Hi Ray

Yes, part of the fun even if it doesn't feel like it sometimes! I've learnt not to tackle things like this in the evening when you're starting to feel tired and want a quick fix – not that kind of fix! Best to leave it to the morning and have all day to think about it and have the time to make the necessary parts and remake if required.

At last I've finished the flippin' bedroom! Not going to do the landing for a couple of weeks so that I can do other things with No. 1 being model boat building!

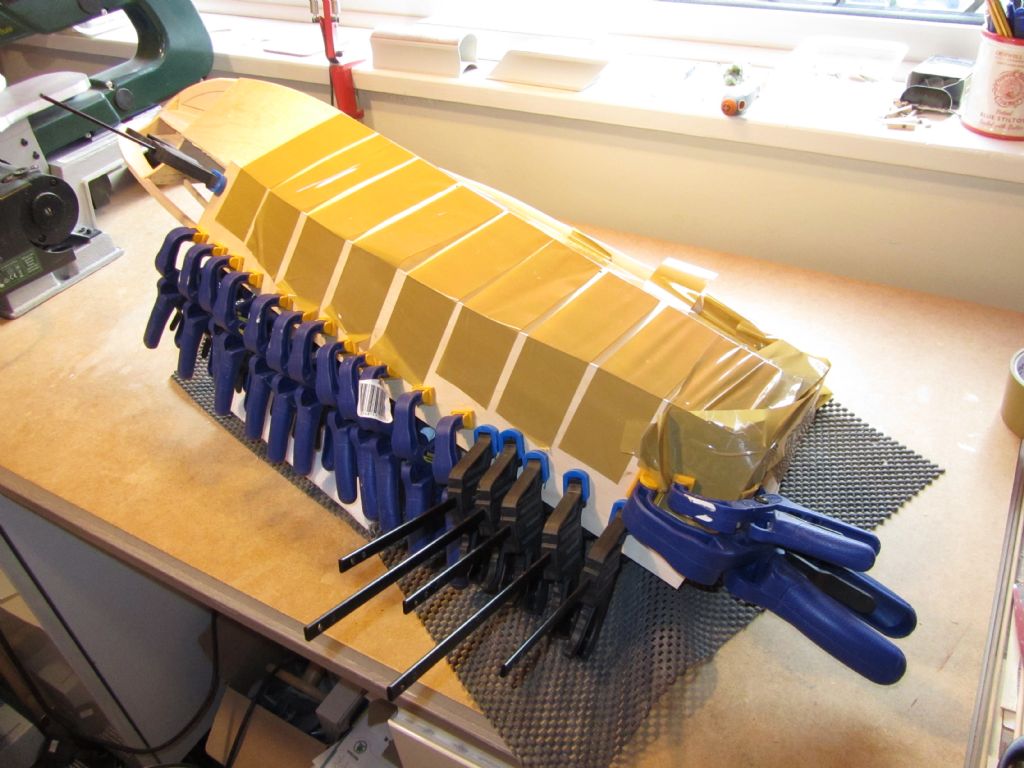

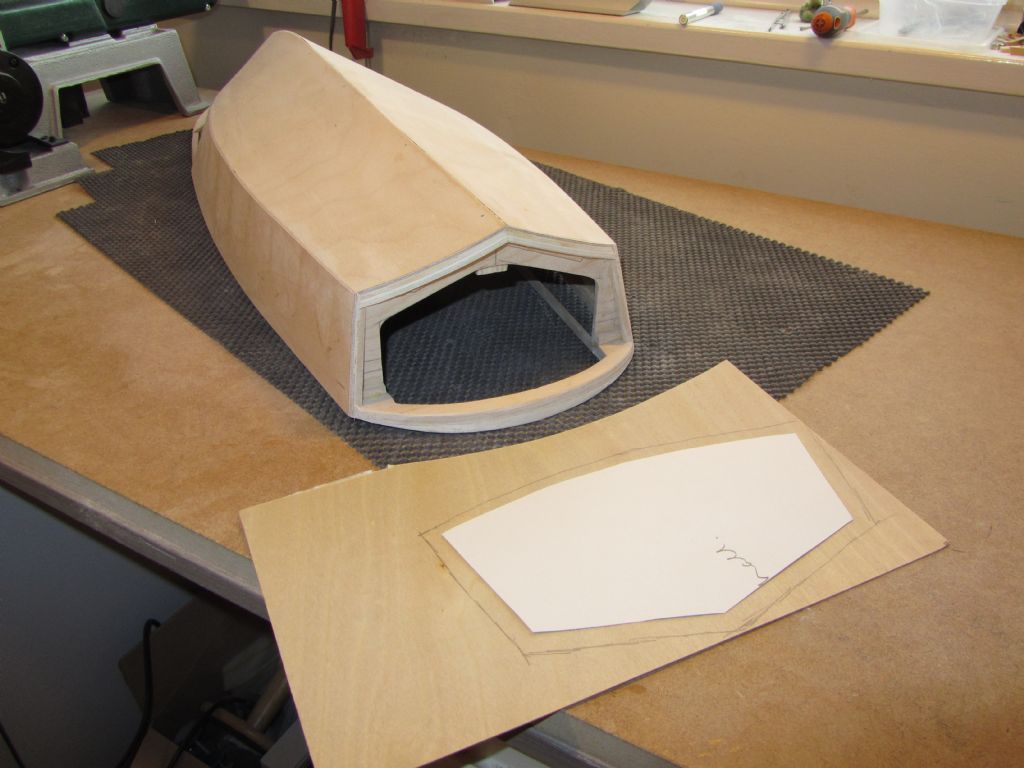

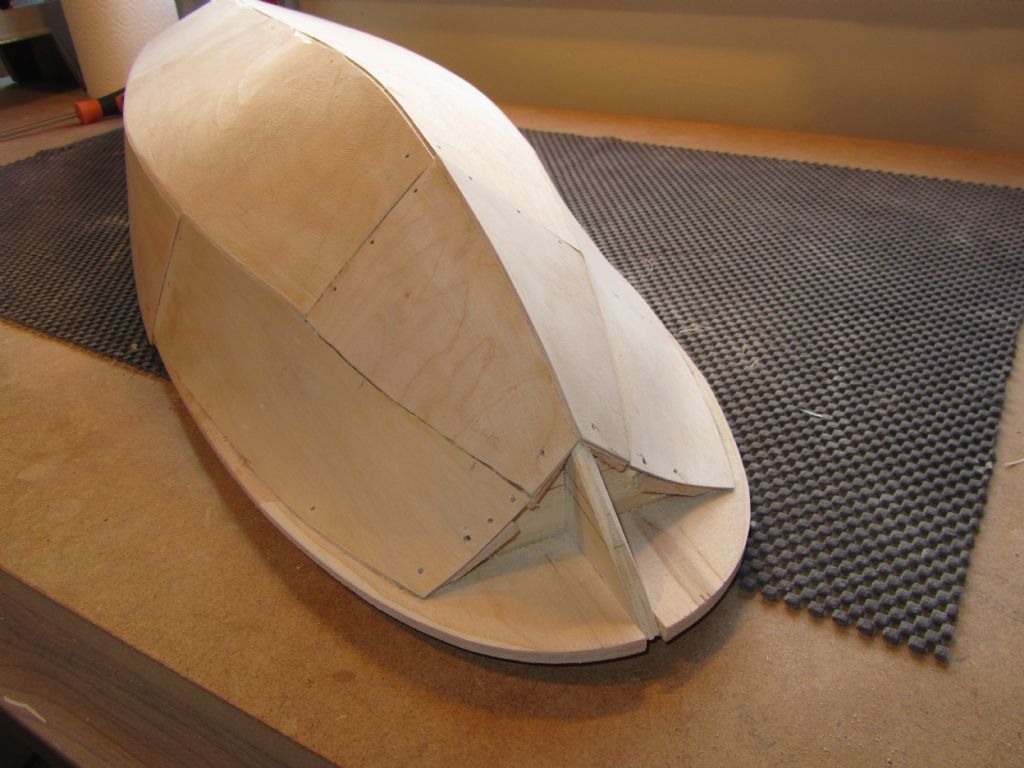

So yesterday it was out with the P38, which I didn't need too much of, and with the weather still being nice did the preliminary sanding outside. Today I finished off that sanding and applied a bit more P38 where required and after leaving for the requisite time sanded it again and it's pretty much there now. Just needs some minor surface filling where the balsa is showing and looks like it's got chicken pox and after a final fine sanding all over the hull it will be ready for cloth and Eze-Kote. It looks better in the "flesh"!

Well not quite on two counts. Firstly, for some reason I didn't cut the slot for the P bracket when I was doing that for the prop shaft when assembling the keel (no problem doing now of course) and secondly, as Old Mother Hubbard found out, the cupboard is bare, well as far as lightweight cloth goes anyway! So today I had to order a couple of packs from Deluxe Materials.

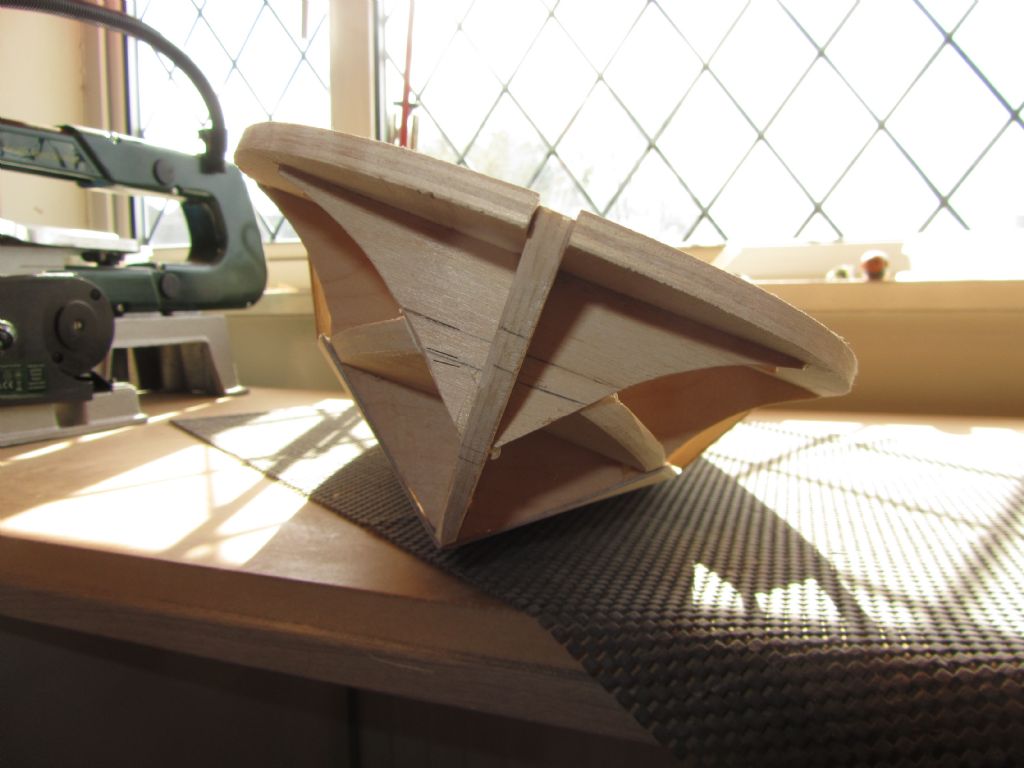

A couple of weeks ago I was pondering on whether to make both superstructures for use on the one hull, i.e. the large cockpit of the Sport version and the aft cabin version. Still pondering but it will be nice to have both complete boats. And a couple of days ago when woken early by the dawn chorus and trying to get back to sleep I was musing over whether I should be even building the Sport and not the aft cabin version. Reason being that I've got the Spearfish kit to build and as the hull is based on the Huntsman 31 hull and it has the full cockpit I will end up with two very similar boats. Added to which I've already got other full cockpit boats with the Huntress and Huntsman 28. Decisions, decisions!

Chris