Hello everyone, I have really enjoyed reading this forum for a while now, I have always had an interest in boats, ships and scale models. I haven’t built a model boat for about 30 years, so I would be very grateful for any comments and suggestions. I am certainly going to need help along the way.

My chosen subject is the “M.V. Sea Nass” formally “M.V. Mini Luck”. The Mini Luck was the first in a series of ten small coasters built in japan. She was completed in 1970, at 65 and a half metres, around 3000 tons, a top speed of 10knots and a range of 4300 nautical miles. She was shallow draft wide beamed and designed to travel into rivers and estuaries. Originally designed to carry general cargo such as Ore, Coal, timber etc, she could also be loaded with 32 twenty foot containers.

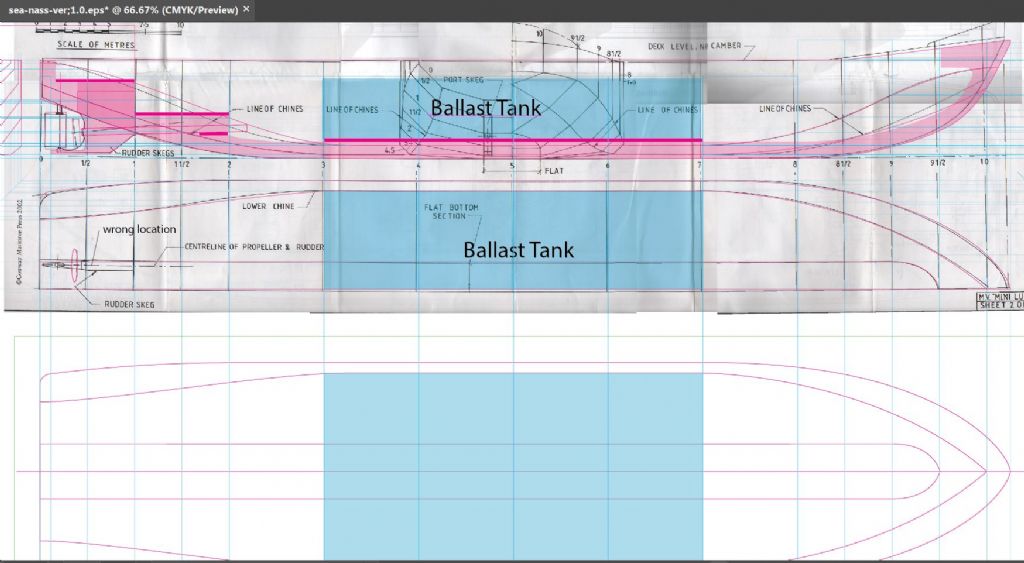

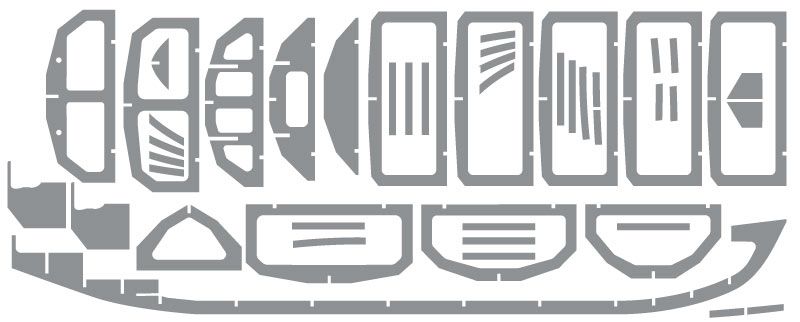

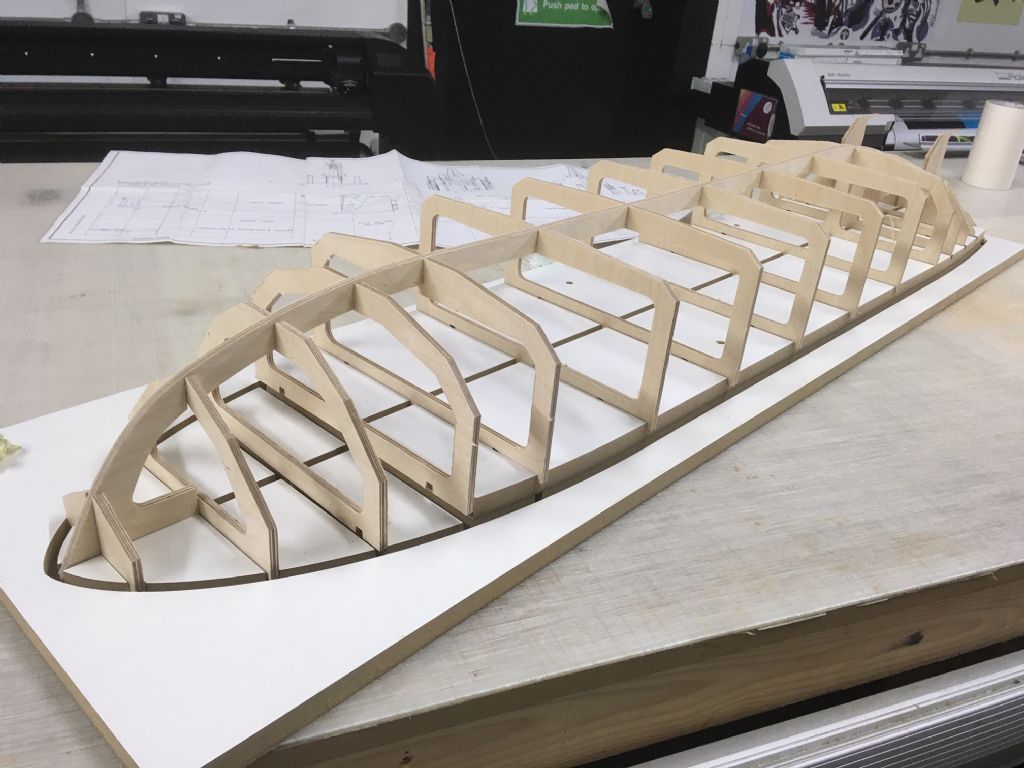

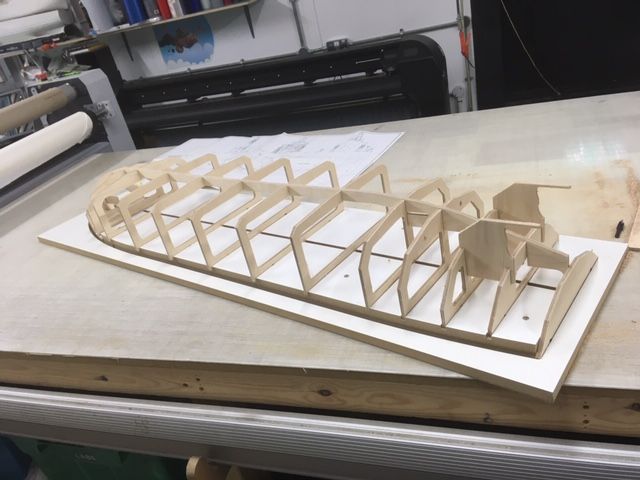

I am using the James Pottinger plans at 1/75 ( model shipwright 119 ) which I have started to redraw digitally so I can cut the frames on a CNC router. I am still deciding on scale but leaning towards 1/48 to give a OAL of 1364mm or 53 and a bit inches.

The hull is hard chine, the frames and keel will be cut from 6mm ply and the hull skin will be whatever I have available in my workshop either 1 or 1.5mm ply. I will probably use the same for the deck and then plasticard for the superstructure etc.

. I have also made a note to invest in some more clamps.

. I have also made a note to invest in some more clamps.