Thanks for the information Richard, I've just spent an enjoyable hour on the engel website and then looking at home built versions of the same idea. It could be a possible solution to the ballast problem, my only concern would be could i make a big enough piston ?

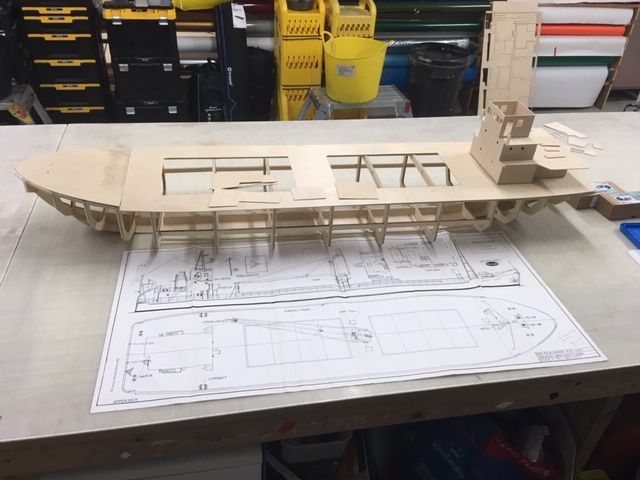

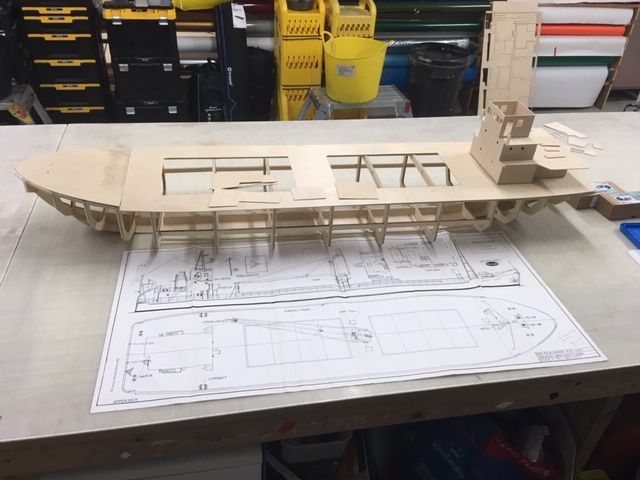

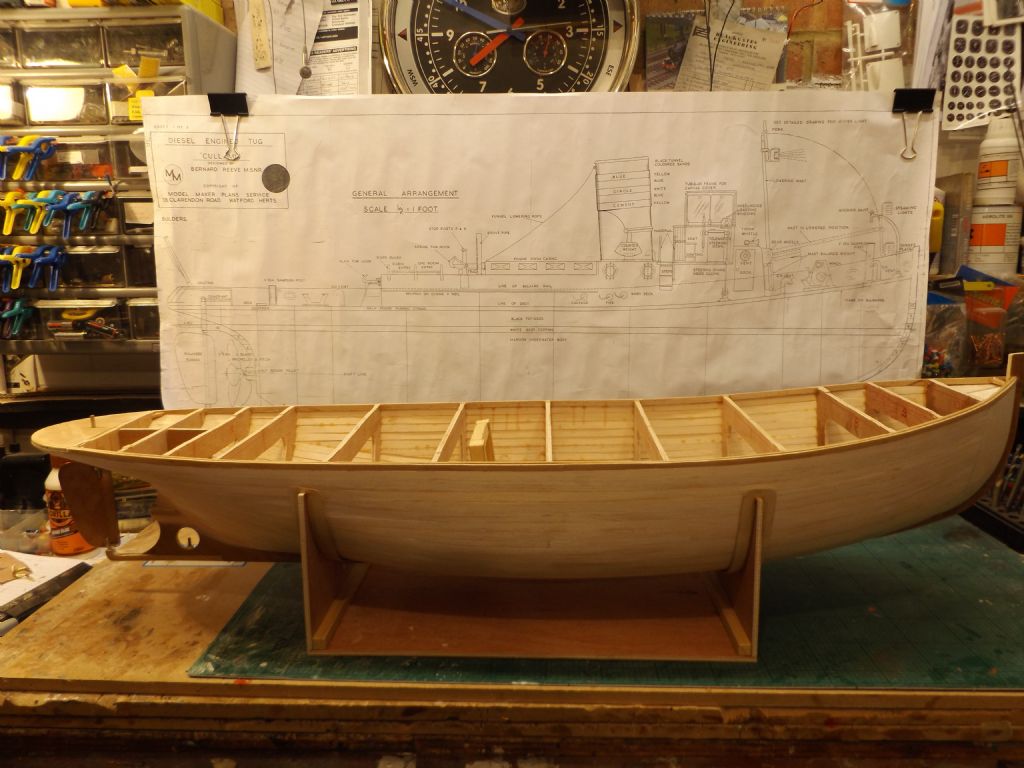

My plan will be to finish the hull with running gear, get the superstructure built and then weigh what i have, add a token amount for fittings etc, do a bath test, play around with some heavy batteries and see where i'm at before the decks get glued down.

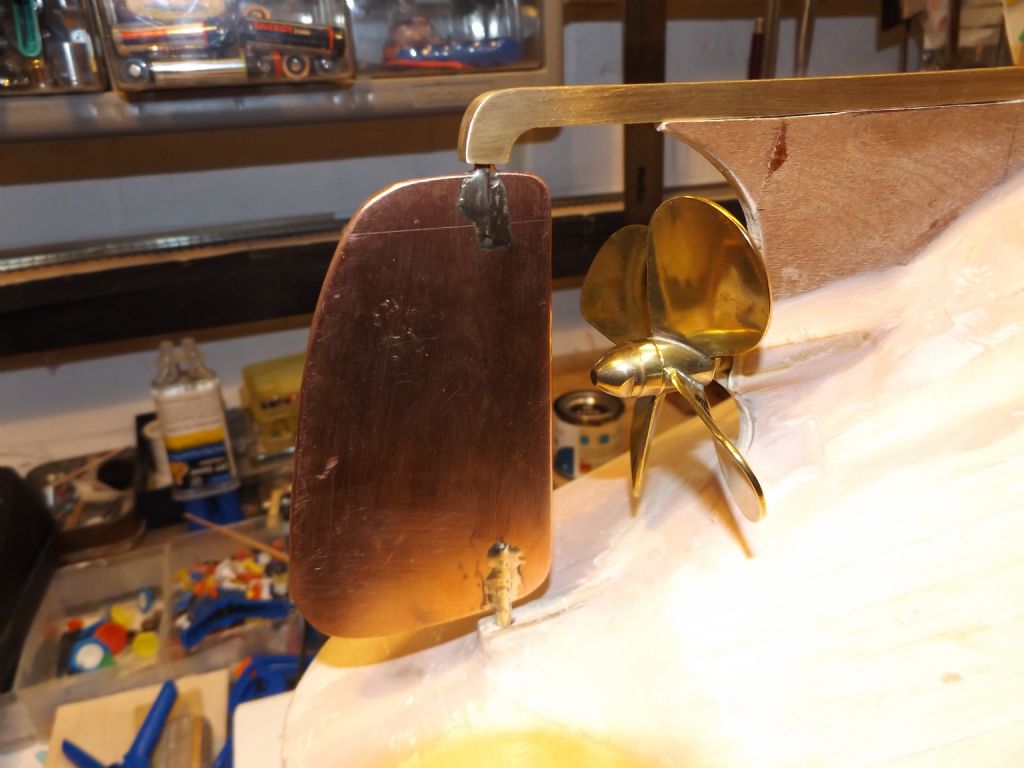

I have just had a delivery of essentials from Cornwall model boats, including my motors. After speaking with the guys at the prop-shop I went for a pair of geared 2.5 to 1 385s.

A good few years ago i donated all of my modelmaking tools, stocks of materials and RC gear to my father-in-law who is an avid aeromodeller. I really took for granted having a fully stocked model making workshop full of all the bits and bobs one acquires over time. It is only now when starting from scratch again I realise what a gave away. It is such a pain to have to buy every servo horn, every pushrod ! ! As soon as we are allowed to visit relatives I'm off to raid his shed !

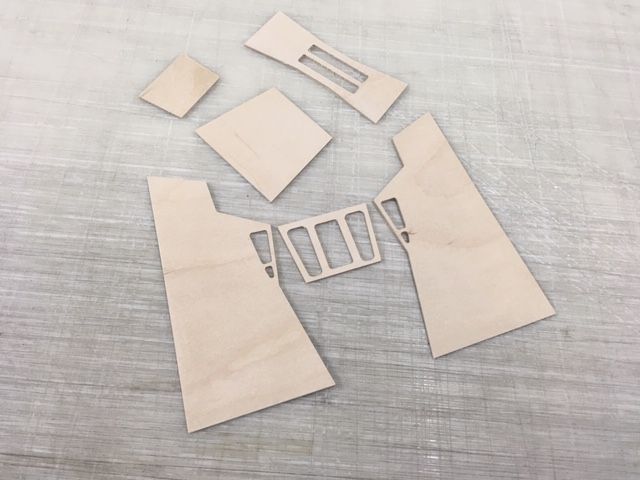

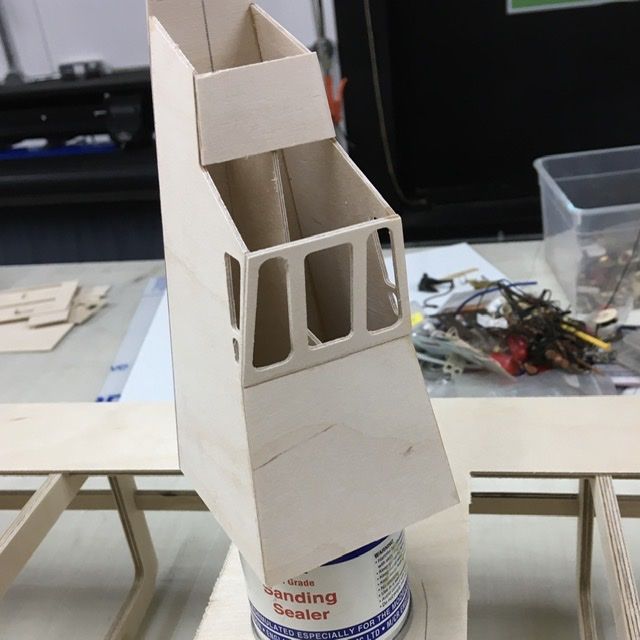

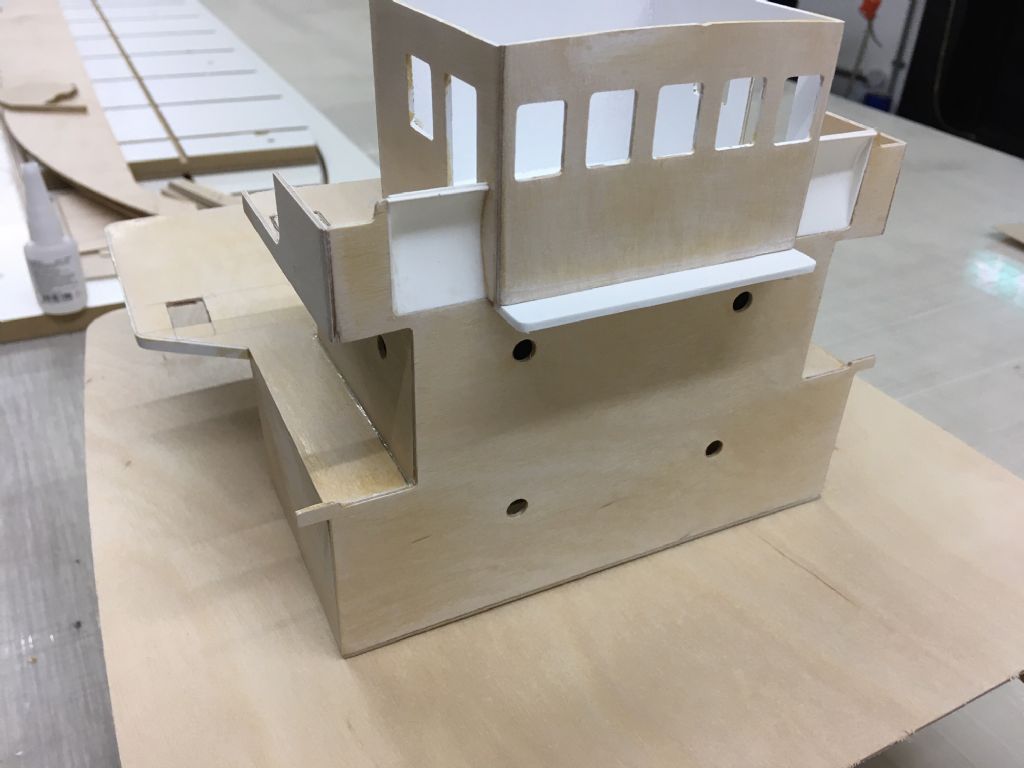

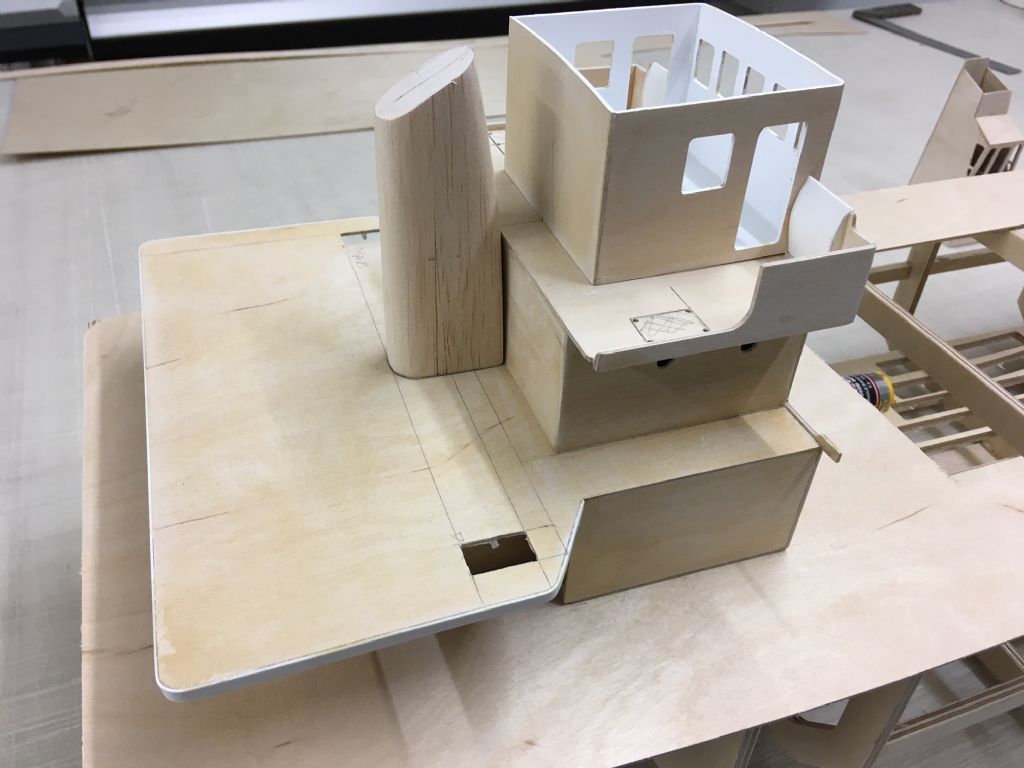

Over the last few days I have managed to spend a few hours making a start of the superstructure. I had planned to construct this out of plasticard but had a 4×4 sheet of 1.5mm birch ply in the off cut rack so decided to use this and save some money. I will use plasticard for the detailing. Just out of interest are 8×4 sheets of plasticard available is it the same as HIPs ?

I have noticed a few differences from the plan to the photos of the full size ship with regards to the superstructure, this maybe because the full size has been modified over the years. While i have many photos of the stern of other vessels in the mini series. I don't have any of the Sea Nass so I am going to use a little modellers / artistic license therefore she will not be a true scale model. ( unless i can convince the crew in Bahrain to walk around with a camera ! )

Thanks everyone Stay Safe.