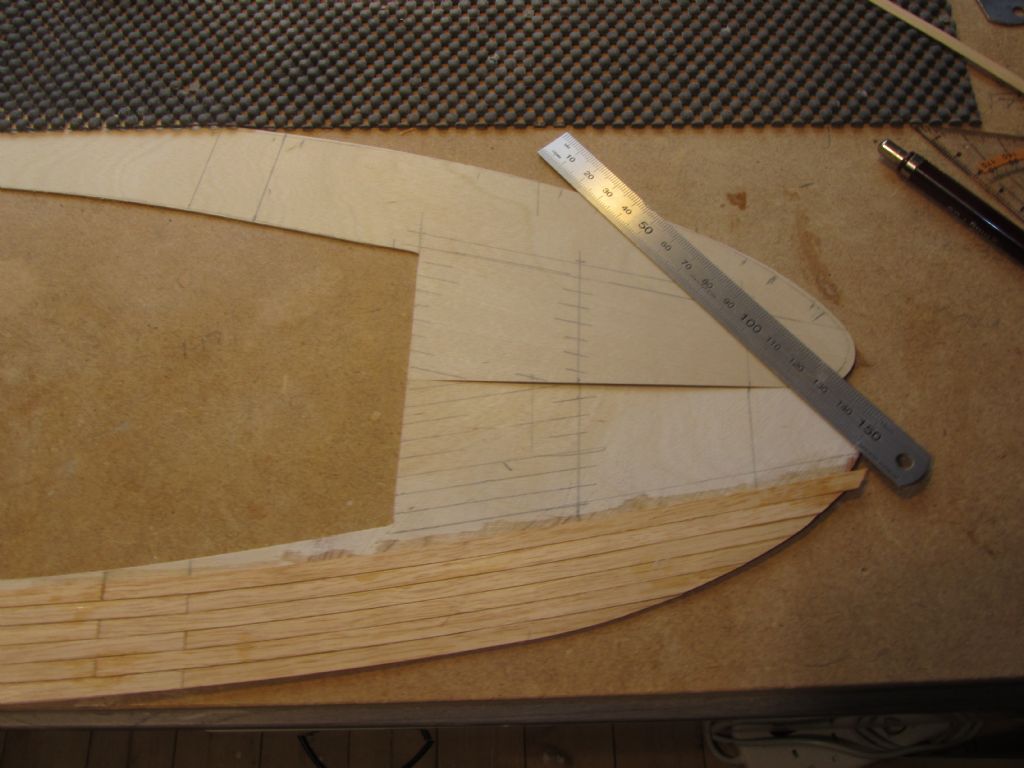

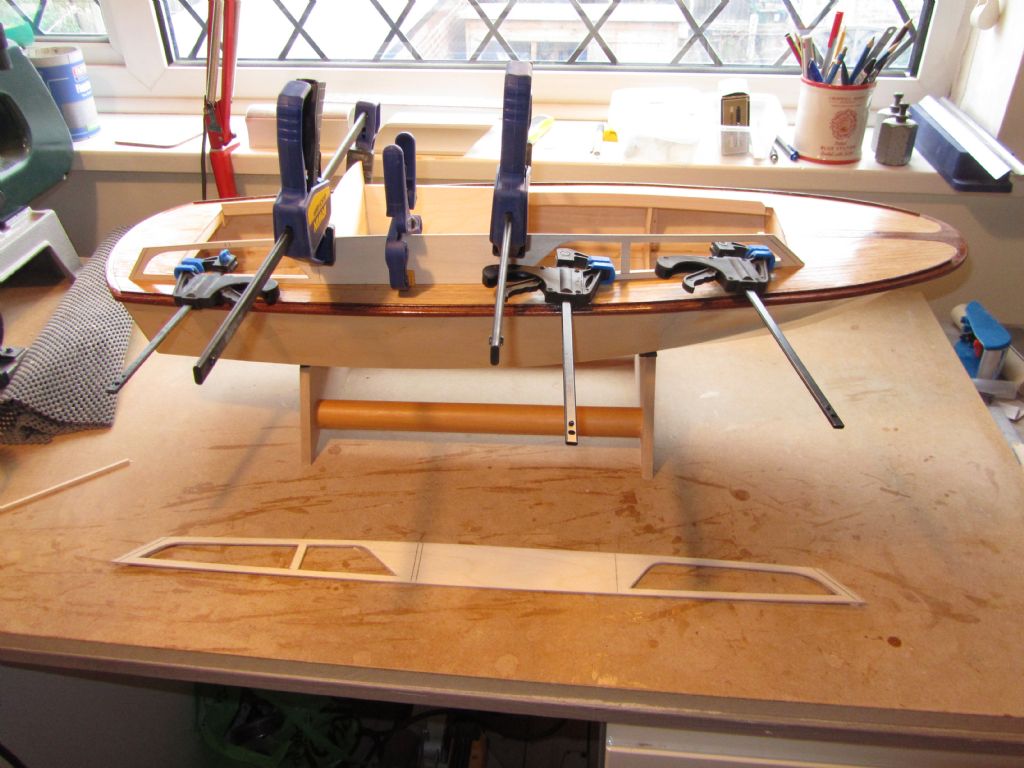

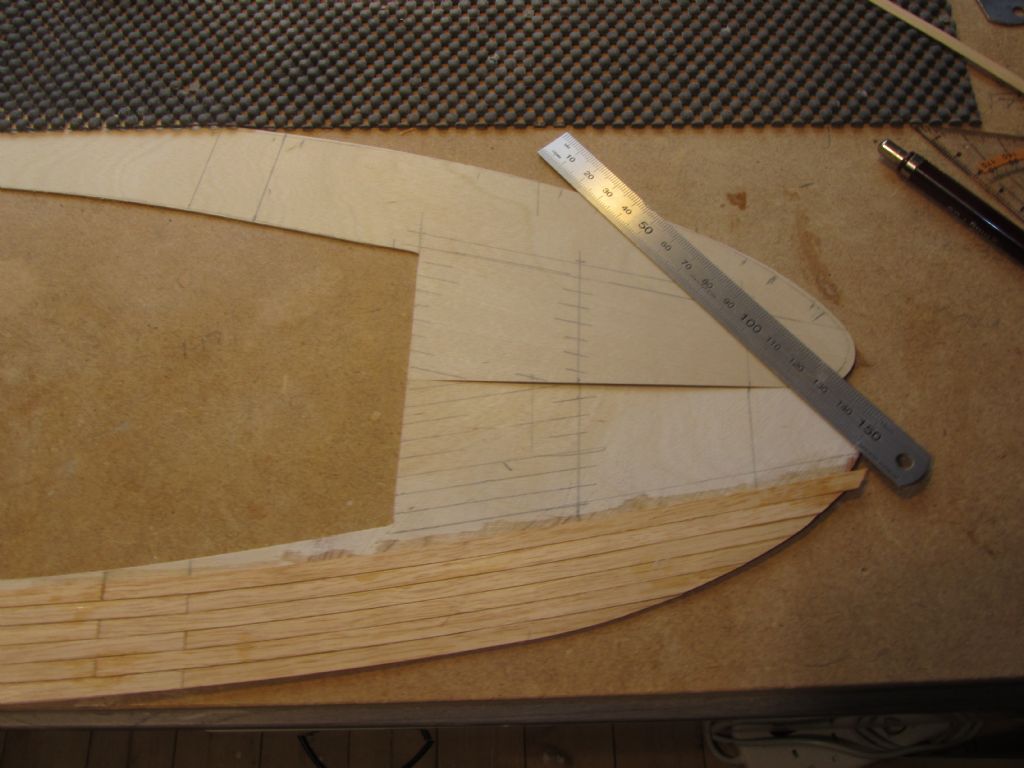

Before starting on the second side it was prudent to do some marking out so that the planks on each would meet the king plank symmetrically. Having done this I planked the rear two thirds of the second side to where the joints are and then added the sixth plank which was the point I'd I'd got to on the first side, along the line marked out. This was a bit of a risk as I would be fitting planks both inside and outside this plank.

I then fitted planks alternately to both sides, approaching the king plank, checking measurements as I went. The last thing you want is a marked difference in size of the last small triangular plank as the eye will be drawn to it. They ended up smaller than drawn out and less than a plank width but at least they are pretty much the same size. This part was definitely the hardest part!

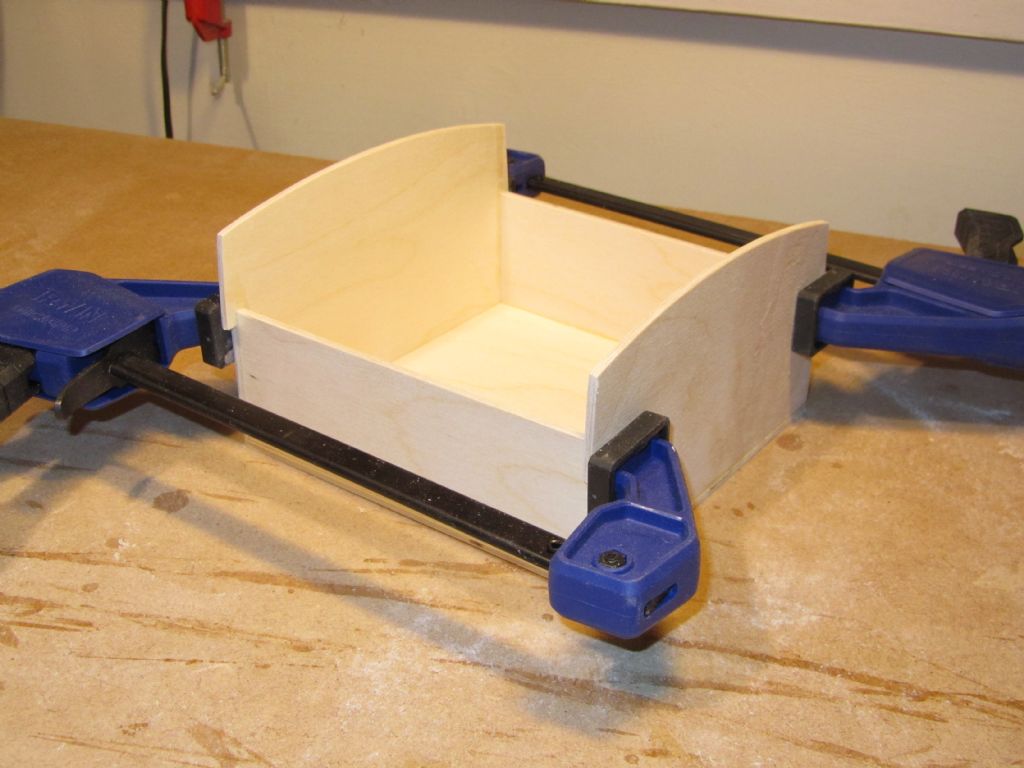

I then added the planks to the outside and thankfully the outermost plank fitted nicely to the outside edge of the ply sub-base. The oversailing planking was then sanded back to the edge of the sub-base and the top given a preliminary sanding. As said, not perfect, but will look nice once varnished and contrasted with the mahogany.

Got the Swordsman to do now and maybe the Huntress!

Chris

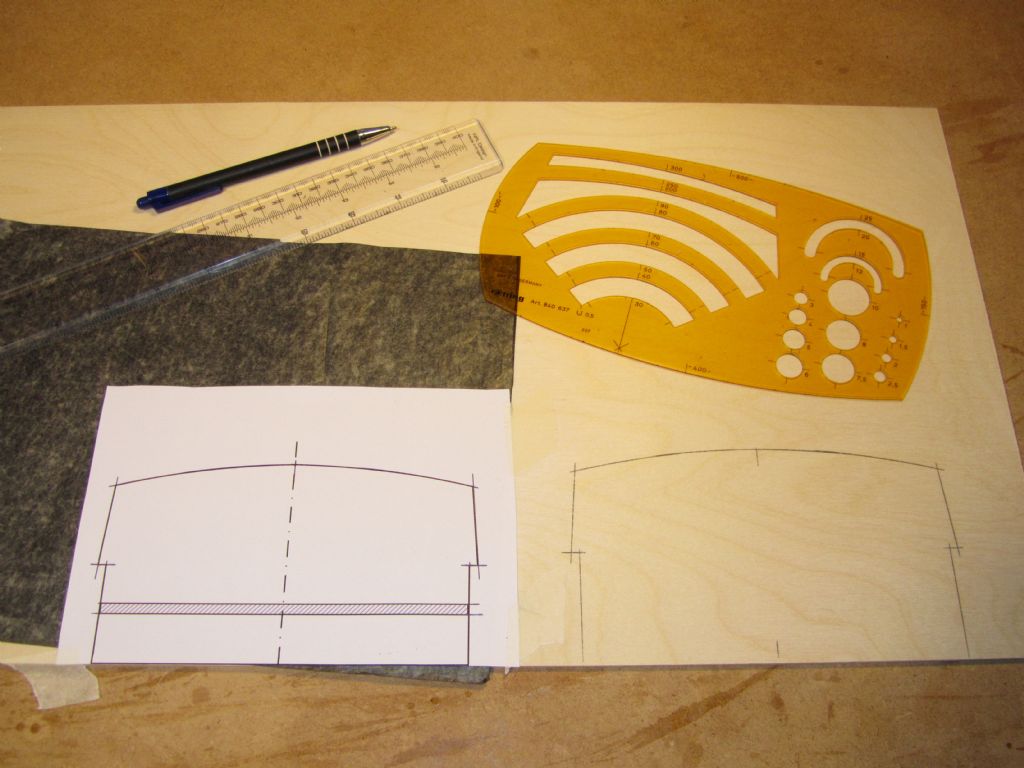

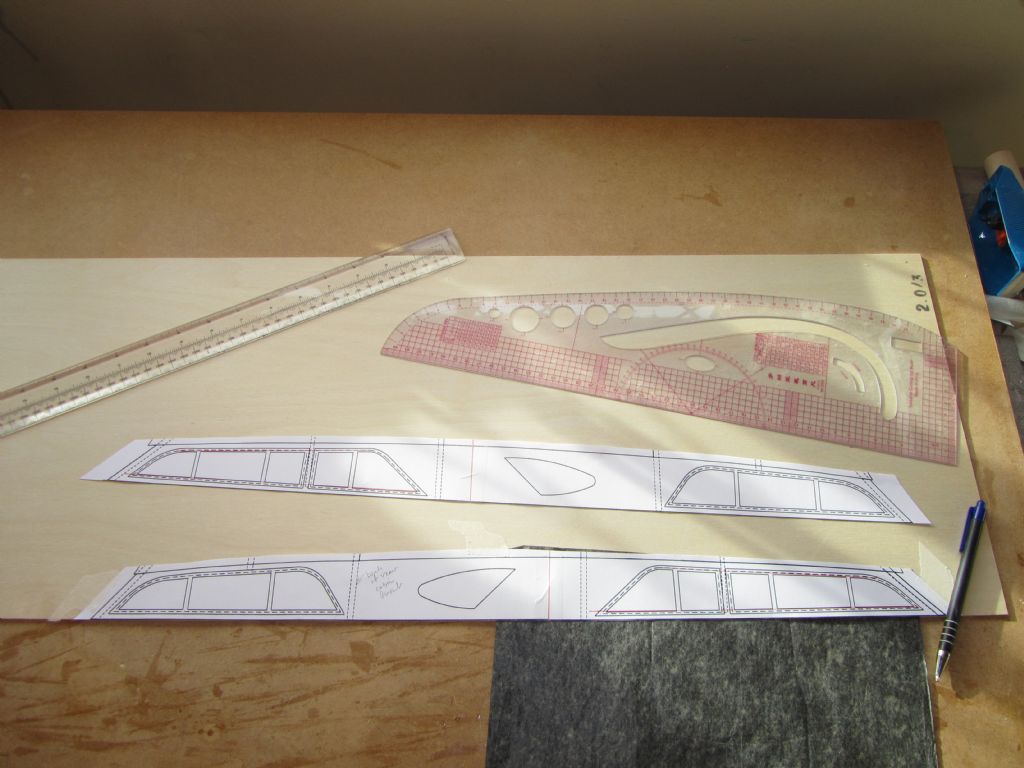

Len Morris 2.