Well! At long last our 1:1 scale doing-up-the-lounge project is sufficiently advanced (if not fully finished) that the spare time availale to me is once more sufficient to include some model boat building

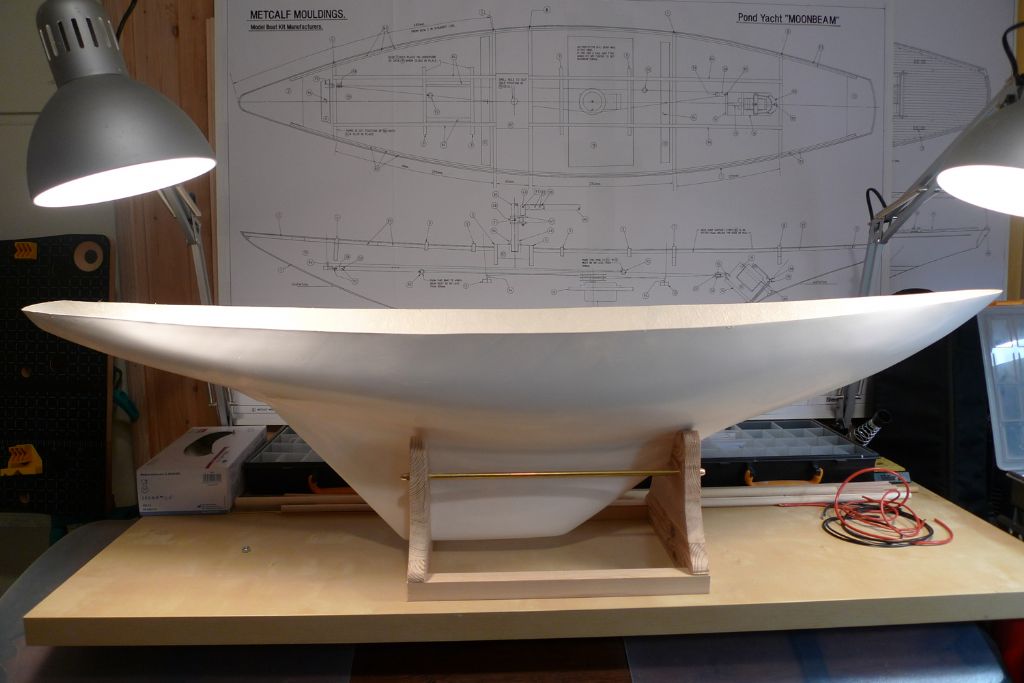

Last Sunday, I therefore put in afternoon of cleaning and sorting out my workshop, before breaking out the first of three upcoming build projects, namely the Moonbeam pond yacht kit from Metcalf Mouldings.

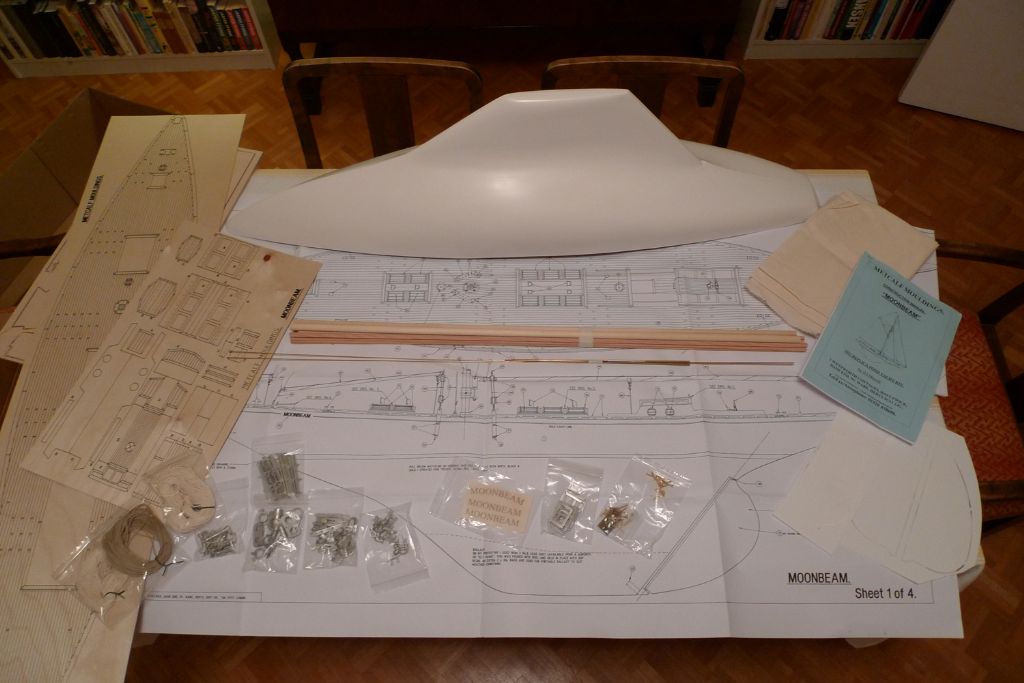

I actually bought this kit back in October last year, and it duly arrived in a fairly hefty double envelope cardboard box.

Inside the outer box was a smaller one, and inside that was (of course) the kit, very well packed, padded and protected.

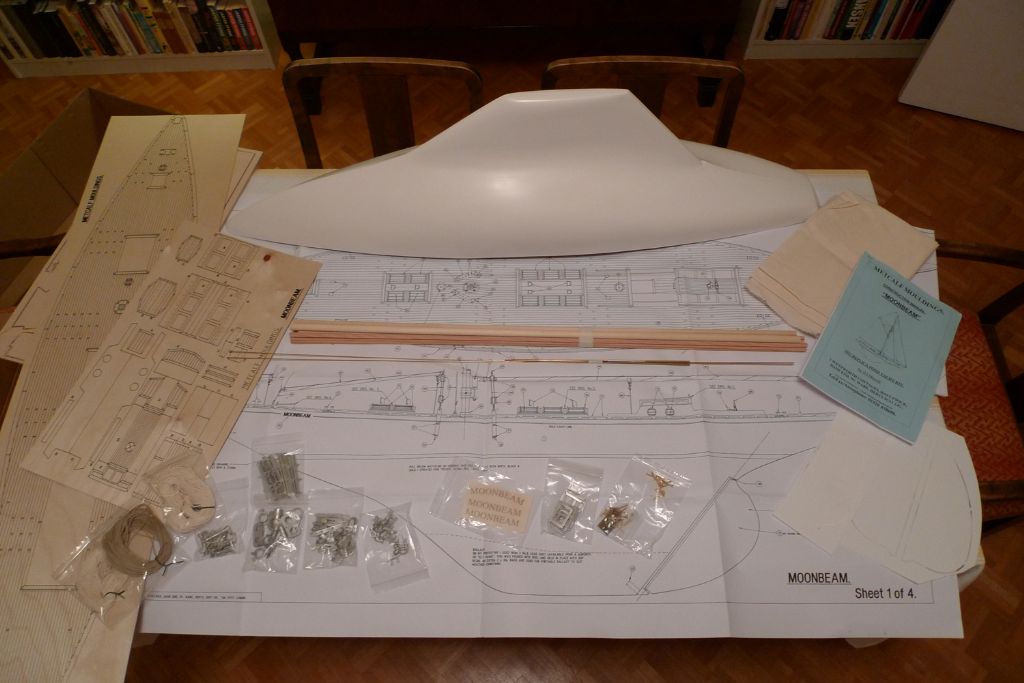

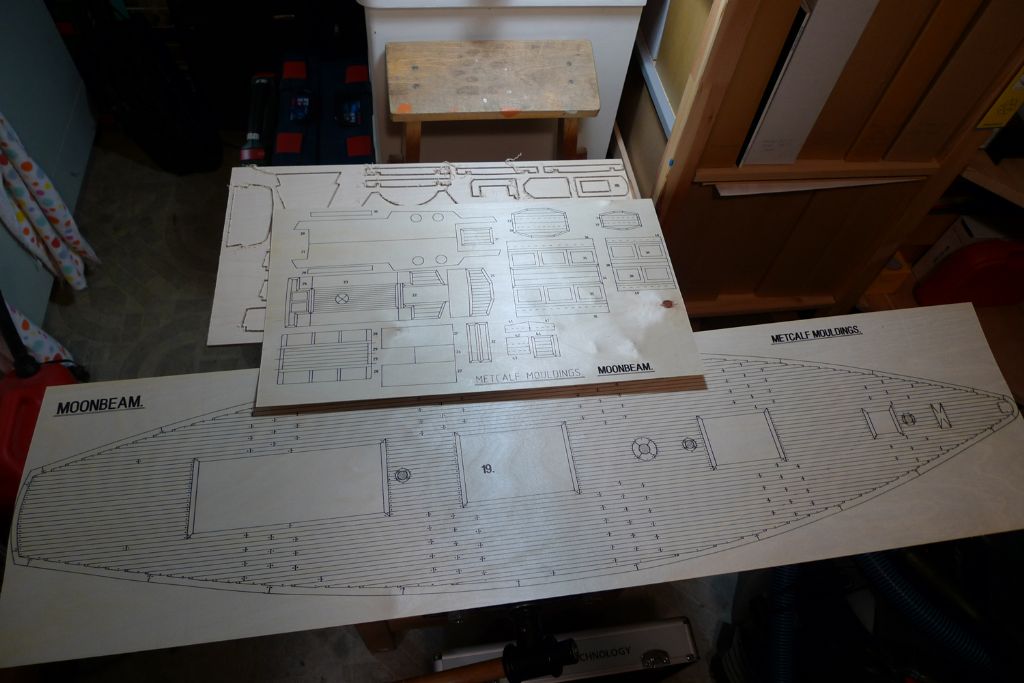

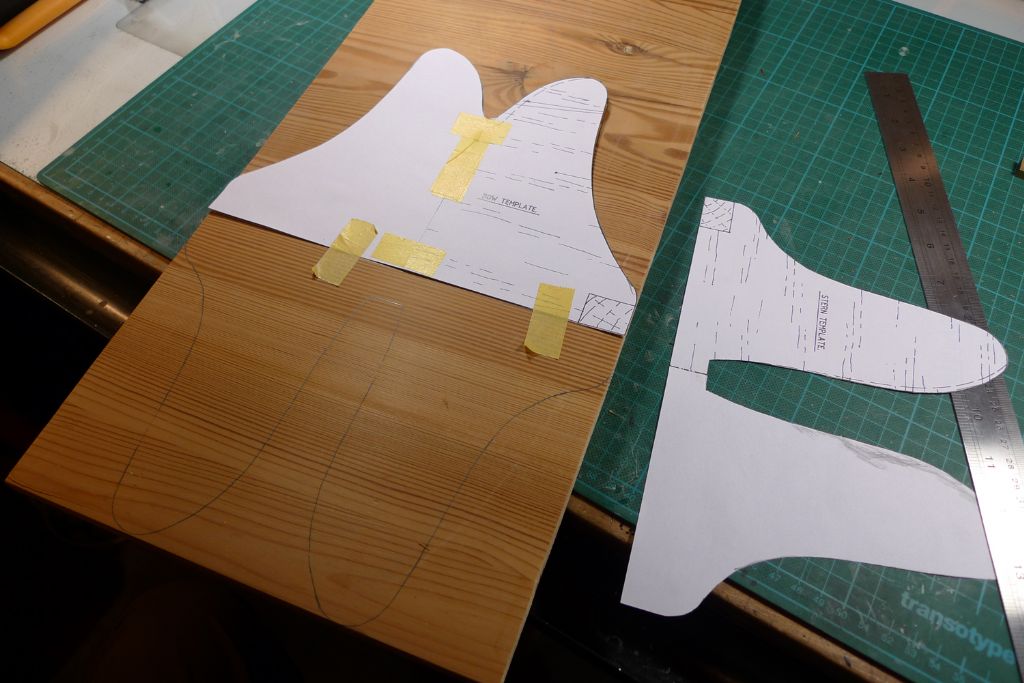

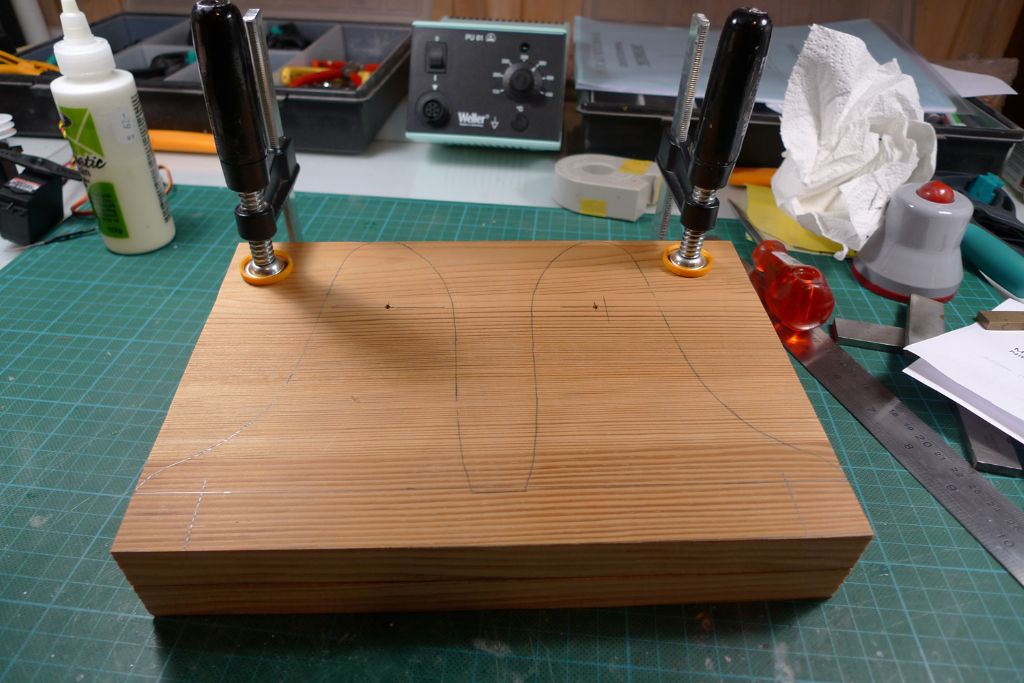

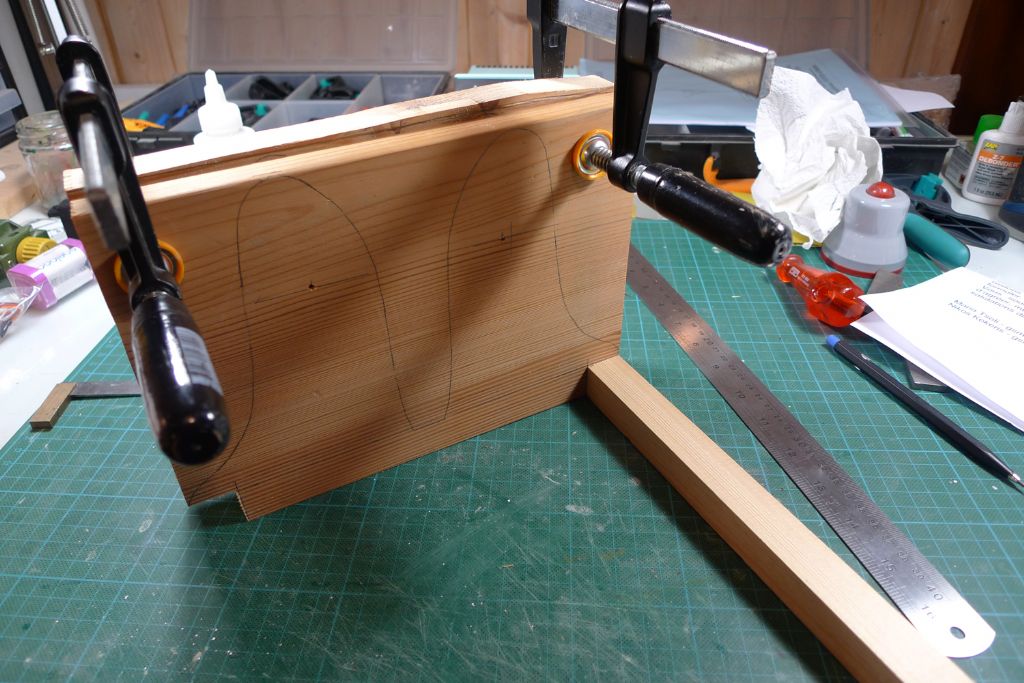

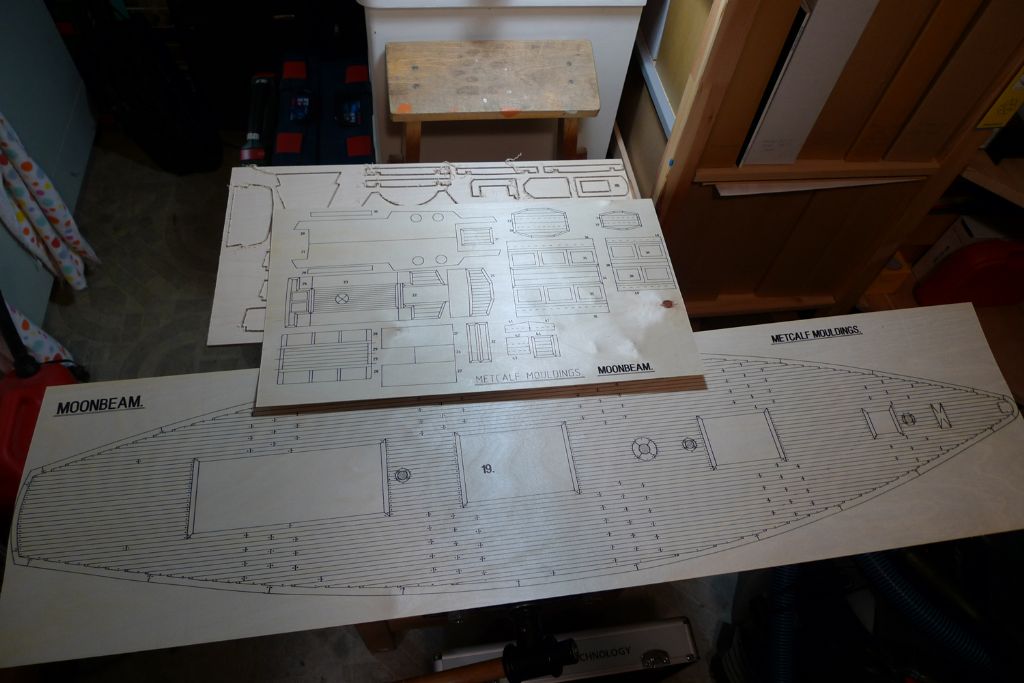

The GRP hull looked very nice indeed, and the kit also included laser cut and pre-printed plywood, dowel and wood of various sizes, white metal fitting, rigging thread, cotton fabric for the sails, four large, full-size plans and a booklet of building instructions.

David Metcalf had also separately sent me a cd-rom with some hundred or so photos from his prototype build.

Before I begin the build proper, I have gotten started on some of the preparations; I thus took the opportunity, while out carpet hunting for the lounge last Saturday, to also pop into Albatros Modelbouw (**LINK**) where I picked up a Spektrum receiver, a 4.8 V NiMH battery pack, a Hitec HS785HB sail winch and a Hitec HS645MG ultra torque servo.

On Sunday, with the workshop neat and clean, I then duly set up a new model memoryin the t/x, bound the new r/x to the t/x and tested the set-up, which (rather unsurprisingly, given the lack of complexity) seems to work just as it should.

I also unpacked everything …

… in further preparation.

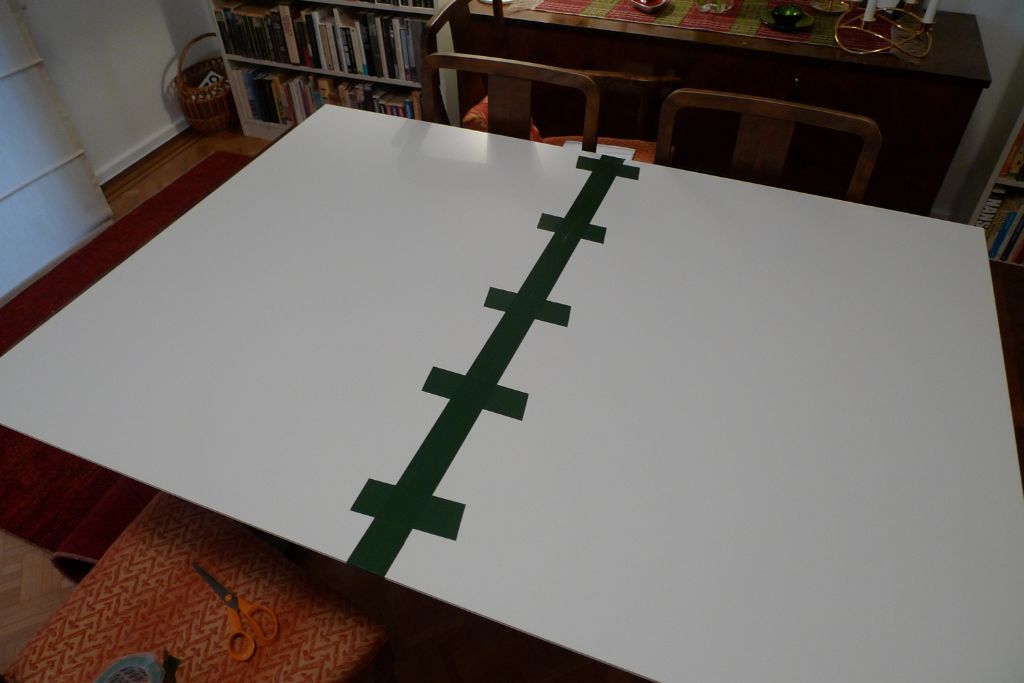

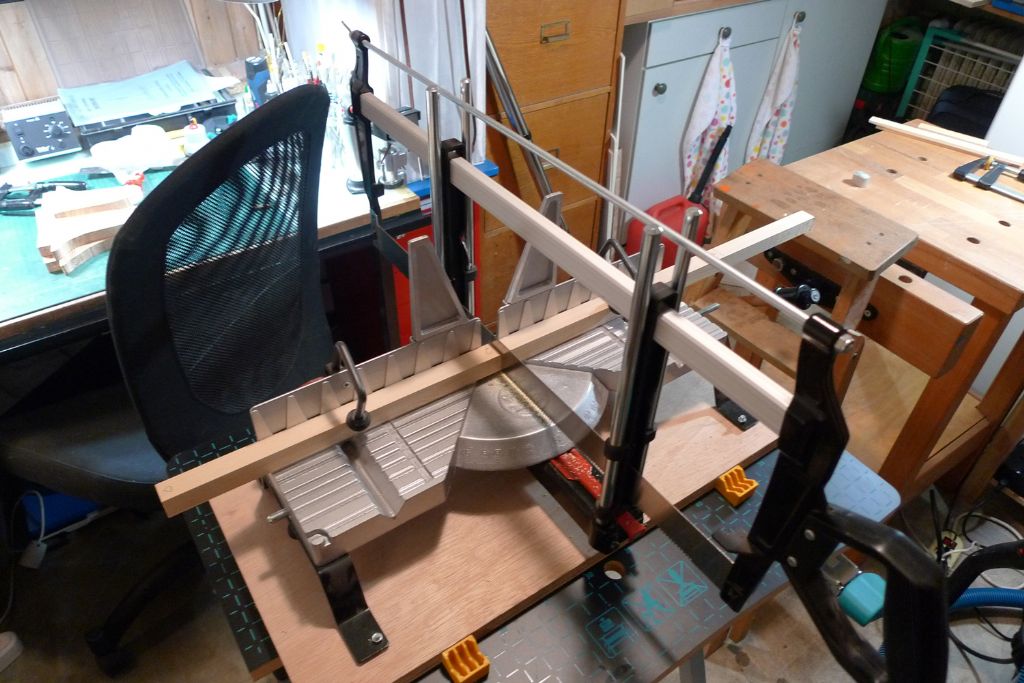

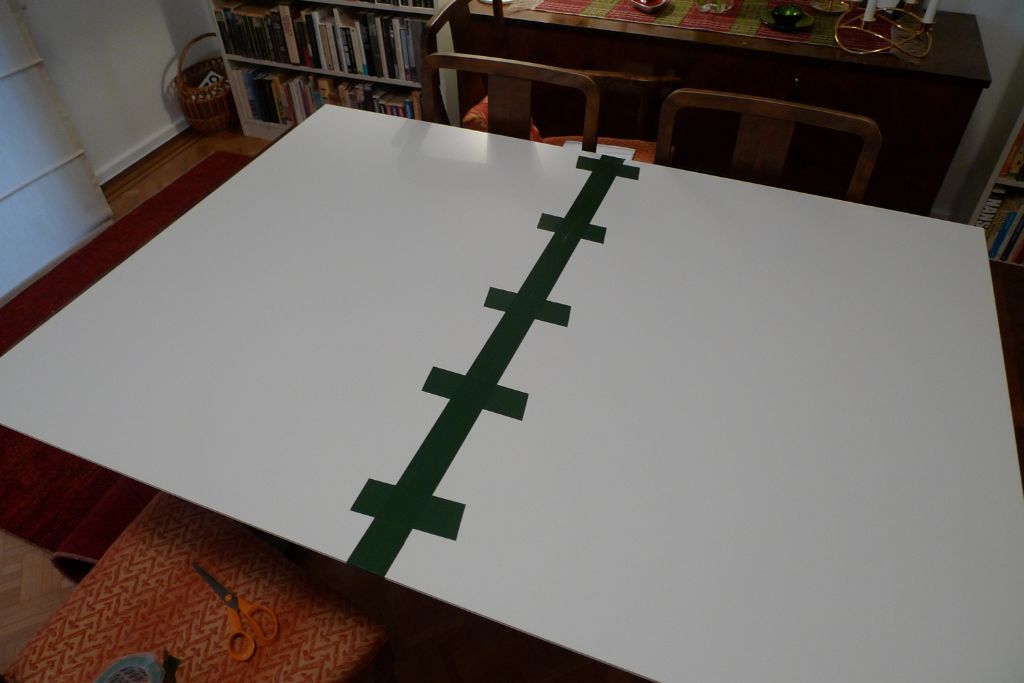

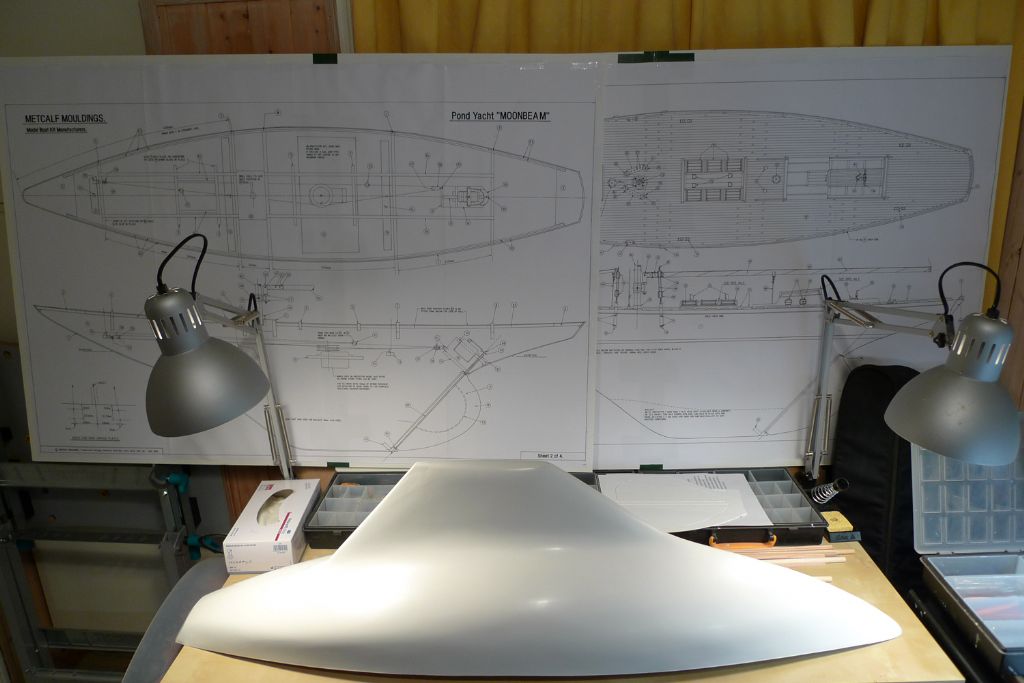

Monday, I picked up four 70×100 cm foam boards from an art supply shop, and proceeded to join these together, two and two, first with some toothpicks …

… and then with fabric-backed sticky tape, in order to form large enough boards …

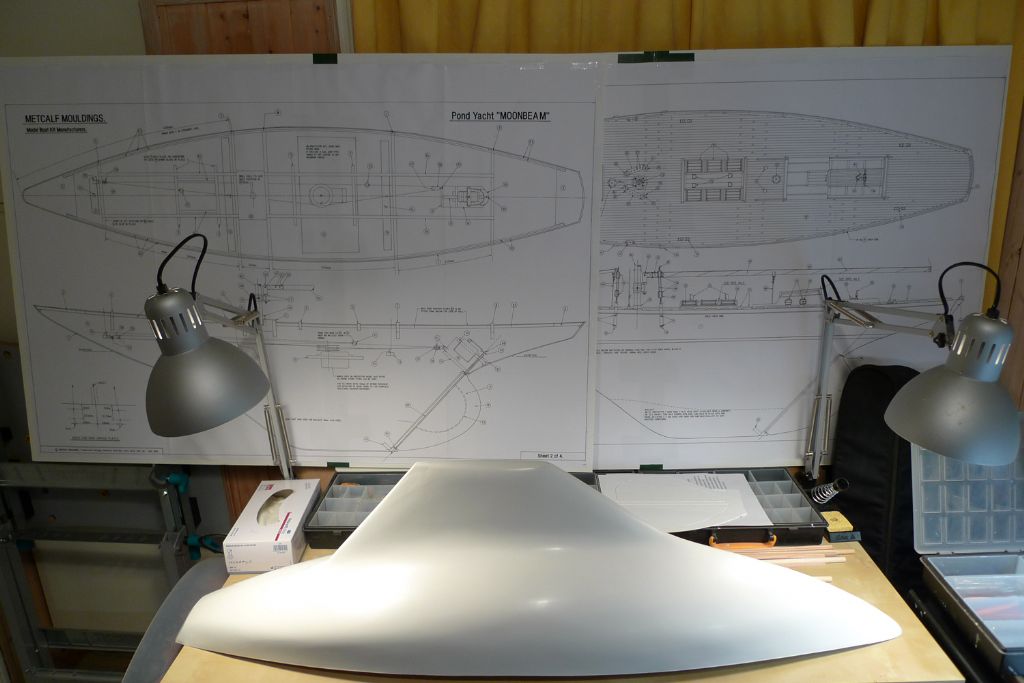

.. that the plans (which I'd first gone over with an iron on low heat to take out the worst of the folds) could be mounted flat on them and stood up against a wall for (comparatively) easy reference.

To be continued …

/Mattias

Edited By Banjoman on 09/03/2016 07:27:40

Edited By Banjoman on 09/03/2016 07:30:52