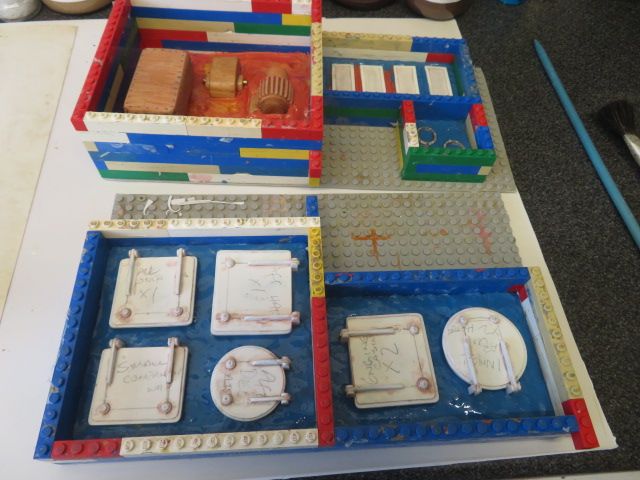

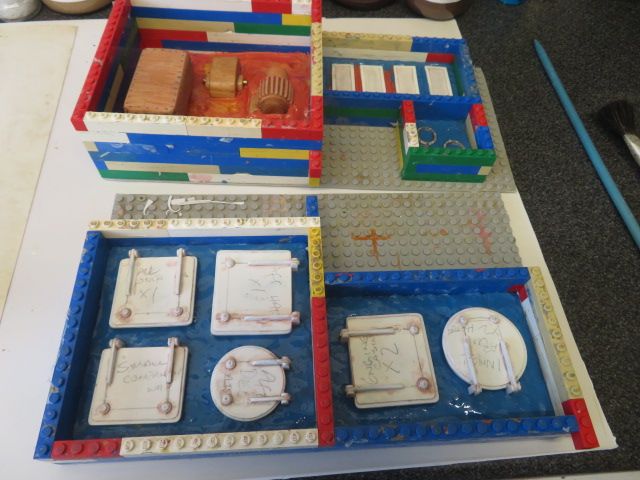

Casting moulds for resin fittings:

Nothing simpler really than doing your own fittings as long as you prepar the scene first, and go about it methodically.

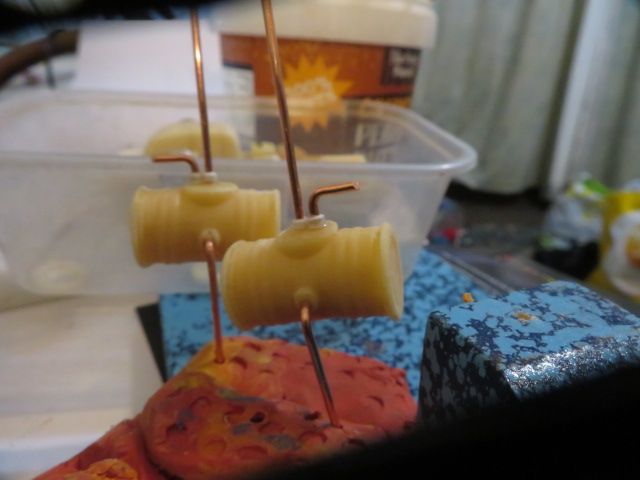

Once the fitting is made, cleaned up and mounted in or on plasticine in a box, there should be no ploblem or "scary bits"

And this was what i did this morning.

Items needed:……mixing "bowls", spatula for scraping out the remains in the bowl, mixing stick…[my choice a knitting neadle], fittings [of course], a glass of water, rubber and hardener, and most importantly!, a release agent, as the rubber will stick to almost anything.

Now!, I used to buy a spray on, none silicon release agent from Tiranti's of Reading until one day one of the technical guys told me that they could no longer send spray release agent out in the post, and was collect only.

"What can I use then,"……

"easy" the techy said, "you can use vasiline/petroleum jelly, just rub it on with your finger or a small soft paint brush, or you can even paint on some ordinary cooking vegitable oil………..both work great"

And they did and still do!

The water was also a mystery to start with, as this type of rubber hardens quicker so the instructions say if it can set with an ambiant moisture content in the air, like in an airing cupboard, but my ex went balistic when i tried the first and only time………Not only did the cloths and towels smell of rubber, but i think the last straw was that i couldn't get the rubber out of a wooly jumper that had dripped on to it…….

So back to the teckies, and they said add a mix of a tea spoon of water into the resin/hardener, and that takes care of the moisture in the atmosphere…….no more ruined or smelly cloths, lol.

the rest is plain sailing, just mix to the recommended quantities as sent out in the sales label, add water…..give a great deal of thorough mixing and pour into the moulds…….but dont add too much hardener/catylist or you might end up with just a block of rubber in your bowl.

However if this ever does happen……….keep the block, cut it up into very small pieces and add a little into the top of a mix next time you have some big moulds to do to bulk out the content of rubber……..that works as well.

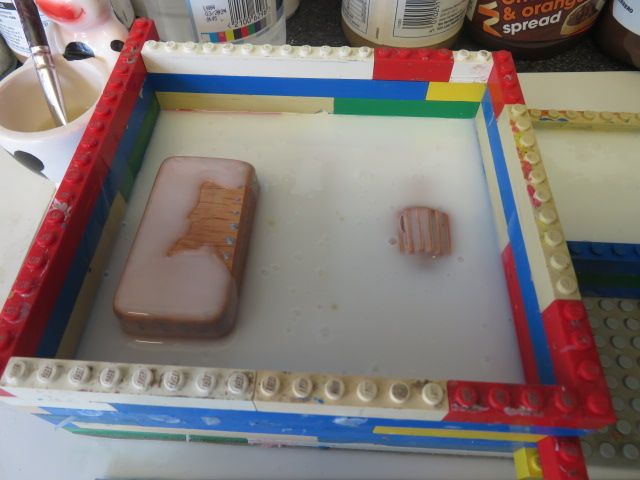

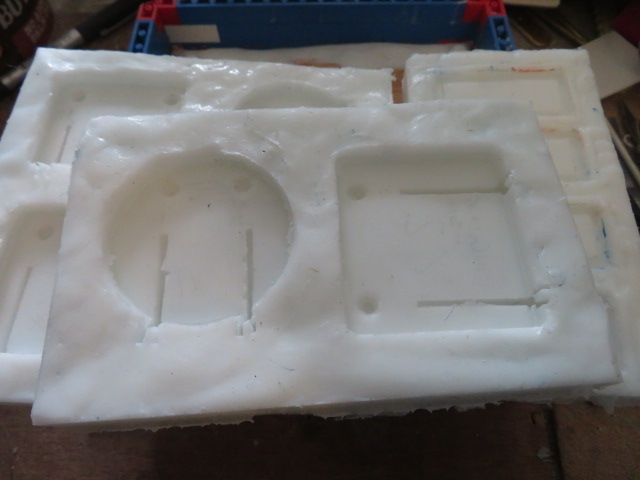

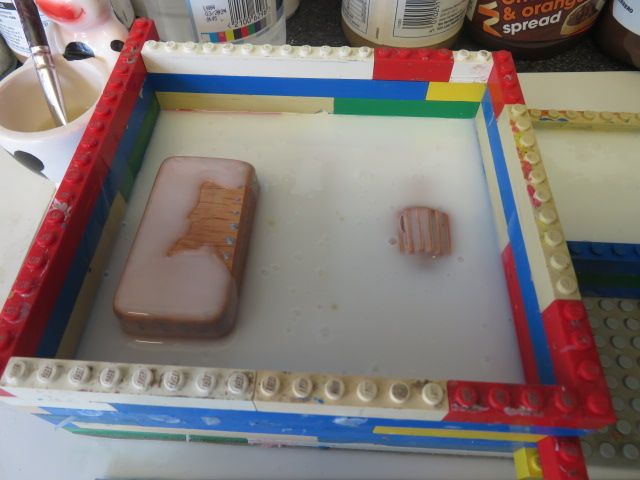

And so, having set the fittings into the boxes the rubber was poured, but you will note that in the box for the anchor windless, only half the large fitting is covered…….this is because if you are ,as i did mount the base flat surface on to flat plasticine, it can have a tendency to "float" up into the rubber whilst the rubber is cgoing off…..so once the rubber is set in this mould i will then mix a little more and pour on top of the original……the second layer WILL BOND with the first layer as no release agent will get between these two layers.

Just my own method , but for those for those who, like me would find "making my fittings " in graphics for a printer to do the job…….find this an infinitely more enjoyable way of making my fittings……..

Edited By neil howard-pritchard on 08/09/2022 10:04:21

neil hp.