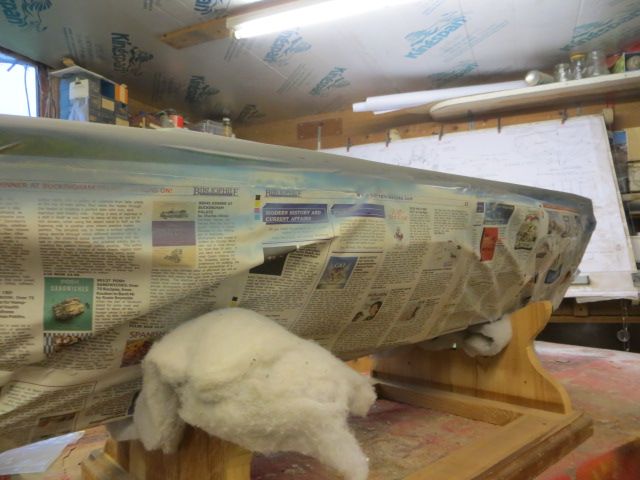

even though my workshop is a s*** tip, and will take major removeable of c**p to fully operate, i can actually do bits to help clear the detritus whilst i wait fro filler, paint and glue to dry…..

and so with renewed vigor i desided to fit the prop shafts into the tubes, and fit the motors.

the main object though, was how to get over the millenium question of how to lubricate and waterproof the tubes and shafts from water ingress.

and this, true to the advice i give regularly, i followed my own advice. as i have done for the past 30 years.

i took the lid off my slowly diminishing stock of printers graphite powder and mixed 3 teaspoons full to half a tub of vasiline petroleum jelly. "Spooned" it in to a syringe [obtained foc from a local dispensary who looked at me with puzzlement when replying to them of the use that i was going to grease the propshafts of a model boat] and injected the concoction into the open stern end of the tube. 2 syringe fulls was just a little too much as there was a little squirt out from the motor end.

JOB DONE.

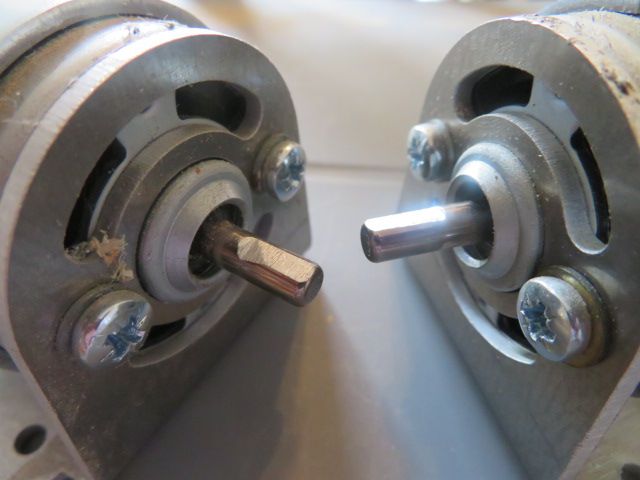

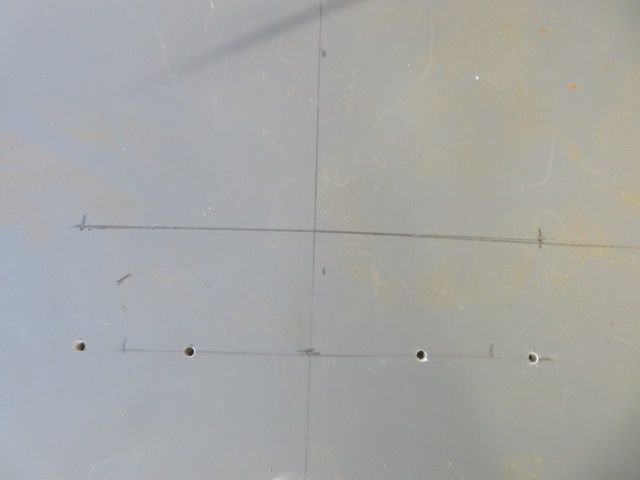

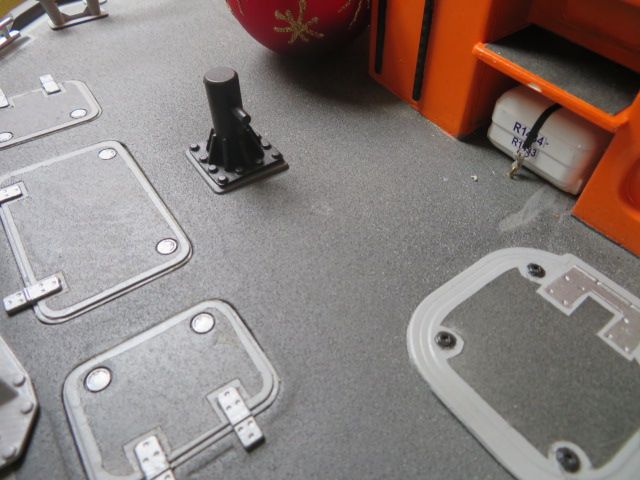

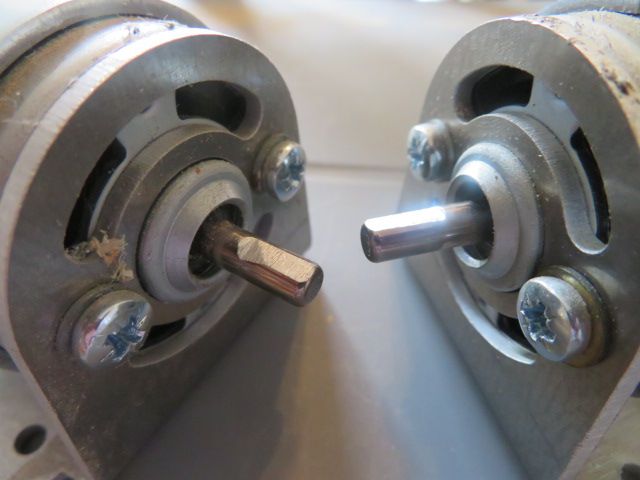

Then it was fitting the motors to the shafts……i used the rigid shaft coupling for straight alignment and to measure the thickness of the wooden engine bed to sit the motor on. meaqsurement fixced, i cut two out, mounted the motors on and then set the blocks into the hull using P38………not a glue, but sticky enough to keep the wooden blocks in place.

just one slight problem was that when i took my eye off the game, the starboard one slipped slightly and i will have to unscrew the motor………fill the screw holes with epoxy and then refit the motor so it is back in alignment with the shaft , thus avoiding out of line vibration. i alsi made my thrust washers from silicon tubing, rather than washers.

Also before fitting all, i filed flats onto both the inboard ends of the shafts and the output shafts of the motors to aid the grip of the allan studs

i came to the conlusion that my usual method of fixing motors into my old slow reving lifeboats……bluetack, just wouldn't cut the mustard with 19000 rpm motors, lol.

and miraculously more by good luck that management and fore thought, I managed to get the right propellors and shafts into the right tubes so that when rotating outwards from the fop they produce forward motion……………not done that before