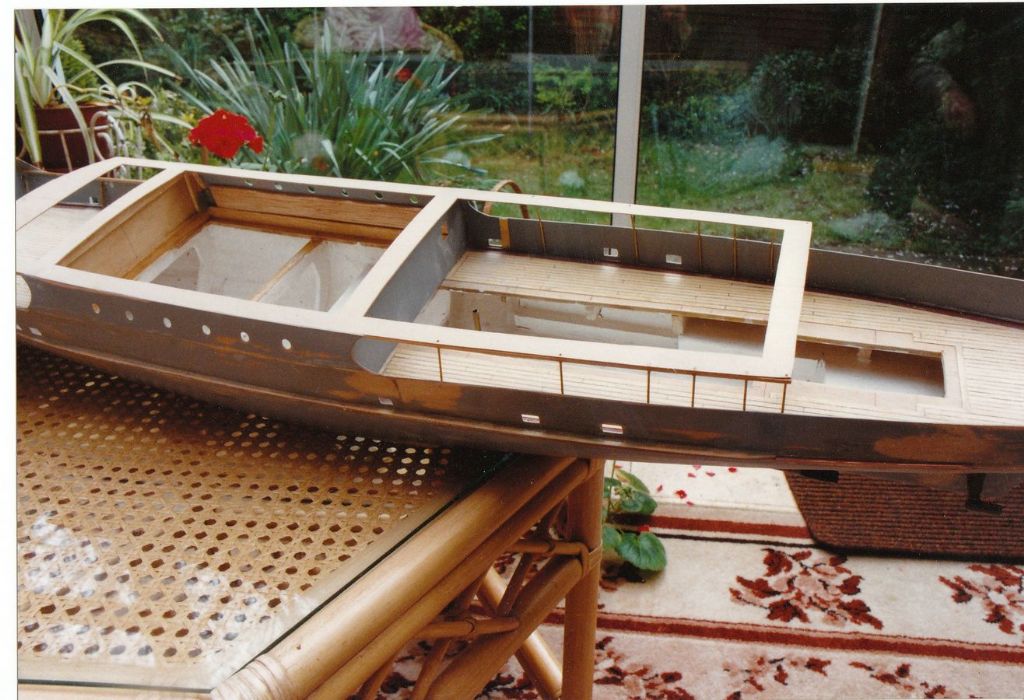

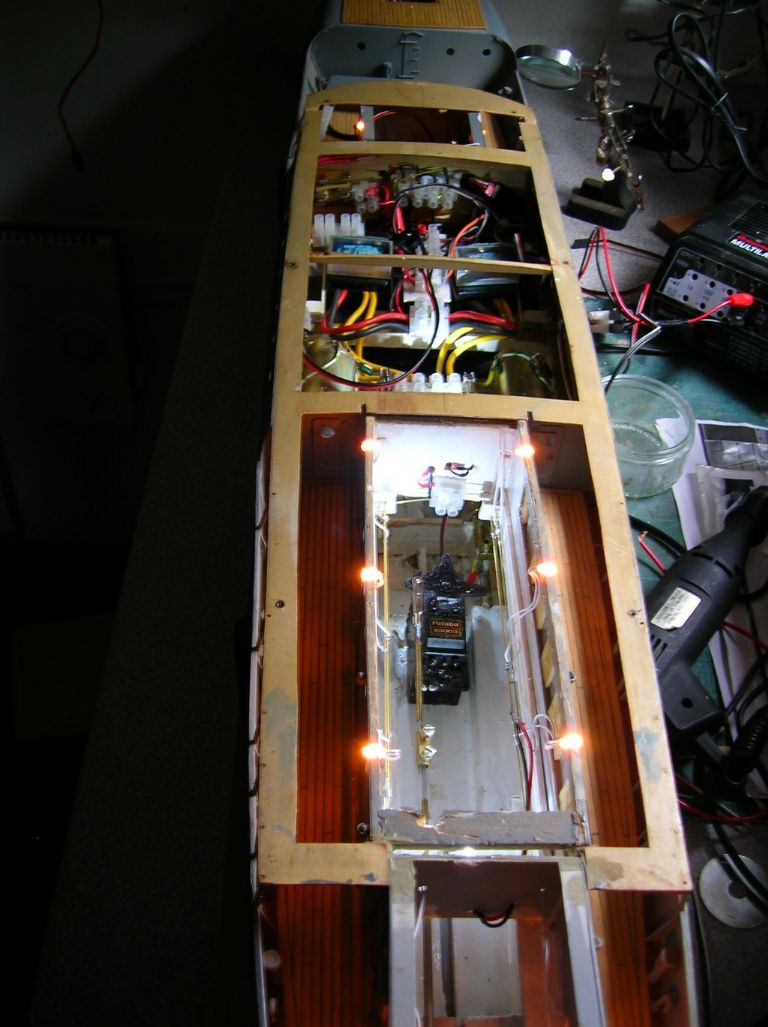

Usually once you have built a boat that is it but I am currently resorting to major surgery on an unfinished project. I have four of these on the go at the moment and having put the new Special issue of Model Boats to bed thought I would actually do some modelling at last. One long standing project is a 1:48 scale model of the fishery cruiser Brenda. I originally started this back in 1992 just before I got involved in full sized sailing so the model has sort of been on the shelf ever since although it has the motors and R/C installed and kept in working order. It has been sitting on my work bench ever since so I thought I would make an effort to complete it.

The prop shafts and tubes were made for me by my late, very good friend Ronnie Lawson and somewhere along the way I managed to bend the port side tube while installing it so while the starboard one purrs away very nicely the port one screeched for no obvious reason. Something would have to be done! Unfortunately the tube was deeply buried in the model hull and only partially accessible at the inboard end .My initial efforts concentrated on exposing the tube within the model with some brutal applications from a power drill and attempting to adjust it to allow the shaft to run with less friction. This was unsuccessful as only the newly exposed part of the tube could be bent and it was of thin wall brass so eventually I managed to tear holes in it with the Dremel and totally ruined it. So what to do?

Obviously, like an impacted wisdom tooth, the defective tube would have to come out but not easy without damaging the model as it was very firmly epoxied in. I dug out as much as I could from the inside and then applied the traumatic effect of a hammer to the outside. Eventually the tube moved whereupon I applied a pair of pliers to the outside crushed and twisted and pulled it free. It eventually gave up the struggle and came loose without too much external damage to the hull, much to my surprise. The next step has been to clean up and slightly enlarge the hole ready for a replacement. I have ordered an 11 inch tube and shaft from Cornwall Model Boats which should be a straight swap for the tube although I will use the existing shaft as it is much longer and supported by an A frame at the stern of the model.

So, now awaiting the replacement tube and relieved that more damage wasn’t done in extracting the old one which is not something you would expect to do in a scale model!

Wait for the next thrilling instalment.

Colin

Edited By Colin Bishop, Website Editor on 11/04/2015 18:24:01