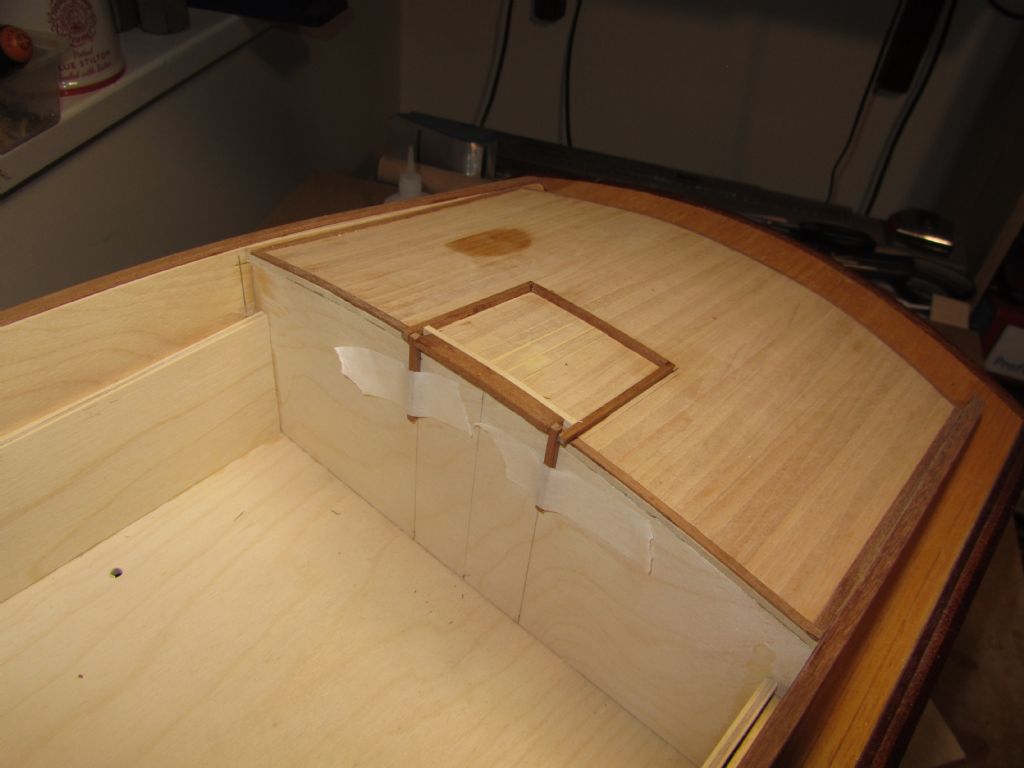

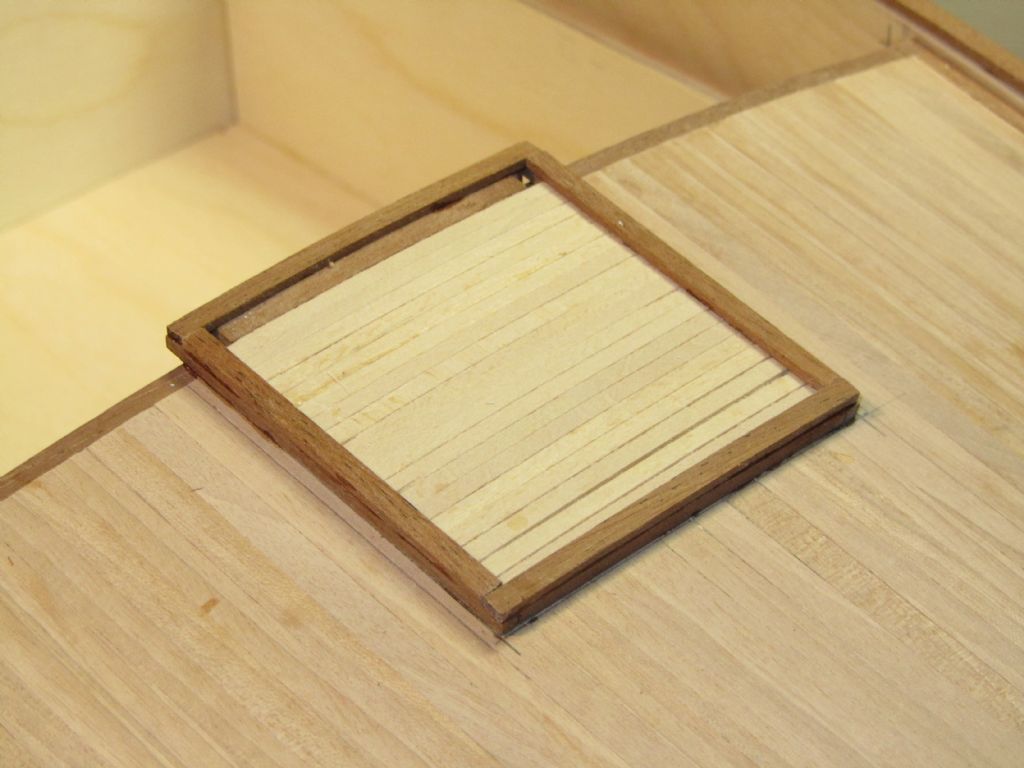

I was all set to build the hatch after looking at those on the full-size craft and deciding what size to make it but to look right it needs to be slightly curved to follow the line of the roof and to do that it will be easier to build it straight onto the roof. But before doing that I thought it would be better to fit the doors and frames first as the sides of the frame carry up to form the runners for the hatch!

And as parts will be sticking out into the cabin (also applies to the doors and frames for the front cabin) I decided that the floor needs to be done first otherwise I won't be able to get it in! The joy of scratch building!

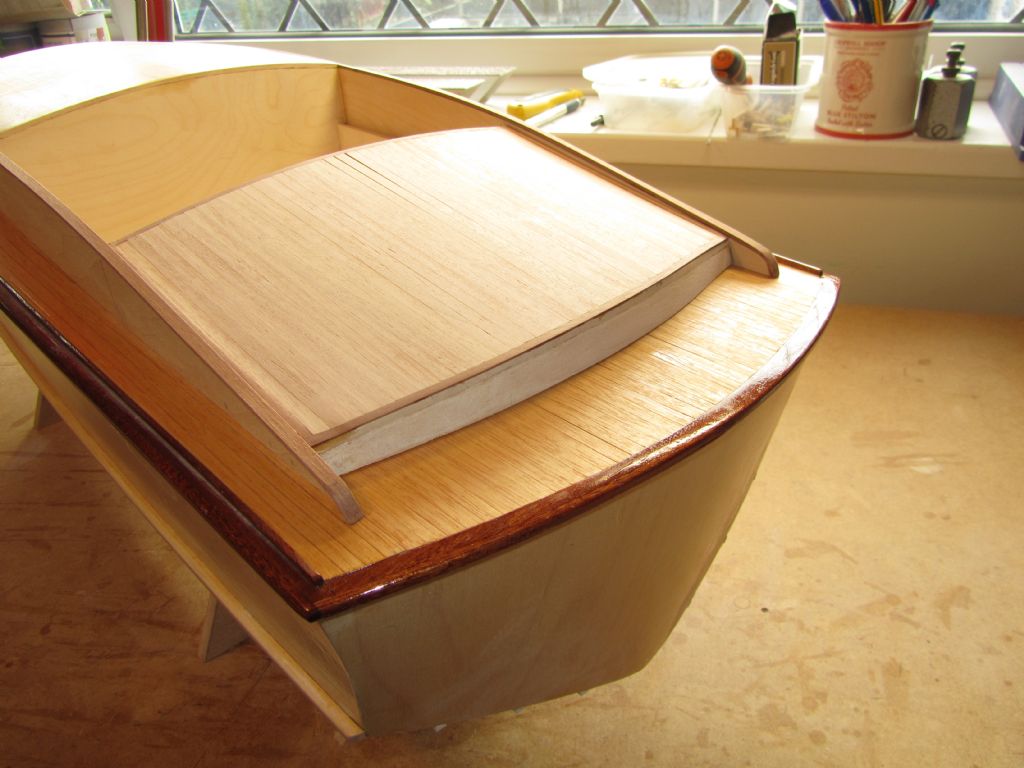

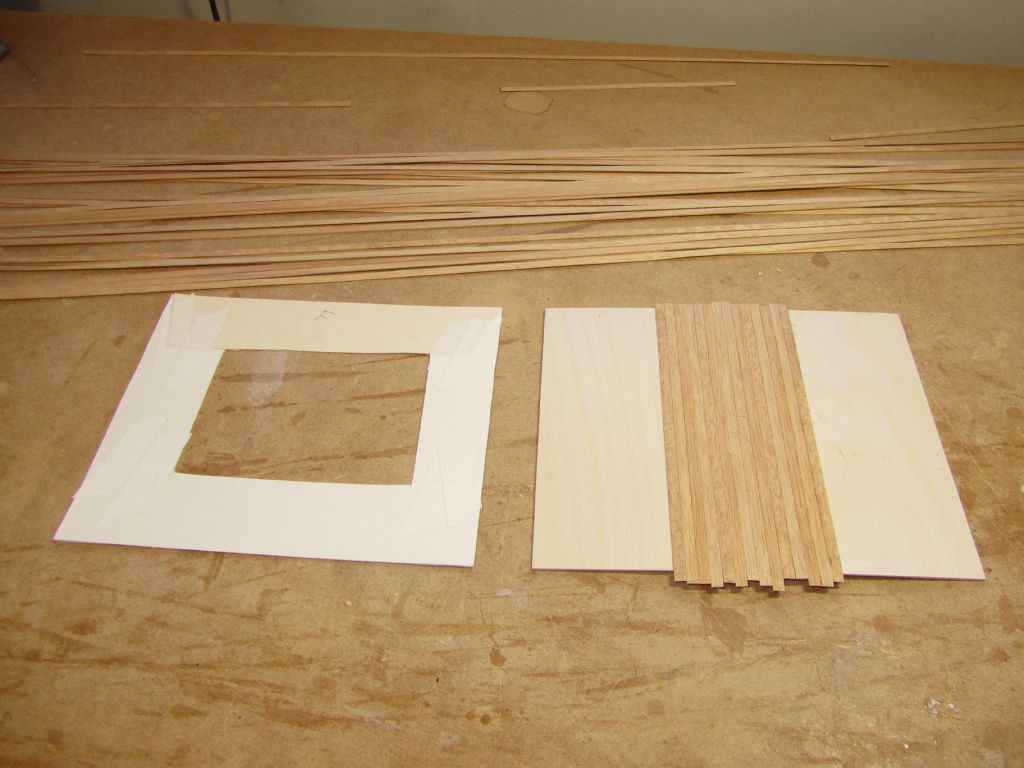

So floor it was. I've reverted to the 0.5mm thick planks as used on the deck, basically because I've got more of those in stock. I'm going to put some detail into this build but not go mad and so I'm just going to do straightforward planking rather than the more intricate full-size examples where access hatches etc. are framed etc. Anyway a lot of it will be covered up by the seating and storage boxes etc.

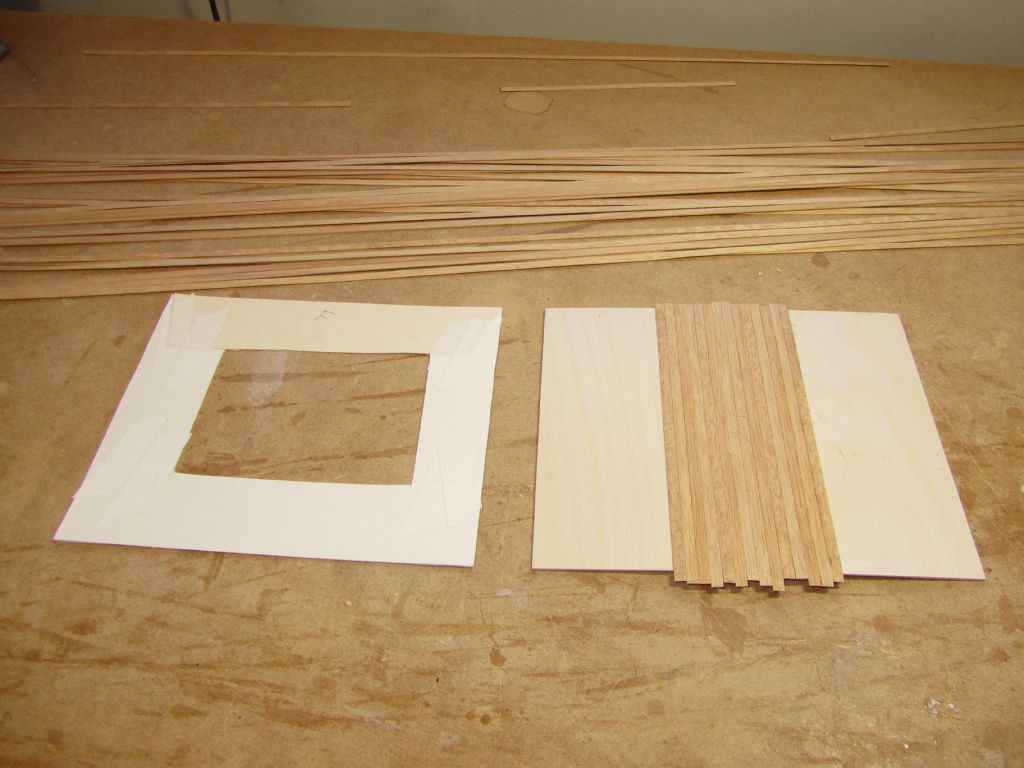

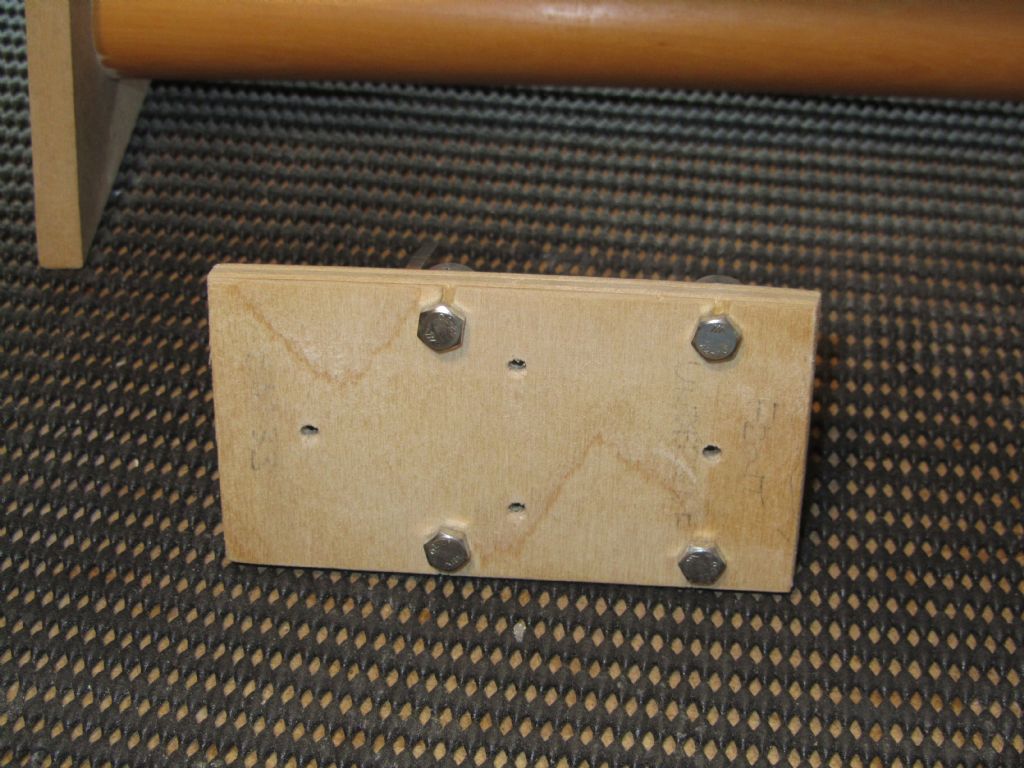

I want the floor to be a snug fit and so first of all I made a card template. This was transferred to 1.5mm ply and cut out and sanded gradually until it fitted. Tip – drill a small hole through the bottom of the cockpit so that you can push the ply base out as you fit it!

Once it was a good fit a centre-line was drawn on and planks laid out dry to avoid very thin strips at each side – either start each side of the centre or with the first plank central. The planks were then glued in place using Canopy Glue and to avoid blocks of darker colour cut planks from a number of different long lengths and fitted those from each length symmetrically – this also ensured that the outermost plank on each side would be the same width as the planks do vary in width a bit. Once dry the overhangs can be trimmedsanded back to the ply base and the top of the planks sanded smooth.

Before gluing in place I shall fit the sides of the storage box so that I can give the planking a couple of coats of varnish.

Chris

Edited By Chris Fellows on 30/10/2021 19:45:46