Hi there

The Aliphatic glue that I am using comes from a Company called M.D. Products and I have been trying to find a link for it – but – the only place I can find this product at the moment is on Ebay – I have the Deluxe version of this, which I will be using very shortly. The original bottle has about ran out after me using it for about 5 years – so not bad.

In the past I have used EvoStik brand of PVA when planking models but it isn't truly 100% waterproof but as long as it was covered well (I used to coat over the top with fibre glass resin to seal them). I have never had a hull fall apart yet (touch wood) when using EvoStik.

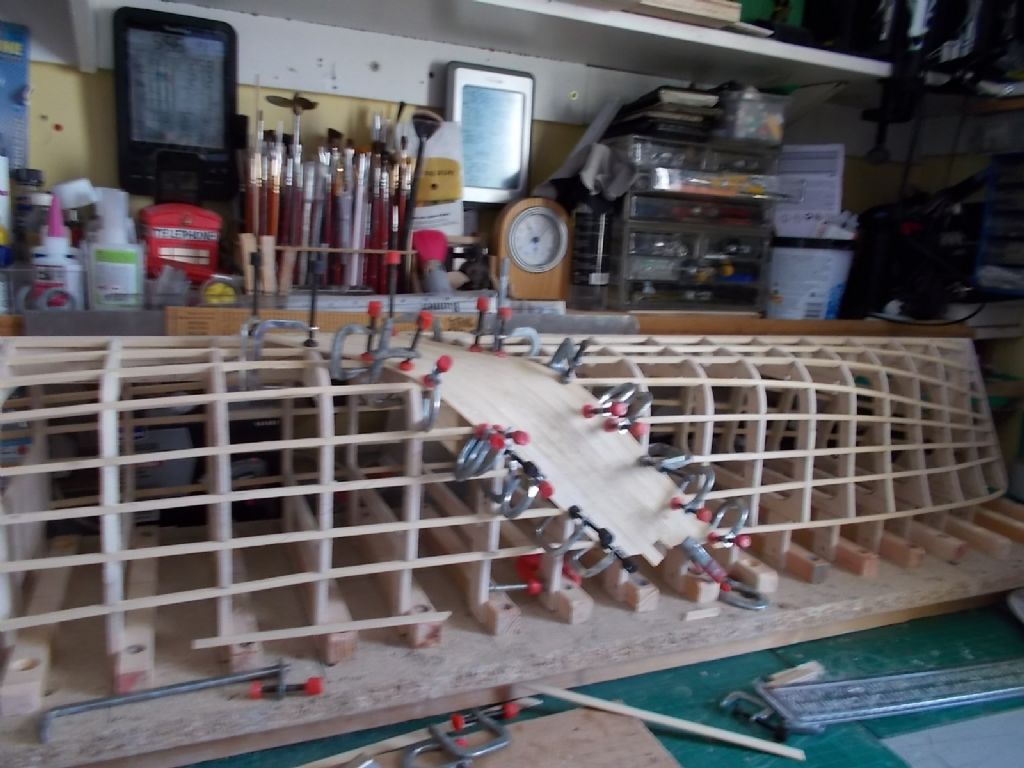

Sometimes when I am building superstructures etc I will use the cheaper Wilko PVA glue; I tend to only use superglue for gluing either metal or when I assimulate plating on a hull using plasticard. When I plank any hull longitudinal – I either use dressmakers pins/ brass pins to hold the planks in place. Brass pins are normally permanent but obviously dressmaker pins you take out when the glue is dry.

Depending on the planking a quick wipe with a wet cloth will close up the holes in the timber after dressmakers pins have been removed.

I did invest in a load of these fancy 'T building pins' for holding planks in place, but, I found anything harder than balsa wood they tended to bend so they stay in the drawer in readiness for building another balsa wood model.

I will carry on planking now my friends. John

Edited By John W E on 29/06/2020 09:24:47

![007 [800x600].jpg 007 [800x600].jpg](/wp-content/uploads/sites/5/images/member_albums/2391/870052.jpg)