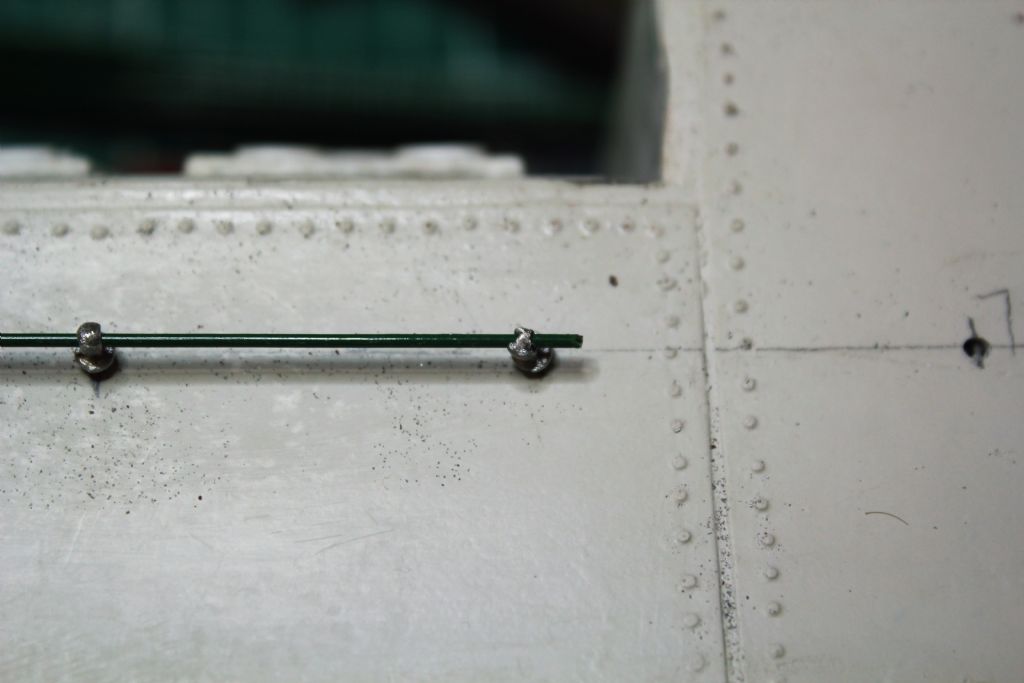

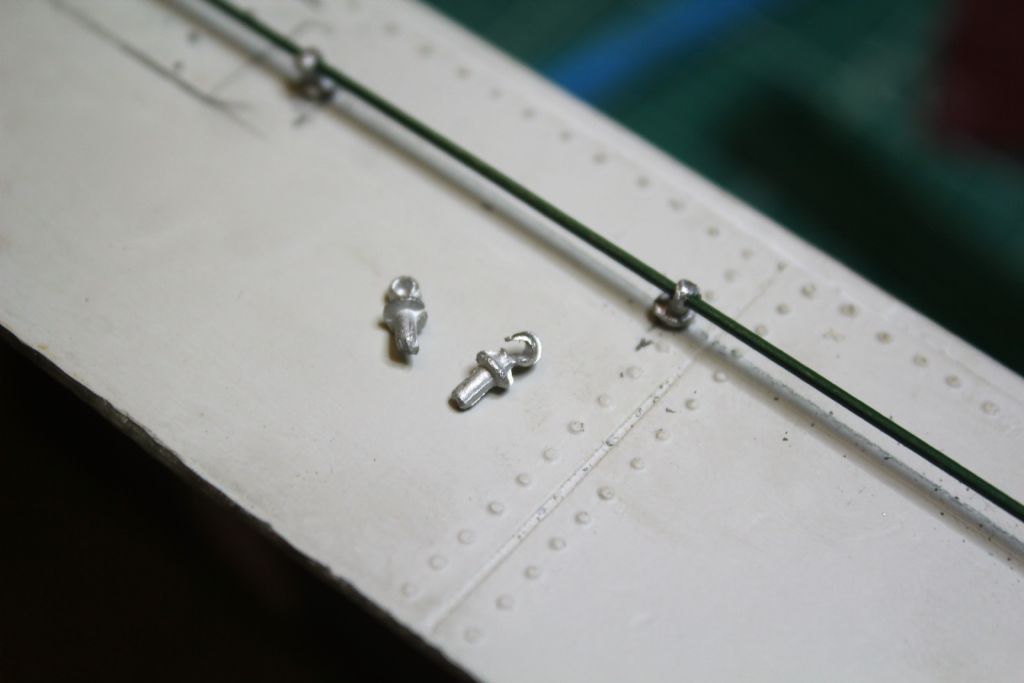

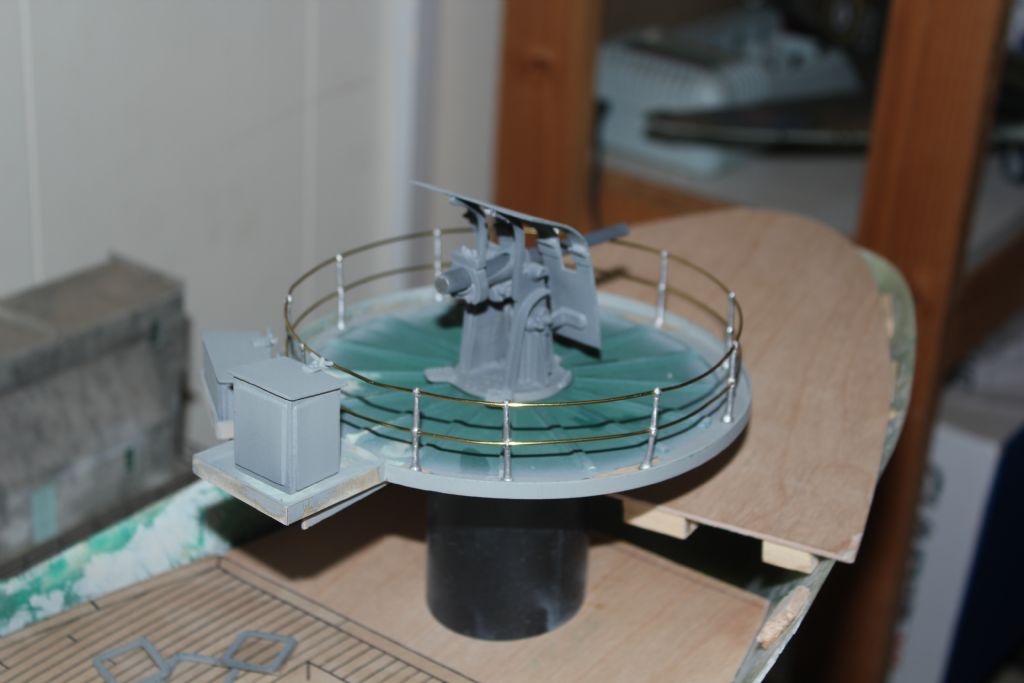

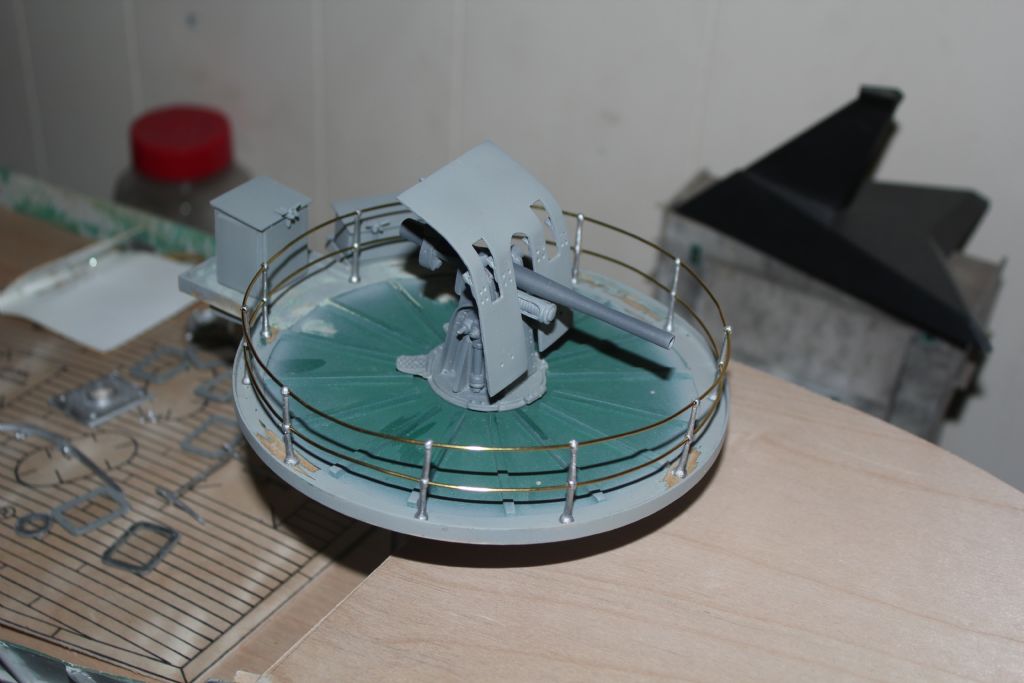

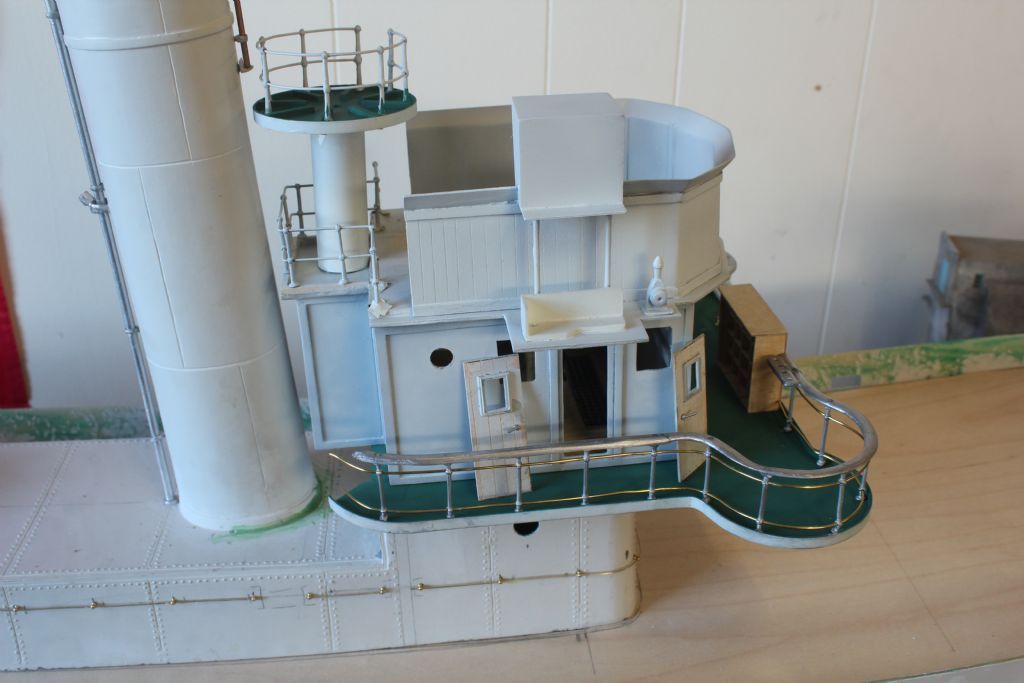

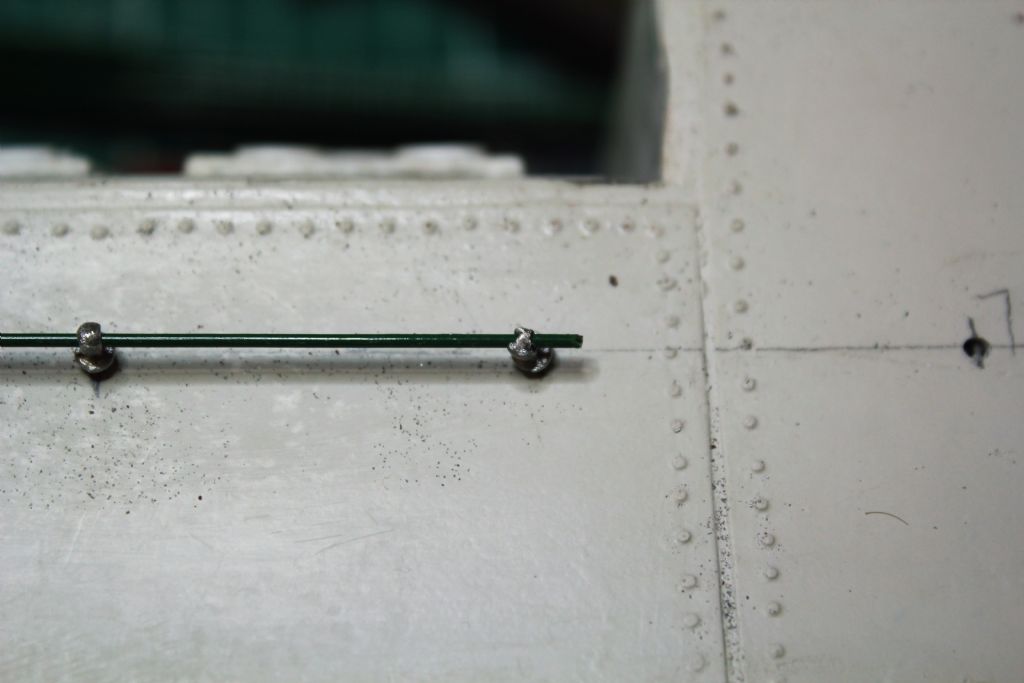

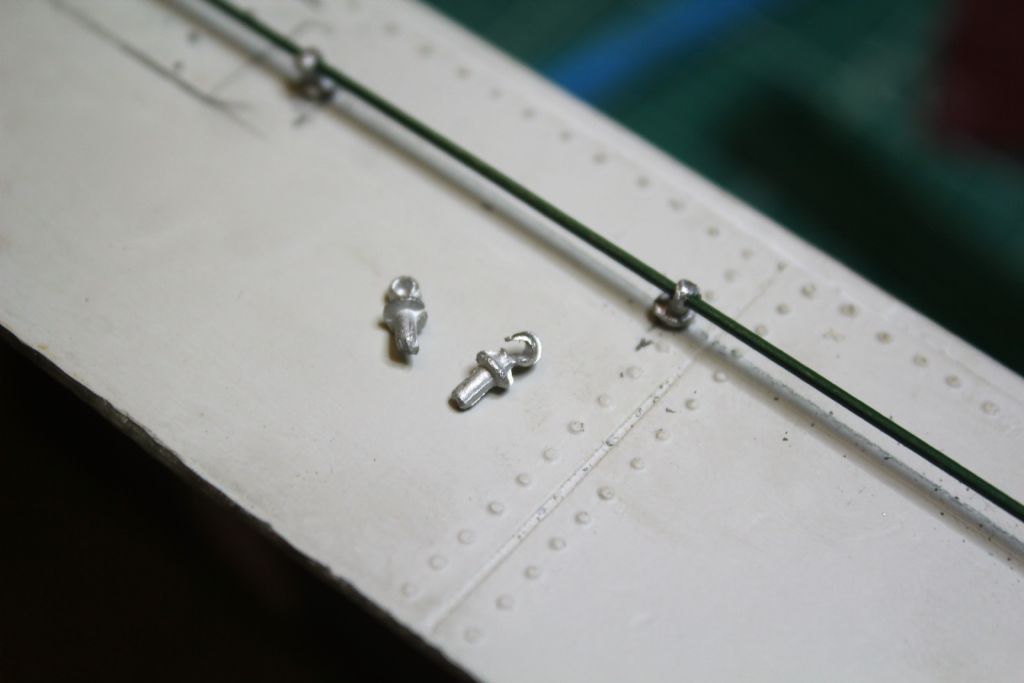

Shortly after that Victory I decided to move along and concentrate on Superstructure and started off with the Handrails and drilling the holes. I went to stick in the hand Rail Stanchions but these are pretty poor and mis-molded or short molded so and order went out for some brass ones. No point in putting Crap ones on it after spending out so much on the model itself so I will have wait for those to arrive also.

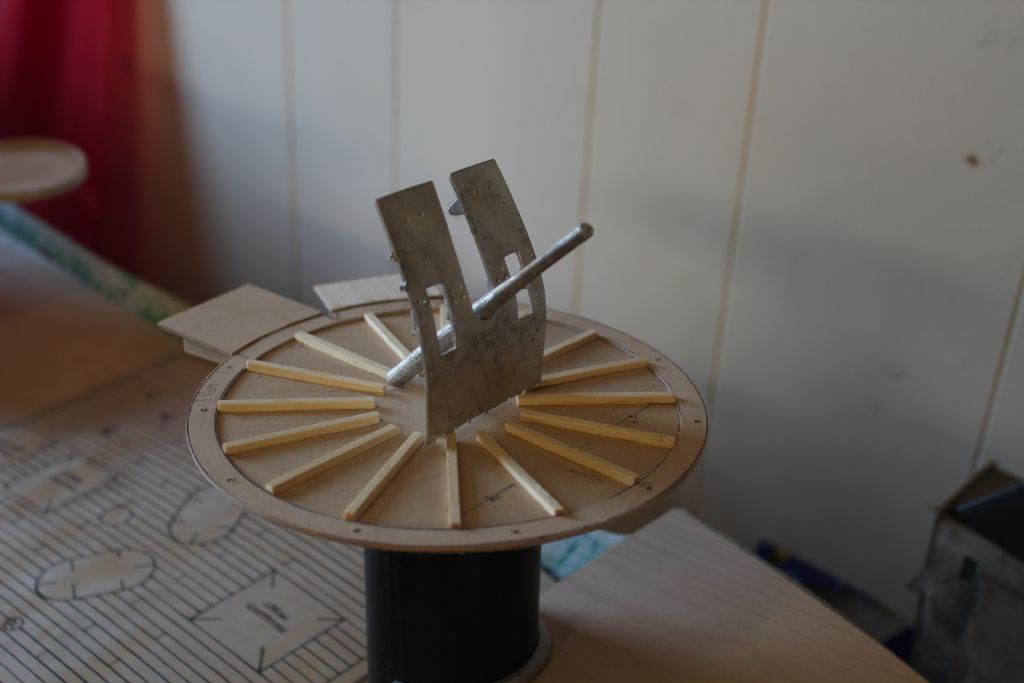

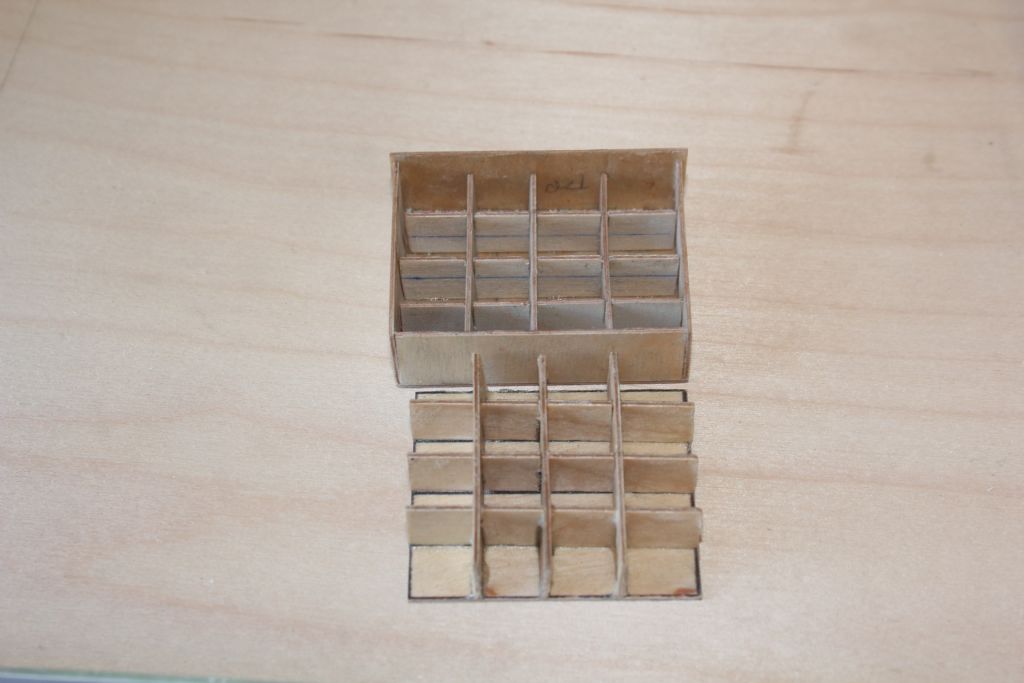

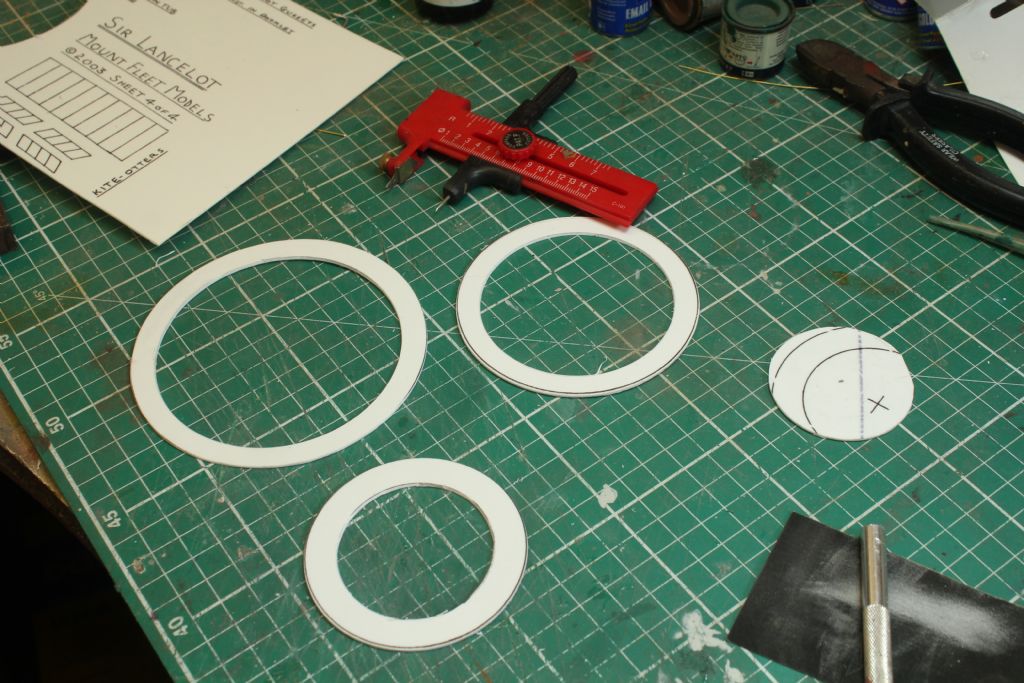

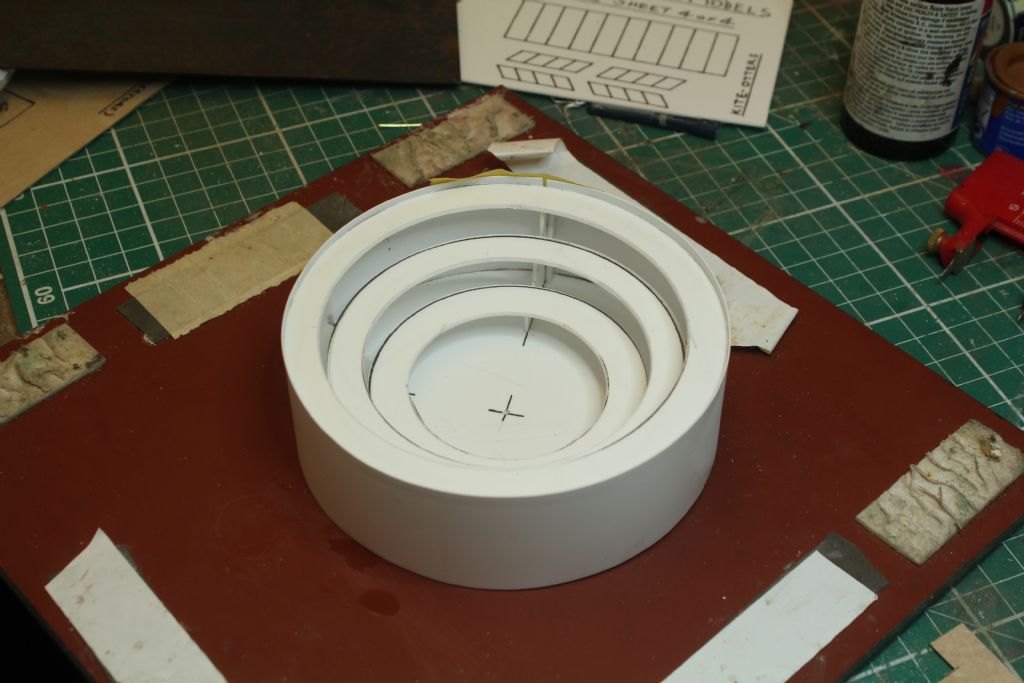

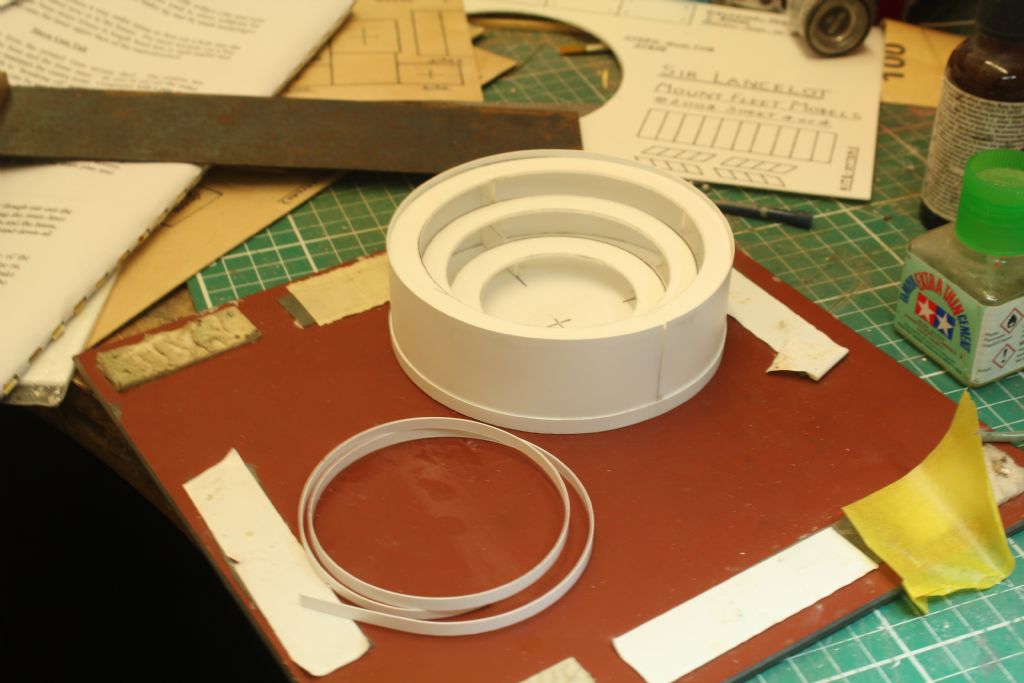

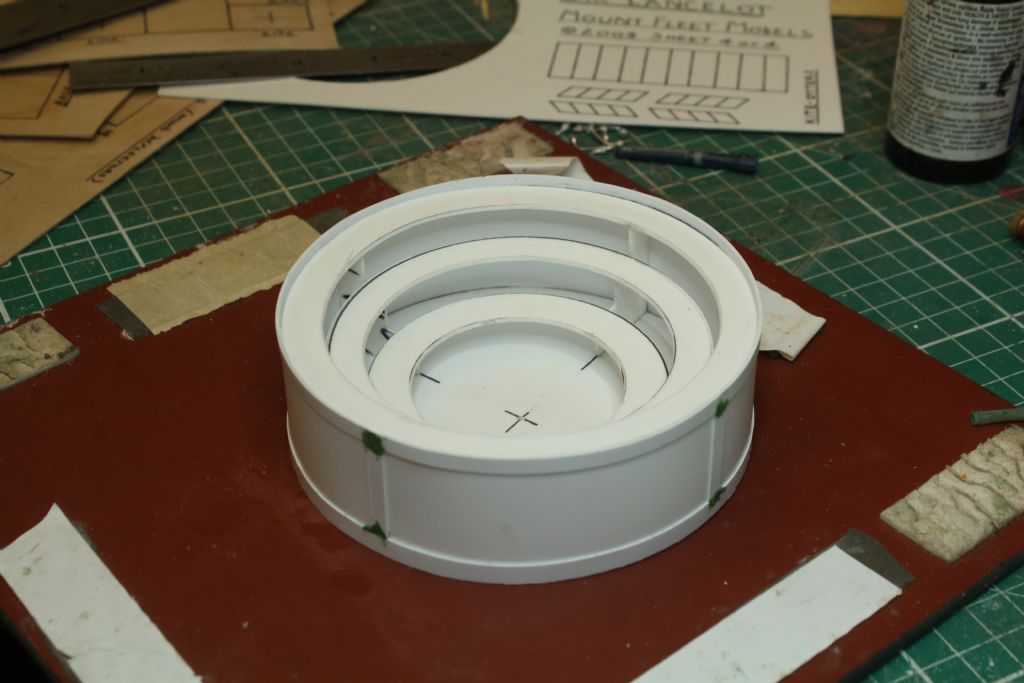

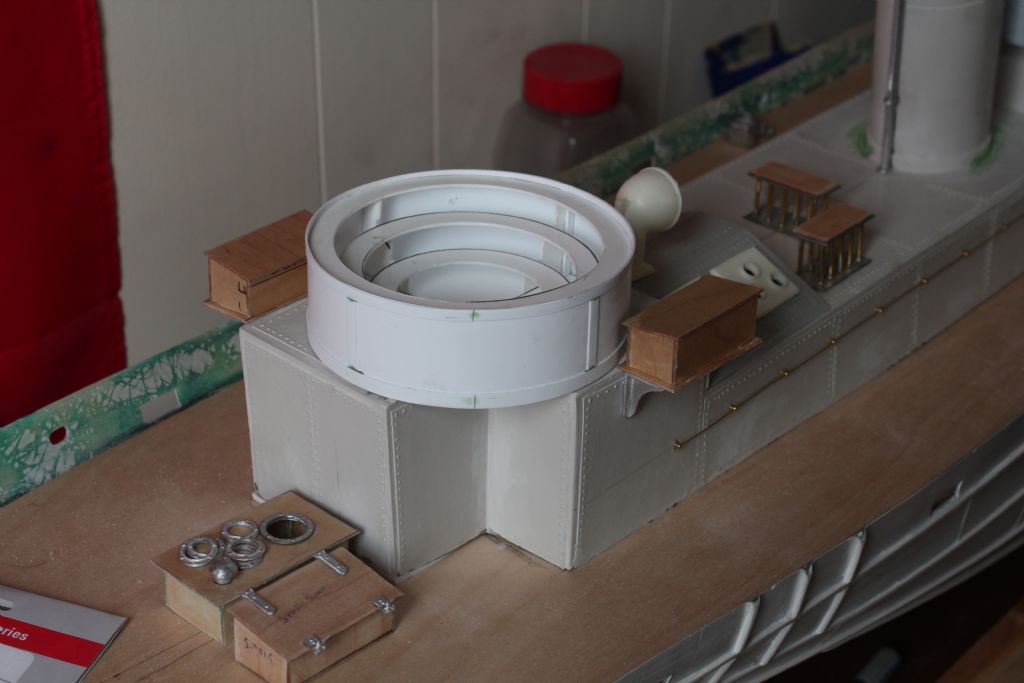

Marks Model Bits Posted me over a Foggy unit, Could make one myself as I had a few spare Misters in the shed but time does not allow that so a tray was made for that and a hole sanded out. In the end I decided to Recess the Funnel into the superstructure for Strength and the whole shaped so the base of the funnel sat inside as no doubt if that gets a knock it will be a problem if it just sat there!

I managed to straighten as best I can the Superstructure and have stuck the Engine room skylight parts also on. The Rear of the superstructure was about 3mm too high over the deck so a piece of plastic sheet was glued to the rear part and Sanded down so the unit sits nice a flush on the deck.

You can see the rear of the Superstructure sitting a few mm over the deck.

I also stuck the Steam pipe onto the rear of the Funnel and managed to drill the 4 holes Waaaaaaay off Centre for the Mast so had to re fill those holes. Too much Rushing Rushing Rushing!!!

To finish the hull I need a sheet of 14" 2mm plastic sheet to make the bilge keels, Of course I can't get this in Ireland right now either so another order to the UK for this will have to be made adding to the cost :/ . I don't fancy having the wood soaked each time it gets a dip so plastic is better for me here.

The Vents are just placed BTW before you start to Panic! I will use brass / Alloy tubing for the Vent Shafts even though dowls are included, The Vent cowls are not the best TBH so I will think about replacing those if I can make them a lot better after some grinding with the dremel.

Next the 0.08mm Bending Miracle around the base of the wheel house floor section!

Cheers for now

George