you get to a stage in life, never mind model building, when you are not quite in control of your "destiny" and in model building it is exactly the same.and its two steps forward and one back…………………..or in todays fiasco it was one forward and TWO back

fitted all of the pulpit rails to the to boards via the toe board brackets. i had made them from cast polyurethane resin some time back, thinking they were strong enough…….could have used some white metal ones but chanced it………that gamble didn't pay off as one of them broke almost immediately when i accidentally dropped it on the floor and the plastic gave in, where as the brass rails didn't.

the plastic stanchions with molded brackets wont be so tender.

Hoever after a little giggery pokery and some strengthening with brass tubing [although not quite to scale] will be strong enough to stand the rogours of even Mick French's handling.

and so i fitted the rails top the toe boards and then dry fit them all to the deck so that both the pulpit rails and the tops of the stanchions sit level on the deck.

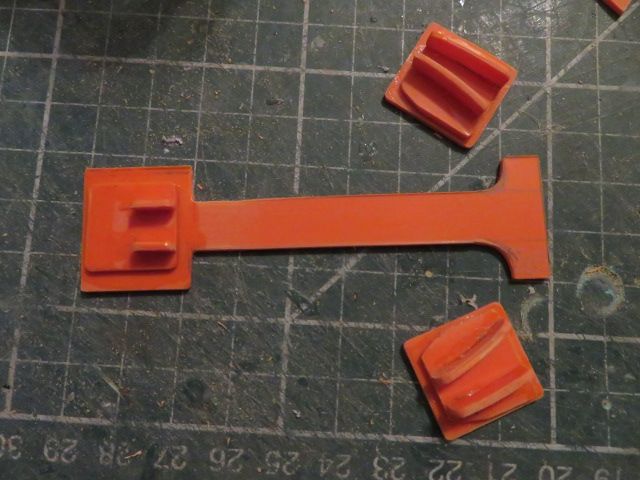

and then………the other step backward. on looking at the life ring brackets, one U shaped holder on the bottom of the bracket had "pinged" off somewhere, and so i had to make another of those, using plasticard and heating it on the cooker to bend it………….small job, that could have not been neaded had i not been clumsy myself….

the bracket is still loose somewhere……………..grrrrrr.

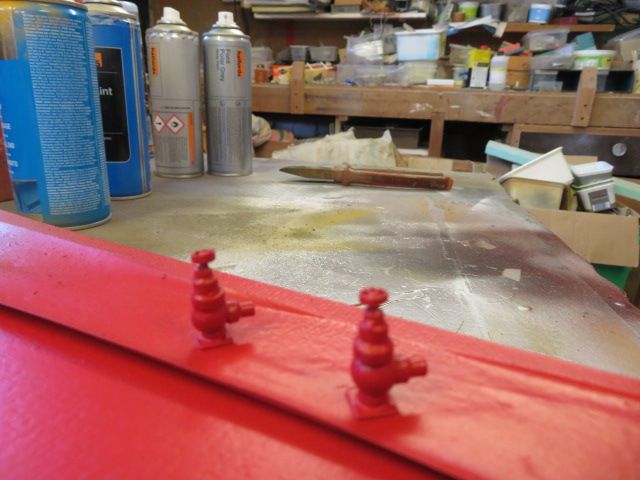

but at least all stanchions and rails can now be painted, ready for fitting.

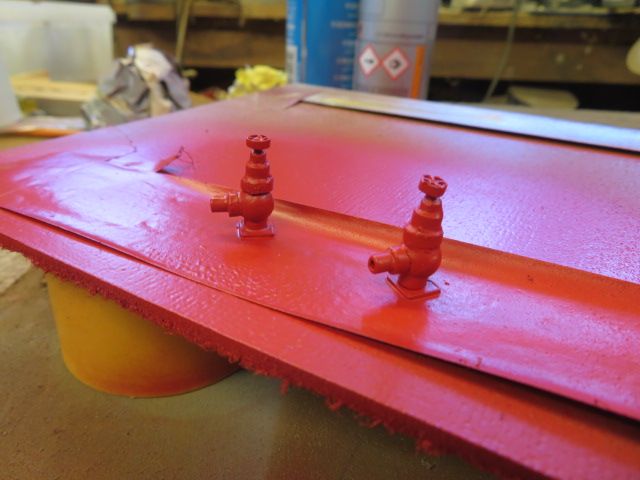

the bed for the two quick release towing fairleads on the stern, with the small brass roller bollard have been sized up and the base for the roller bollard and fairlead have benn chopped down from that fitting made for the Tyne class stern fairlead and bollard……..fits a treat.

theres going to be a lit of painting tomorrow, lol.