A few photos

Ray: I tried 3D printing but the parts were to heavy plus the fact that my 3Dprinter is quite small so I couldn't print the larger pieces. Yes it will be a flying model but not sure if it will be electric of petrol, electric will be easier but have limited flight time, petrol will sound better and have a longer flight time but the bits of engine sticking out of the body can ruin the look of the model.

Captain Bob: The Typhoon and Tempest were very impressive aircraft and, for me better than the Spitfire, the laser will let me cut out all of the parts but I don't know where I will keep the plane when it is built, at 1/4 scale I will need a hanger. Photos of Spitfire and Seafire for you and Ray.

Red: I researched this for a long time before buying it, I also bought a good pair of laser goggles at the right frequency for the 40w laser. Thanks for the cutting tip.

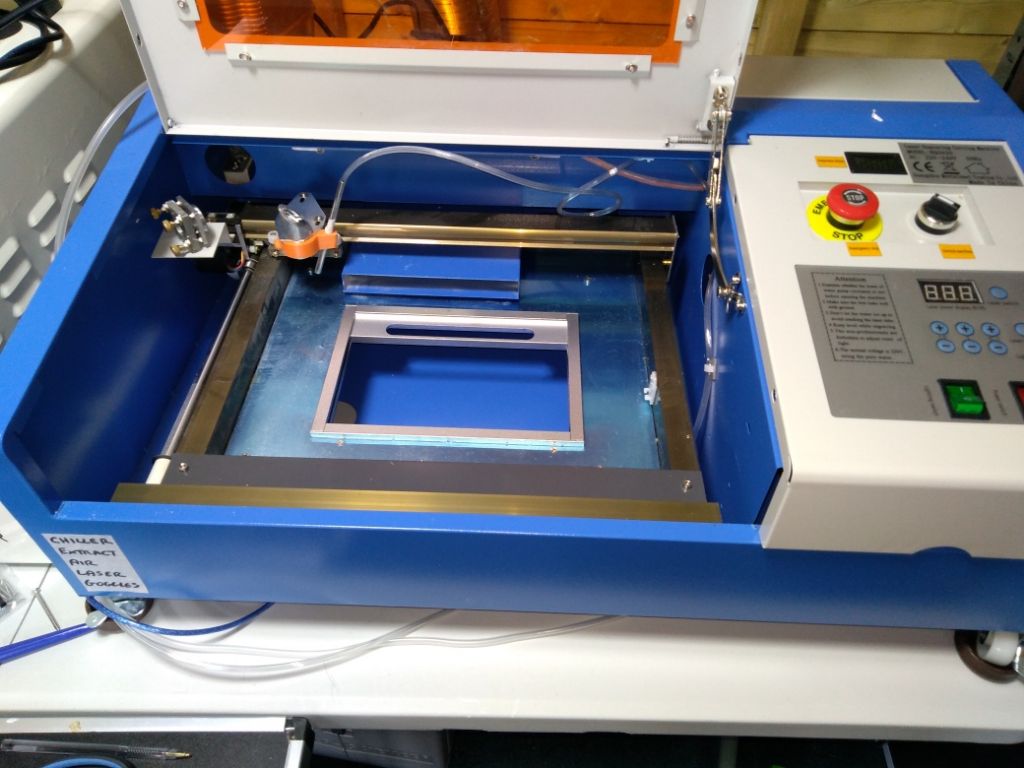

Chris: You can get a good idea of size from the photos but the actual cutting area is only 300mm x 200mm , it etches very well and is ideal for etching complicated deck planking.

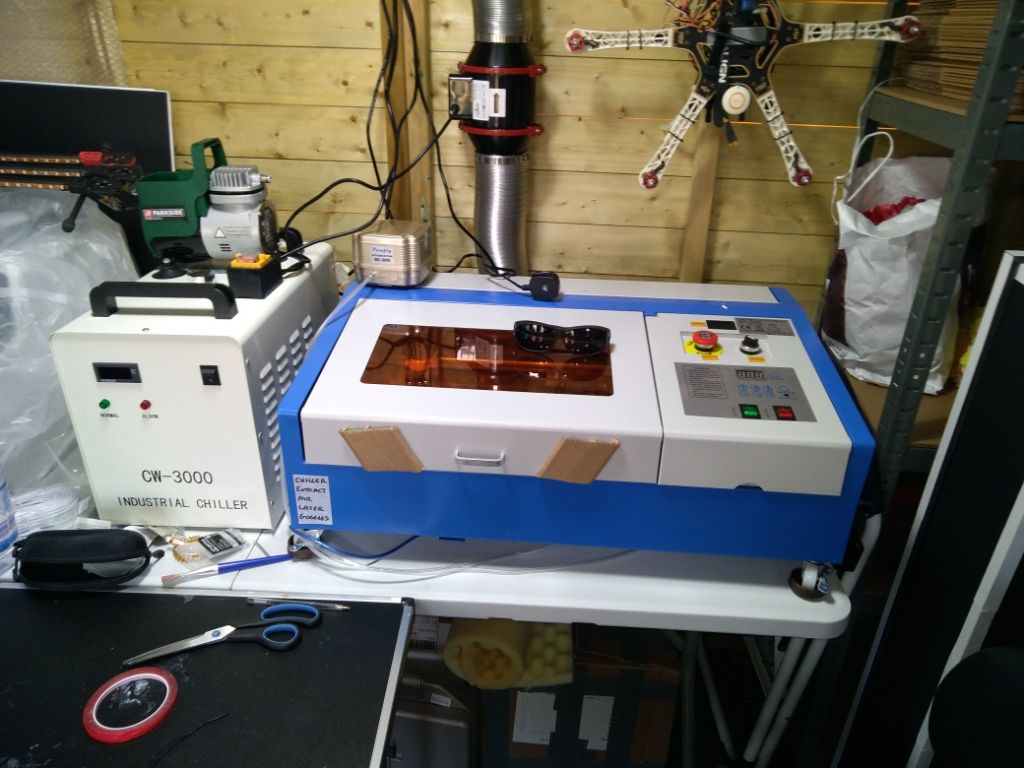

The laser itself is a decent piece of kit for the money but the 'support kit' that comes with it is cheap and best replaced with better equipment.

For example the supplied fume extract is a cheap fan and a paper hose, I replaced them with a good 'inline' fan and steel hose.

The laser has to be water cooled and the supplied equipment is a small fountain pump that you are advised to place in a bucket of water and hope that it cools the tube, I replaced it with a sealed chiller filled with distilled water.

Last of all I added an 'air assist' which blows air over the cutting point and really helps with a decent cut, for my first attempt I used an airbrush compressor but this overheated so I replaced it with a large air pump, usually used with large fish tanks.

Paul

Edited By Paul T on 24/03/2020 12:25:42