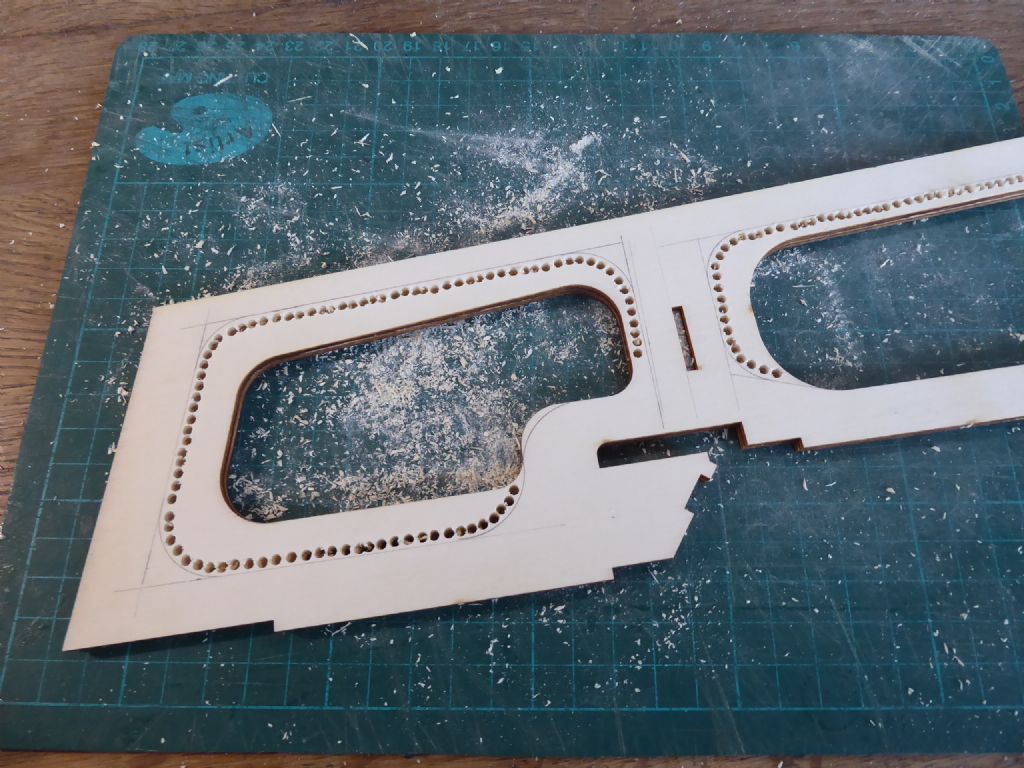

The laser cut fuselage parts assemble with tabs and slots which is helpful as they were quite accurate. It goes with saying that both pieces of ply for the main body were curved the same way so I could not "hand" them to cancel out the bend. Even with the tabs it would be very easy to build in a bend and a twist. Nobody would want that in a boat – unless of course they were building a Gondola – but in something that hopefully is going to fly, it is very bad news as it affects the incidences and could induce some very unpleasant characteristics. Actually the instructions are quite and stress the importance of accurate alignment.

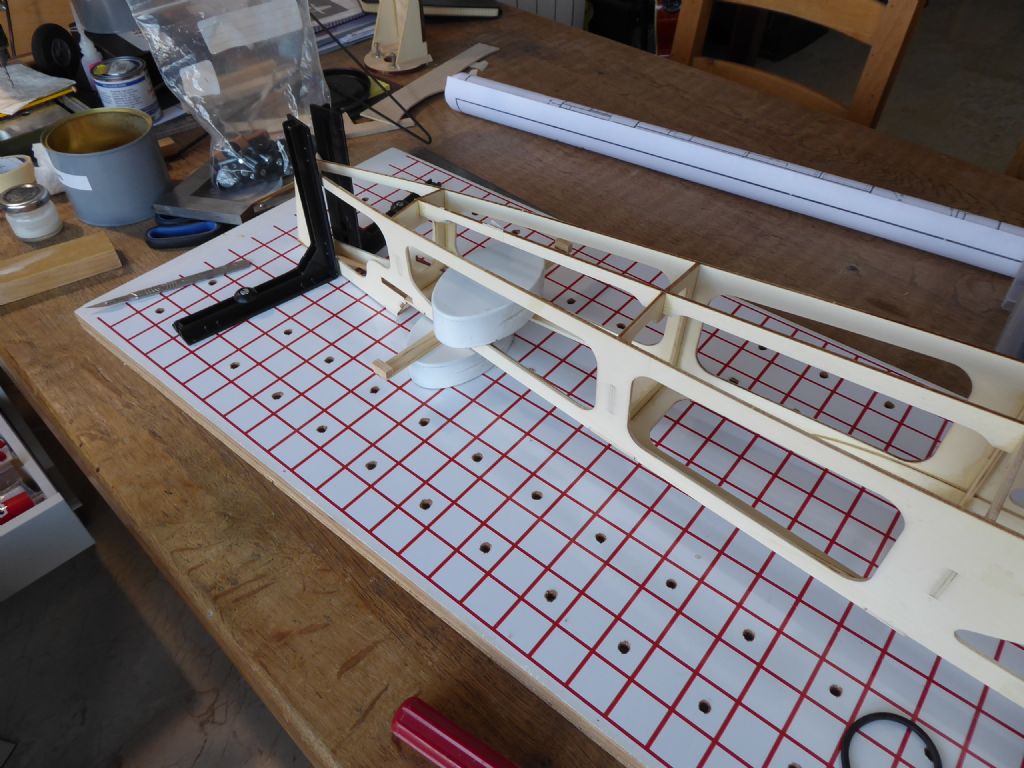

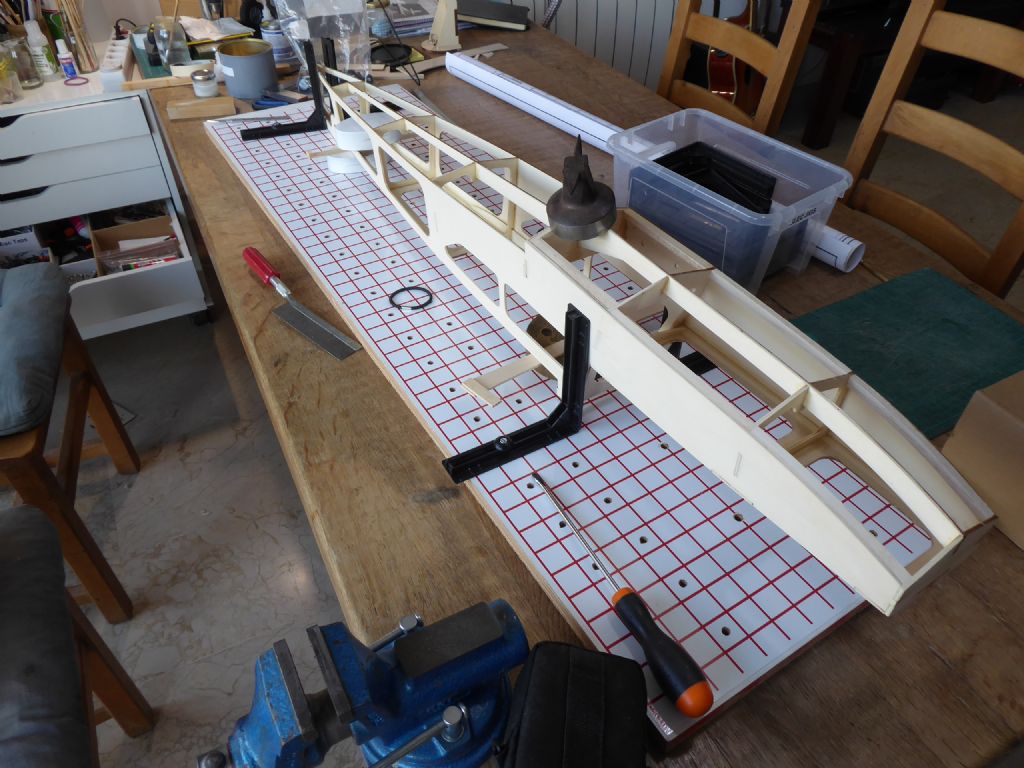

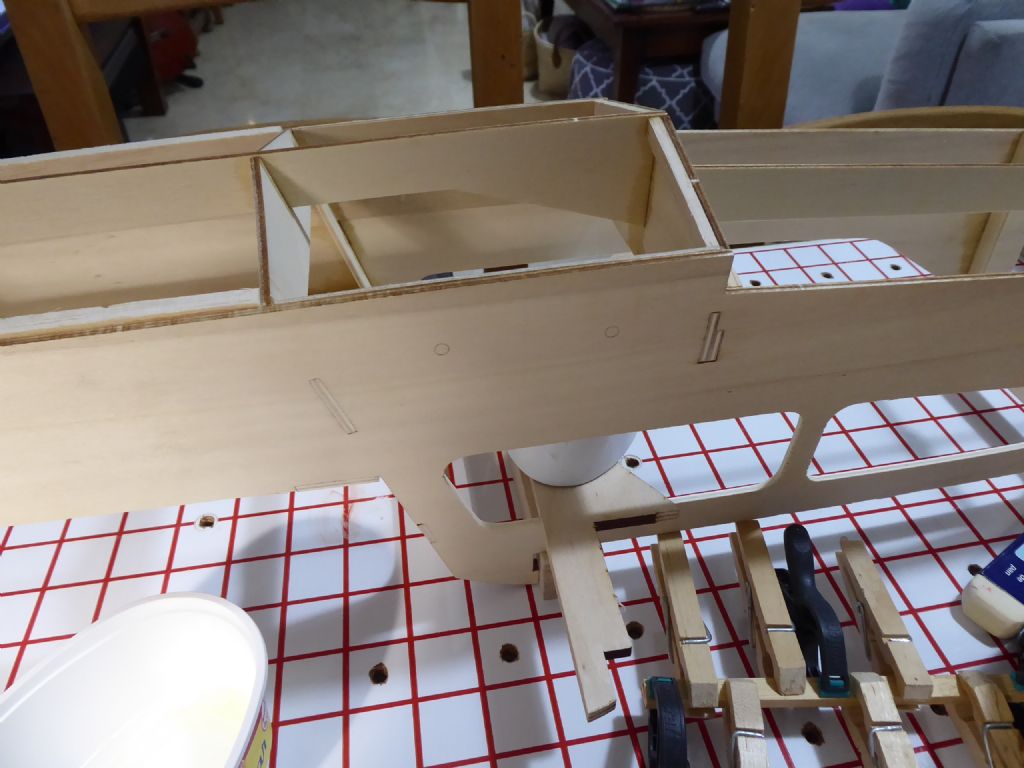

Here is the first former going in. The big round weight is holding the fuselage locally flat and two engineer's squares are holding the former vertical. I needed two because guess what – the former was twisted. The miniature anvil is simply pushing against one square to keep it in place.

Incidentally I am using aliphatic glue which I decant into one of those individual portion jam pots and brush it on the joint using a small brush that lives in a jar of water which gets changed every week or so. The aliphatic I use is not water proof and is at best water resistant when fully cured. I like it though because it grabs very quickly and it is light. Most of the weight is water and evaporates away. It is unlikely that this model will spend huge amounts of time on the water but nonetheless I am brushing the glue on both side of all joints as this will provide some semblance of sealing as I go along. I don't bother doing this on normal aircraft.

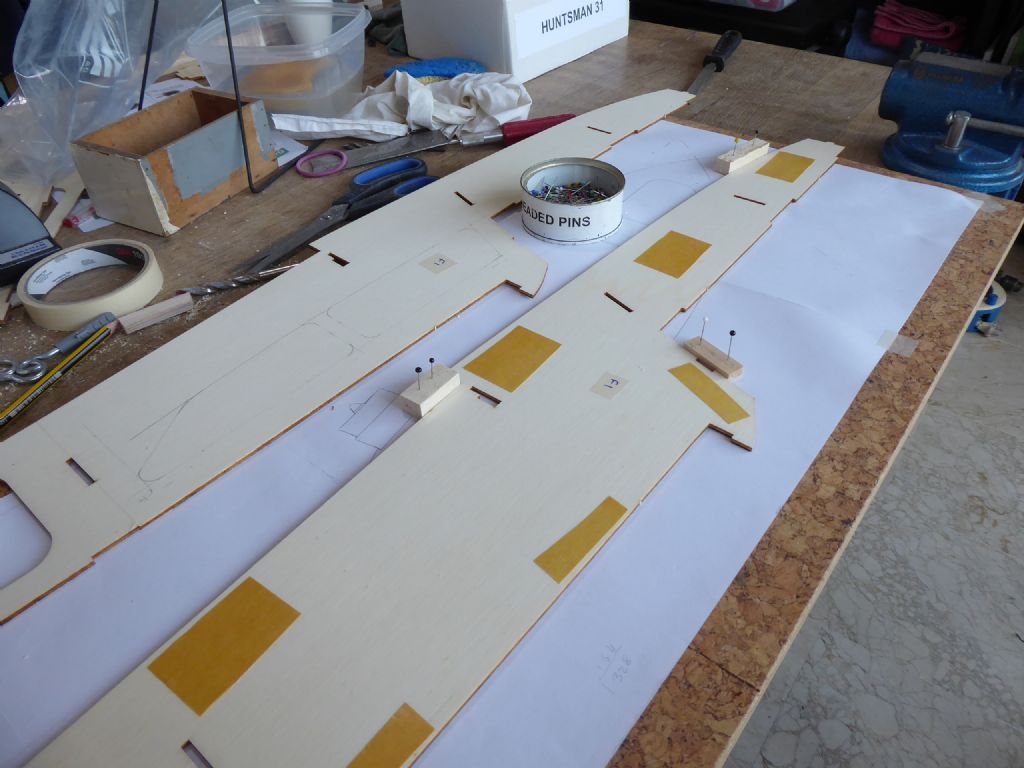

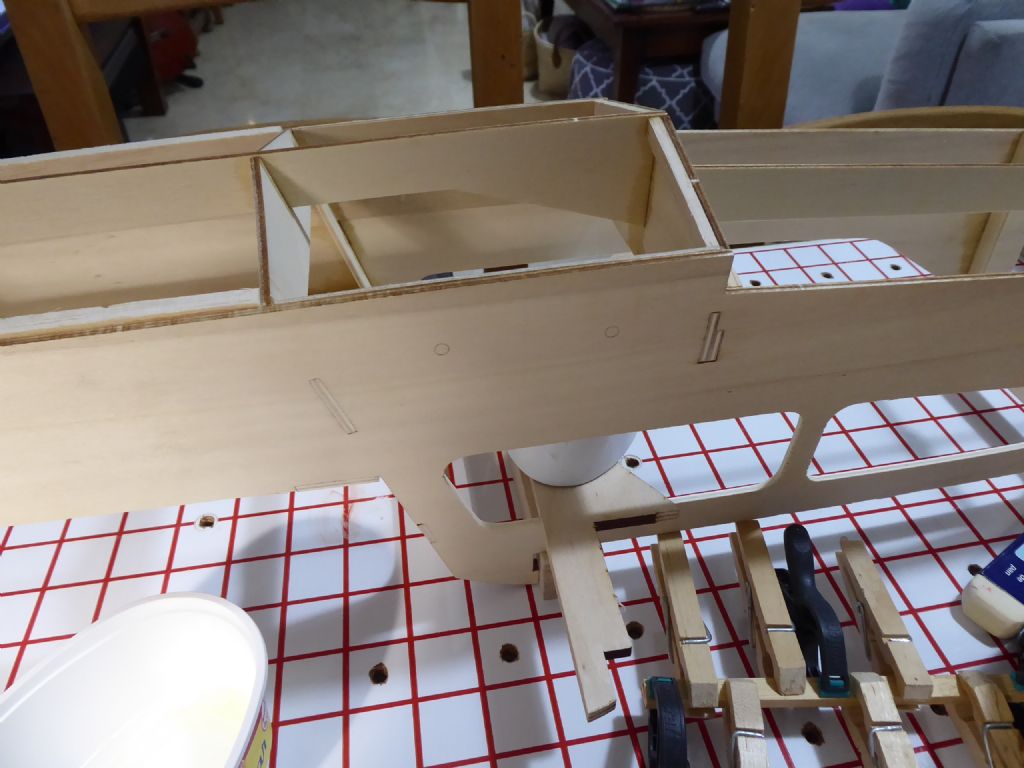

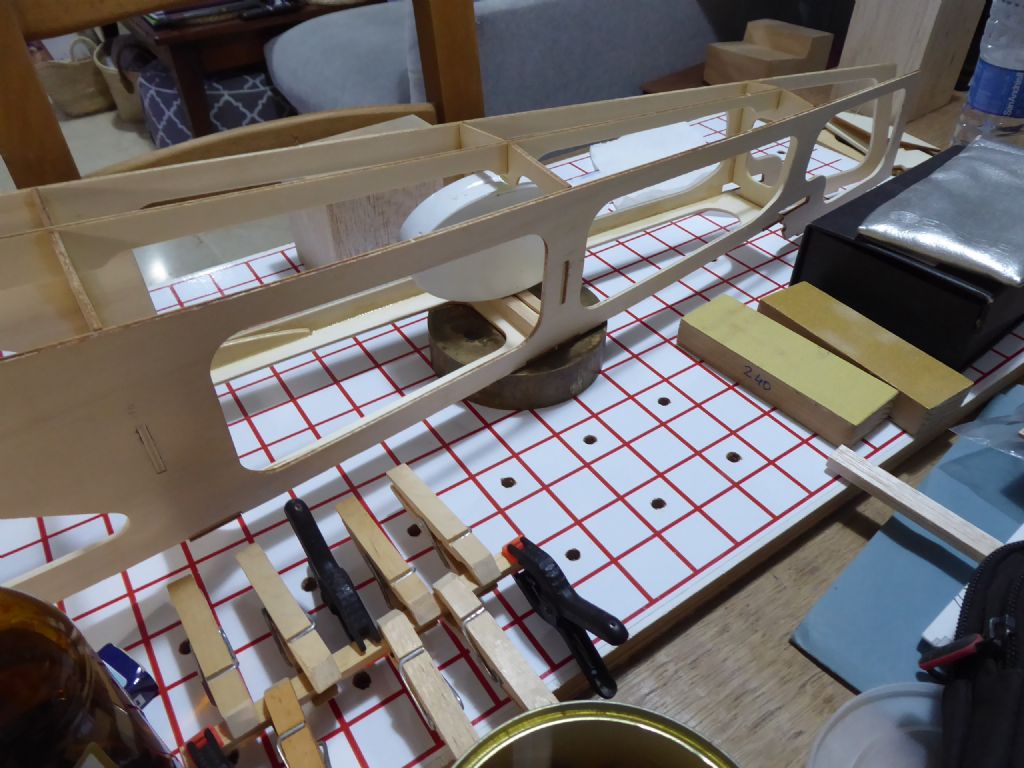

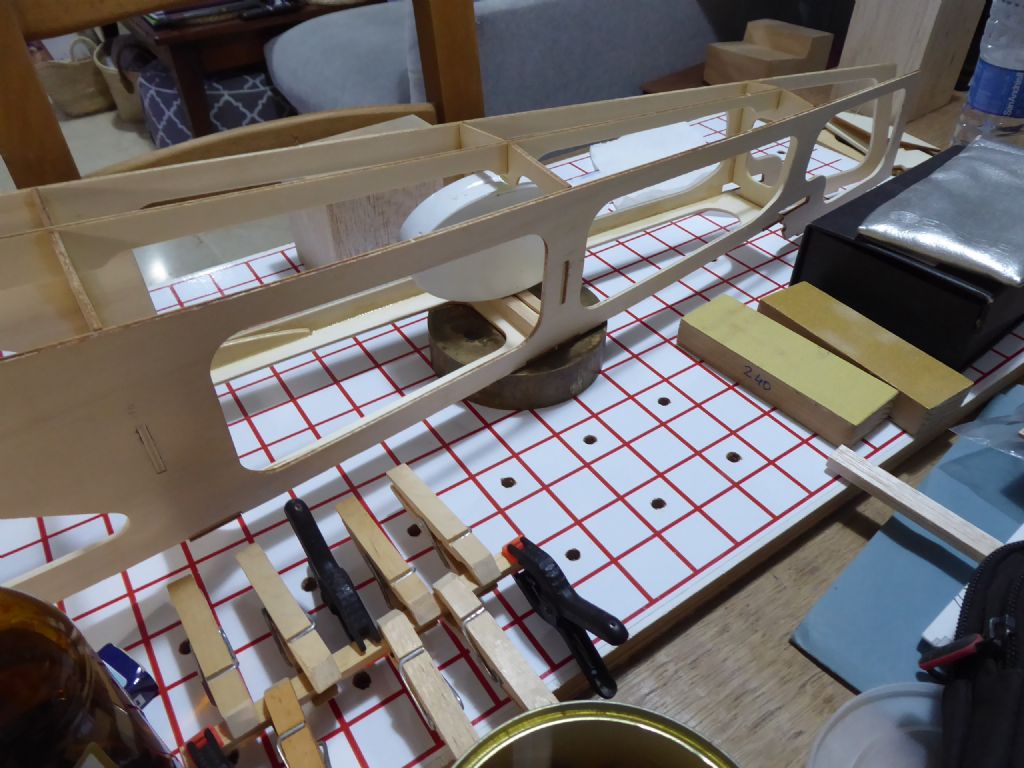

We are now on the SLEC fuselage jig. It's one of those things that make you wonder how you managed before getting it. You have to buy a board to put the vinyl sticker on and I bought maybe three times as many blind nuts and screws as supplied to increase the number of jig position options. Since I bought it I don't think there is a single model that hasn't been on it.

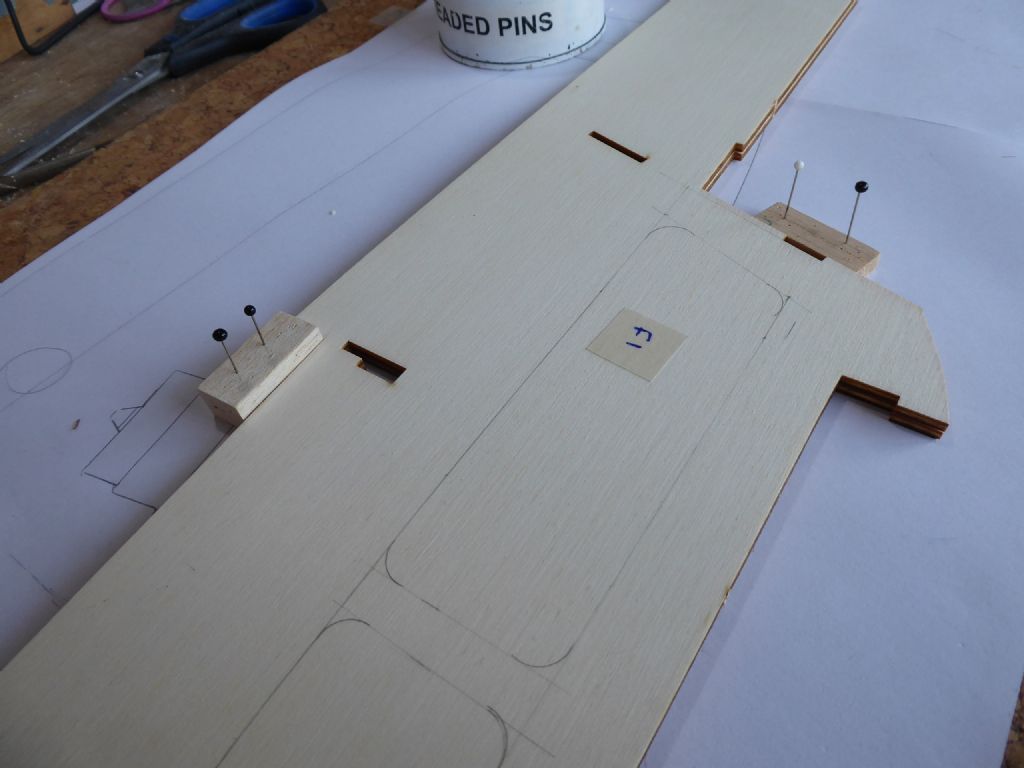

In this photo you can see the step and the bow is off to the left. This forward section is the one that will get most of the pounding taking off and landing. I wasn't keen on gluing the bottom sheeting to the edge of the ply alone. It would be a bit like building a chine but omitting the chine stringer. On the fore side of the step I have glued a balsa doubler and later I did the same all around the front end. I now have a decent gluing area with a ting fraction of weigh gain.

Here is the aft end showing the keel in place. On the water at rest all this has to do is keep the thing afloat and hold the tail in the right place. Very quickly the hull will be riding on the step and this bit will just be receiving spray. I have glued the bottom skins to the ply edges with the doubler following the instructions this time and to keep to the them of keeping the aft end as light as possible.

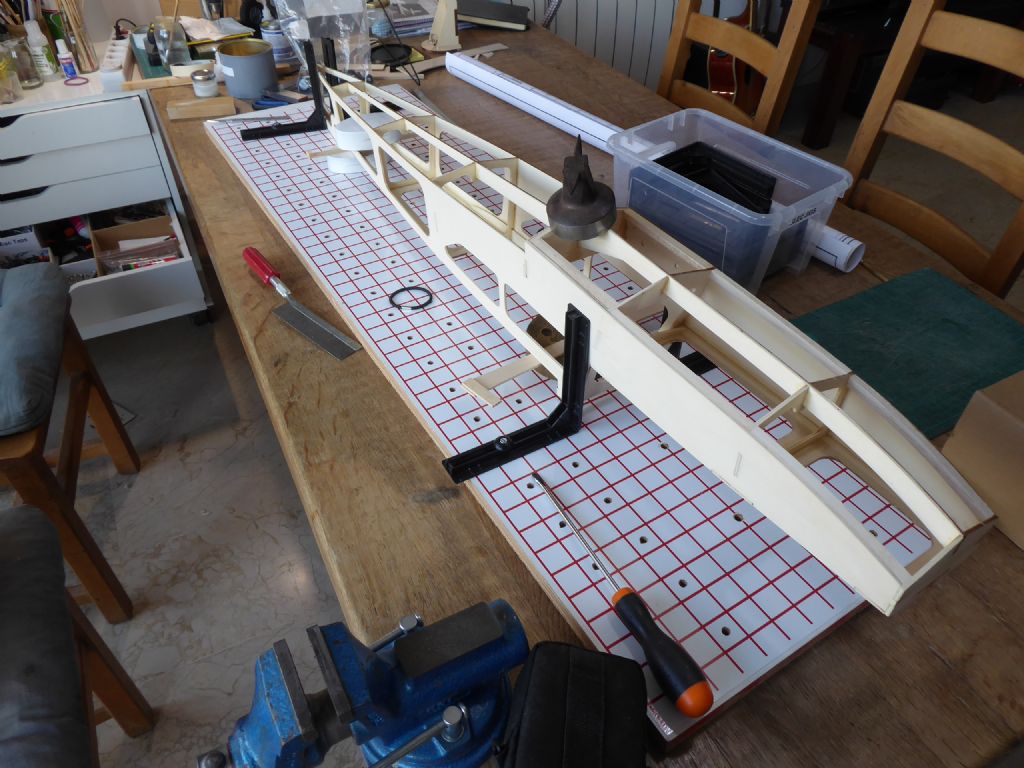

Here the hull is in the SLEC jig and weighted down to take out the twist. The lines on the jig make it a doddle to make sure everything is straight and the brackets hold it in correct alignment for the bottom sheeting. Once the bottom sheeting is on, the structure becomes a box and resists twisting (or straightening if you get it wrong!)

Near the bow you can see the doublers down each side. I did not try to bend these from stock but cut the curve out of sheet. Medium soft balsa, light and very easy to sand.

The only thing I don't like about laser cut wood is the brown scorched wood. You will have seen some in earlier photos but I HATE it and at some point, all cut edges will get a sanding to remove it. Actually on very light aircraft construction where the minimum amount of glue is used, I remove it because I don't trust gluing onto the charred material. Fortunately I am not totally alone in this affliction!

Next job is the sheeting.

Tim R