I am embarking on my first ever scratch build. It is Mr. Dave Milbourn’s design of the Fairey Huntress 23, published in the Model Boats magazine autumn special 2017.

The first difference I have noticed is how much longer it takes, compared to a pre formed kit. I think it will be considerably cheaper as well.

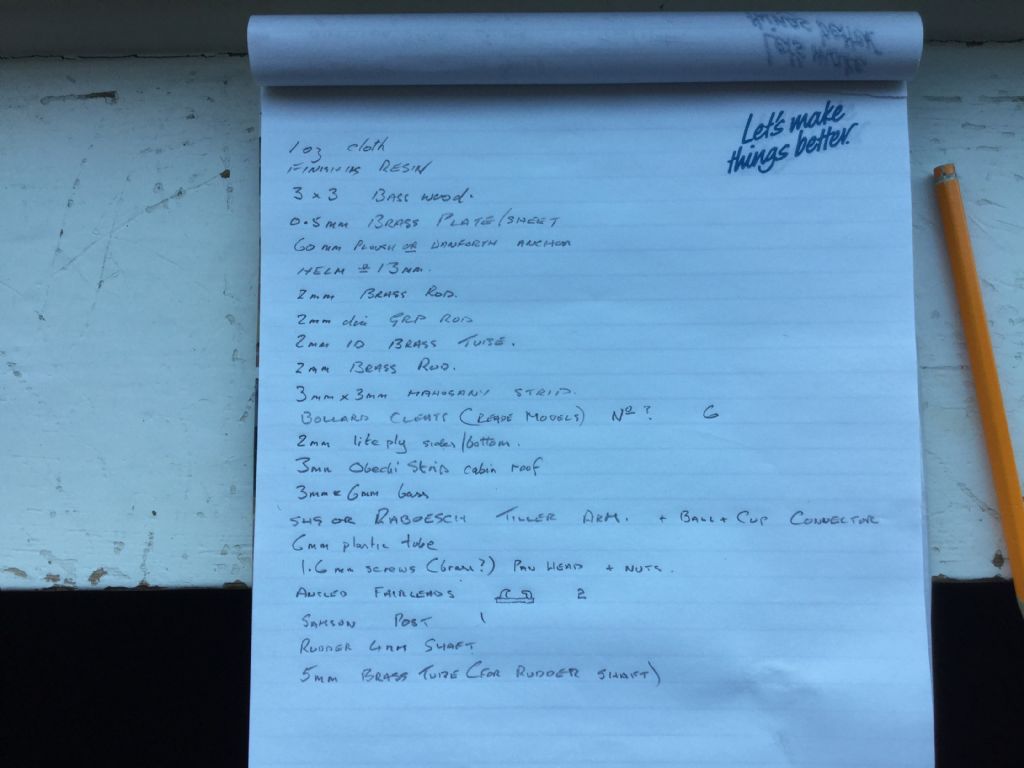

.I bought as much wood and parts as possible at the Warwick show, but as I delve deeper into the plan, and instructions I am forever making lists, and buying via the internet. ( There are no model shops around my area, as far as I am aware.) I also had a 2nd copy made of the plan.

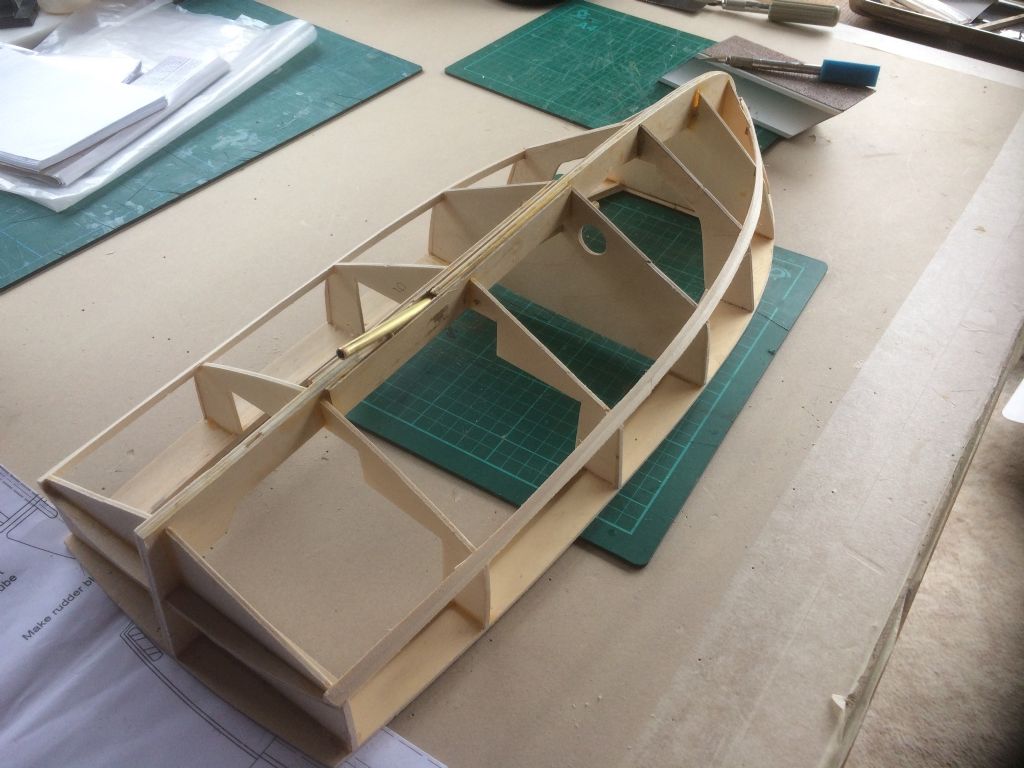

I started by cutting out the parts for the hull, and sticking them onto my plywood, using double sided sellotape.

Then time to try out my recently purchased scroll and small table saw. Learning curve was fairly steep but managed to get the parts cut eventually. I still have a fear of turning the ply when scroll cutting, when the blade snaps it’s makes me jump, and I’m always on edge waiting for it to happen! Must practice.

Today I have virtually finished the assembly.

I think I have a little trimming to do so as to achieve a uniform distance from the edge of the deck to the point of contact of the ribs so that the sheeting will align correctly along the length of the hull.

The next job is to make the brushless motor mount support and align motor to shaft. I think?

Well its starting to look like boat, to me anyway.

PS it’s a real pain typing this onan ipad. The text and curser keep disappearing out of view. Ball ache.

To be continued..