This is an update on progress on the build of my 36R model yacht.

After some thought I have made a keel to one of the designs suggested on the American Model Yachting Association website. It consists of a 1/32 ply core sandwiched between two pieces of 3/32 balsa. This was sanded to shape and then covered in two layers of unidirectional carbon fibre cloth followed by a single layer of woven carbon fibre cloth. Each layer of cloth was separately coated in Z-poxy resin before adding the next. The resulting keel seems pretty stiff.

I have made two supporting frames from 4 mm liteply which tie the keel to the sides of the hull and added a longitudinal stringer at deck level. All the parts interlock so the keel is very rigidly located and supported.

The rudder skeg was made from 4 mm ply covered in glass cloth and also locates in the longitudinal stringer. The rudder is of similar construction with a brass tube keyed to the rudder with three 1/16 brass rods as a pintle.

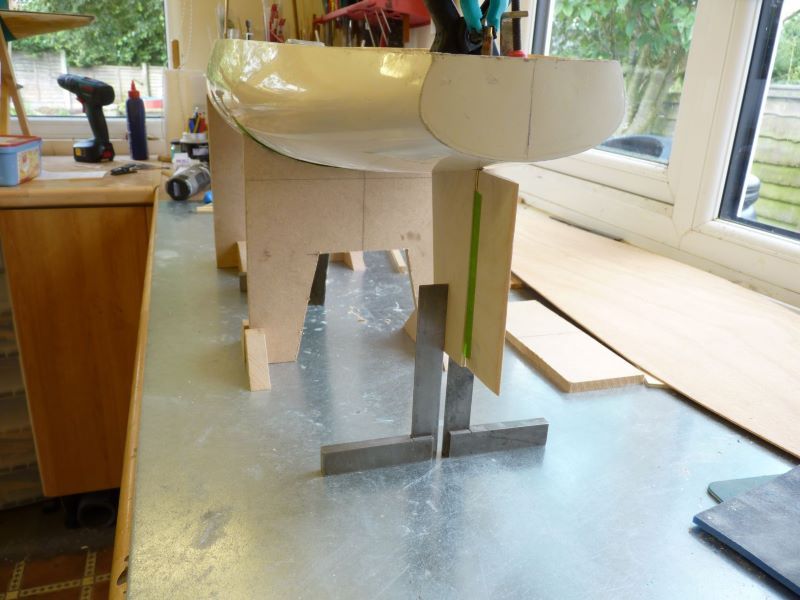

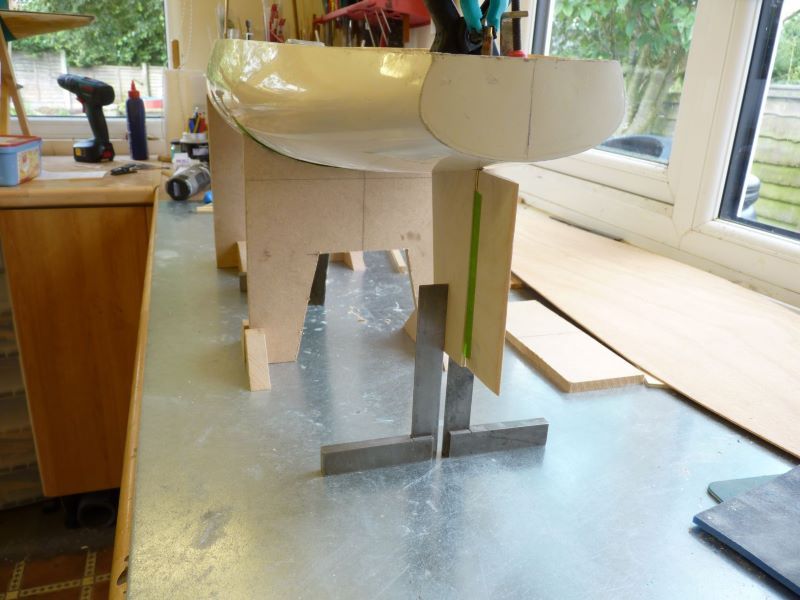

I made a stand which supports the hull with the waterline horizontal and the hull laterally level so that I could check the keel and skeg are both vertical and in line. The stand is just a couple of scrap pieces of 9 mm MDF, supported on a magnetic working board.

After sanding down and drilling some lightening holes the whole assembly has been glued together with Araldite. I have added a small ply plate to form the basis of the mast step.

My next task was to cut a slot in the lead keel weight to take the bottom of the fin. I worked out the C of G of the keel weight by balancing it on a round piece of dowel. I have a drawing of a similar 36R hull which showed the centre of buoyancy of the hull and assumed for the time being this is the same on my hull. I then marked the position of the slot in the ballast weight so that its Cof G will be directly below the hulls C of B.

After marking the required position of the slot I chain drilled a series of 6 mm holes about 30 mm into the ballast weight. I then fixed the ballast weight on to my workmate and using a 6 mm cutter in my router, cleaned up the slot to the full length and depth, gradually increasing the depth of cut by a couple of mm each time. This gave me a nice clean slot with no apparent damage to the cutter or router. (I carefully swept up all the bits of lead afterwards)

I have made the deck from 2 mm liteply with cutouts that will be covered in adhesive deck patches to give access to the interior and reduce weight. The deck has been given a couple of coats of Z-poxy to seal the surface but needs to be rubbed down and will be given a final coat of varnish after its glued on.

I made a mount for the vane mechanism from a piece of 1 inch wide carbon fibre strip that I found in my new desk during an office move about 30 years ago. I knew it would come in useful one day. Its very light and very stiff.

I have estimated the weight of the mast, sails and rest of the rig by weighing a Marblehead rig I have and assuming the 36R will be about 90% of the weight. A tin of salmon and packet of Oxo came close to the estimate at about 420 grms.

Next came the first bath test with the keel weight held on the bottom of the keel with tape.

Miraculously everything seems in balance so my next job is to fix the keel weight permanently

A bit more progress to report shortly.

Gareth