Hi all,

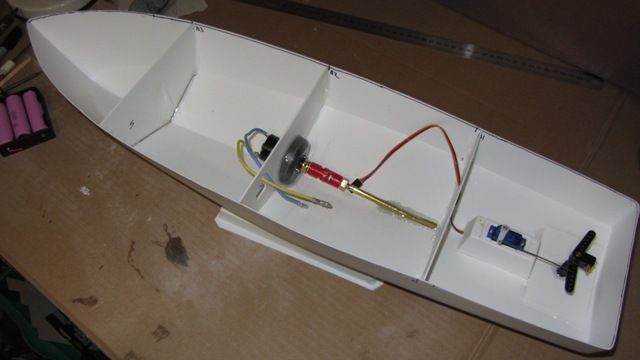

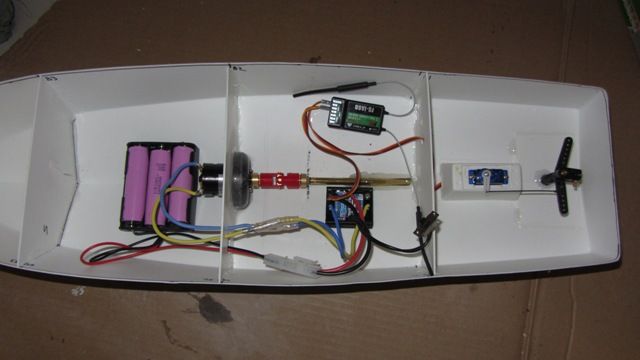

I’m a beginner to boat models and thought it might be useful to other beginners to share my first kit build experience. I’m building the Sarik ASRL, Whaleback version (Sarik No:TW29) not the Vosper version.

There are 6 similar sized kits in the range on the Sarik web site, the Vosper kit has a magazine article by an experienced modeller in the photos. I’m using this and other invaluable information from people on this and other forums to get me on the right path.

I would like to invite experienced boat builders to comment, particularly when I’ve made mistakes so other beginners can learn from them.

So lets get started.

The kit contains:

Instructions, Hull, Deck ,Superstructure, Servo mount, Motor mount, Transparent windscreen, Transparent gun canopies x2, Gun mounts x2, Aerial (mast and cross member), Carley float, Plastic sheet for bulkheads / trim (33x23cm), Stand.