Today is the first day in about 10 or so years that I have used this power tool that has great sentimental value to me.

It is the first ever modelling power tool that I bought, and has always been there for me.

When my first pay packet for the month was £242.16p as a teacher in my first post in 1973 I couldnt afford a new one but used it in the woodwork room to show kids how versetile it was in cutting shapes, and at home for my own modelling…….was great for deaqling with the crap wood supplied in early Billing kits.

It had been on a shelf in the store room unused for 6 years.

When I left 2.5 years later to go to Australia to teach, I asked head of department if I could buy it as no one other than I had ever used it….."give the school 15 quid for it fir the Christmas staff party and you can have it…….15 quid was a chunk out of my last UK pay packet which had gone up to 360 quid pcm by then as I was saving to go out to Ozz, I knocked him down to £12 quid!, BUT what a stallwart it has been in my workshop ever since, and always very reliable,touch wood!

The tool in question is an Aero Piccola Vibro saw, and just brilliant.

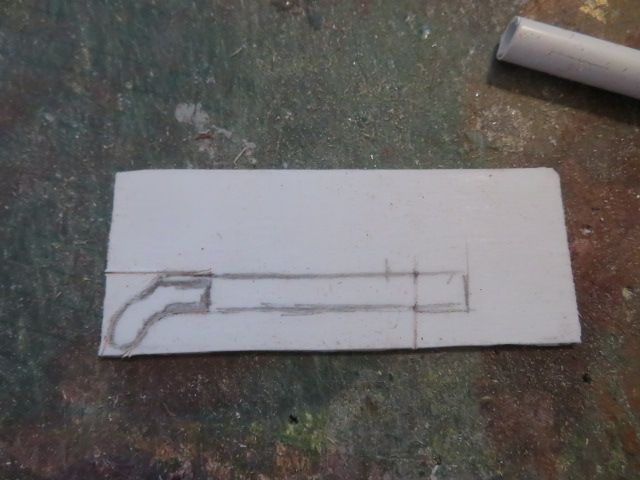

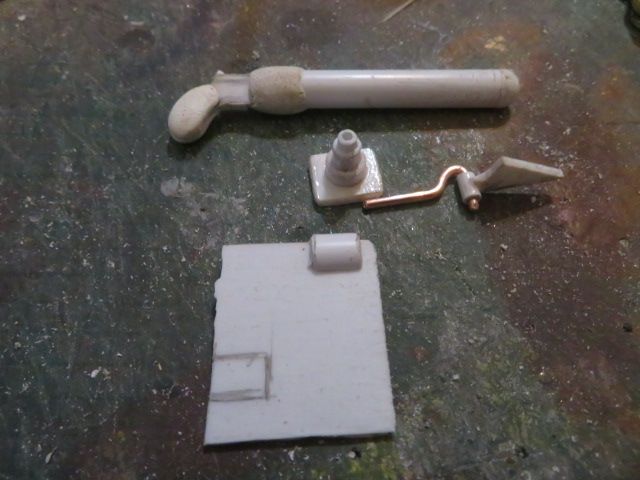

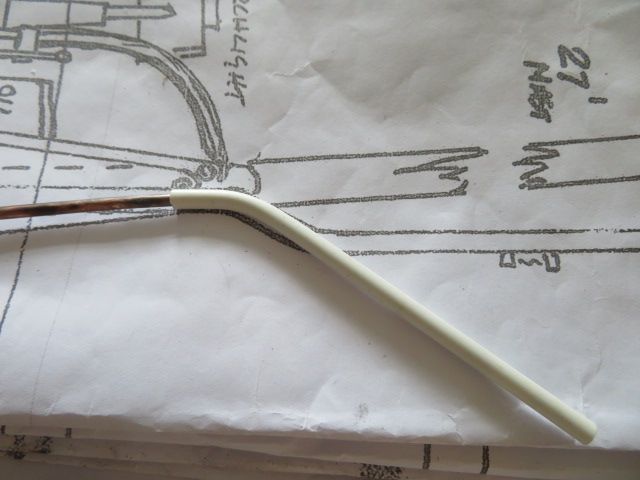

And to that fact I dug it out from the dust to cut both sets of brackets and seats for both vertically hung, asnd flat stored life rings for the boats.

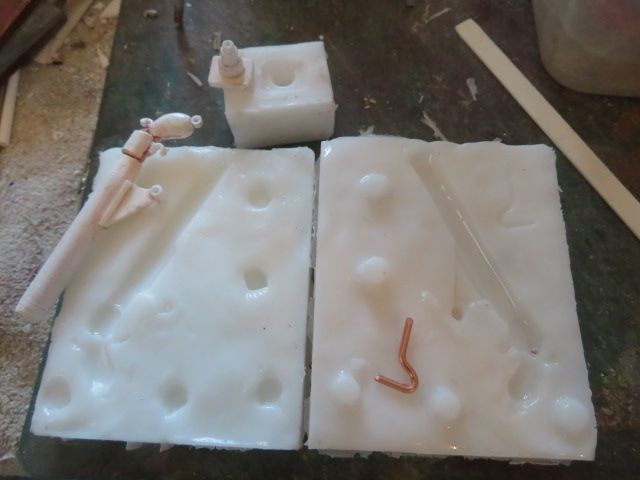

Finally came another old faithfull, my lego bricks that was given to me by a very kind man [who never wanted to be named, but he knows who he is] and have been used in probably getting on for over 100 moulds.

The mould made today was a surface poured mould for those brackets that were cut and sanded out of Obeche'.

neil hp.

especially the lockers hasp and staples and I'm sure the padlocks work as well.

especially the lockers hasp and staples and I'm sure the padlocks work as well.