Whilst working in the garden on my Princess Mary of Padstow with the sunshine on my shoulder, [reminds me of my favourite song] I was visited by the dead.

I openly admit that I believe in ghosts and the spirit world, and I lived in a written about haunted house in Fleetwood, and a pub near Maidenhead……….both with history to them!

I was taught woodwork by a GREAT man. He was called "taffy" Evans, a Welsh man from the Rhondda Valley and I think I had more respect for him than any teacher I had ever had or ever came across in my teaching career.

And I always took notice of what he said, until today.

A little bit about the man. He was in the RAF from college graduate and flew Spitfires and hurricanes during WW2, earning 12 kills and 3 possibles, but seldom talked about his background. I learned this when studying at A level,

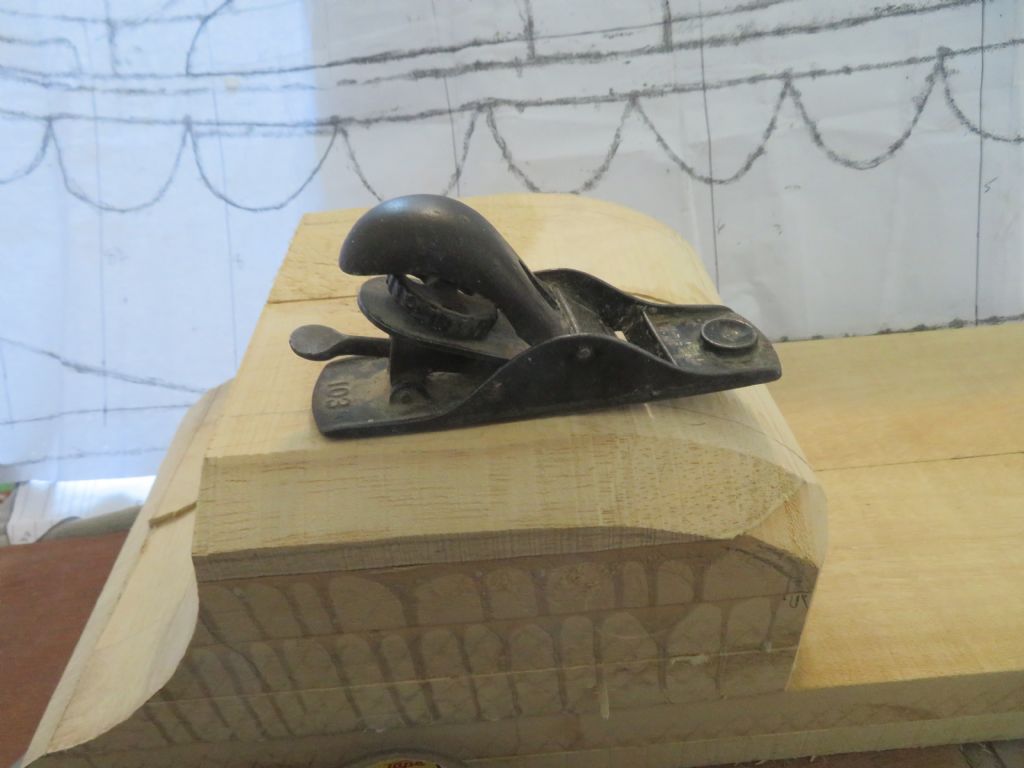

He was strict, but fair, and unlike almost every other teacher in that school who took great delight in wheelding a cane like a cowboy his colt 45, I never in my 7 years at that school saw him need to cane a lad, even the roughest of kids respected him. But I would have got 6 of the best had he seen me doing what I had done today.

His pet hate was anyone using a hammer on a chisel, rather than a wooden mallet.

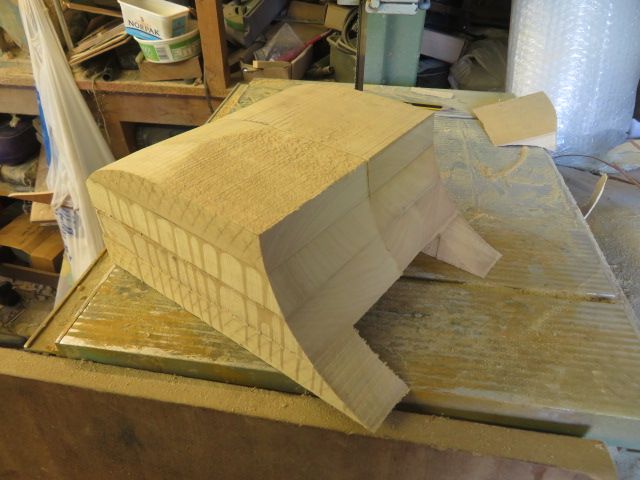

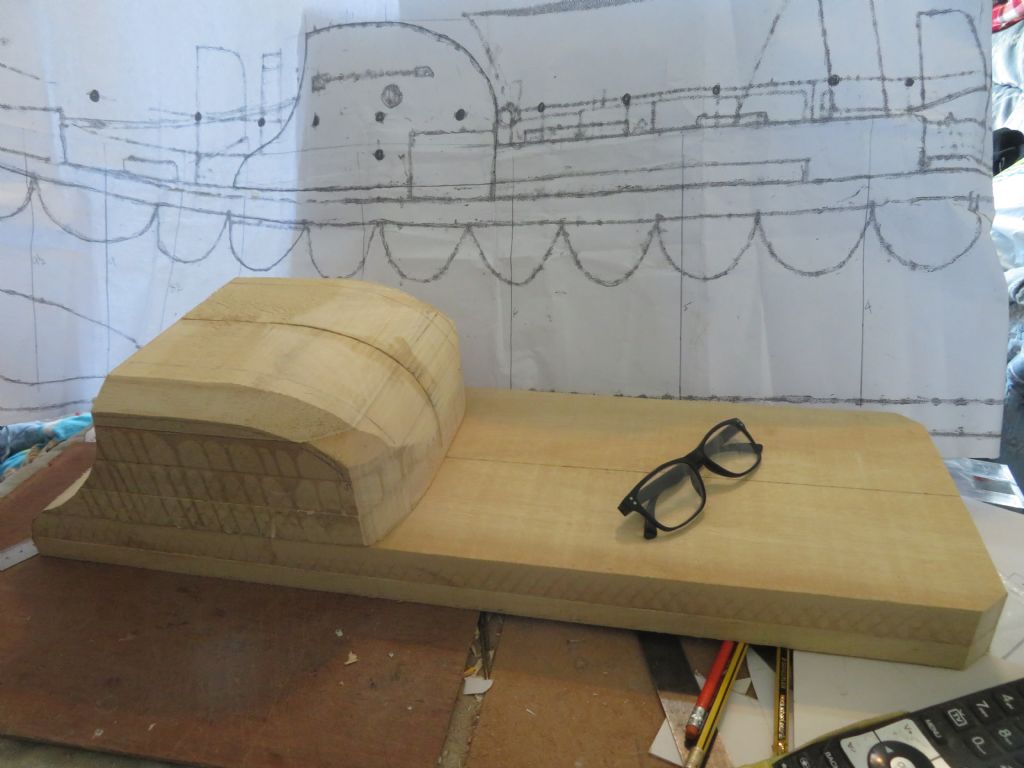

Today I found that sanding the boat level with all the blocks was going to take a lifetime, it is so big, and after an hour of getting little where fast, decided that I would dig out one of my 1" mortice chisels and a mallet………only problem was that I couldn't find a mallet, and so, much against my training I started using a claw hammer with my mortice chisel.

All was fine for about 20 minutes without his prophesy of broken thumbs coming true, when a hammer is used…..when sudenly overhead flew a Spitfire from the Memorial flight that was taking part in the Blackpool airshow this weekend!. I looked up to see it and yes………..I clouted my bloody thumb and hurt it. the head flew off the hammer and I dropped the chissel on my bloody foot, luckily without further injury.

I looked up, and as sure as is gospel, I am sure the wings tipped once in recognition!

And I'm bloody sure that "Taffy" Evens spirit was in that aeroplane telling me I was an ass h***

Anyway, I went into the workshop and pulled out a piece of hard wood to use as a temporary mallet with no further injuries.

The Spitfire came around a second time and I pictured its "dot" in the sky as a mark of respect, lol….the old sod finally told me off. hahaa

But I did get a whole side of the boat done to rough shaping with the sanders next, before filling and skimming once the other side is done hopefully tomorrow.

neil hp.