Some more layout work before sticking anything together. Actually the two halves of the keel have been stuck together and apart from the cockpit that's about it.

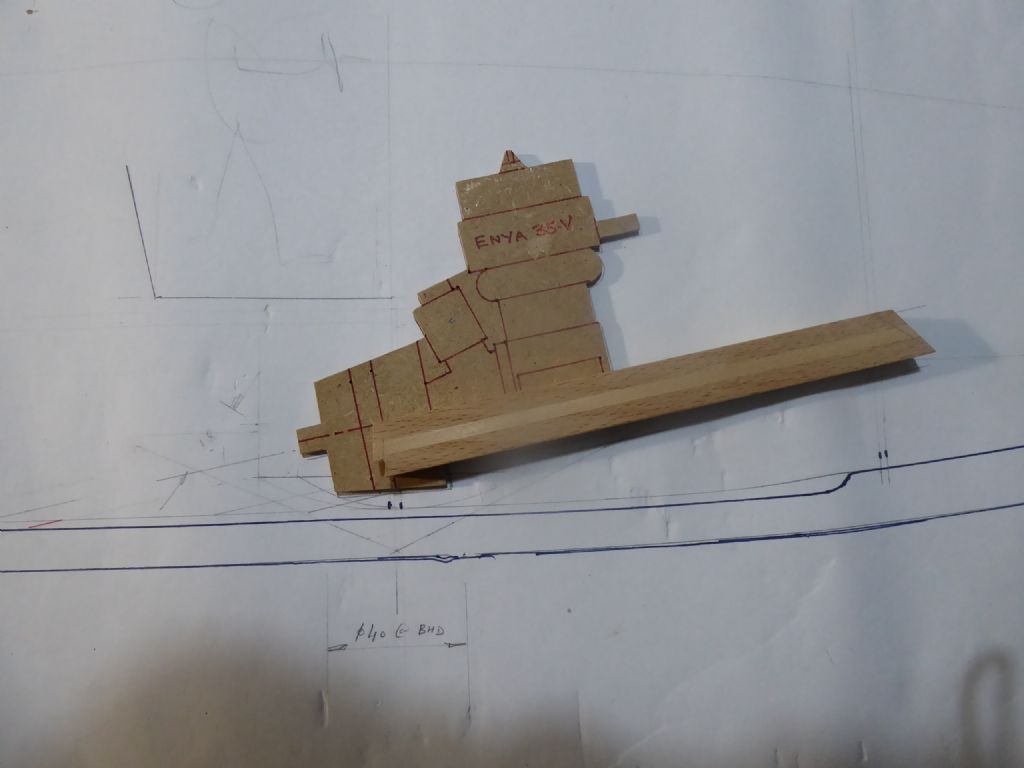

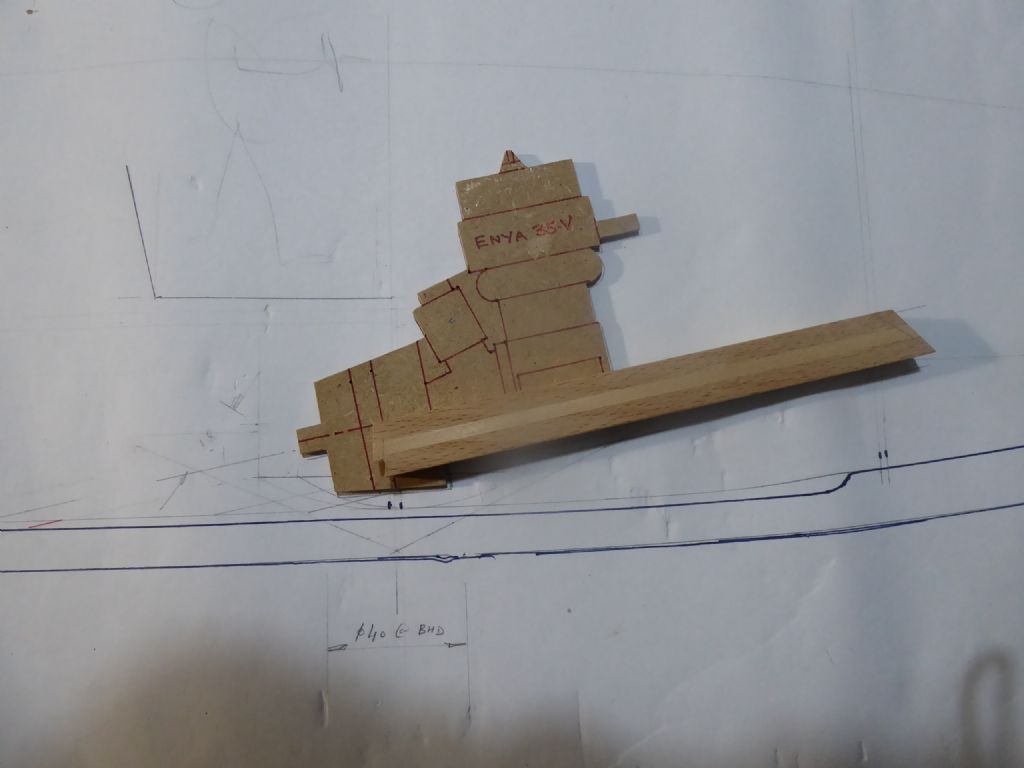

Here's the shadow engine on the bearers. The bearers have been spaced quite a bit wider than the actual engine mounts and the idea is that the engine sits on two aluminium plates to make up the difference. The fixings to the bearers will always have the same pitch but if I ever want to change the engine, all I have to do is make another set of adaptor plates. The plates are 3mm thick and I have allowed that thickness when setting out the height of the bearers. The bearers are beech and as hard as nails. They had grooves in them because they are for aircraft undercarriage piano wires but they have been repurposed by filling the groove with some hard white wood hence the two-tone effect.

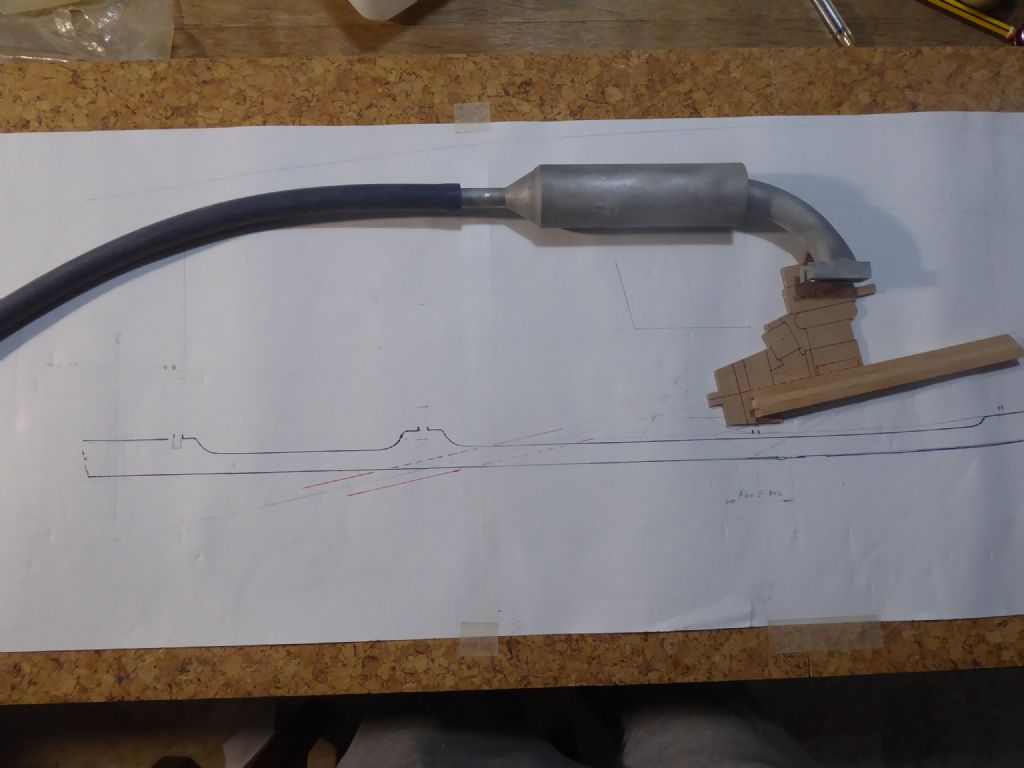

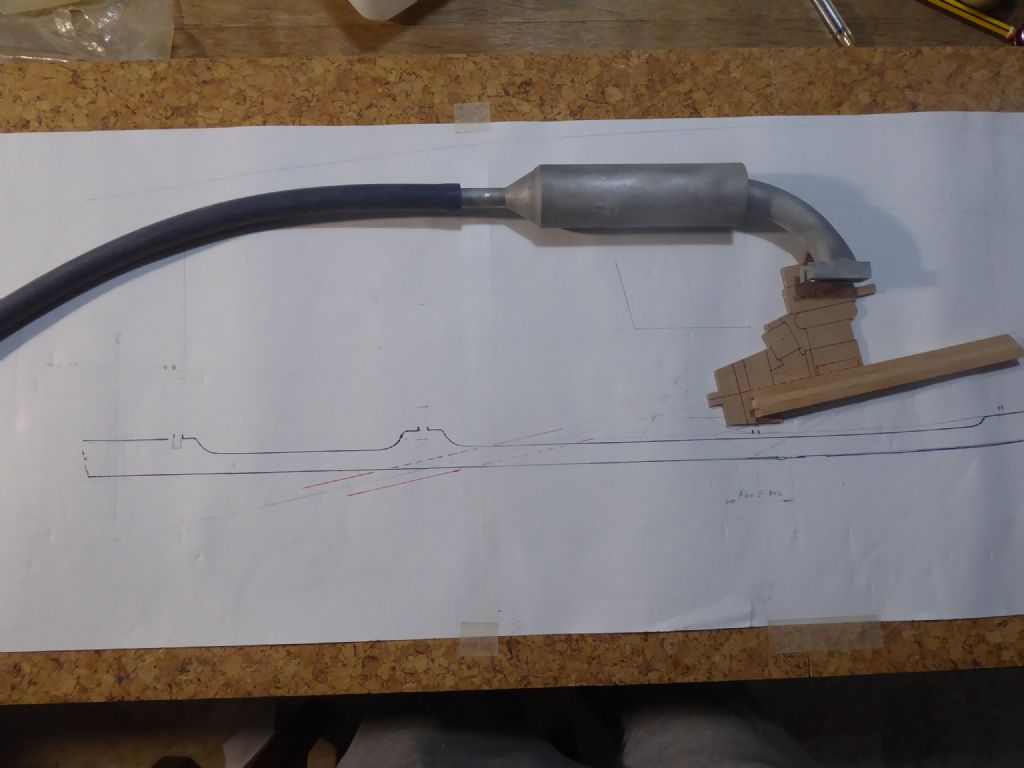

Here is the silencer and the silicone tube exhaust tail. The silencer arrived in a lucky-dip job lot I bought some time ago. It is aluminium. I have no idea how it will affect the performance of the engine but that's for later.

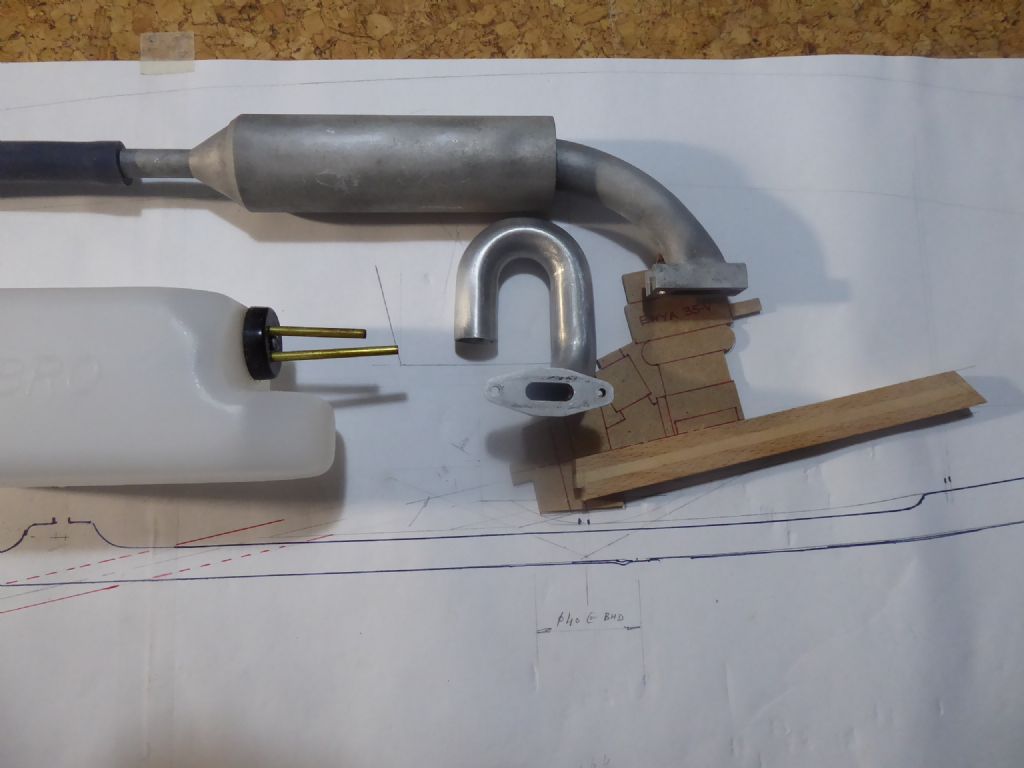

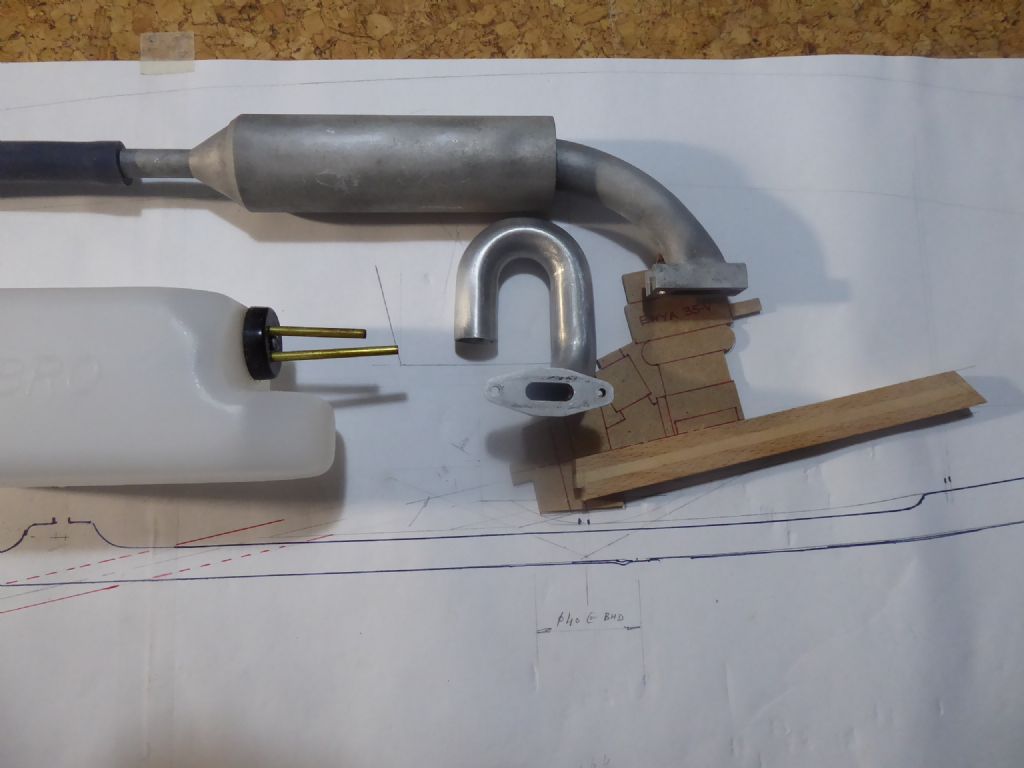

Same job lot and I have a rather nice exhaust riser. I have to adjust the pitch of the holes on the riser to suit the engine or I may make an adaptor. The flange on the silencer will be cut off and the two parts joined with silicone tube. I am going to bright polish the exhaust parts to add a bit of bling. There were bright shiny parts on the Ford Mermaid and Sabre engines that went into a lot of the Faireys.

Also showing is the fuel tank. Relatively speaking it is quite large for the engine which should give me a decent duration if I don't have to use full throttle all the time. It is an American Du-Bro tank marked in US fluid ounces. No idea what that is but there are 16 of them.

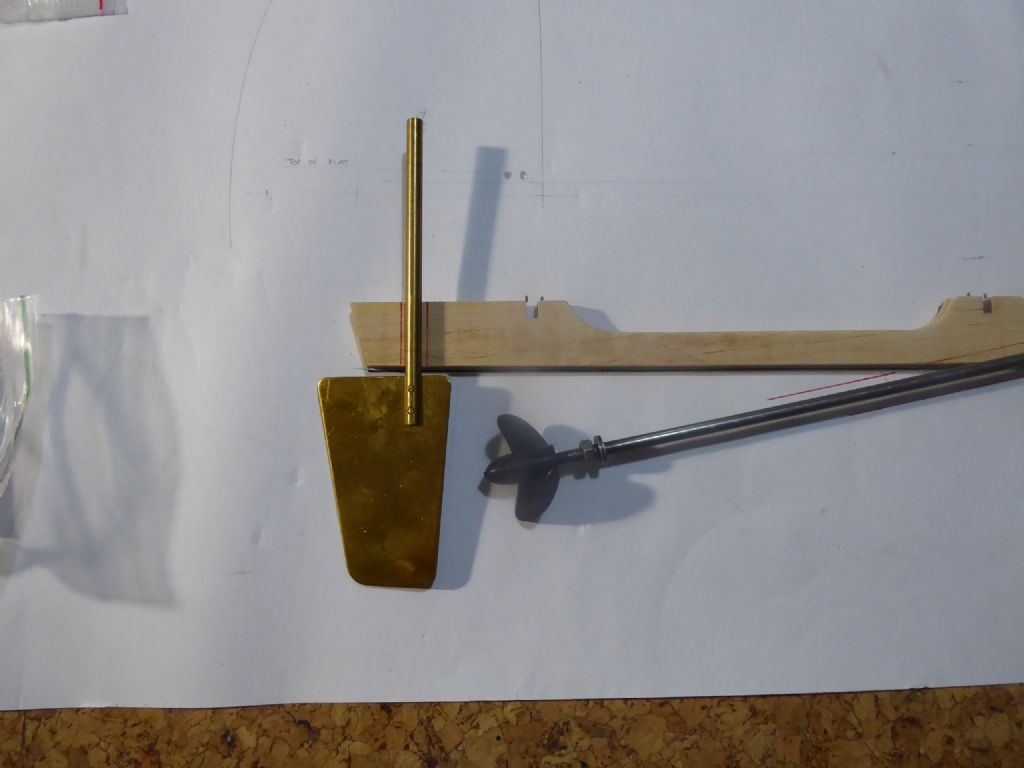

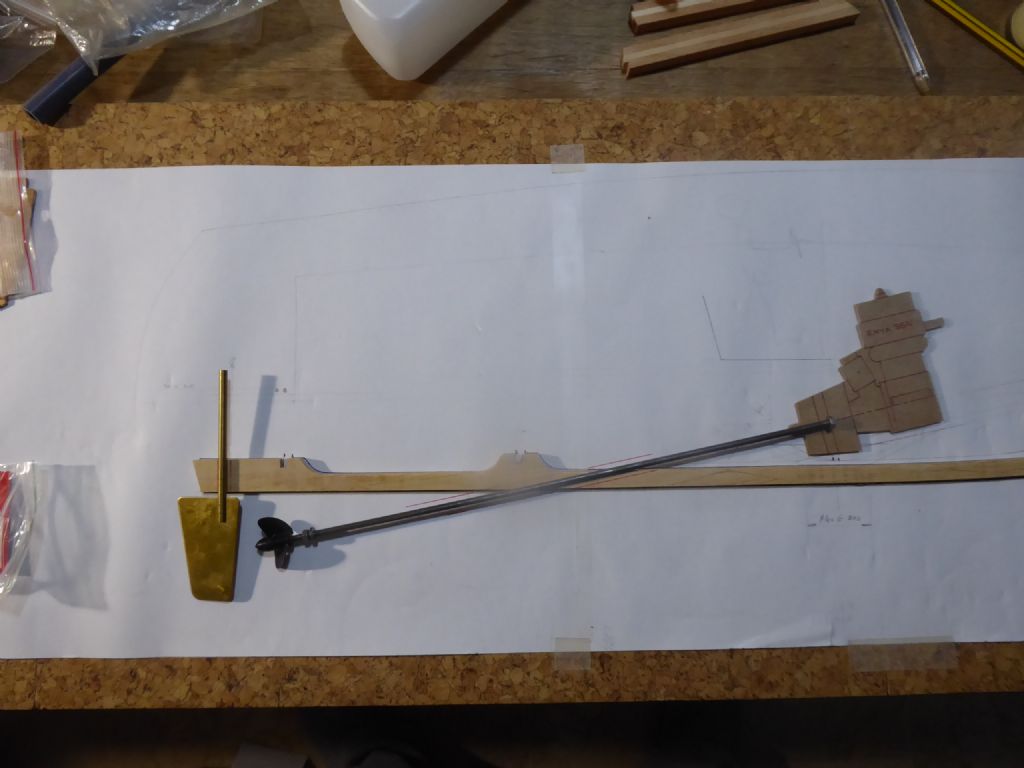

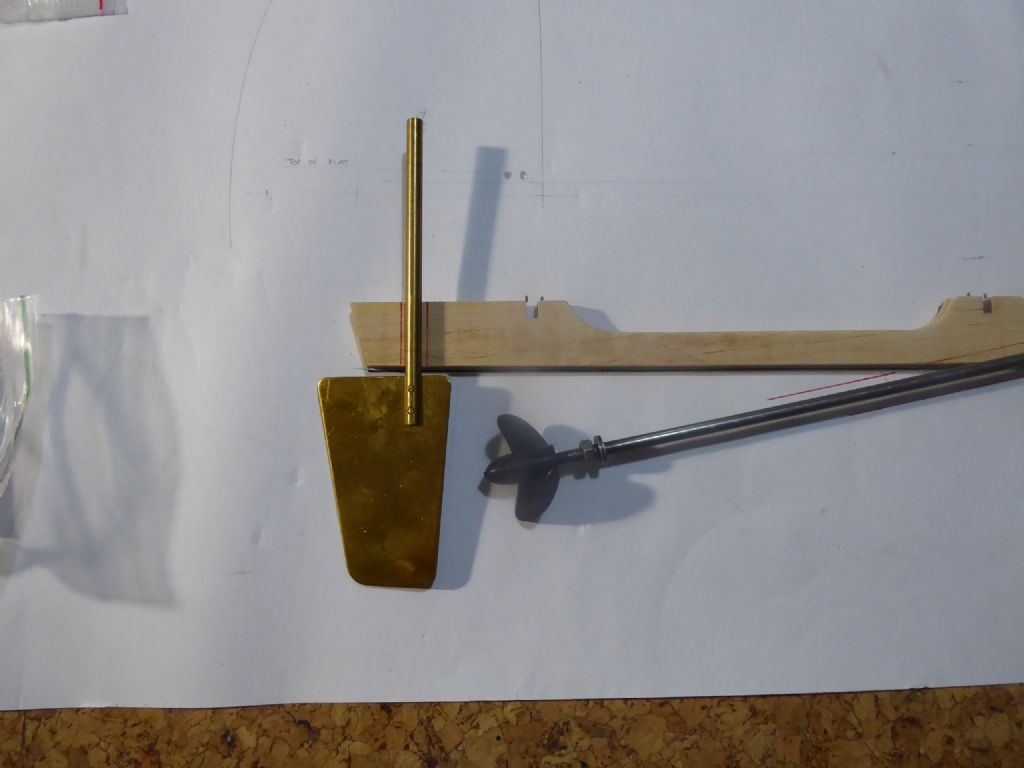

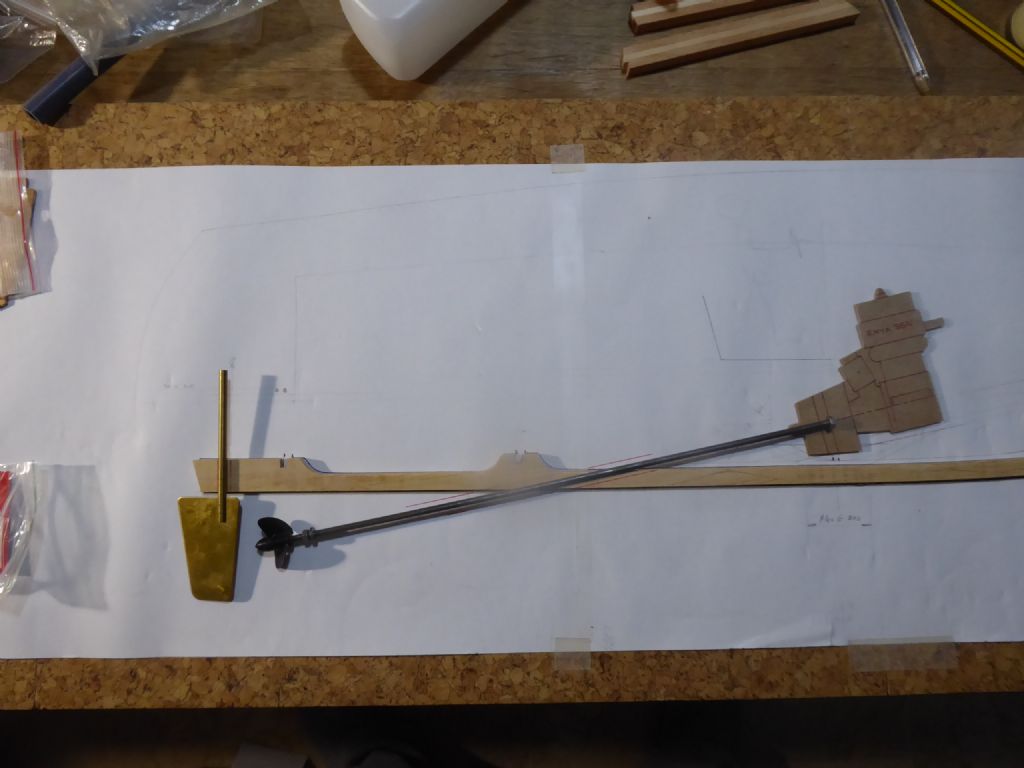

The rudder is as far aft as I can get it. It overhangs the lower part of the transom but is inside the top line of the transom due to it being raked. This has allowed me to get the engine further aft and to tweak the shaft angle.

Roaring ahead now with the shaft lined up. Somewhere in there I will have to fit a scoop for the water cooling pick-up. The shaft and tube is too long but I could easily sort that out. I don't know however whether it is any good or whether I should buy something better. Ideally it would like to have a short tube and run the shaft in a bearing in a P bracket like full size. I shall be picking brains on that later as modelling wise this is new to me.

Final check to see if the cockpit will miss the bits. The photo is biased and in fact the engine is clear from the front of the cockpit with plenty of breathing room around the carb. You can now see that the tank goes about 1/2 way through a frame and is supported by the cut-out. It will need a steady at the front when everything is finally being assembled for real.

I like to try to arrange things to have dual purpose and in this case the bulkhead avoids me having to make a separate cradle and keeps everything nice and simple inside.

I'll have to do some more building now as this is about where I am.

Tim R

Edited By Tim Rowe on 24/05/2020 20:26:19