I needed to make a ships wheel for my Great Eastern, and decided to make a decent job of it, for once……..Rather than guess it and hope for the best!

The tricky part was……….How to drill the spoke holes in the wheel rim, accurately?

Without a dividing head, this is quite a problem.

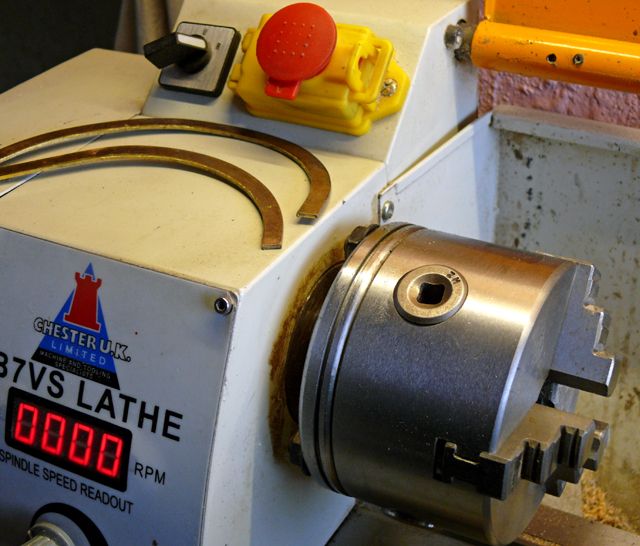

The lathe spindle was a good starting point, on removing the gearchange cover, I was pleased to see a 40 tooth sprocket on the spindle

I made a metal lever, pivotting on a nearby stud and filed a single gear tooth on it. which engaged with the spindle sprocket………..Nice eh?

I next made a drill guide that fitted the toolpost and was positioned in front of a length of tube material, gripped in the chuck.

With the gear and spindle clamped up, it was a simple matter to drill the tube by hand, using the toolpost guide to line up the 1.5mm drill.

The process was repeated, eight times, drilling a hole every five gear tooth spacing.

The process was a complete success and the precisely drilled ring was a thing of great beauty and a joy forever!

The dividing mechanism…………..Just so fiendishly clever?

It was an absolute treat to see the holes so neatly drilled.

Can`t wait to use this feature again, soon!

Well, I hope you chaps appreciated this little Eureka moment?……..I certainly did!

Bob

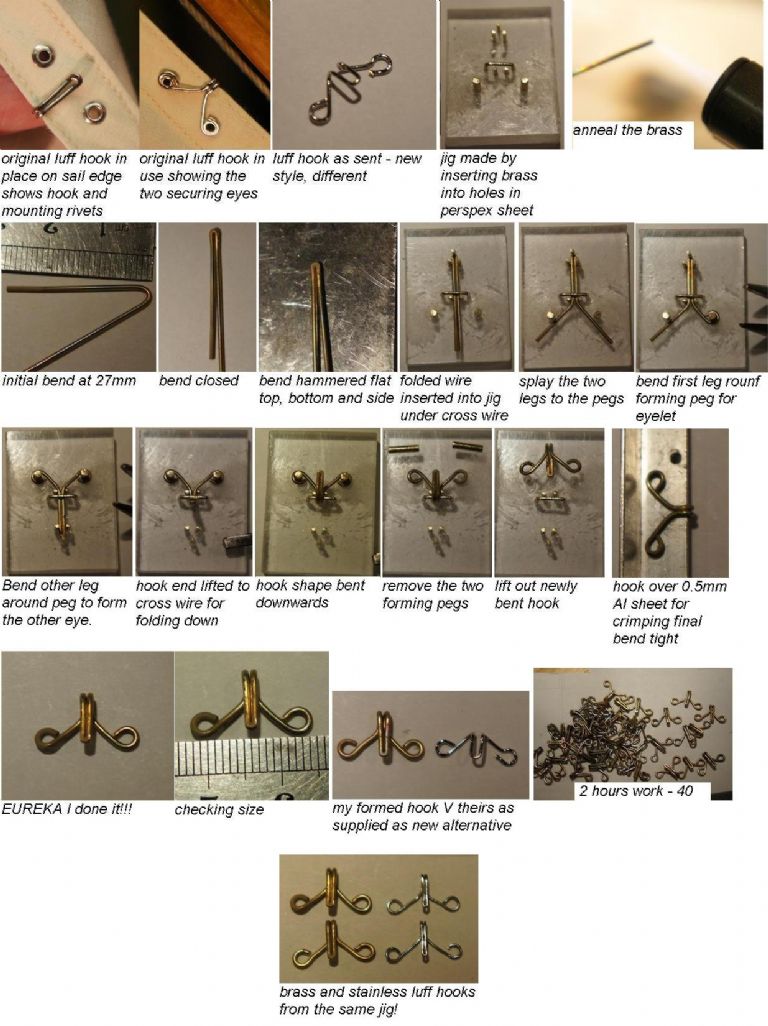

came up with this one for me.

came up with this one for me.