Posted by James Hill 5 on 09/05/2023 10:33:41:

Hi Neil. I`ve read your post from the start.

An amazing project with a lot of work, but what a result. Beautiful models. Are you having a break once these are finished or is there something else planned?

Jim.

no Jim, its straight on to two part buil pulling/sailing liverpool static lifeboats than a gent who owns the real boat daiting back to 1899 that is in the Lytham museum asked me to build in January. U got up to deck level in January-March whilst the weather was too cold to paint.

After those two are finished, it will be a change.

Two years ago my good friend and coxs'n of Fleetwood Lifeboat retired gave me a Cheddar Steam Plant on the contition that i would put it into a boat of some sort.

I felt guilty that i hadn't done so when Ian died just before Christmas and in february after his funeral i hugged his widow and asked her if she wanted it back as it was worth a tidy sum. She said that Ian had bequeathed it to me in his will, which i fealt very humble about.

So for the next week i scowered face book adds and ebay and eventually found a Mountfleet Steam trawler, Boston Typhoon for sale at £350……….i made an offer and got it for a rediculous bargain.

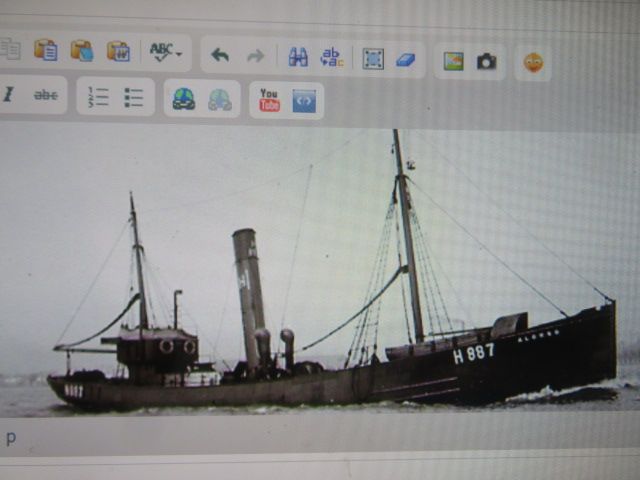

And so, in honour of a very dear friend and drinking buddy, i am going to build it…………but not the Boston Typhoon but naming it after my friend [which i have never ever done before] i am going to chop and change it about and build it as what was called a Bridge aft Sider, where the funnel is at the fore end of the cabin and the wheel house is right at the aft end of the superstructure, with things like lifeboat aft as on a drifter and an open fo'csle, like one i built years ago and appeared in the late yearly edition of Model Shipwright.

So that will be my next model.

The model will be called WILLIAM IAN FAIRCLOUGH

A typical bridge aft sider

Edited By neil howard-pritchard on 09/05/2023 16:45:38

neil hp.