Thanks you very much again, Gareth! I'll keep that in mind when adding the ballast!

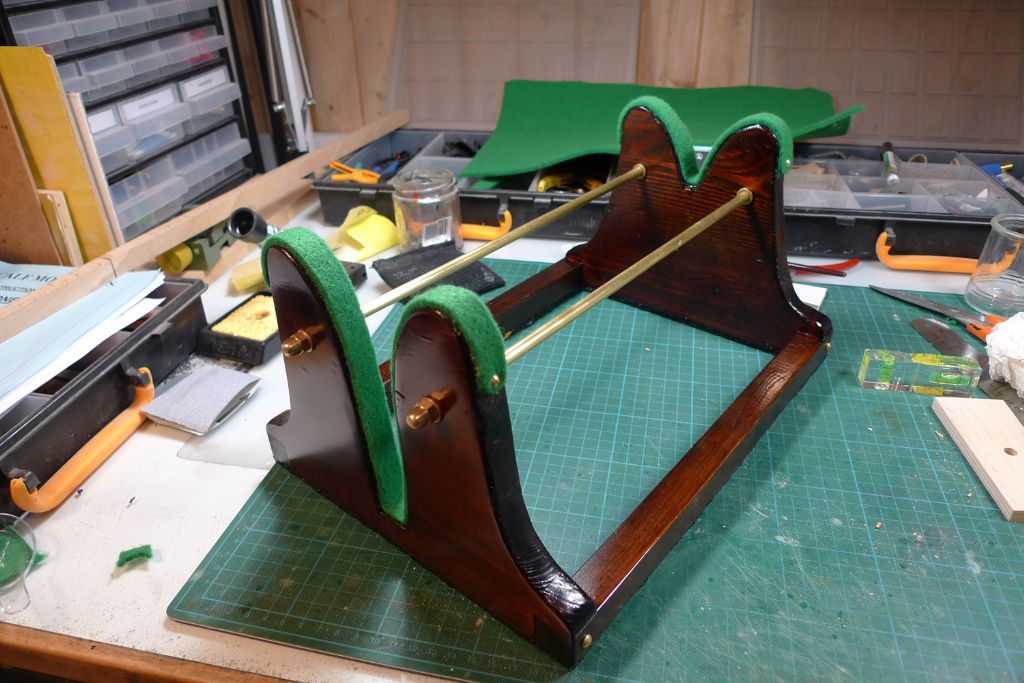

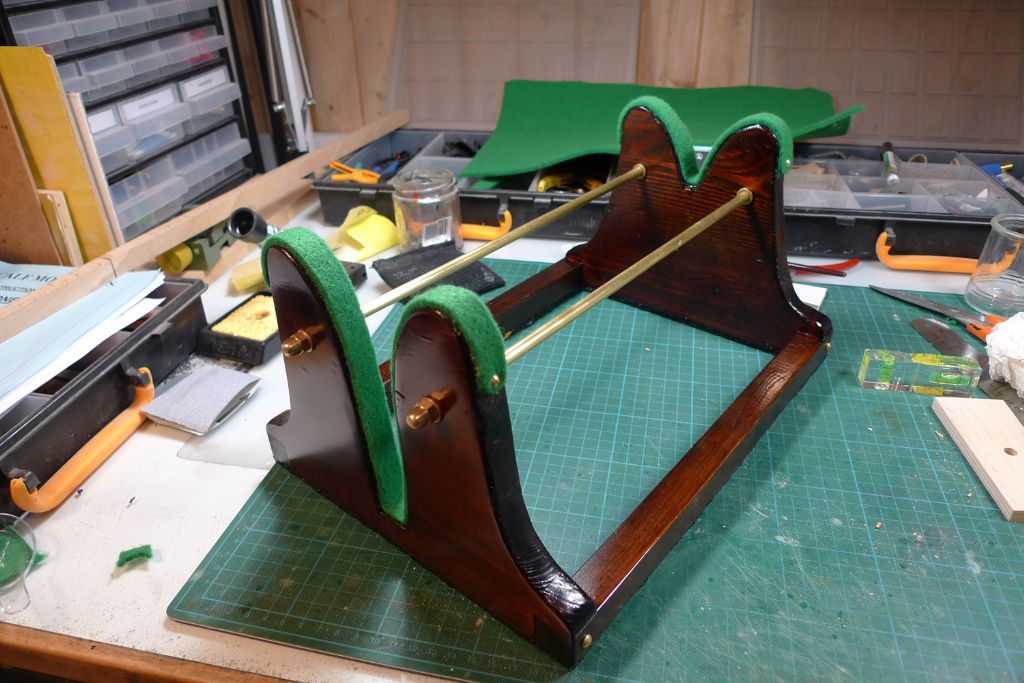

In the meantime, I have continued adding coats of varnish to the stand until, after the 25th one, I was satisfied with the result.

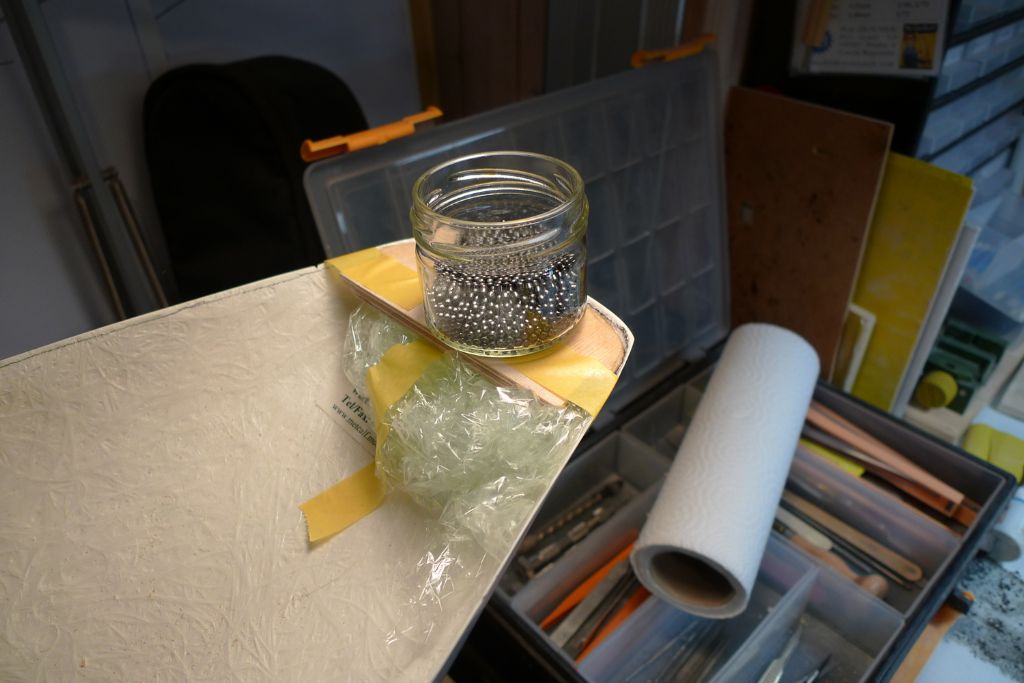

Next up, I cut out some strips of green polyester felt, which I had previously tested for compatibility with water, as it is likely to get wet when the boat is put back on the stand after sailing. Happily (but also unsurprisingly, given the 100% polyester) even several hours of soaking did not change or affect the felt, nor did it, when wet, give off any colour.

Anyway, I first glued it down under weights at the bottom of each cutout, and left the glue to set …

… after which the ends were trimmed and rounded off, the remainder of the felt glued down and the ends further secured with brass screws.

This finishes the stand that, as can be seen, fits the hull nice and tight.

And so, finally, on to the actual build!

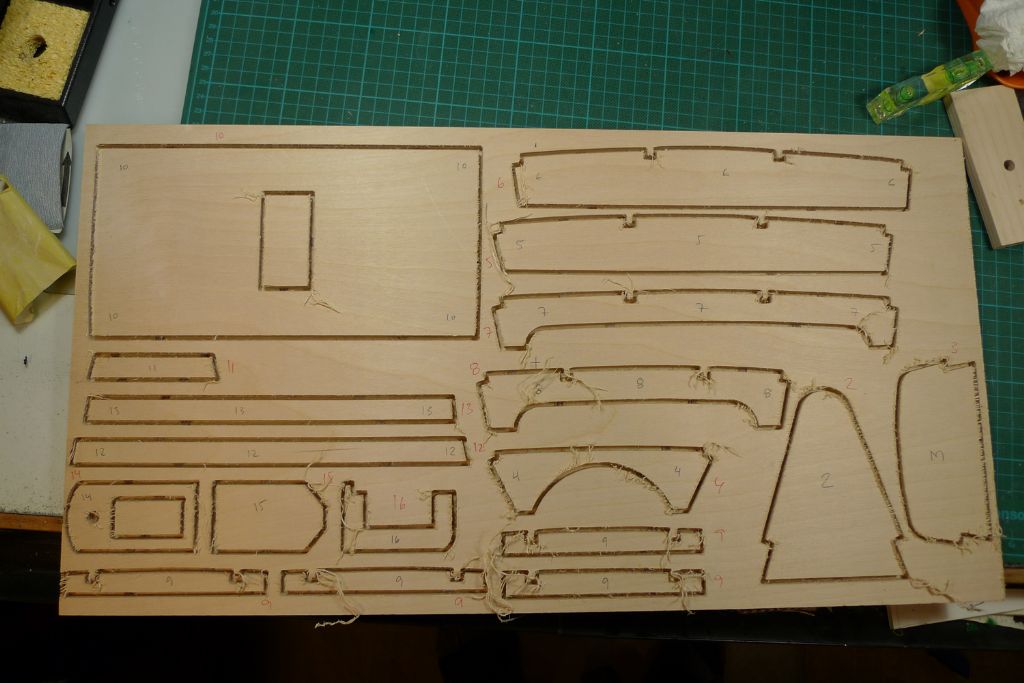

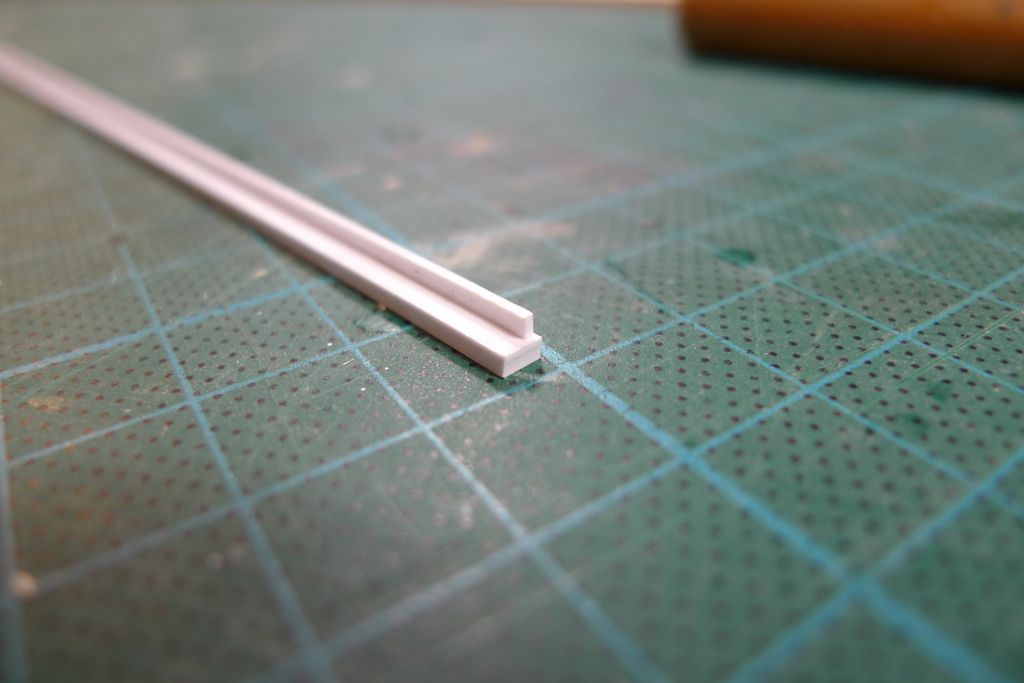

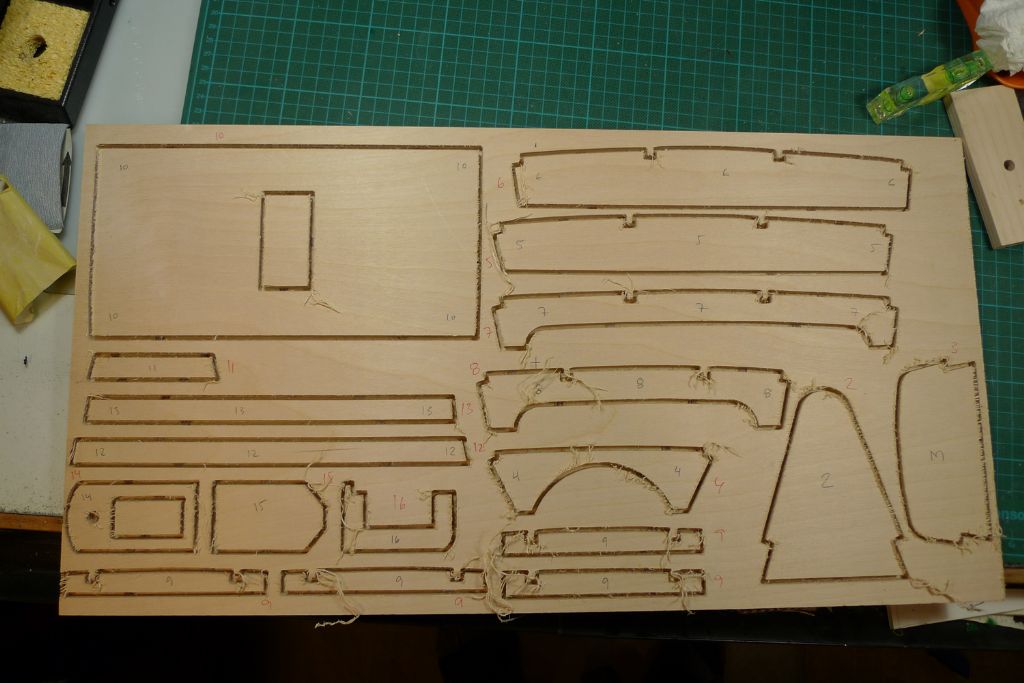

First job here was to cut out the deack beams and other interior struts, strengthenings and structures from the CNC-routed plywood sheet.

To separte the parts from each other, and for the rough cutouts along the grain, In used the scroll saw …

… and then cut off the remainder excess with a scalpel and/or pair of side cutters.

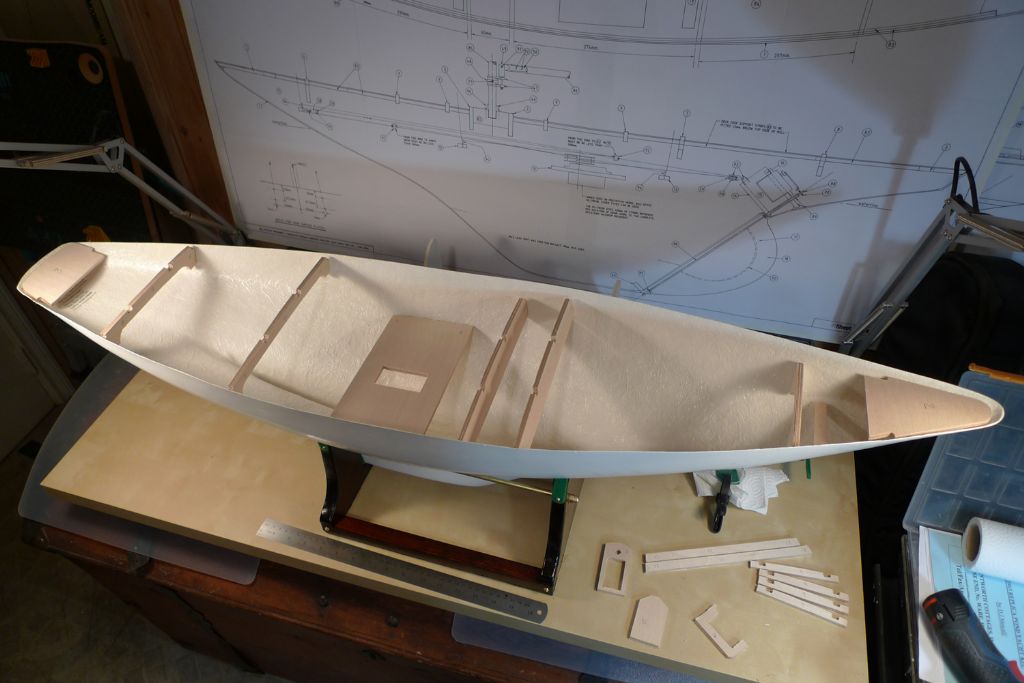

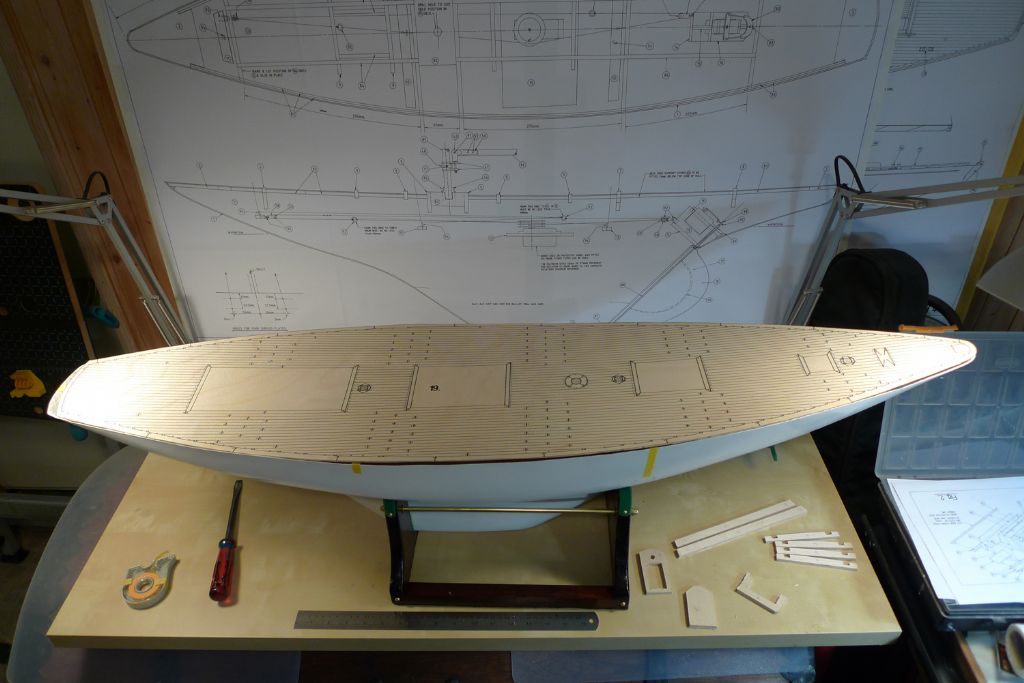

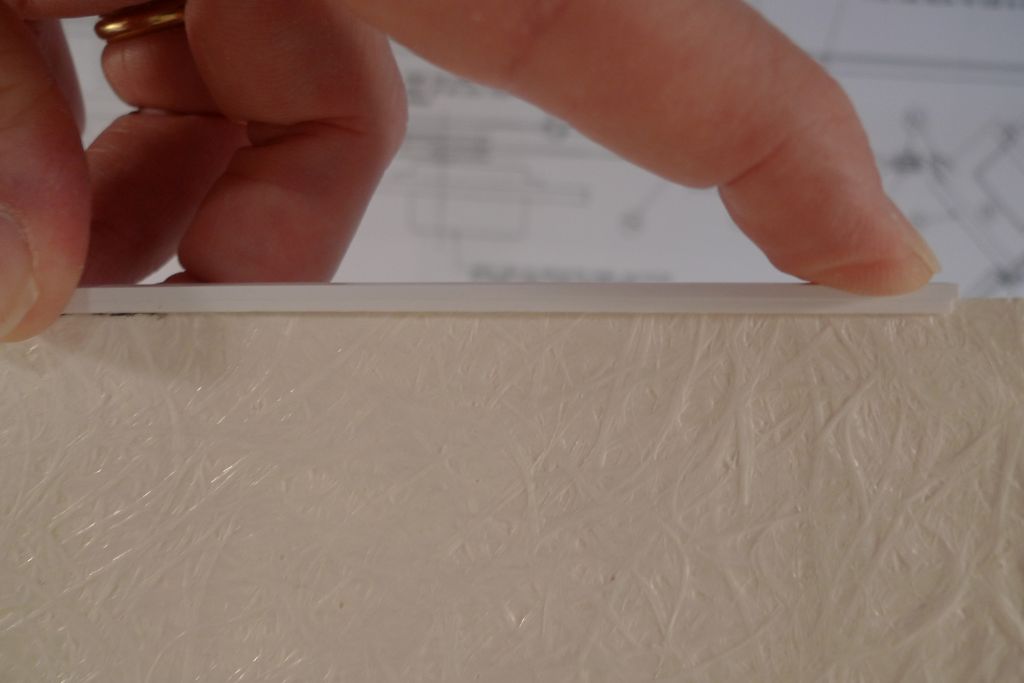

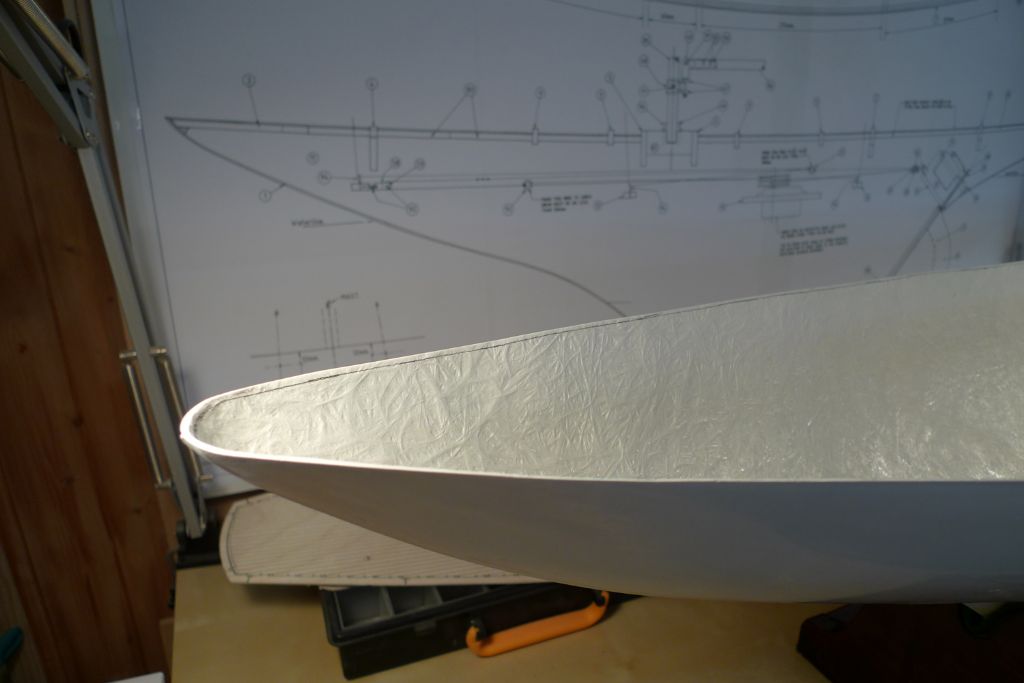

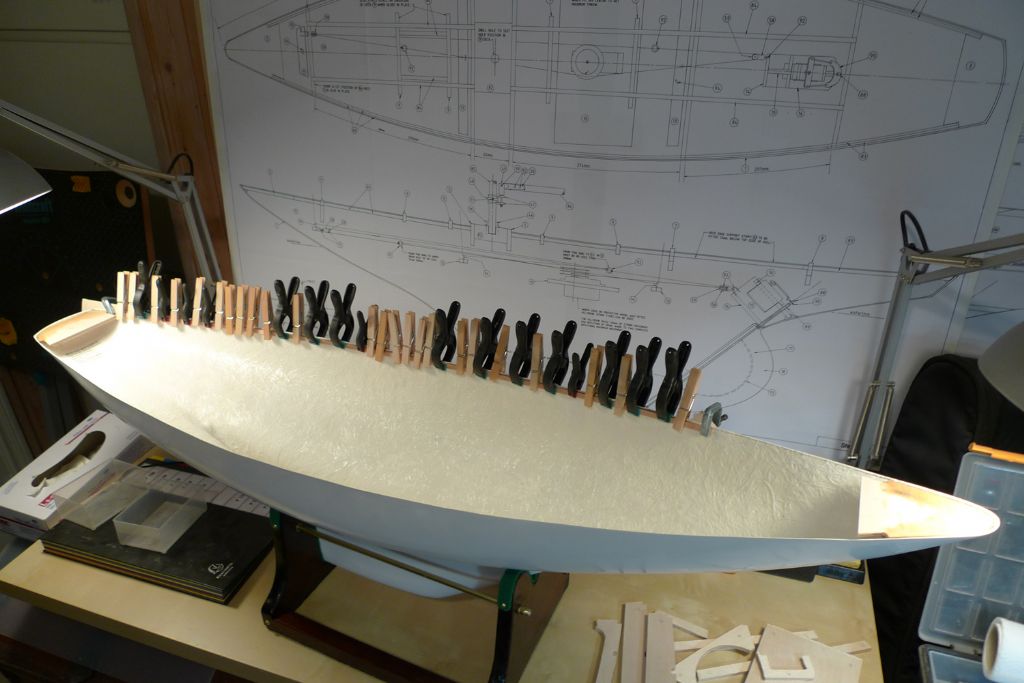

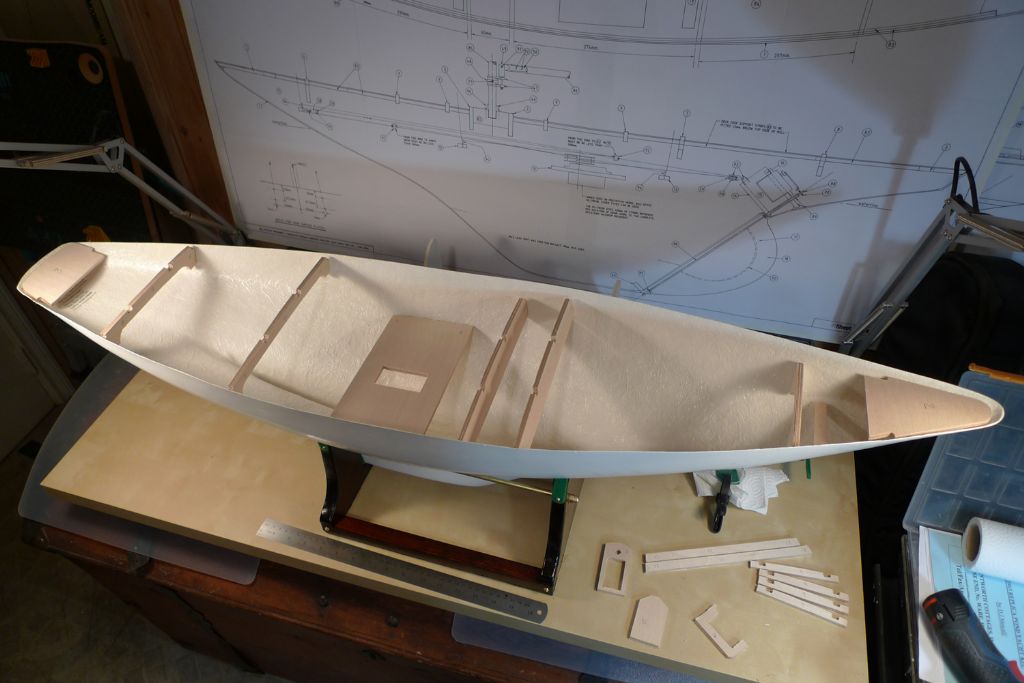

A quick dryfit of the deckbeams showed that most of the fits nicely, but that there might be a slight problem with the hull shape amidships, where beams 5 and 6 sit quite close together.

Atually, the instructions warn against the eventuality that the hull might get slightly out of shape between moulding and build, so the next step will be to measure very carefully to establish the exact position for each beam, and, while taking into account any necessary chamfering of the beam ends, check whether the hull side edges needs to be brought back in by taping them together for a while.

Remains to be seen, thus, and hopefully I will have enough time this weekend to do a proper job of it!

To be continued …

/Mattias