OK Neil, first that is a superb model to put the Gemini in, although you will be denied the pleasure of watching the engine operate. It is a powerful slide valve engine though and deserving of an unusual and attractive model.

Unfortunately my spec sheet does not include the Gemini so I assume it was published prior to the Gemini being released however we might be able to pick the bones of it if you can measure the diameter across the end plate. I expect it to be either three and a half inch or four and one eighth inch. If you could also measure the length of the boiler that should help us to identify it and therefore the designed working pressure.

As for assembly, on the end of the pipe that comes from your gas tank you will see the nozzle. This fits into the fitting on the side of the burner and is held in place by the grub screw. The position of the nozzle determines the air/gas mix so you light the burner outside the boiler and slide the nozzle in and out to give you the best flame. When it is the best nip up the grub screw. I would start with the tip of the nozzle half way across the air hole. You might have problems with a dirty and blocked nozzle orifice if it has not been used for a long time, in which case blow back with compressed air. Do not use anything physical or you may bruise the orifice and the nozzle is ruined.

If the boiler has been sat for a long time I would recommend pickling it. This is just an acid clean of the internal surfaces. I use coffee machine cleaning tablets. Ideally you should remove the boiler, strip everything off, including the lagging and put it in a bucket of boiling water, add the tablets and then pump the hot liquid through the boiler with some sort of small pump. If you don't fancy that, mix up a couple of tablets in hot water and pour it into the boiler. Leave to cool then flush through with a small pump and fresh water. When done remove the cap on top of the sight glass and force some fresh water through under pressure to ensure that the sight glass connections are clean and free of sludge.

So clean boiler, fill with water to three quarters of a sight glass, close the outlet valve, fit the burner, turn on the gas and ignite from the top of the funnel. All you want to do at this stage is ensure the boiler raises steam, there are no leaks, the pressure gauge works and the safety valve lifts at no higher than the working pressure then keeps the pressure below working pressure plus 10% with the burner on full. I will let you know what the working pressure should be when you give me the dimensions.

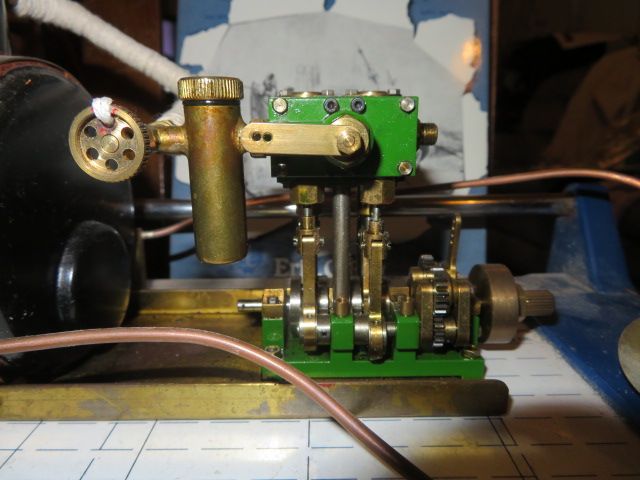

Now we can turn to the engine. If it has never been run it should be run in, if it has been run it should be OK. Again ideally I would recommend a strip down, clean and reoil everything but if everything looks well oiled and it turns smoothly you probably just want to have a crack at it. I would recommend however that you at least run it on compressed air first, just briefly, to check that it runs OK. This will help you to determine the correct positions of the reversing lever and the throttle before you start playing with hot steam. Empty the displacement lubricator of anything there may be in it, then fill with fresh steam oil. Liberally oil all external surfaces with normal engine oil.

Now we need to check that the separator is empty. Connect a large syringe to the stub pipe on the top surface towards the edge. Use a couple of inches of the silicone pipe that you already have connecting the two stubs. Draw on the syringe. If you get any mucky oily water out keep sucking until it is empty. Then stick a small brass screw into the end of the pipe and leave it connected to the separator. If you do not seal this pipe you will get exhaust steam coming out of it when you run the engine. Then connect the separator inlet to the engine outlet, the hose goes in the side of the separator, then connect the separator outlet, which I believe is the centre connection, to the pipe that sticks out from the base of the funnel.

So time to give it a go. Fill the gas tank, you will need a Ronson type filling valve to screw into your disposable bottle of 70-30 Butane/Propane camping gas to fill your gas tank. Turn the gas on, ignite at the top of the funnel, close the steam outlet valve and wait for pressure. Ten minutes should be more than enough. Set the throttle to zero and the direction lever to one way or another and open the steam outlet. Check no leaks. Very slowly open the throttle valve. There will be a slug of water first that will spit all over the place but your engine should then settle down to a nice quiet ticking over. Stop again and reverse before trying again. Play around until the water gets to the bottom of the sight glass then call it a day.

You will need to check that you have used most of your steam oil for one fill of the boiler. The oil in the lubricator should have been replaced by water so you will need to syringe the water out and put fresh oil in for the next run. I don't think your lubricator is adjustable nor does it have a drain fitted.