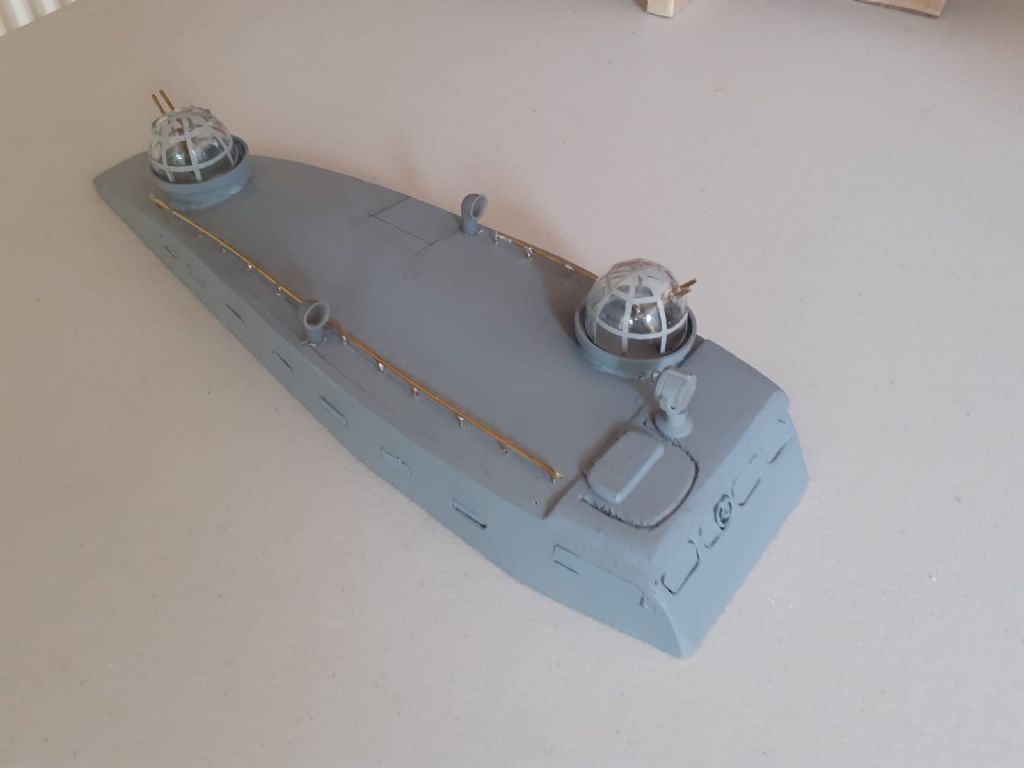

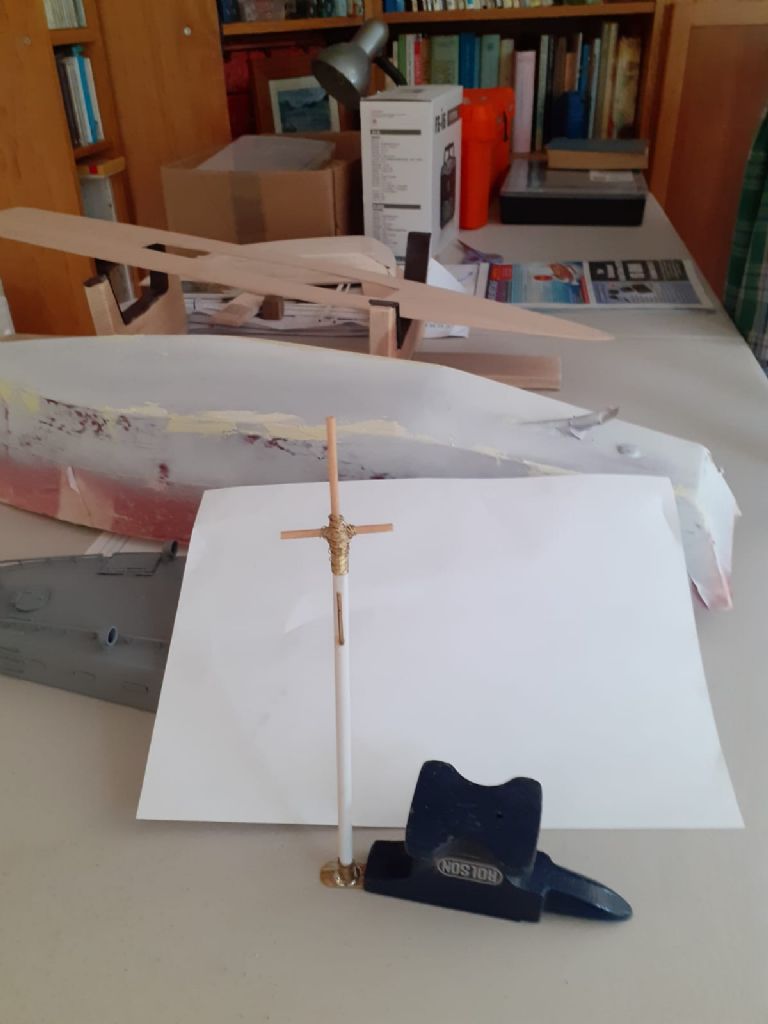

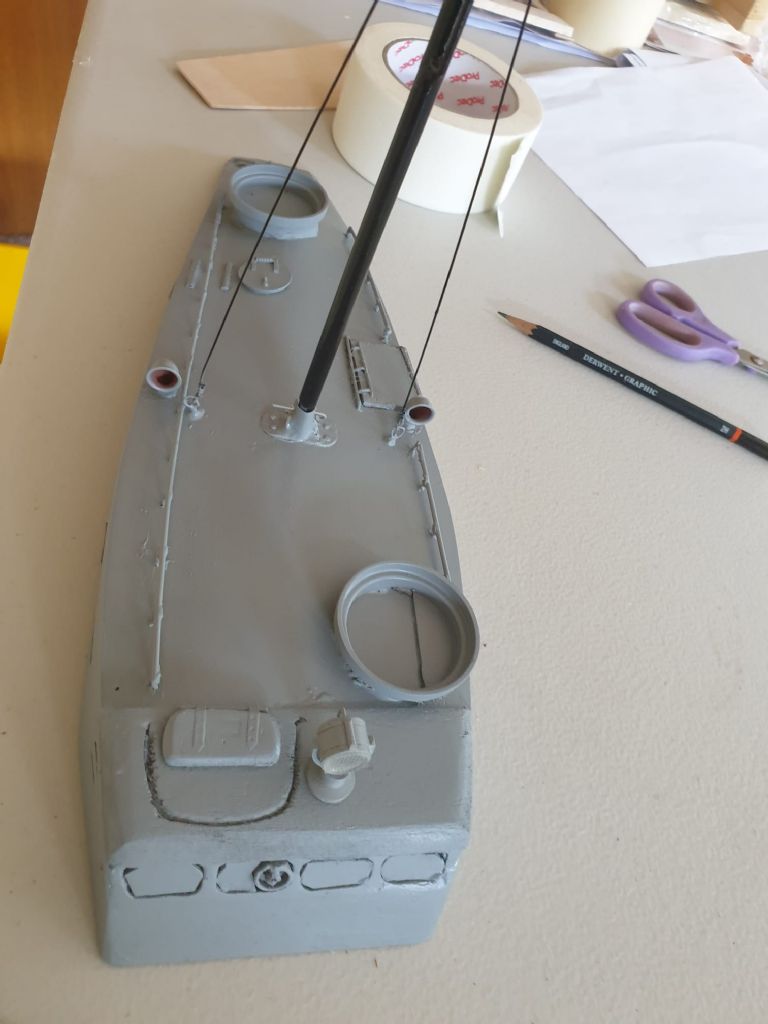

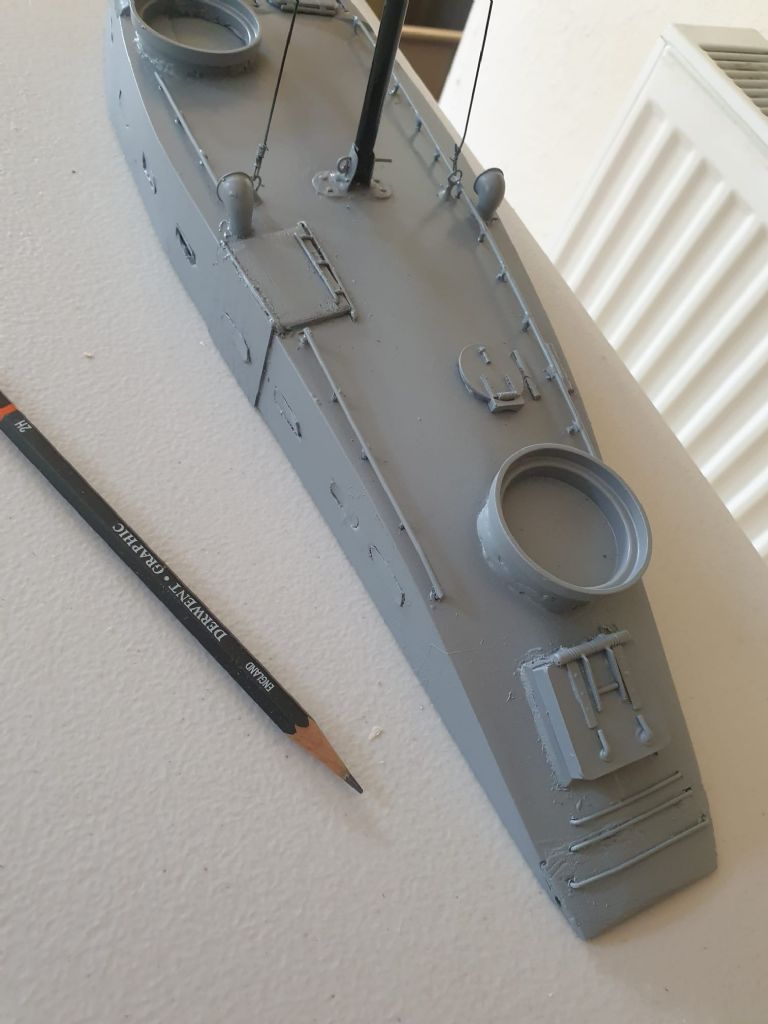

RAF rescue launch ASR HSL

RAF rescue launch ASR HSL

Code of conduct | Forum Help/FAQs

Latest Replies

Viewing 25 topics - 1 through 25 (of 25 total)

-

- Topic

- Voices

- Last Post

-

- My Clyde Puffer 1 2 … 9 10

- 17

- 1 week, 4 days ago

Viewing 25 topics - 1 through 25 (of 25 total)