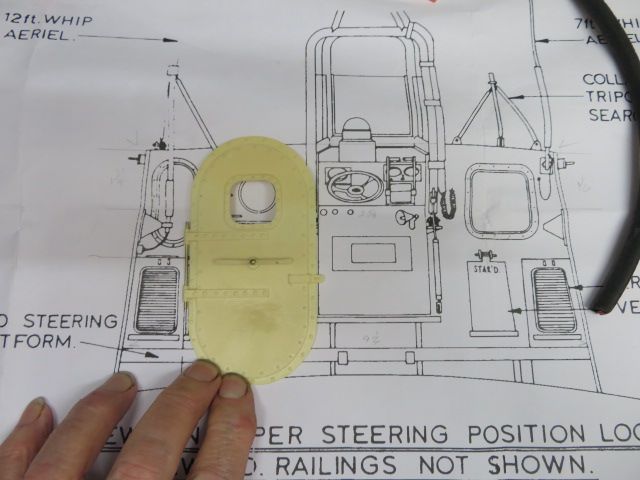

needed to fit the "A" frames for the prop shafts and tubes.

measured up from the plans and drilled firstly for the "A" frames…. Simples or so I thought.

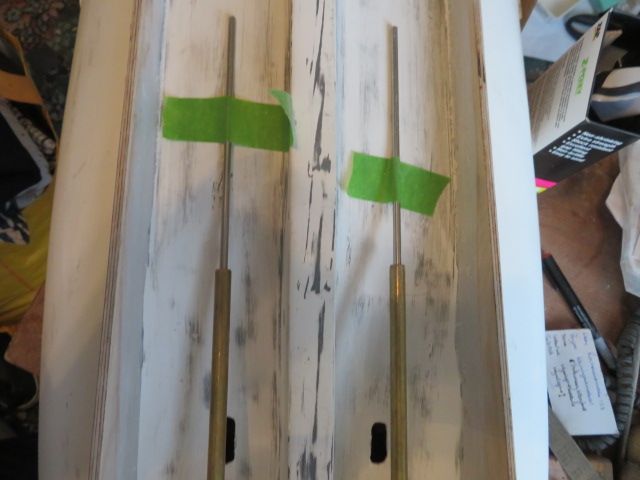

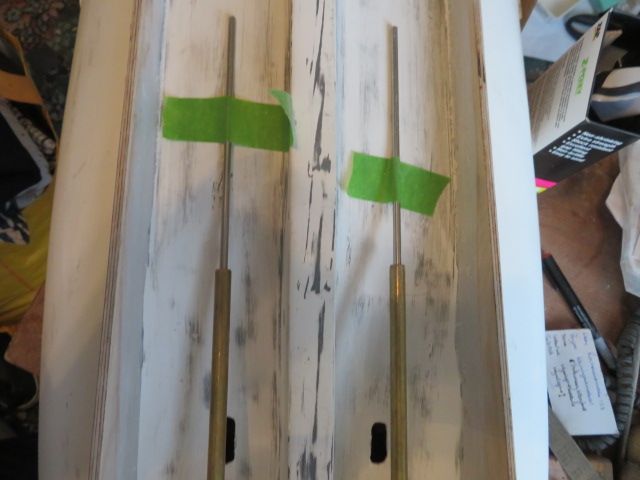

drilled the slots for them to fit through and then "tacked" them in place with cyano at the correct height…. and then measured the positions for the prop tubes to fit into the hull.

I drilled for these to go through the hull and taped them in…WHAT A MISTAKA TO MAKA. They looked as though they were launch pads for rockets they were so high up in the hull.

back to the drawing board. I then tried to take the shafts out, and for some reason one had stuck in the tube……..as I pulled and tugged at it, one of the legs came adrift………oh bummer!!…into the workshop and light up my torch.

got the silver solder out, to find that I was trying to solder over soft solder………no chance ..all I was doing was soldering onto a dirty joint.

And so I had to clean off all the soft solder……but strangely, no matter how much heat I put onto the boss, the leg would not come off, so can only presume that one leg was silver soldered, the other soft…….anyway, after cleaning the joint the wayward leg went on pretty easily with silver solder. job done.

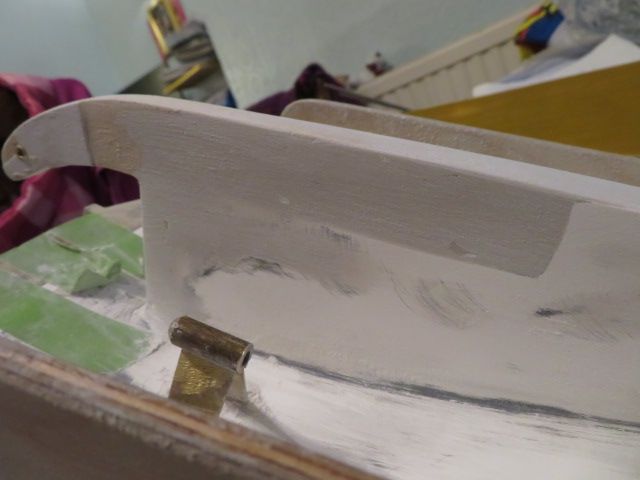

So back to the boat……….repositioned the entry holes for the prop shafts to give a far shallower entry into the hull. tacked them in with masking tape on the outside of the hull, including the now redundant holes and set all in place with 30 minute Zap epoxy.

later tonight whilst having a beer I will back all this up with polyester filler.