Hello Gareth,

Warmest thanks for your very helpful comments! As you will see below, I have adopted a similar solution to the problem of making sure the main skylight stays on, no matter what. But more about that further down!

As for the matter of the set-up of the shrouds to keep the mast from bending to much forwards, I think I'll keep things as they are until I've had a couple of trial runs, but if needs be, the idea of de-coupling the shrouds sounds well worth looking into! For my part, though, I think I would probably prefer to use the deadeyes for adjustment rather than add bowsies; mine are set up in such a way that it wouldn't be too difficult to use them in such a way … But we'll see once she's been on the water a few times!

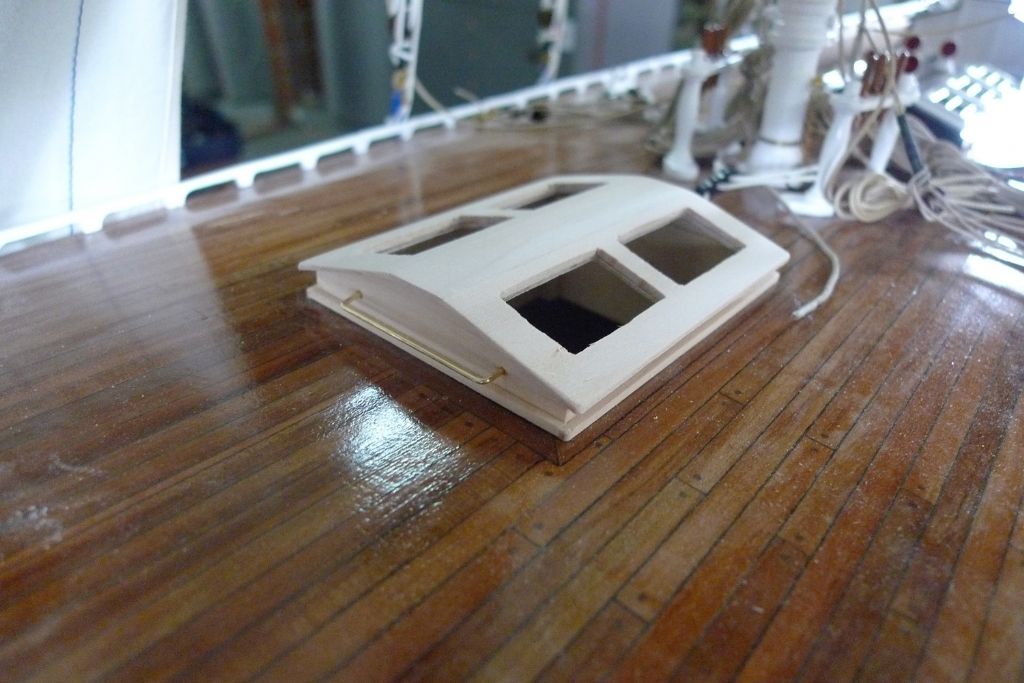

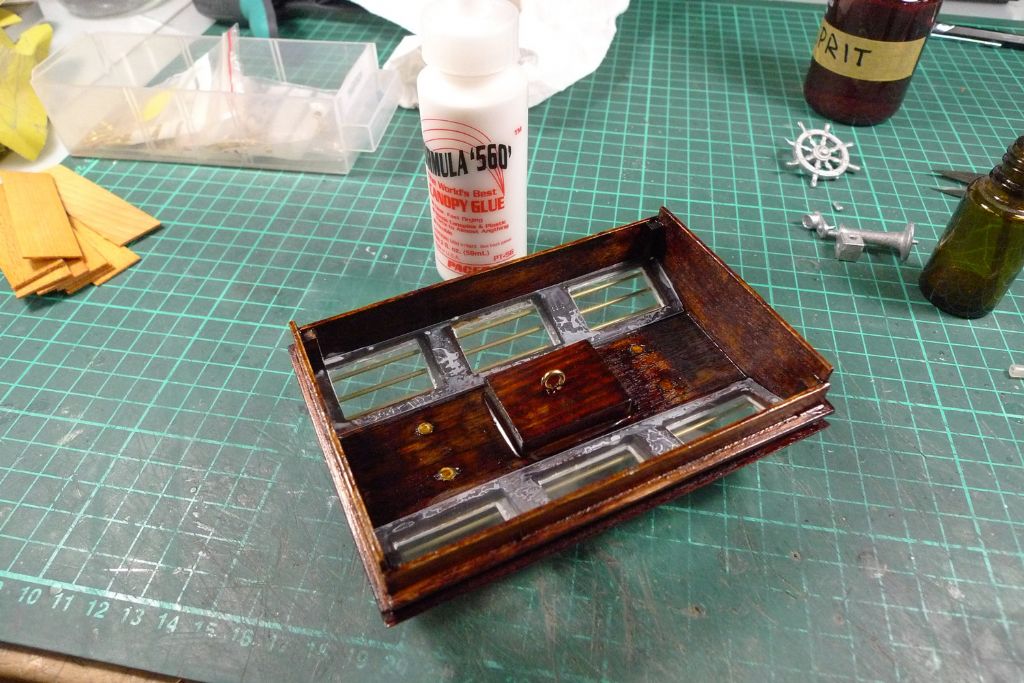

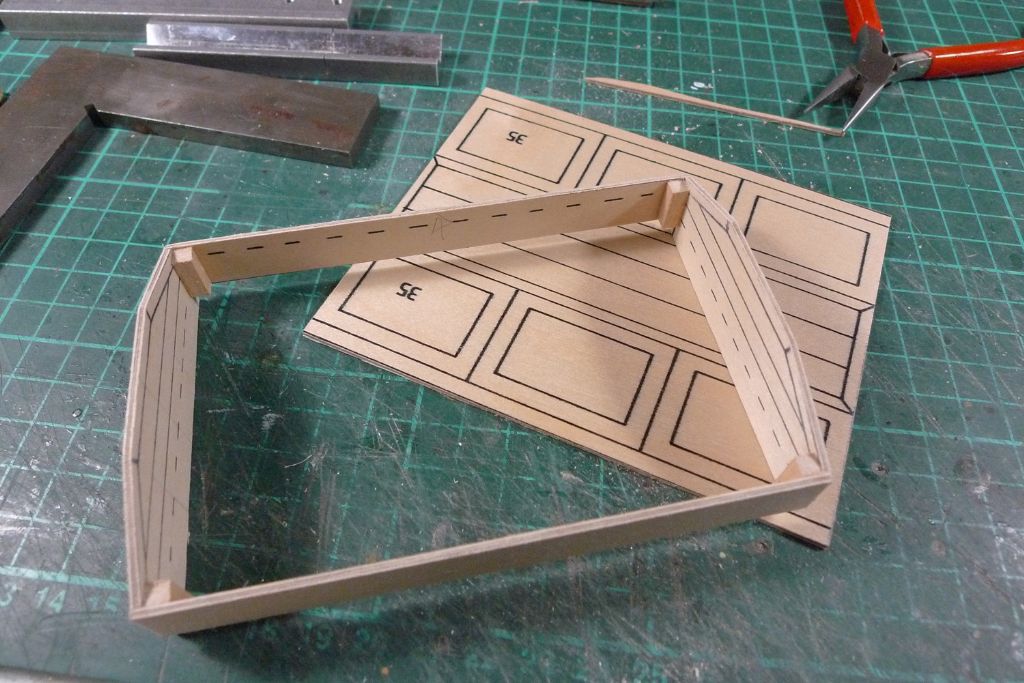

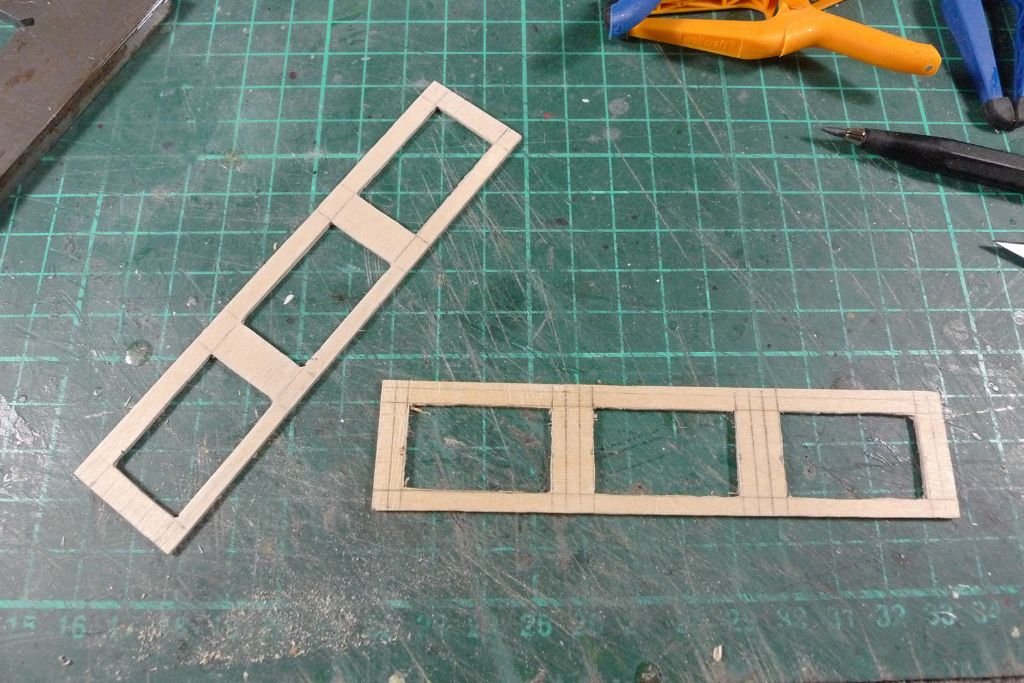

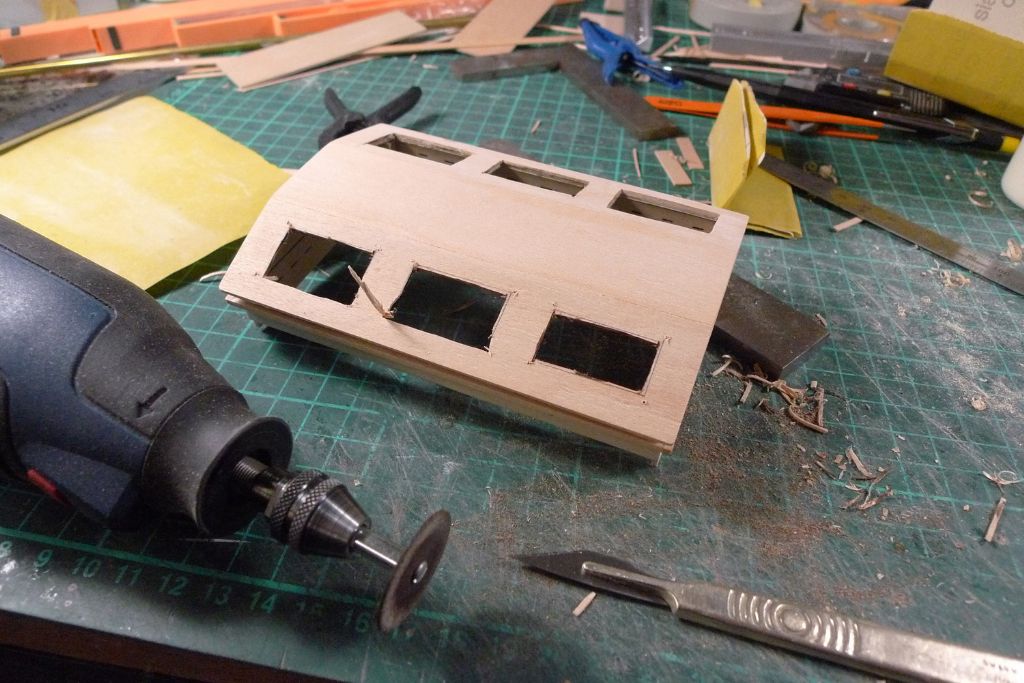

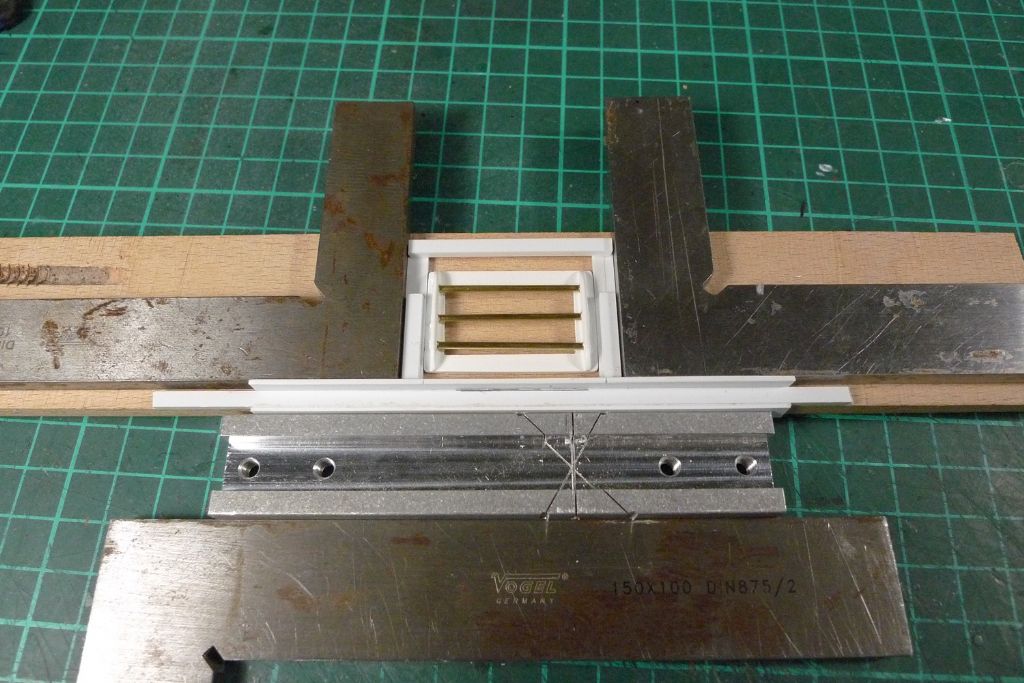

Anyway, back to the build! With the window frames in place on the forrard skylight as well …

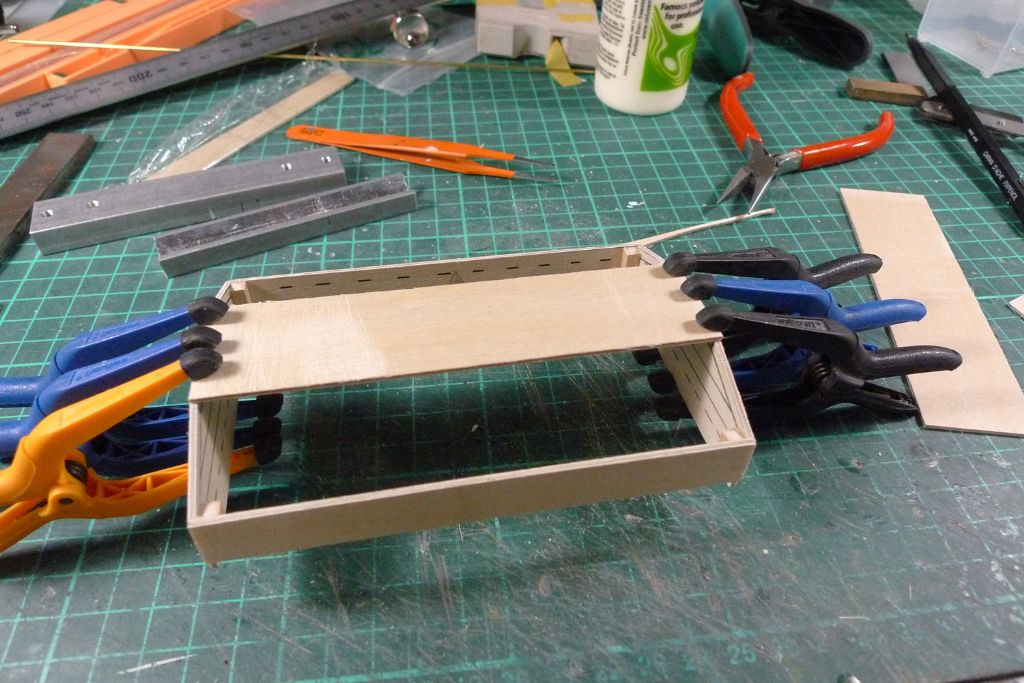

… it was once more time a-varnishing to go …

… until a total of eight coats of gloss varnish had been applied.

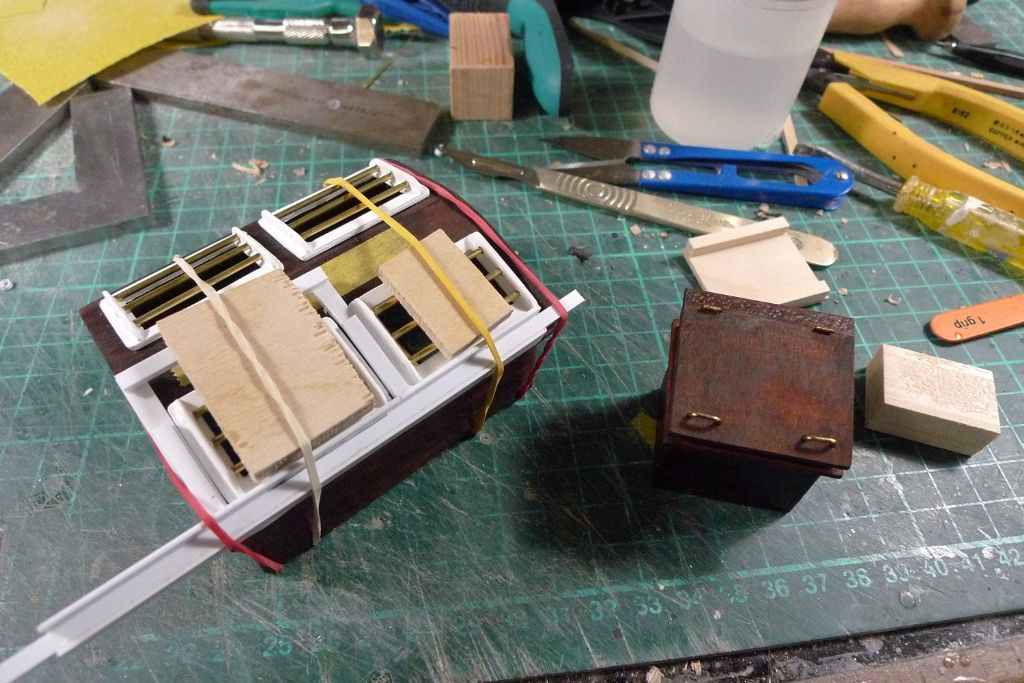

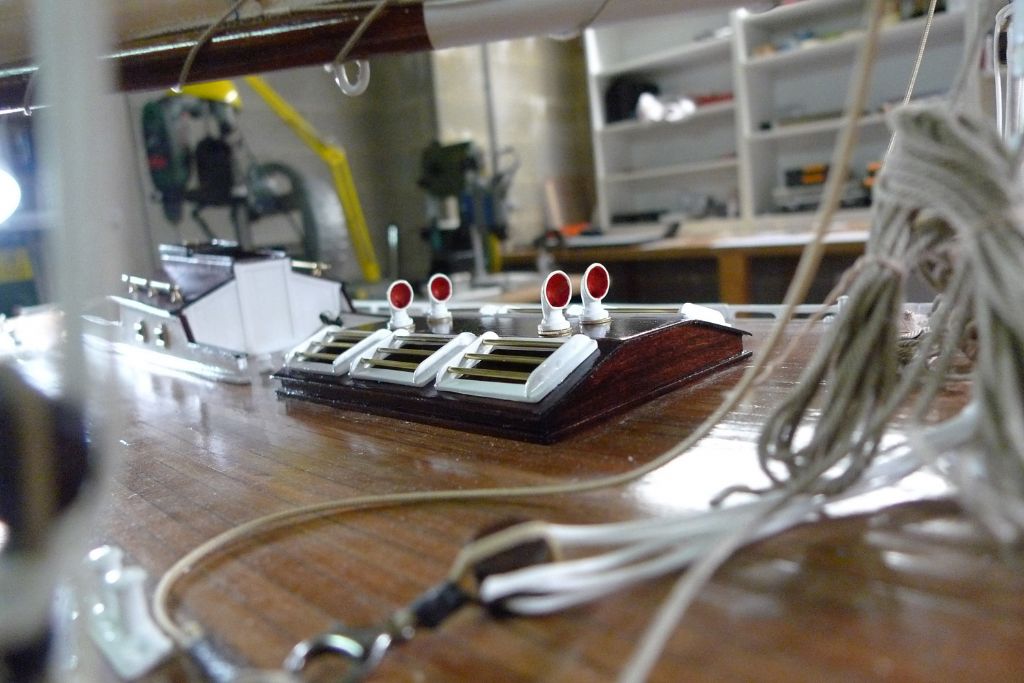

This means that the build is now structurally complete …

… looking like this. The reason why the jib is not fully hoist is of course the lack of ceiling space in our basement – for the boat to sit at comfortable working height on a table, I have to let the topmast down.

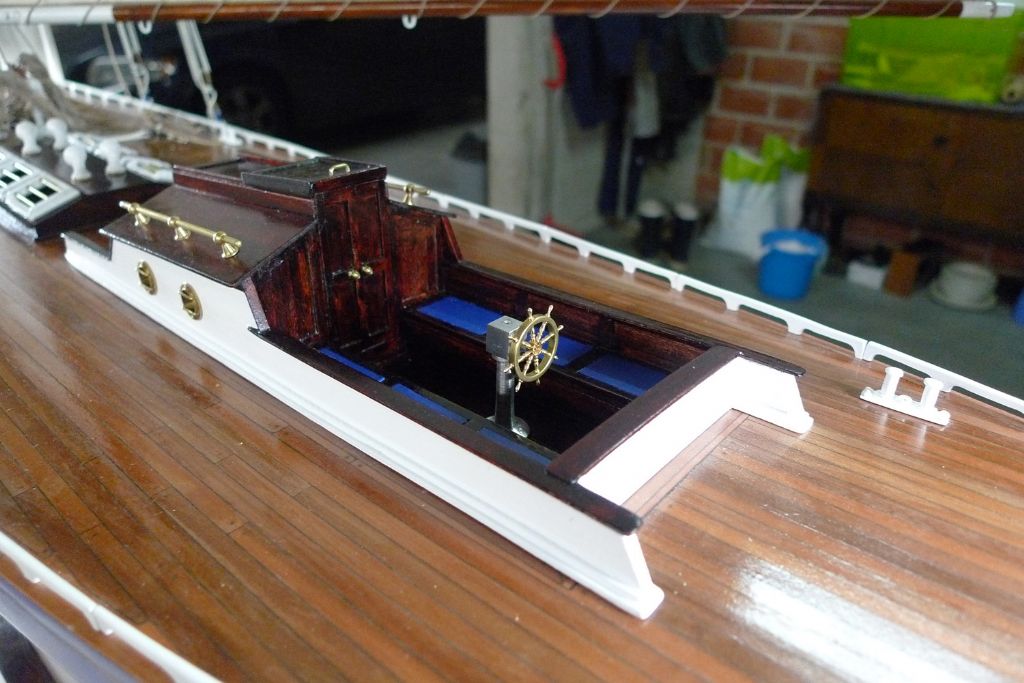

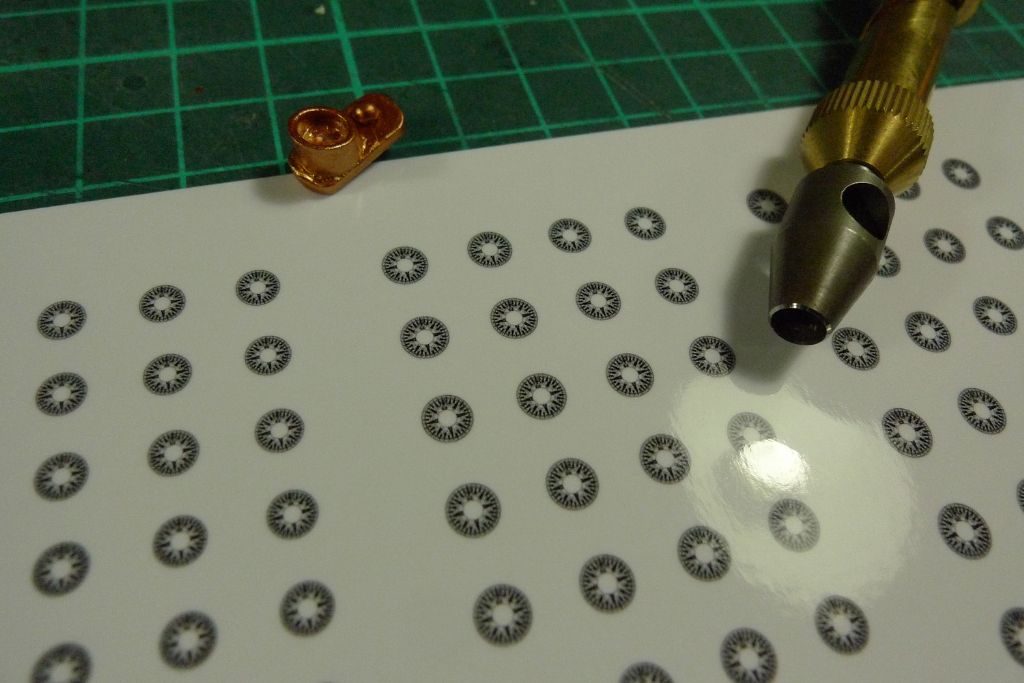

For the next small job, I had originally planned to use some thin real leather from my may-come-in-handy box (in this case a set of leather samples from back in the day, when one of my younger brothers was working as bookbinder), but in the end decided to get some fake leather instead, not least because I found some in a blue colour that nicely matches the hull above the boot top.

After cutting pieces to size, their edges were stained a similar blue with a permanent marker pen …

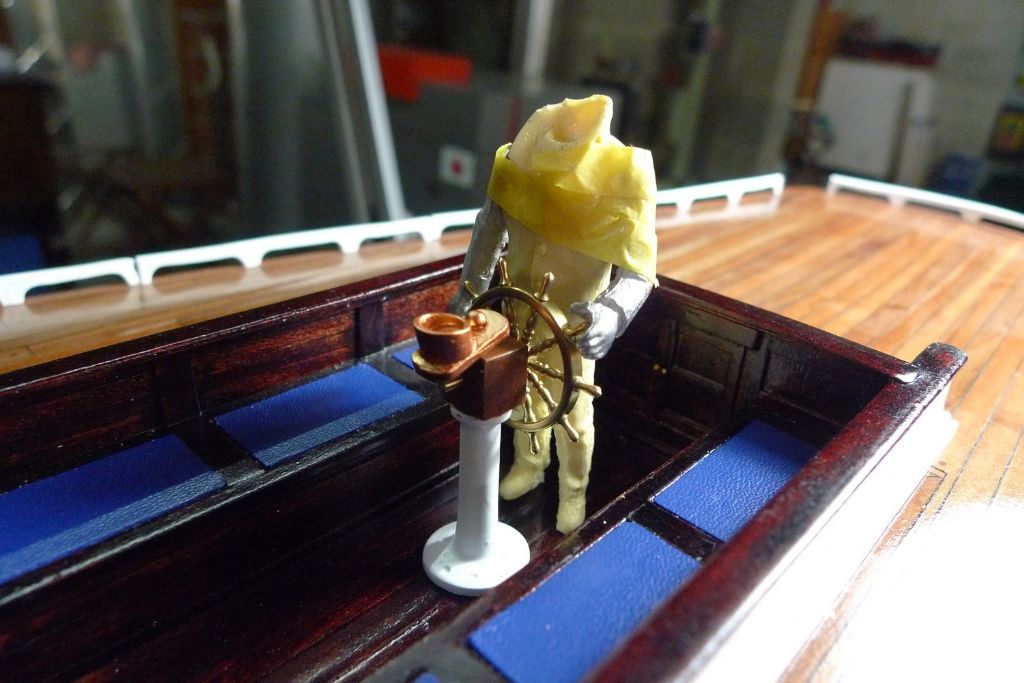

… and then glued in place on the cockpit benches.

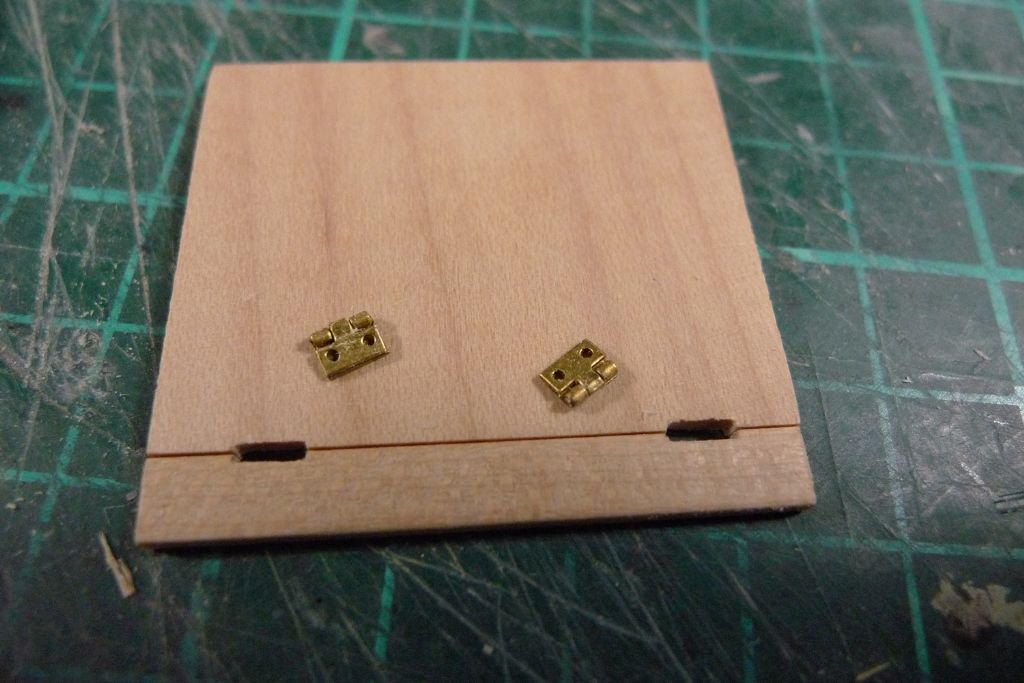

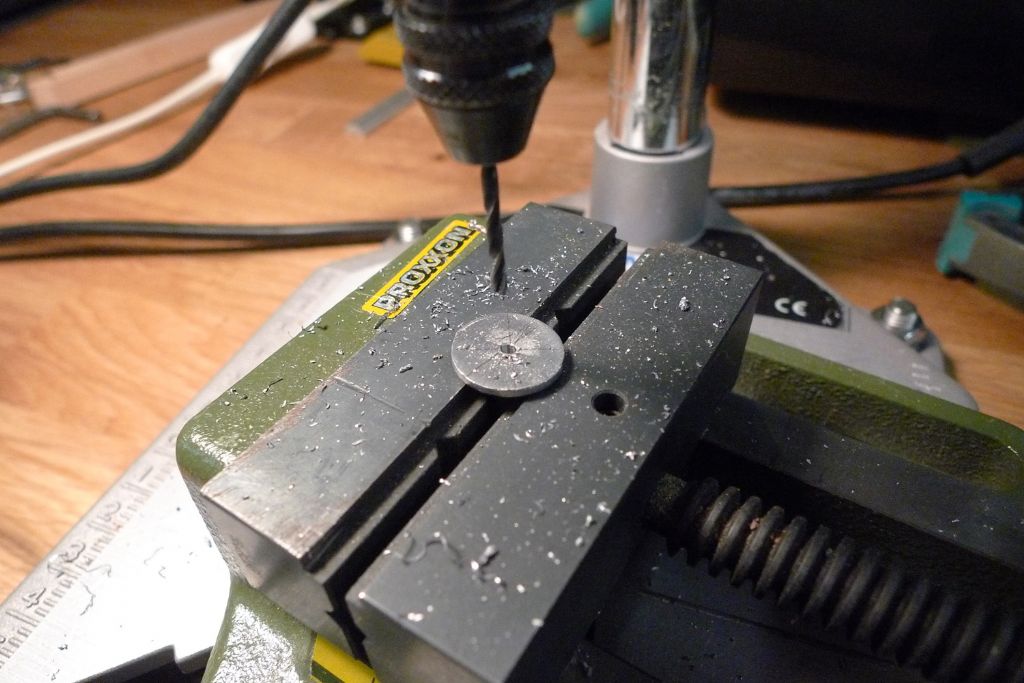

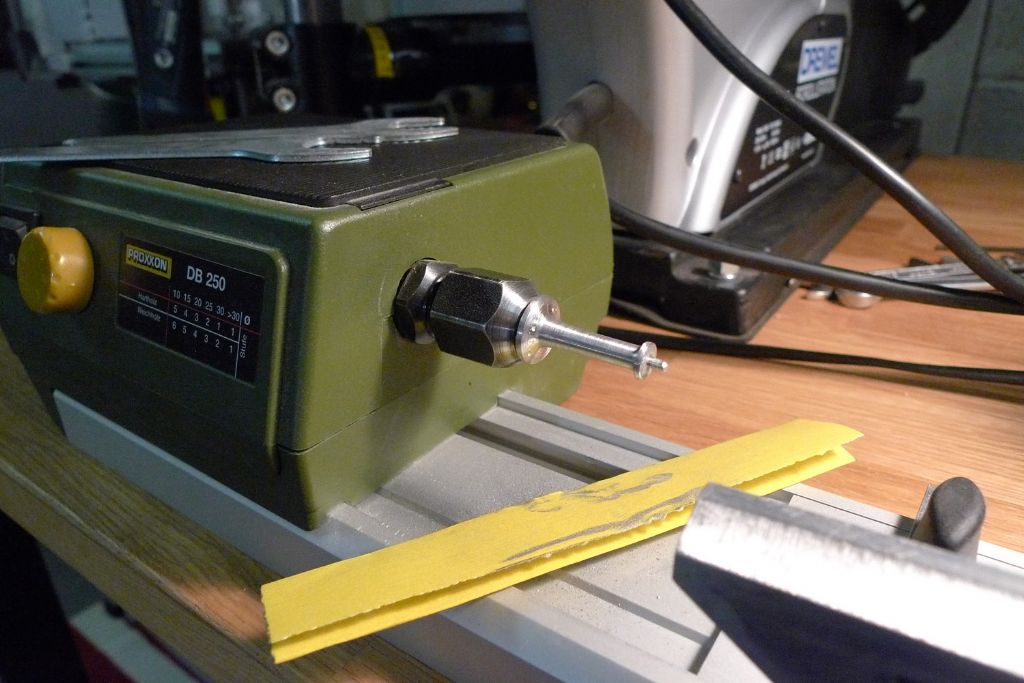

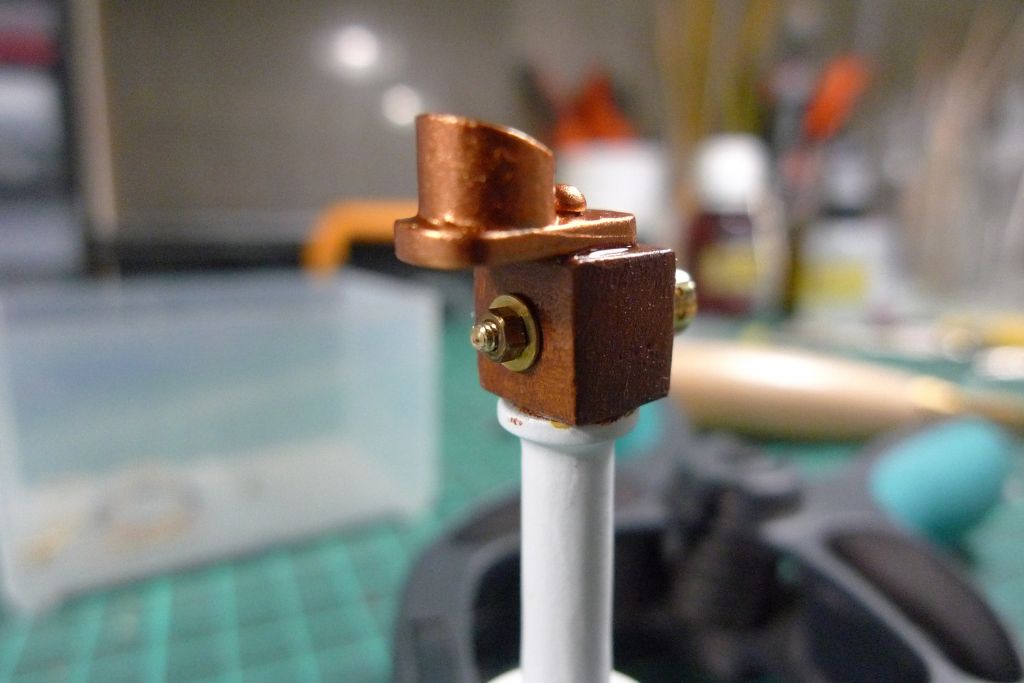

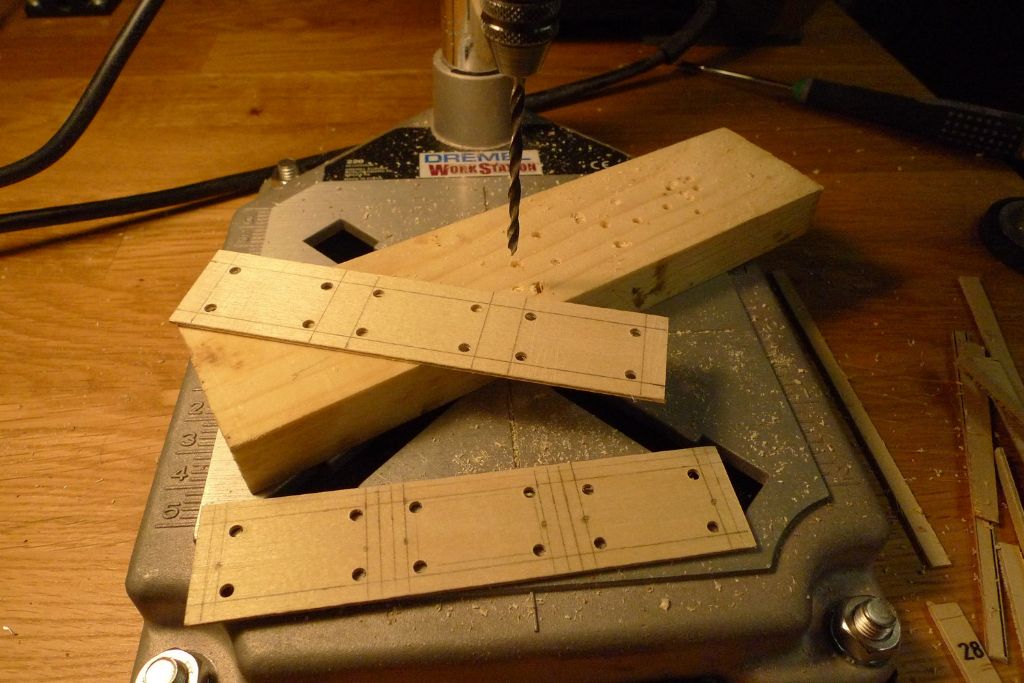

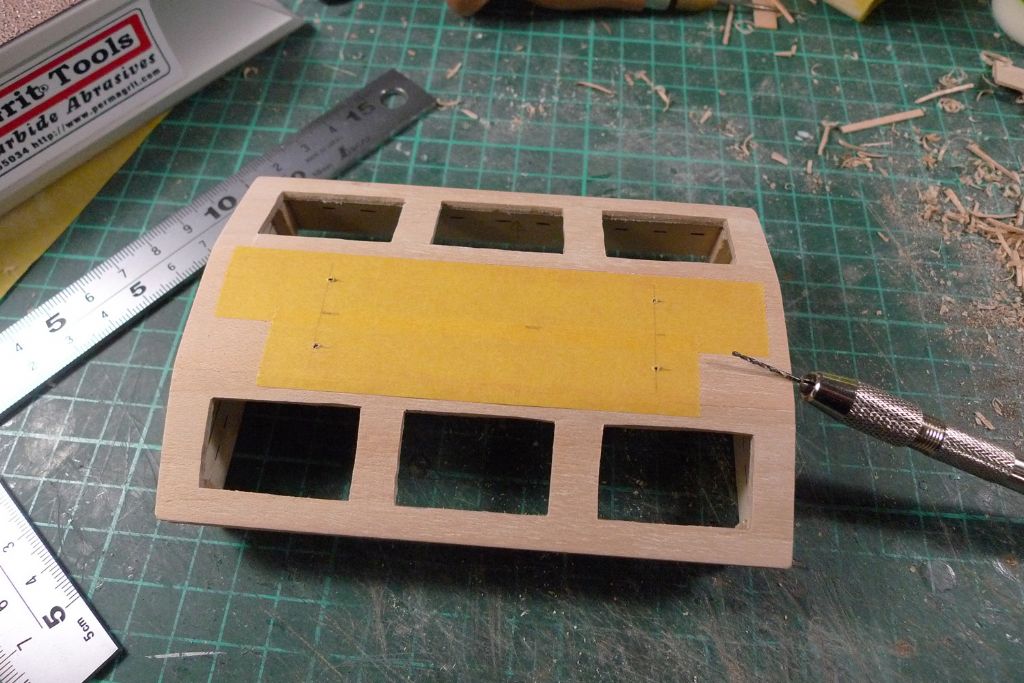

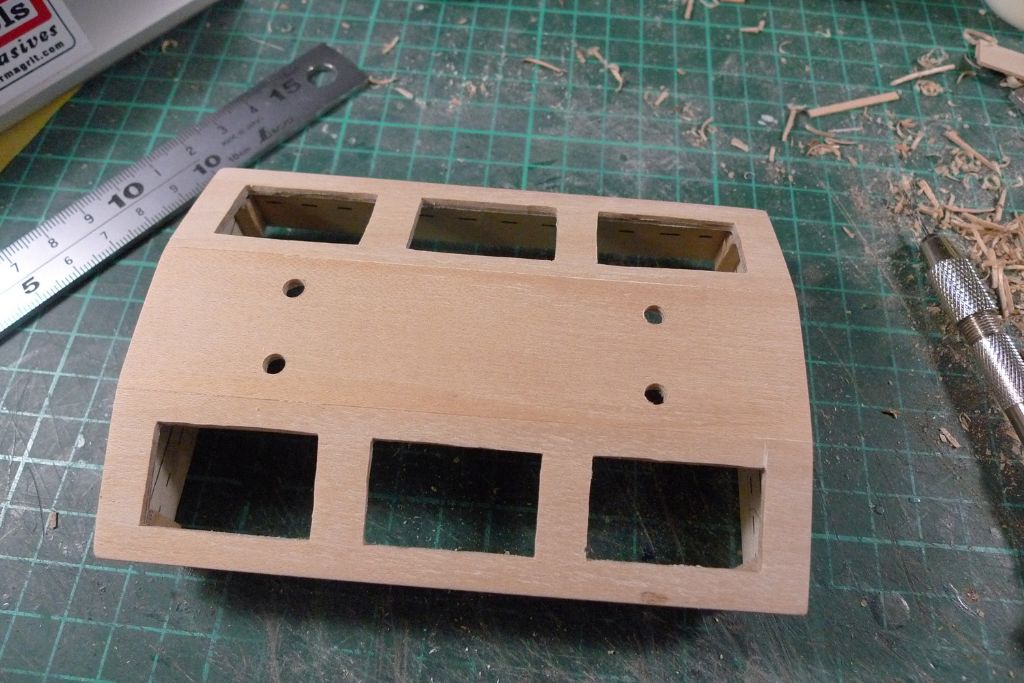

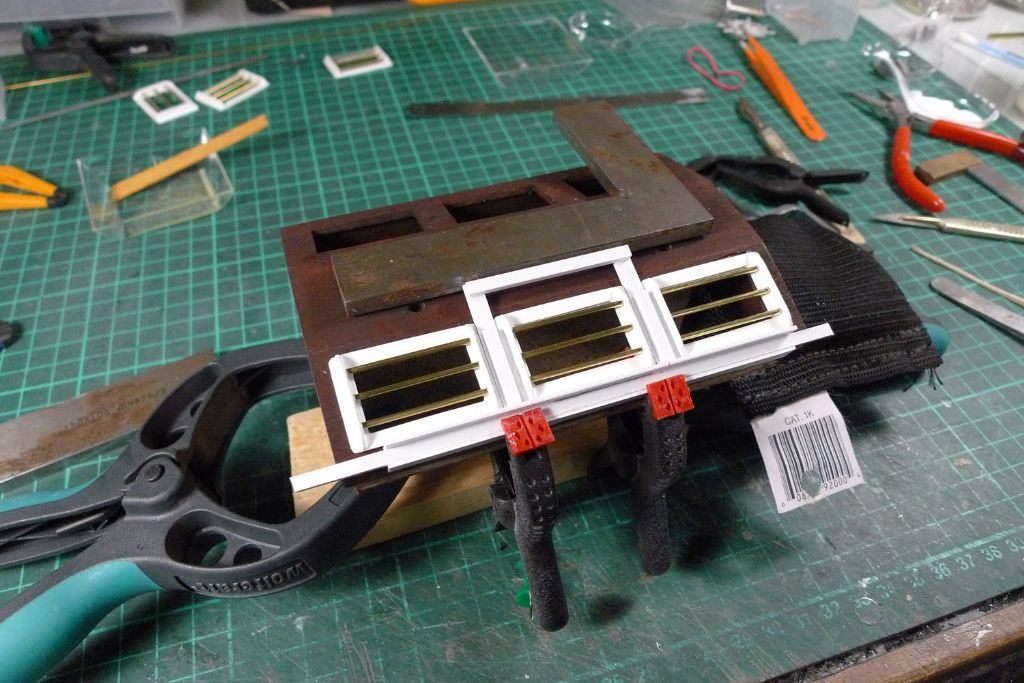

Next, I went about sorting out the secure attachment of the main skylight. To this end, I drilled 2 mm holes in the middle of the fore-and-aft coamings, both port and starboard …

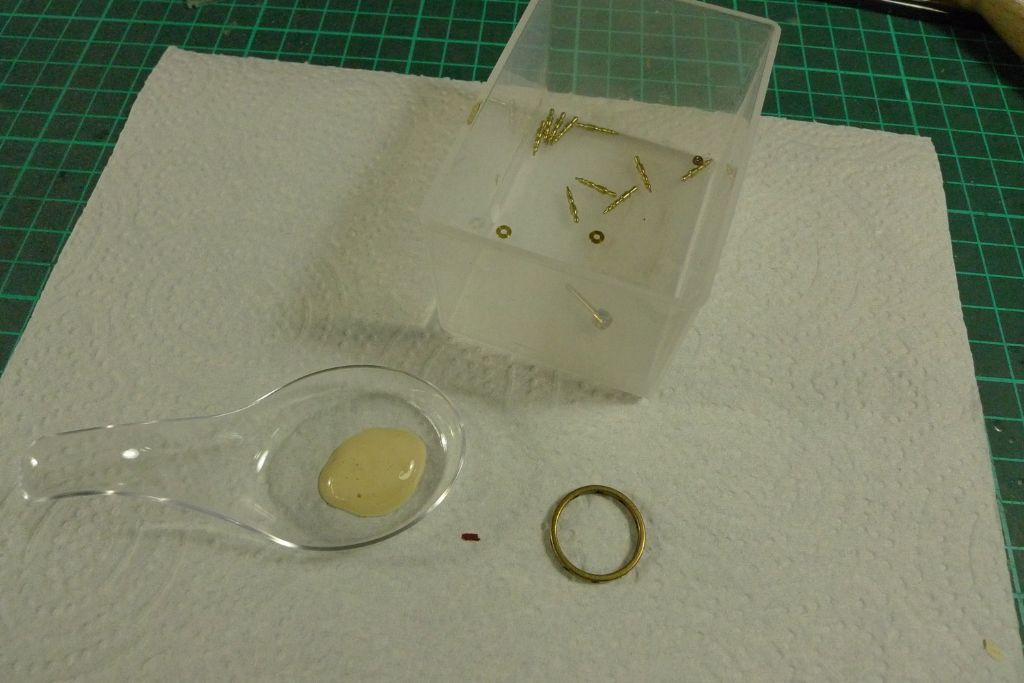

… then cut of two short lengths of 2 mm brass rod …

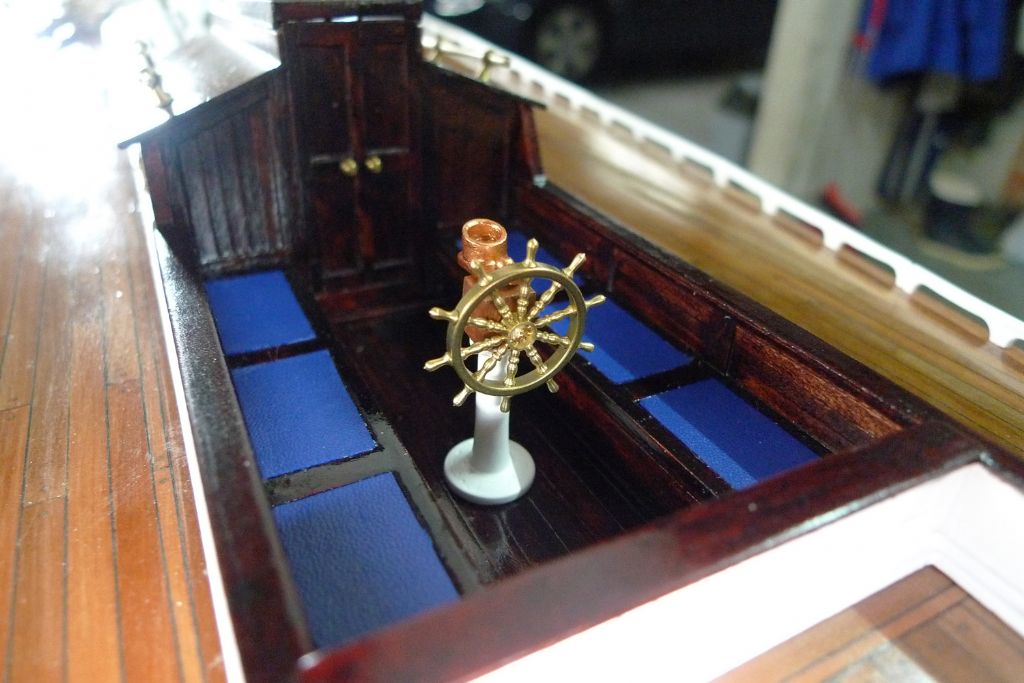

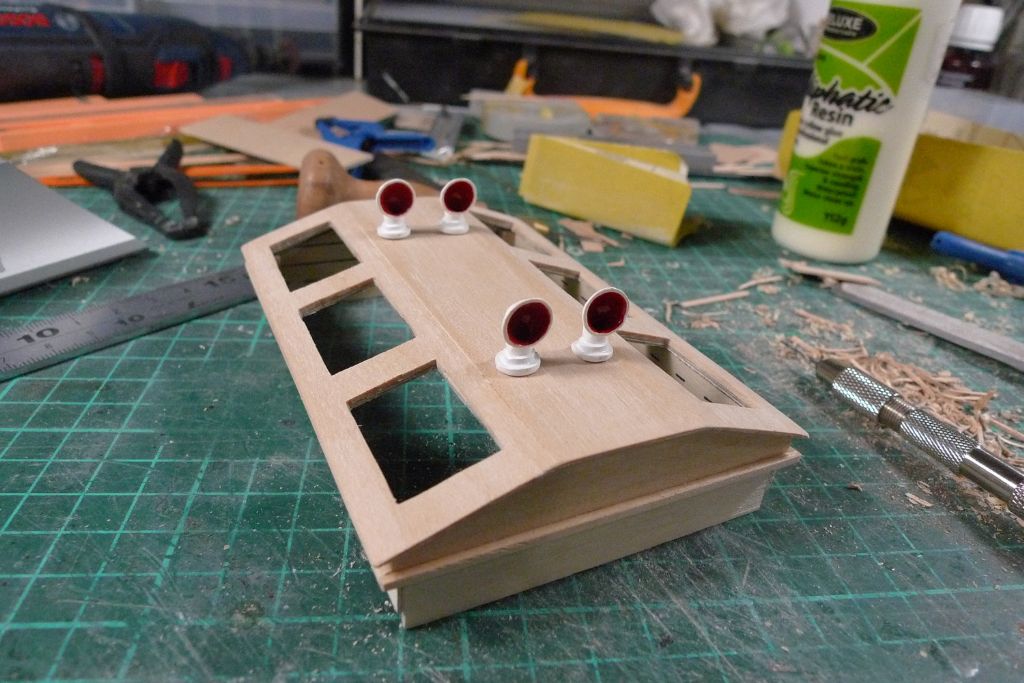

… push fitted the rod through the holes in the coamings, and set up a loop of elastic thread between the two brass pins.

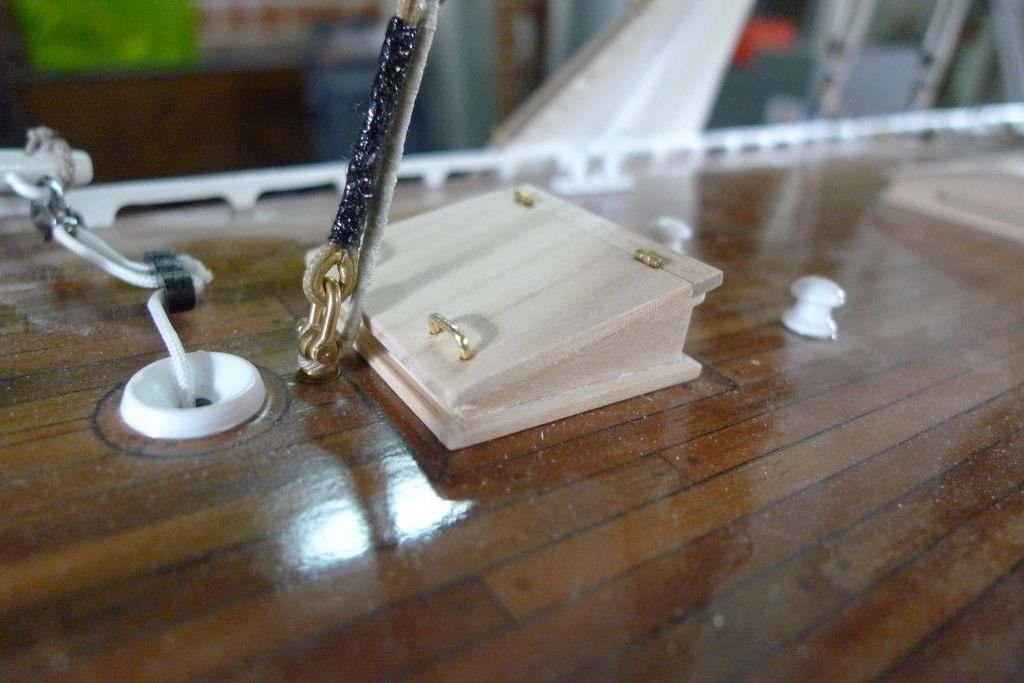

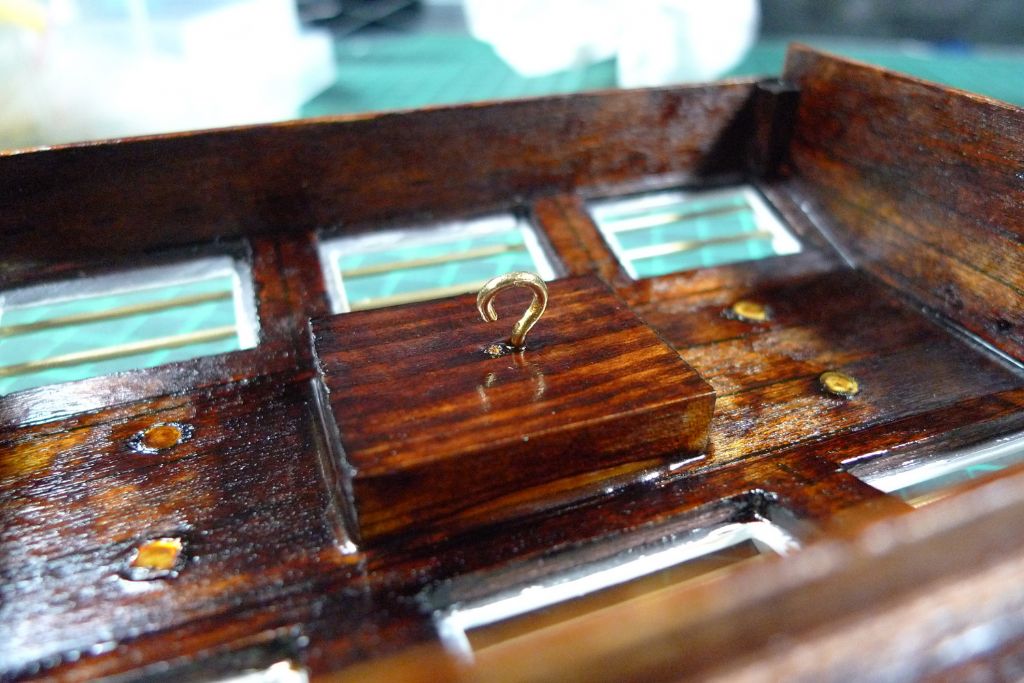

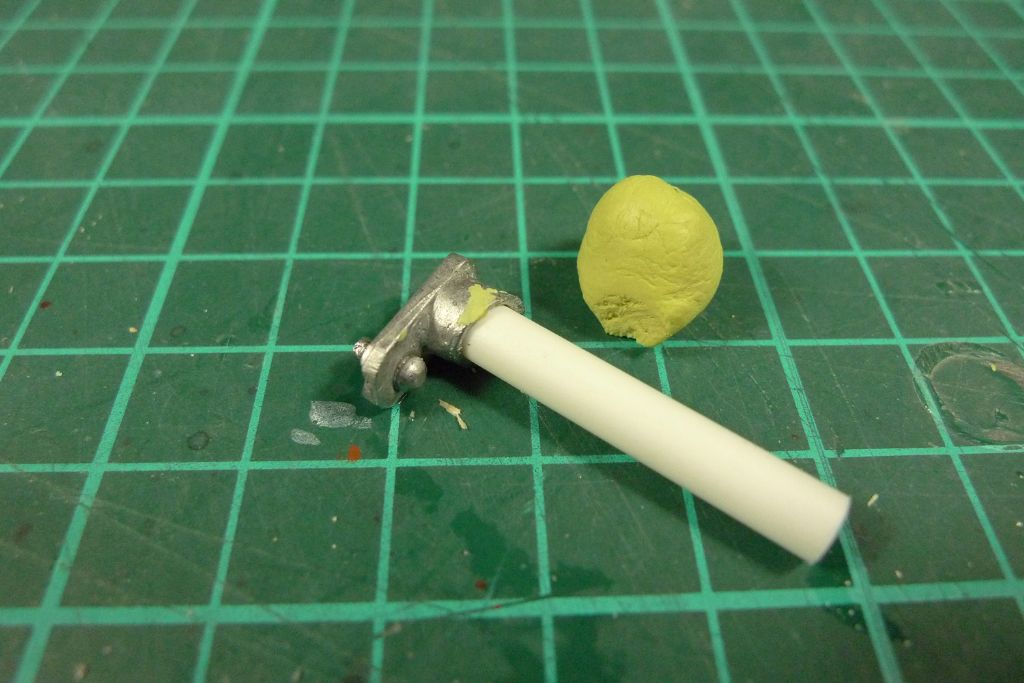

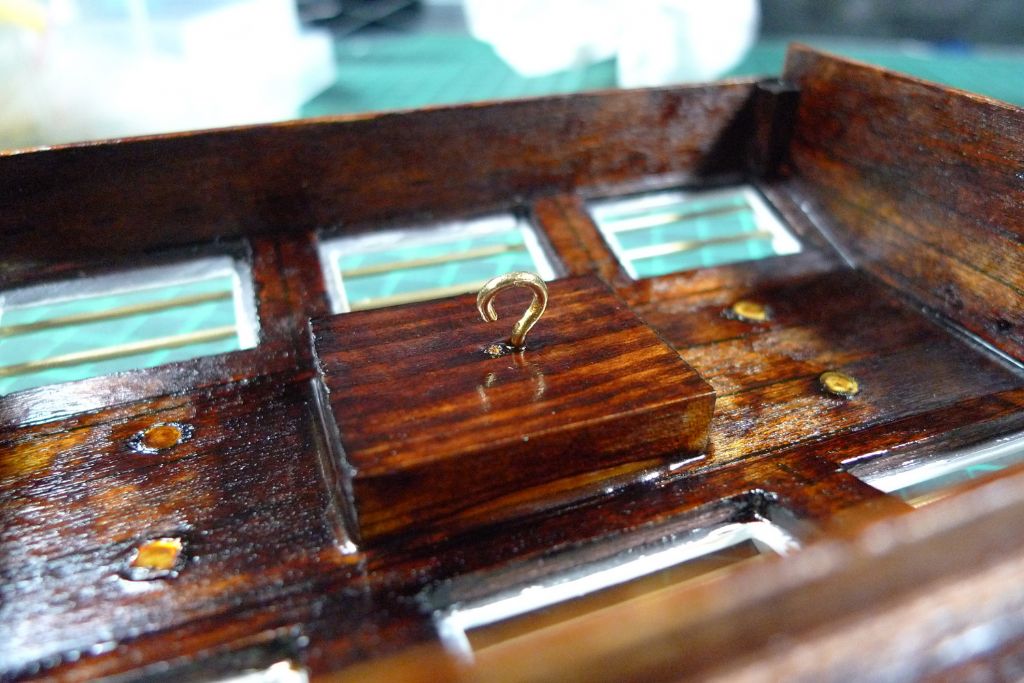

A block of wood was then epoxied to the underside of the skylight roof …

… stained and coated with sanding sealer, after which a hook made from a brass screw eye was screwed into it. By hooking this over the elastic, the skylight is properly secured – it can still move a bit, but cannot come loose unless one puts one's fingers underneath the skylight to onhook the elastic.

To be continued …

Mattias

Edited By Banjoman on 21/01/2018 20:39:07

Edited By Banjoman on 21/01/2018 20:41:42

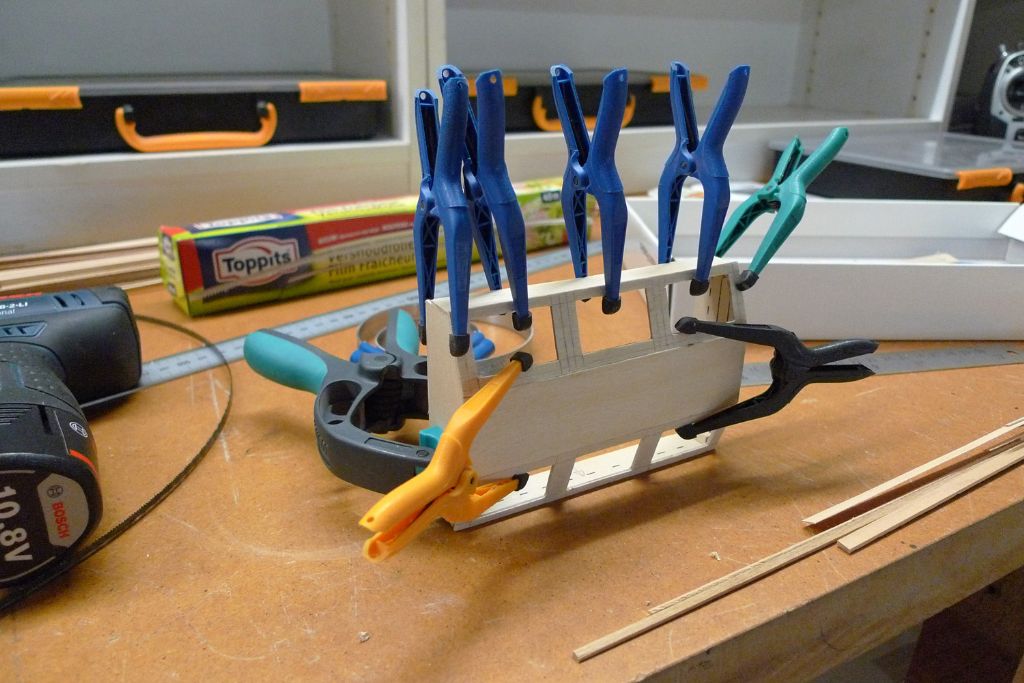

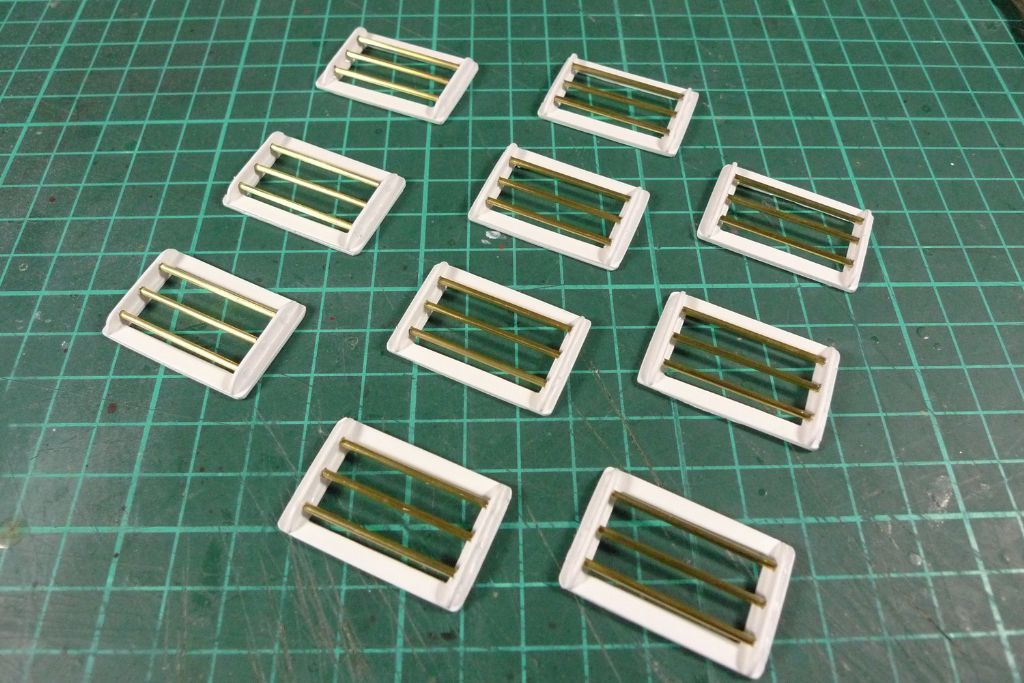

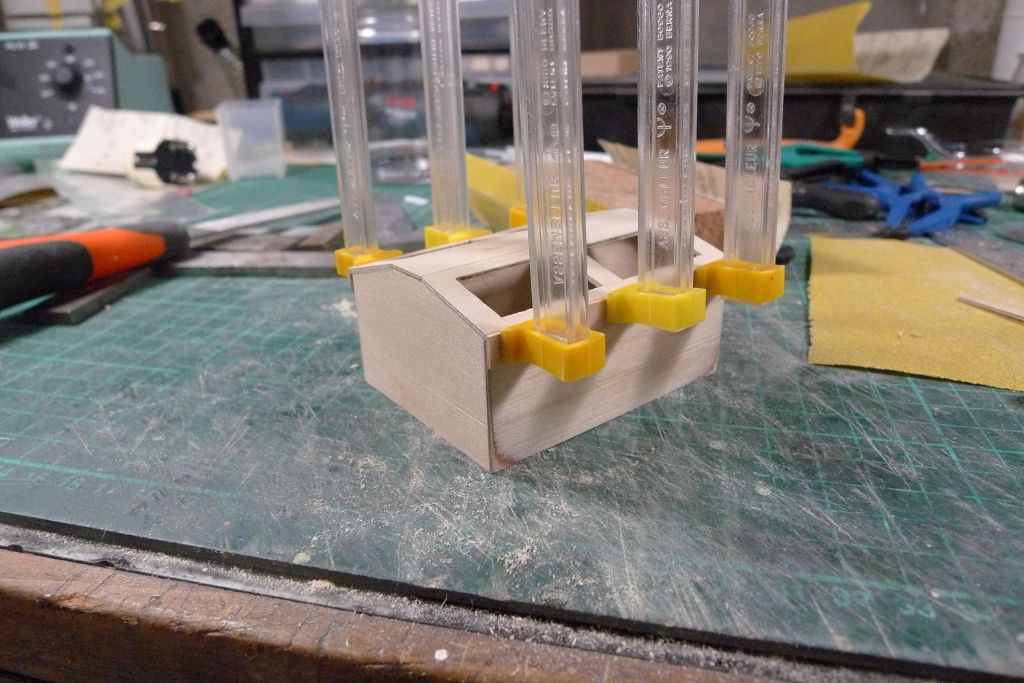

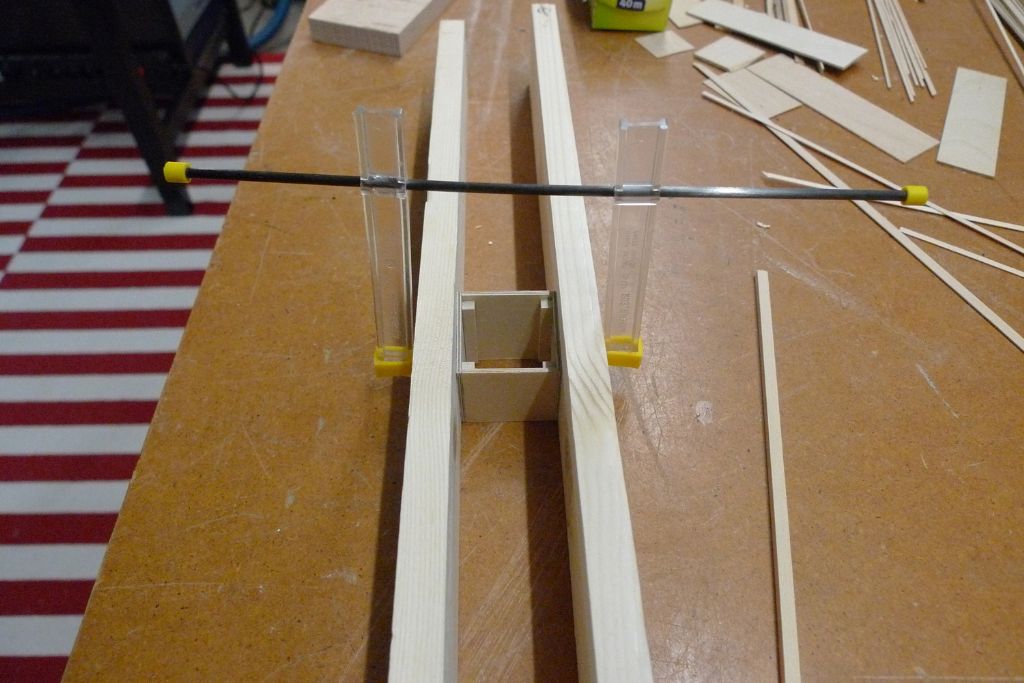

but wow I like your cutting to length jig, I will be making one of those soon.

but wow I like your cutting to length jig, I will be making one of those soon.

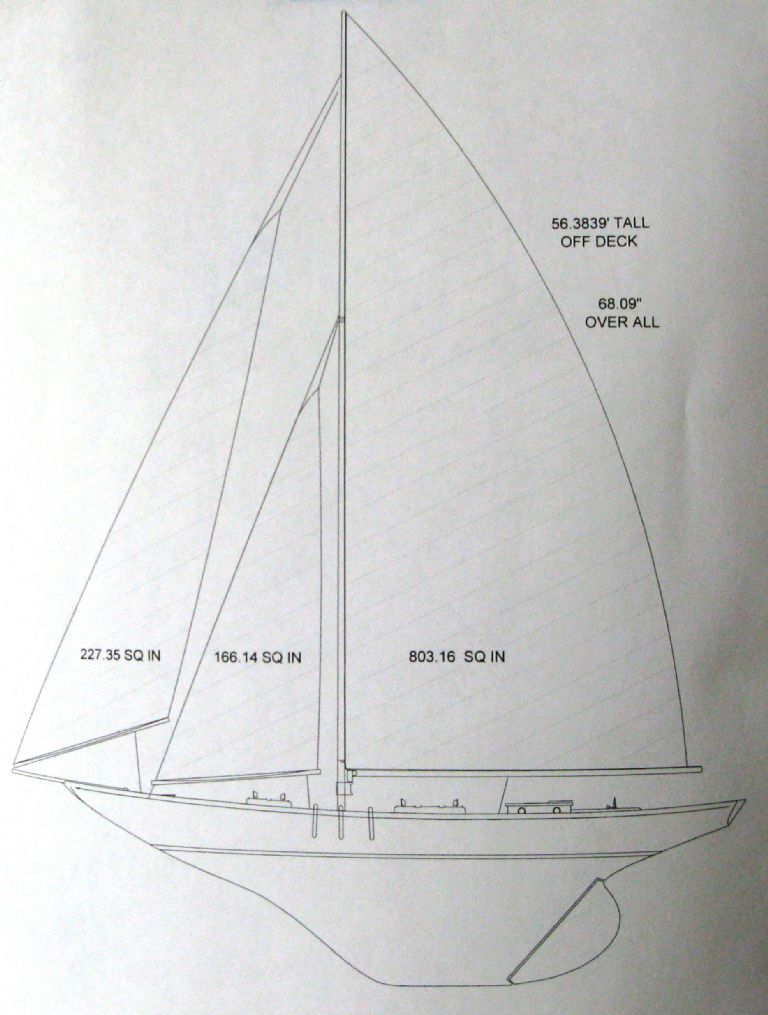

This is a drawing of what Moonbeam could look like with a different sail plan, too. We'll see about that…

This is a drawing of what Moonbeam could look like with a different sail plan, too. We'll see about that…