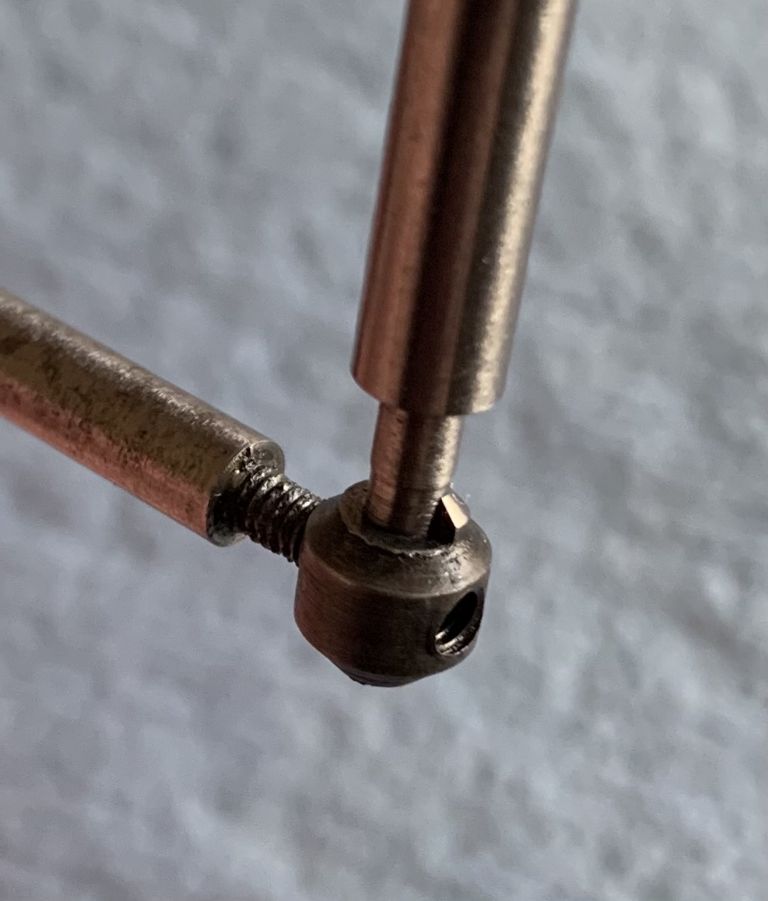

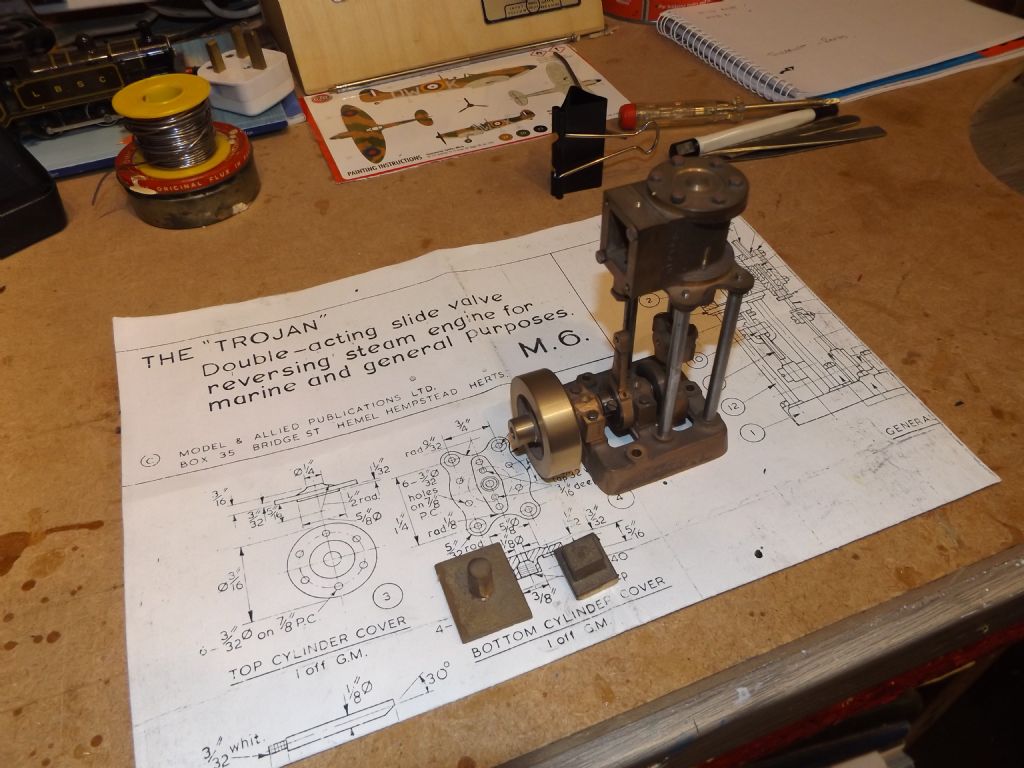

Mark, without taking it apart fro a look I cannot say for sure but those slots you can see may be for valve adjustment, in which case we are looking at the top of the piston valve itself. If that is the case and you have leaks there your only options are to dismantle it and see if there are any internal sealing arrangements such as 'O' rings, which can be replaced. If not, and you are getting leaks past the valve then your only option is a repeat of the process you are going through with the main reversing valve, which is a real pain. You could try threading the outside of the boss that supports the valve and fitting a cap, which might just be an easier option.

Unfortunately piston valves are notorious for passing as there has to be a clearance for smooth running however make sure you run the engine with a good supply of steam oil in it as that helps to seal the piston. I don't think you can do any more than you are however the danger is that you are going to get the best possible fit you can when it is cold, which will change when it is up to temperature, and could lead to seizure if tolerances are too fine. Unfortunately the fit has to be a compromise between allowing free movement and resisting leaks. You will find you will have to compromise somewhere and that will inevitably mean putting up with a degree of leakage.