As with the River Cruiser I started a thread on the Swordsman (subsequently moved to Building Kits) when I was producing the drawings and as I’ve also made a start on building it as well I’m continuing in here.

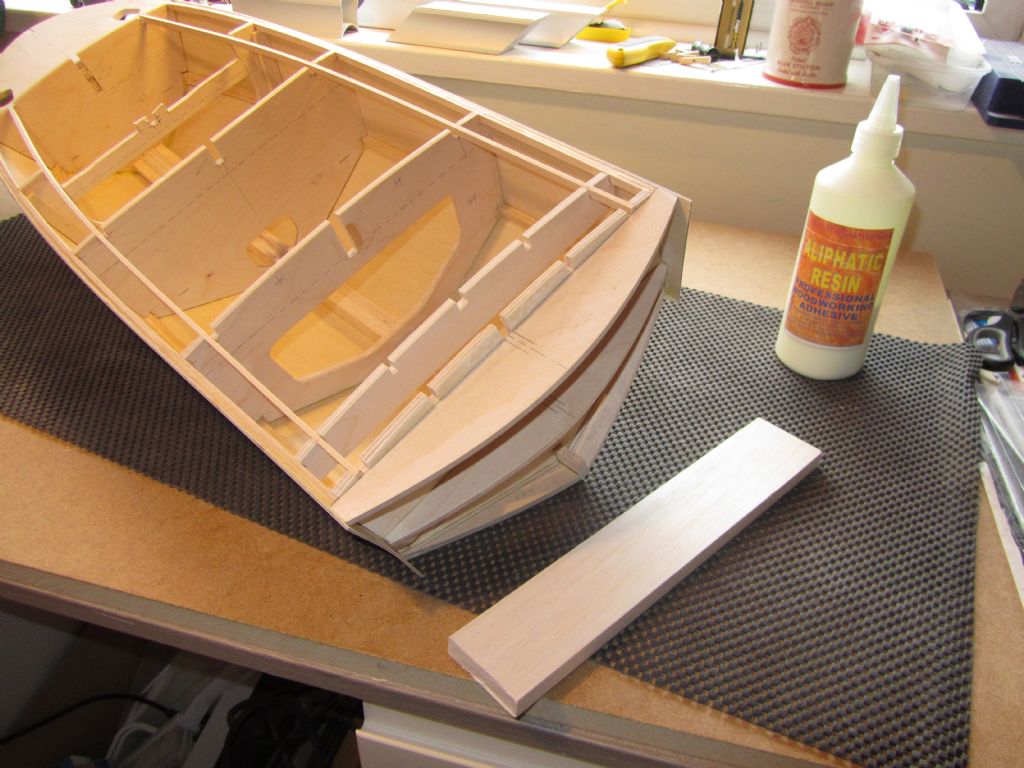

I used the Aerokits kit drawings (plan and side view) for the basis of the drawings but have modified them for the version of the Swordsman 33 that I want i.e. the one with the aft cabin that has the roof just sitting under the top of the coamings.

The Aerokits has the aft cabin but it is the one where the roof is level with the deck. Fairey Marine aficionados will know that there is also a version without the aft cabin and just a large open cockpit similar to other Faireys. The version I’m building may not be considered to be the best looking of the various options but I’ve not seen a model of that version and hence why I’m attracted to building it.

I actually started cutting out the parts for the hull (as far as I got with the drawings) before Christmas interrupted proceedings and I started on the River Cruiser. In fact the RC has been a distraction, albeit in a good way, as I was going to start building a Huntsman 28, perhaps I’ll build all three at once! Space may well be a problem though!

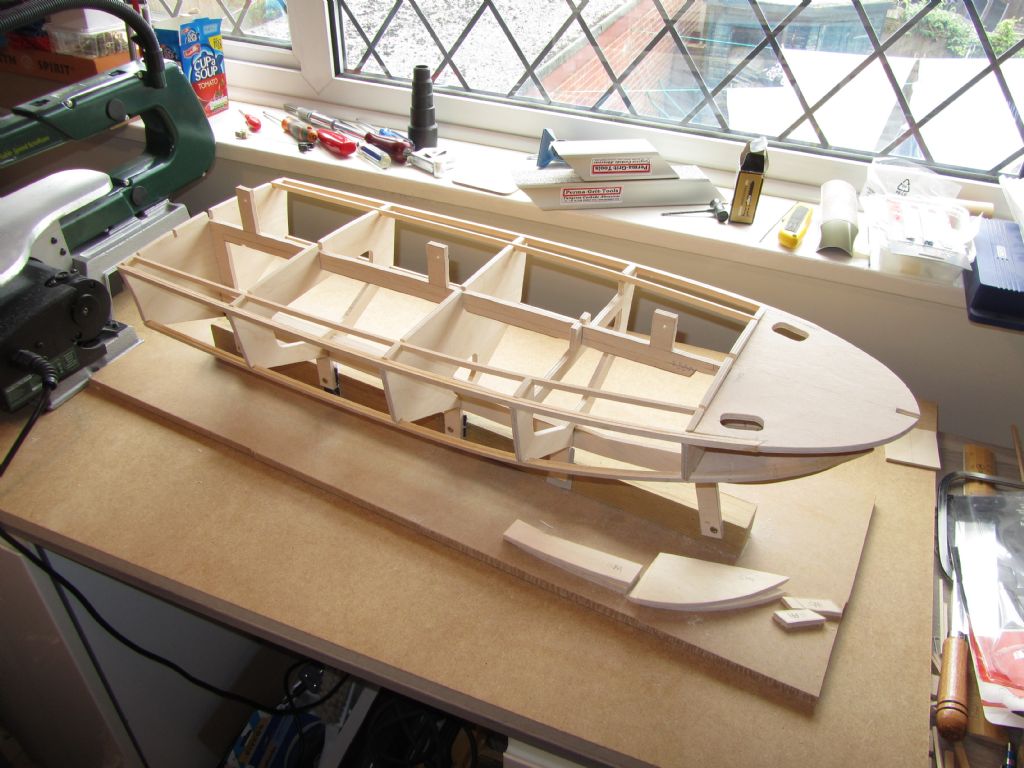

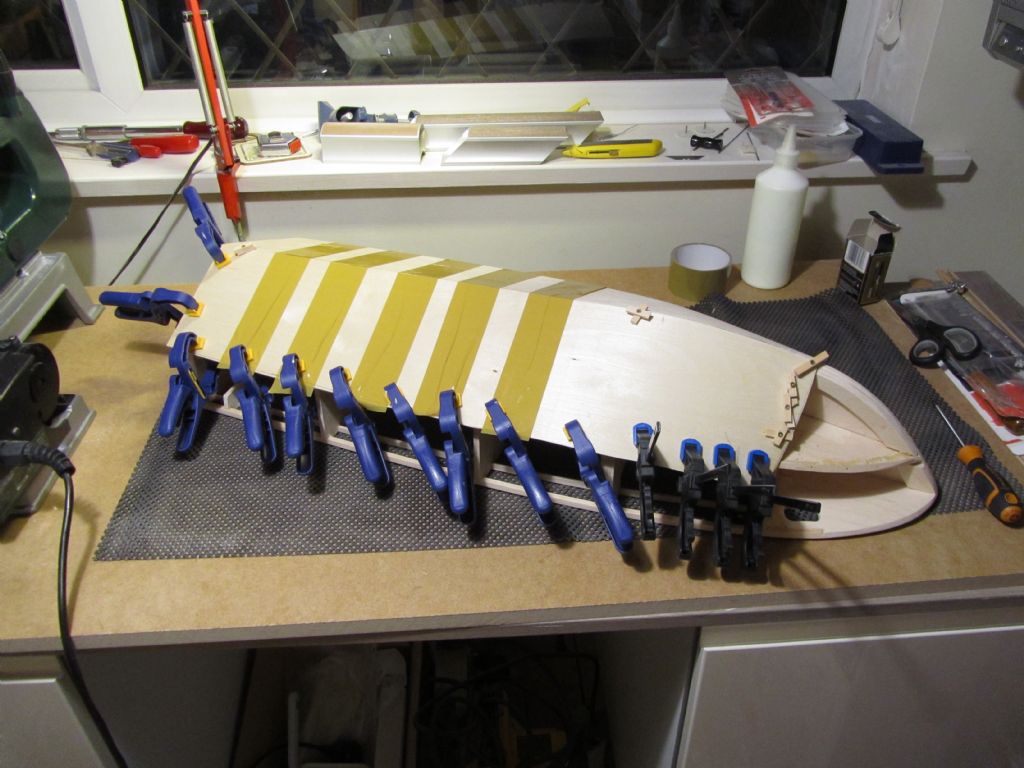

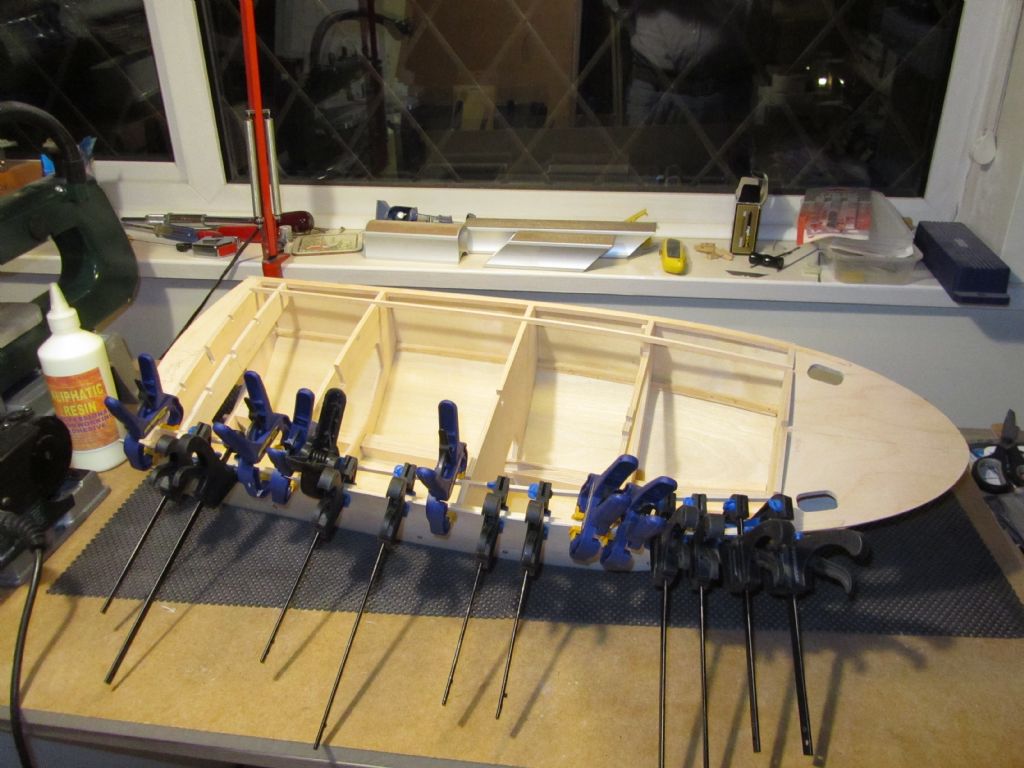

As well as the aft cabin I’ve modified the drawings by adding a temporary spine with “fingers” as well as on the keel. I’m building right way up and the keel fingers are for screwing to a substantial, straight piece of timber which is then screwed to a baseboard. I added them to the spine as well in case I want to work upside down as well, whether I need them or not, time will tell. Obviously the spine will help greatly with alignment and helping to keep the frames in place whilst gluing. This is all a learning curve for me as I’ve never build a model before, well apart from a few Airfix planes when I was young.

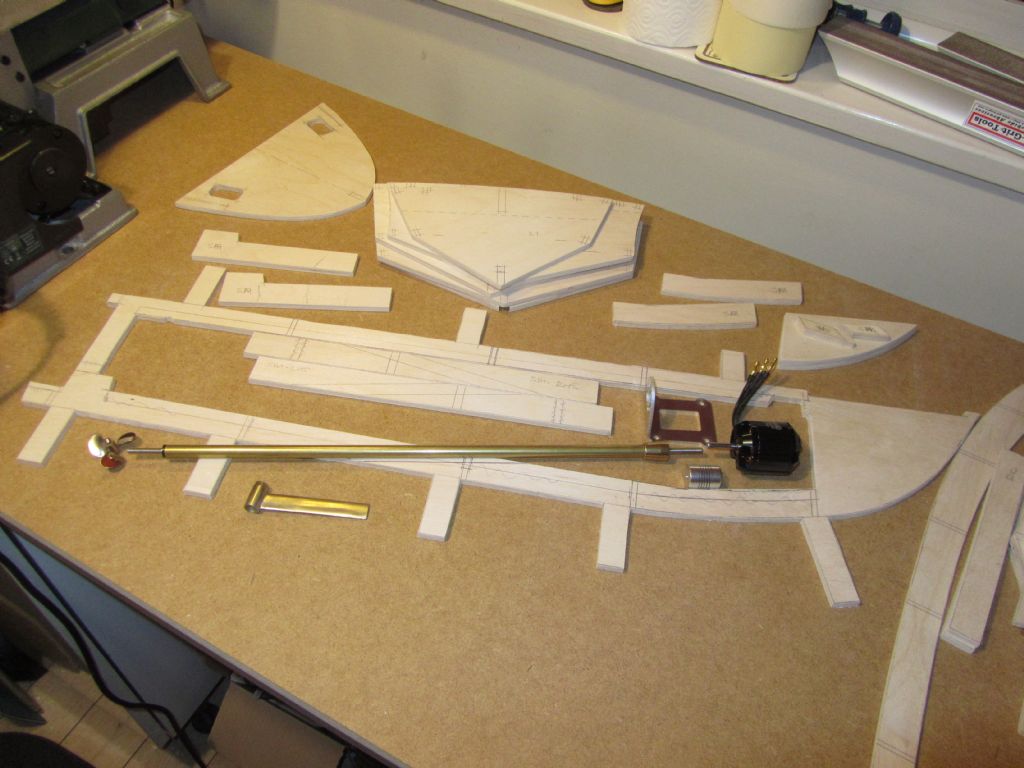

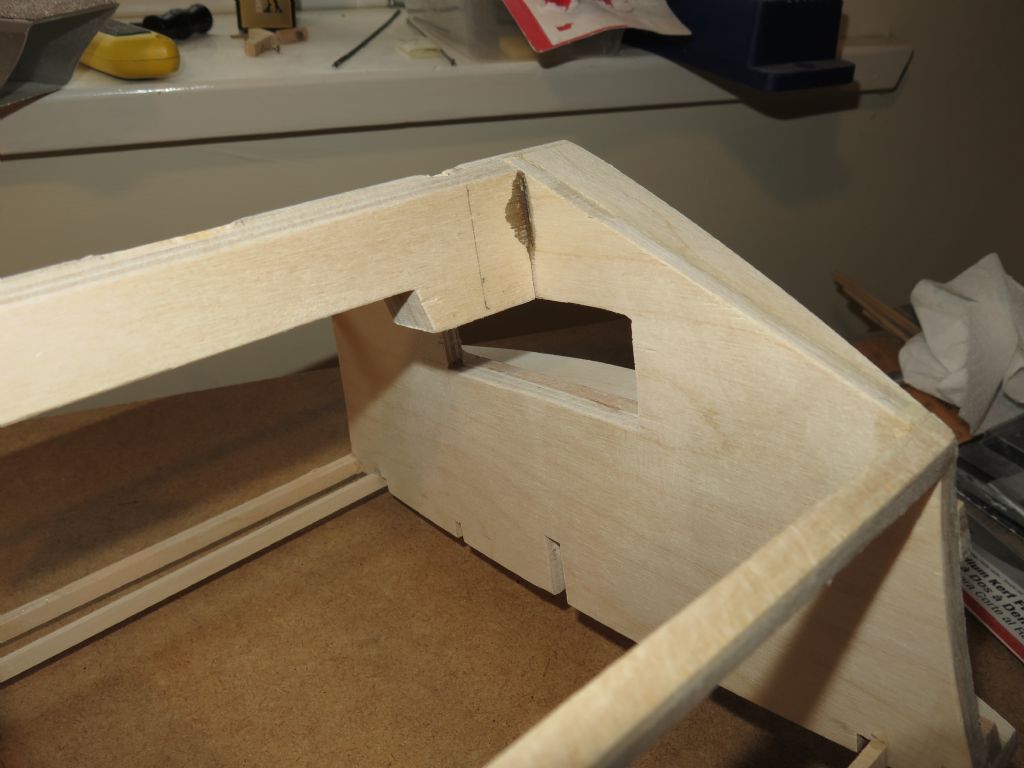

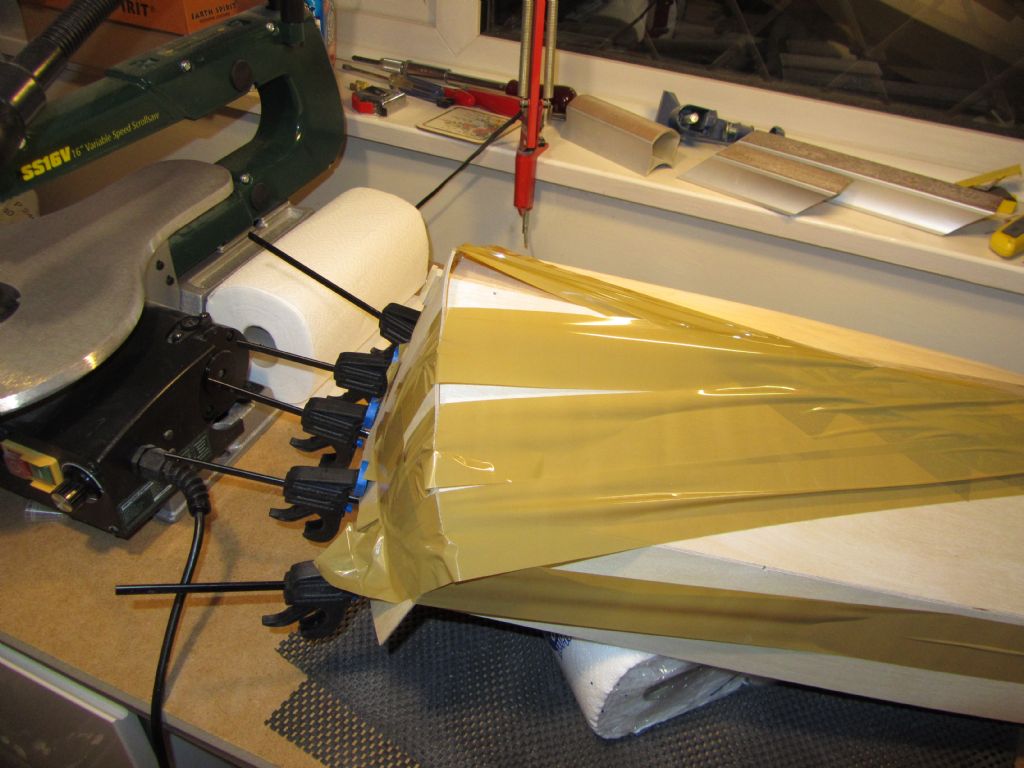

I made quite a few tweaks to the drawings before I was happy with printing them and today I made my first tweak to the parts. The final positioning of the prop shaft was after I’d decided on the frame positions and drawn-up the frames and I subsequently found that the prop shaft cut through the keel at one of the frame positions (see photo). The doublers were going to butt up to this frame and once all glued up would probably be fine. But why take the risk? So, I’ve cut new, longer doublers, to span completely over the prop shaft cut out and have widened the slot in the bottom of the frame as per common practise.

So all parts are almost ready for the hull, just need the cut-outs doing for the stringers and will be ready for gluing.

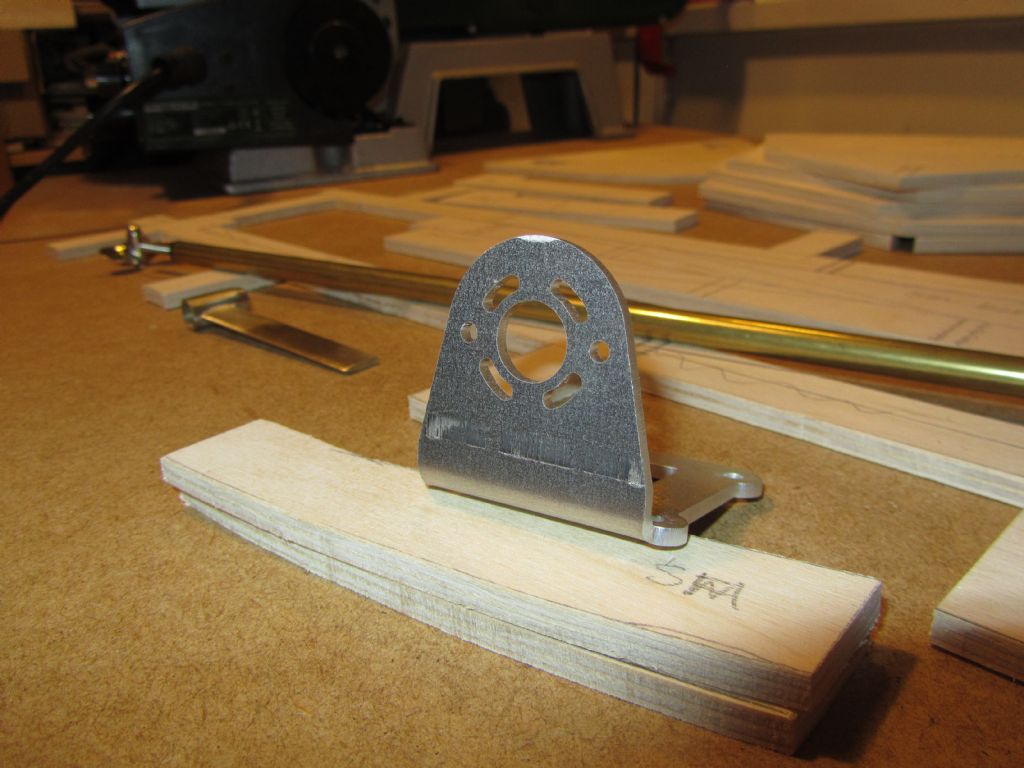

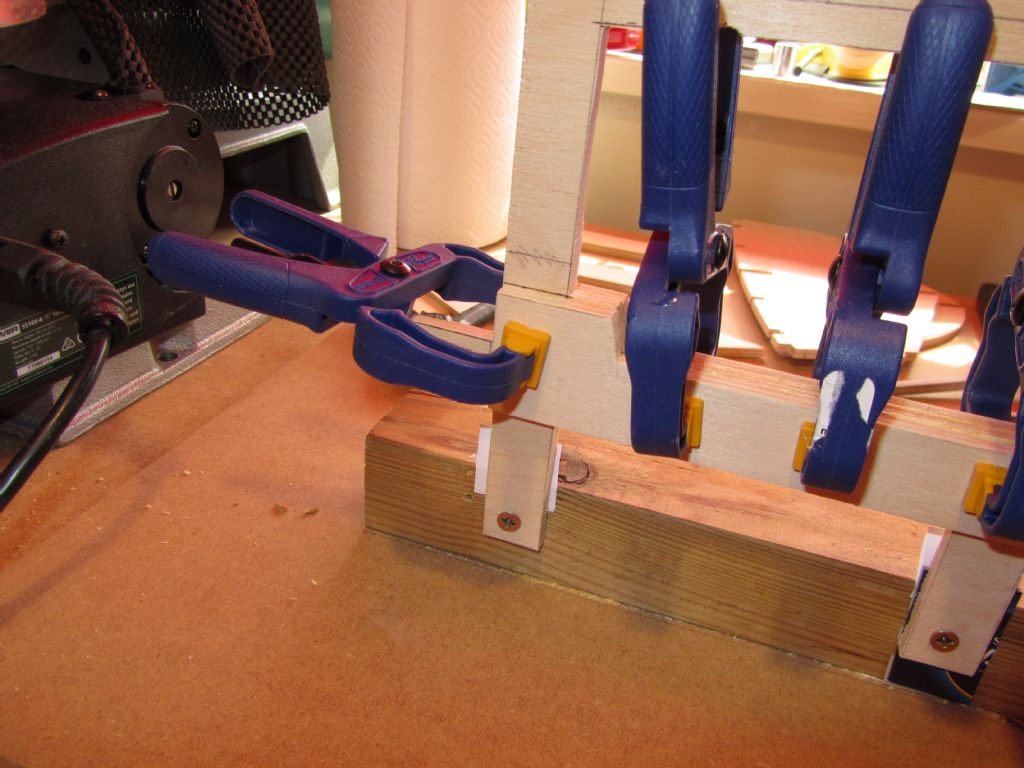

Photos are:

Ply cut-out and sanded and prop shaft etc. laid out. Note the longer doublers.

Goodies from Protean Design. Was expecting the P bracket to be the usual formed from brass strip so this was a nice surprise. Prop as usual is lovely.

Motor mount needs some fettling and holes countersunk.

Chris