Hey, Paul

You do realize that this was a conjectoral suggestion to grip any shape of casting so that it could be worked on, in the vice, for my good friend, Duckie………I don`t really know if it`s a good idea or not!

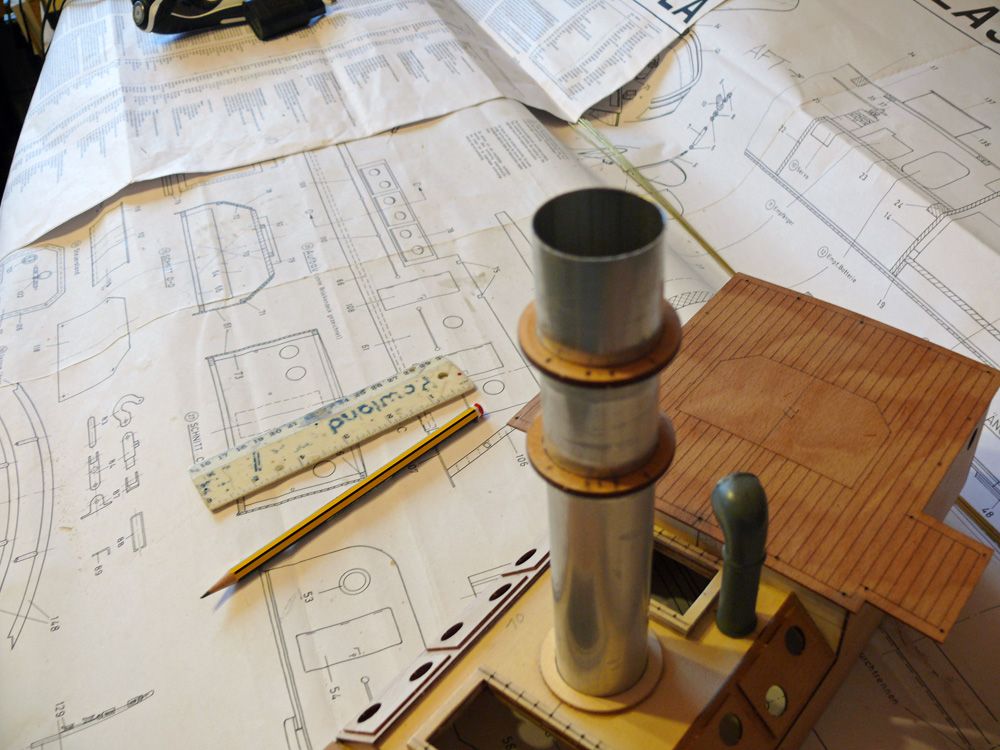

But just for amusement only, I`ve lashed up a sample to get a feel for the job

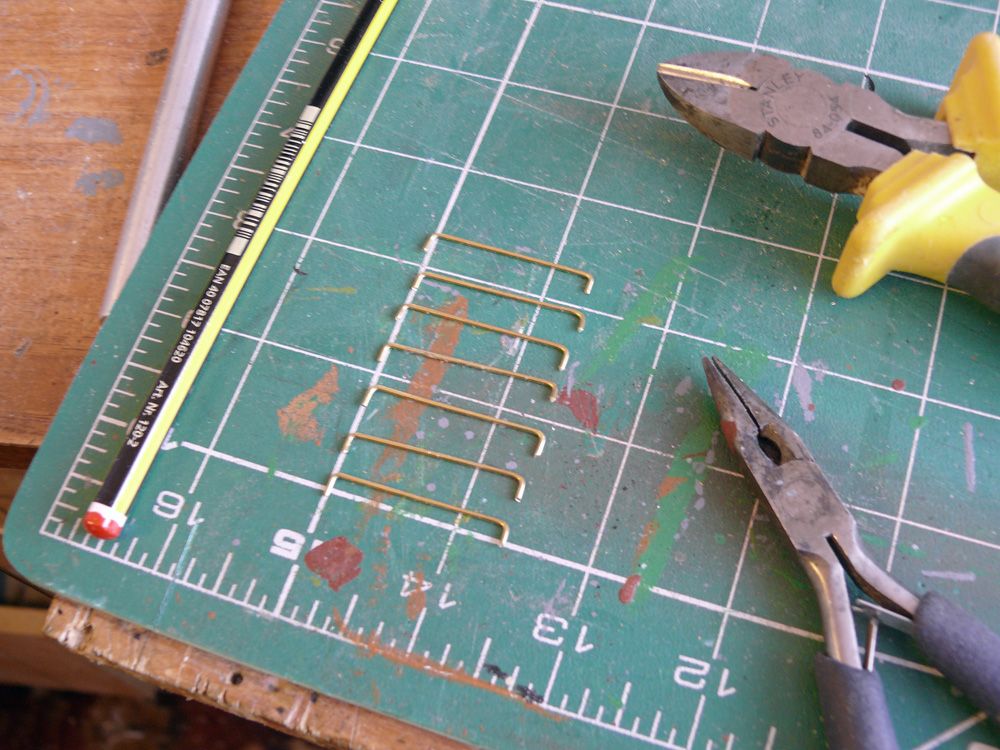

The components parts…..

Tube, needs to be thick wall for gripping in the vice

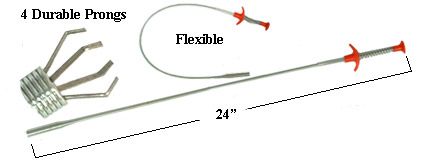

Tension spring, needs to be powerful, with a loop at both ends

Claw parts, strong piano wire……..(it`s a right swine to bend!)

Strong cord for pulling the spring eye end down, to enable holding peg to maintain clamping pressure

This was a great afterthought!

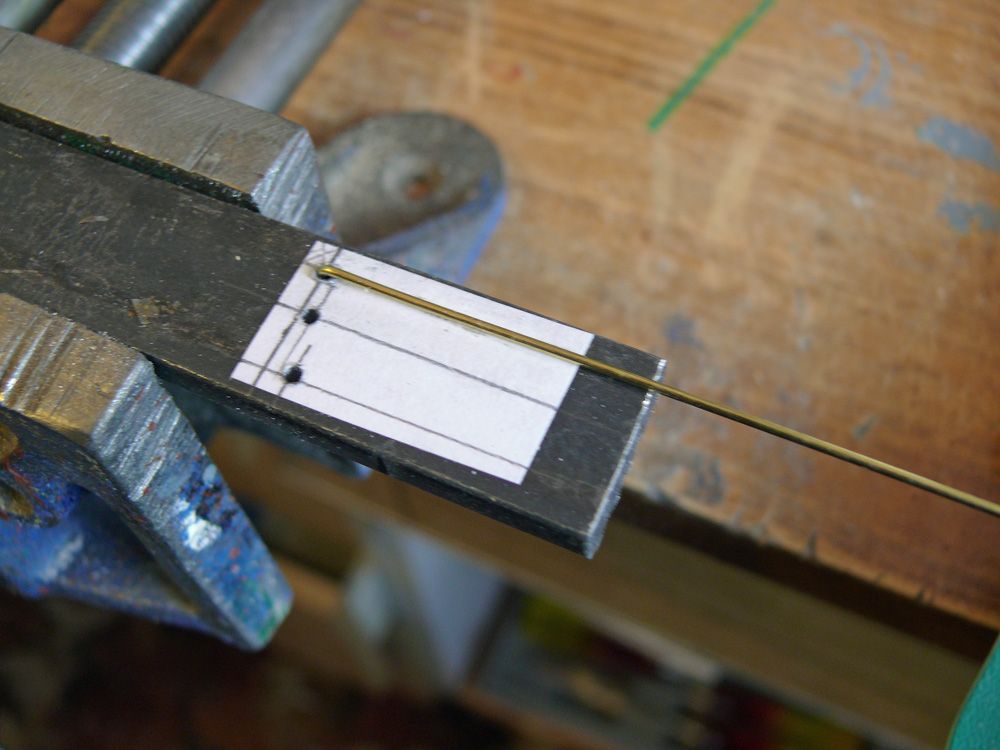

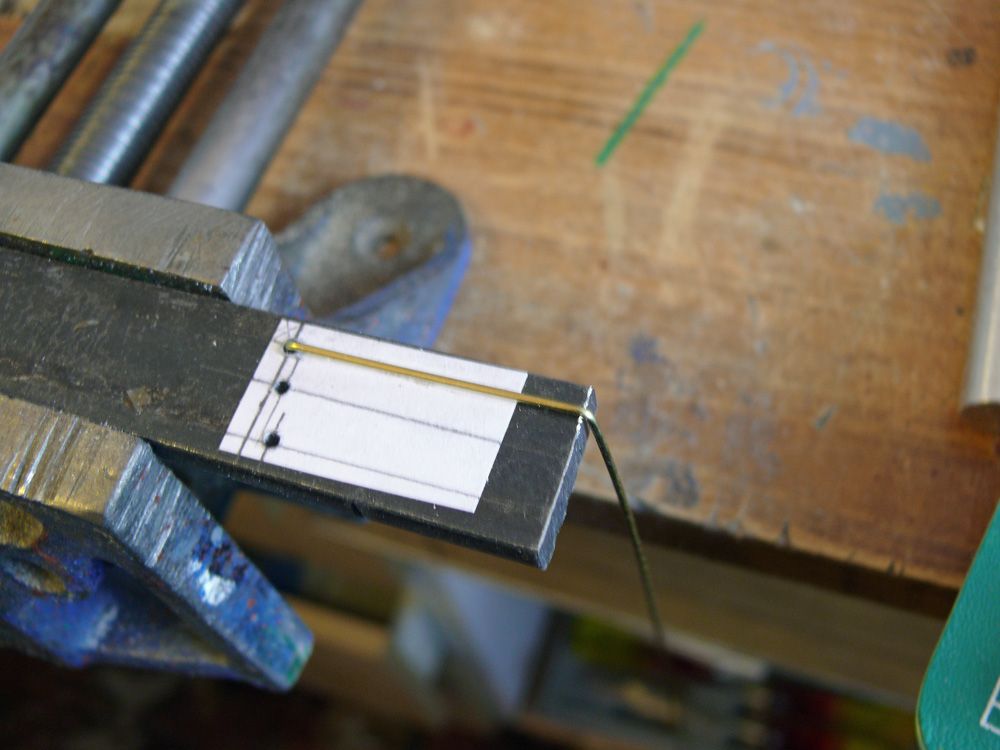

Slots to equally space the claws and provide guidance

By a stroke of luck, when the spring was pulled to test the gripping power, the eye of the spring appeared and it was just right and ideal for the retaining peg

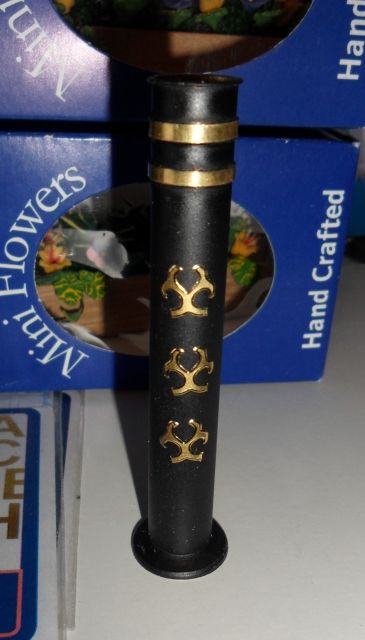

Sample odd shape in the claw

This item looks well gripped?

Anyway chaps, I`ve put my money where my mouth is, so to speak and proved that it is a feasible idea

Come in, Paul

Bob