Good morning Ray, -and of course, anybody else

I too shall be watching with interest! Certainly for a model of this type there is probably only a small performance advantage in utilising a scale-ish genoa. Had I not owned a 1:1 version years ago, I would not have bothered with the genoa hassel. Had I thought about the cost early enough I would deffinateley have reconsidered! Using a small foresail and refering to it as a "working jib" would suffice. Wouldn't even need a servo on it!

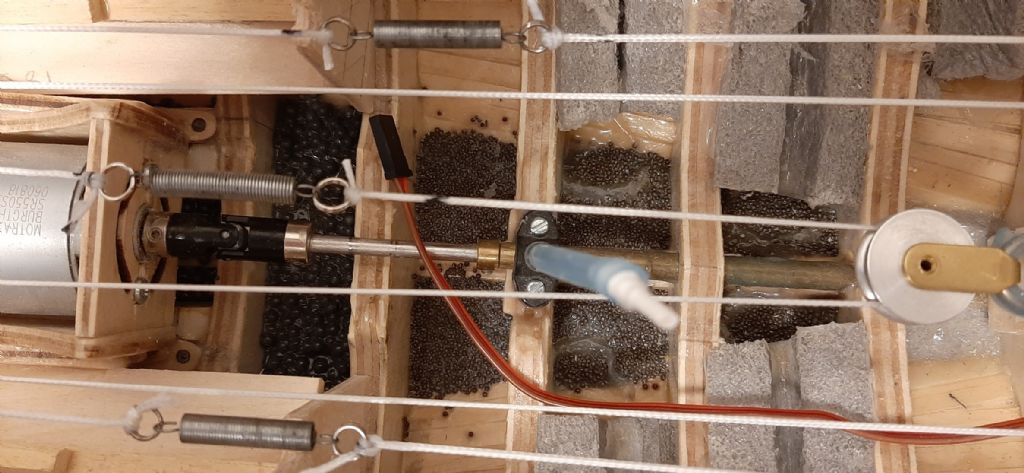

The foresail on Ralph Stockton's F46 was a 'working jib' and he even had electric roller reefing on it! Ralph was an engineer. I'm just a glutton for punishment. I am going to try to make a manual roller reefed genoa so that all sail area can be reefed /stowed to allow for motoring with the sails still visible -but reefed- on the boat.

Some standing rigging will probably have to go onto the aft edge of the wheelhouse roof. I have a plan for this -which is too boring for members to rea d about- so I'll post a photo when it's done…in 2-3 months or so?

d about- so I'll post a photo when it's done…in 2-3 months or so?

Posting a pic of Ralph's F46.

Regards, George

Edited By gecon on 23/08/2020 08:15:04

there are not enough build blogs on here in my opinion !! I hope that doesn't mean nobody is building ??

there are not enough build blogs on here in my opinion !! I hope that doesn't mean nobody is building ??